Characterization of Okra Convective Drying, Influence of Maturity ()

1. Introduction

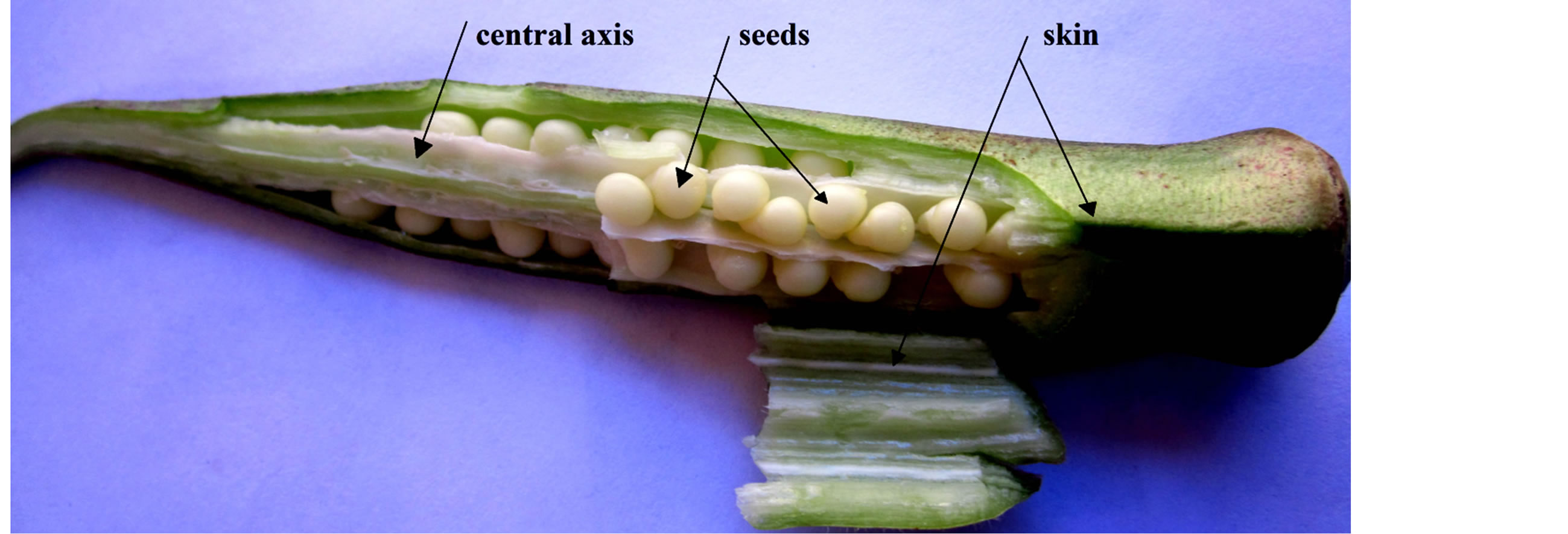

Okra is one of the most significant fruit vegetables grown throughout the tropics and warmer parts of the temperate climatic zone [1] . It is well dried in tropical zone and very appreciated in nutrition, due in part to its content in nutritive elements [2] . Okra seeds have content in oil in order of 15% - 19% and its proteins are in good quality [3] . Also, okra has polysaccharide content giving a strong viscous and sticky solution appearance [4] . Moreover, it has medicinal use to fight against some cardiovascular and dental diseases and decreases gastric irritations. It is also used as diuretic agent. These properties of okra are due to its contain in oligomerics catechins, derived flavonol (respectively 2.5 mg/g and 3.4 mg/g per seeds) and polyphenol with hydroxycinnamic and quercetins (0.2 and 0.3 mg/g of its skins) [5] . Physically, okra has cylindrical shape and conical extremity, supported by a peduncle. It has a complex inside structure. The cut, from the outside to inward, shows a thick skin, then a spongy material in the center. Between both, there are alveoli, creating cavities which accommodate spherical seeds. These three materials have different structures [6] .

The production in 2004 was more than 4.5 millions of tons in more than 33 countries with India in top (3.5 million tons). In West Africa, Nigeria is the largest producer (1,039,000 t) followed by Ivory Coast, Ghana and others [7] .

To preserve the high produced quantity, the producers, generally women in Africa, proceed to its drying. The product is then cut in various sizes [8] and displayed directly in the sun or, more rarely, in solar-dryers. Most of dryings are achieved without control of the relative humidity, air temperature or drying air flow, above all, without distinction of age. The dried product has often doubtful and inhomogeneous quality, losing the initial organoleptic quality. However, it is not advisable, for mastering okra drying phenomena and its mechanical behavior, to study solely the whole okra behavior, without examining the effect of okra age on its convective drying. So, we can obtain an acceptable final quality, which takes into account its appreciation in the food domain and its therapeutic virtues.

In this work, we characterized the convective drying of the whole okra with regard to the influence of maturety on okra convective drying. Through the drying curves as well as effective diffusivity of the whole product and initial water content, we point up the complex character of okra and its age effect during convective drying. A parametric study was carried out in the range of okra old from 2 to 7 days at 60˚C, both fruits gathered on the same plant to avoid divergences due to okra variety, particular physical structure and the chemical composition [9] .

2. Materials and Method

2.1. Experimental Material and Samples Preparation

Freshly okra samples were obtained from a farm in Bobo-Dioulasso, which is located in the west of Burkina Faso, in September 2012. The samples for each experiment were collected on the same tree, to avoid divergences due to variety that can induce difference into physical structure and the chemical composition [9] .

As soon as the plant of the okra is selected, it is marked. In the appearance of a flower, we mark and follow its advancement. When the flower gives a fruit, this day is noted 0. The first day will correspond to the first anniversary of the fruit. Let us note that in the first day the fruit is so young that we do not collect it at first. At the second day, the fruit reaches almost its final size (for a good fertile and rather wet soil). Let us remind that the okra is appreciated in food at 2 - 5 days beyond of which, the fruit increases its content in fiber, hardens and thus unfit for consumption. The okras were washed, and then were transported to Polytechnic University of BoboDioulasso situated about 30 min from the farm where okras were obtained. The initial water content, determined by drying in an oven dryer at 105˚C for 4 h [10] , performed in triplicate, was found to be 8.47% ± 2.067% in dry basis with initial weigh of 11.22 ± 2.55 g.

Figure 1 shows the constitution of the okra, from the outside inward. A thick skin wraps seeds fixed to a spongy material constituting the central axis of the okra.

Figure 2 shows the existing differences between the various states of maturity of the okra. Young fruits which are generally edible are soft and breakable. Advanced in age fruits increase their content in fibers and become flexible.

2.2. Drying Equipment

Drying kinetics of okra samples were established using a natural convection oven-dryer (WTF BINDER). The average temperature was regulated at 60˚C. For drying, the samples were placed in the oven-dryer initially re-

Figure 1. Okra physical external and internal constitution.

Figure 2. Different states of maturity: (A) 2 - 6 days old, no fiber and breakable at the extremity; (B) 5 - 8 days old, high content in fibers, unbreakable at the extremity.

gulated to the drying temperature. During drying, the samples weight was regularly measured with a balance (Master Pro SARTORIUS, 0.001 g precision, France). These measurements were done every 10 - 15 min during the first 200 min. Then, because of the drying rate decrease, measurements were taken every 20 - 25 min until 300 min drying and finally every 30 - 35 min until the last stage of drying. At the end of each experiment, the dry mass  of the product was obtained by drying the sample in the oven dryer at 105˚C for 24 h [10] (AOAC, 1990). From the initial mass

of the product was obtained by drying the sample in the oven dryer at 105˚C for 24 h [10] (AOAC, 1990). From the initial mass  and dry mass

and dry mass , the initial water content of each sample was determined by the following equation:

, the initial water content of each sample was determined by the following equation:

. (1)

. (1)

where  is the mass of water inside the product.

is the mass of water inside the product.

2.3. Okra Convective Drying Characterization

The shrinkage curves were established by measuring the mass  of okra at any time. The mass value decreases in proportion as drying time increase. At the end, the product keeps its mass constant then the dry mass

of okra at any time. The mass value decreases in proportion as drying time increase. At the end, the product keeps its mass constant then the dry mass  is determined.

is determined.

From mass loss curves and dry mass, the water content at each instant of drying and the drying kinetics were determined.

. (2)

. (2)

Drying kinetics of okra samples were established by fitting  versus drying time.

versus drying time.

2.4. Calculation of Moisture Difusivity

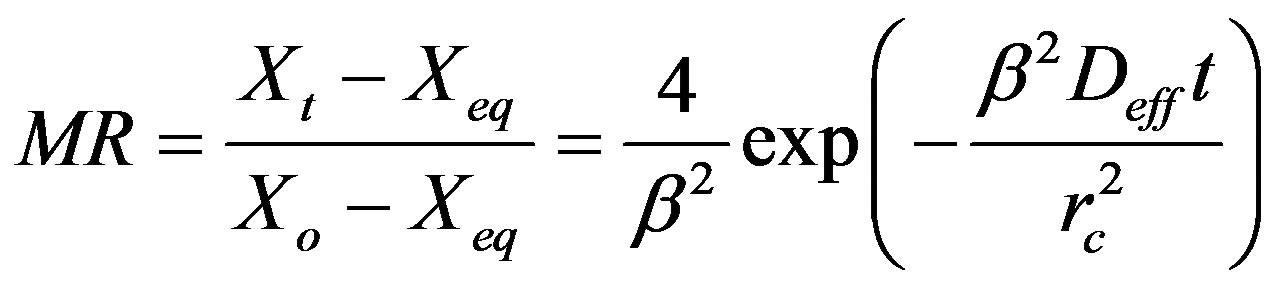

The moisture ratio (MR) of samples was calculated using by the following equation:

. (3)

. (3)

where, in (kgw/kgdm), Xt is the moisture content at any time, X0 is the initial moisture content and Xe is the equilibrium moisture content.

The experimental drying data for the determination of diffusivity coefficient were interpreted by using Fick’s second diffusion model. The solution of Fick’s second law for diffusion out of cylindrical form may be used to fit the experimental drying data [11] :

. (4)

. (4)

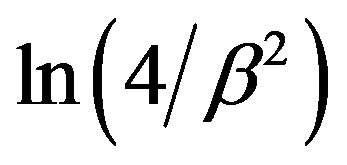

Equation (4) assumes that the effective diffusivity (Deff) is constant, shrinkage of the sample is negligible for long drying times and okra was considered having cylindrical form. Several researchers demonstrated that Equation (4) could be further simplified to a straight-line equation as [12] -[14] :

. (5)

. (5)

The effective diffusivities were determined using the method of slopes. Effective diffusivities are typically determined by plotting experimental drying data in terms of  versus time. From Equation (5), a plot of

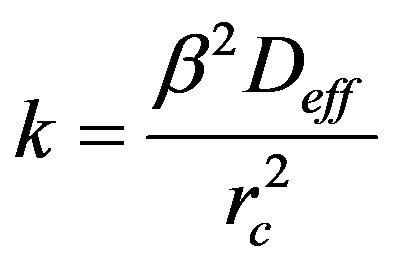

versus time. From Equation (5), a plot of  versus time gives a straight line with a slope k containing Deff:

versus time gives a straight line with a slope k containing Deff:

(6)

(6)

3. Results and Discussion

The drying experiments were carried out using the 2, 3, 4, 5 and 7 days old of okra. The samples presented average initial moisture content from 12.27 Kgw/Kgdm to 4.92 Kgw/Kgdm according to their age. The air drying temperature was settled at 60˚C. All the tests were repeated at least twice for repeatability.

3.1. Water Content Change with Maturity Process

The effect of the age of okra fruit on the variation of the global moisture content of the whole okra during the drying process was evaluated. Figure 3 presents the initial moisture content for the different maturity degree. It can be seen from the results that the initial moisture content values decreased as the maturity degree was growing up. Advanced in age, the fruit becomes more and more steady which decreases the proportion of water in the sample. The experiment were carried out on whole okras gathered on two different plants noted “Plant 1” and “Plant 2”. All of them gave similar results. The younger okra generally had the highest initial water content while the older okra had the least initial water content. Whole okra at 2, 3, 4, 5 and 7 days old has respectively 12.27, 9.00, 7.53, 5.97 and 4.92 Kgw/Kgdm of initial water contain. This suggests that at the first days, okra is affluent in water while solid matter becomes more and more abundant when age increase

3.2. Influence of Okra Maturity on Its Drying Curves

Figure 4 presents the drying curves for samples at 60˚C with maturity (days old) of 2, 3, 4, 5 and 7 days old both from the same plant to reduce variety or other genetic aspect influences on the result. Each drying kinetics experiment was carried out at least twice to check the reproducibility of the drying curves. All the drying in case of okra takes place in the falling rate period. This shows that diffusion is the dominant physical mechanism gov-

Figure 3. Okra initial water content evolution during its maturity.

Figure 4. Influence of okra age on its drying curves (for 2, 3, 4, 5, 7 days old).

erning moisture movement in the samples. Similar results were obtained for green bean [15] , for okra [16] for red chilli [17] . It is obvious from Figure 4 that okra age caused an important impact on its drying curves.

The time required to reduce the moisture ratio to any given level was dependent on the sample age. At 2, 3, 4, 5 and 7 days old, the drying effective time was respectively 780, 1000, 1155, 850 and 750 min. One can divide okra maturity in two periods. The first one (the youngest age or raw fruits), goes from 2 days old to 4days old and the second period (older age or ripe fruit) goes from 4 days old to 7days old. The results indicated that age is an important parameter governing moisture movement in the okra samples during its convective drying. The results showed that increasing the age of okra involved not inevitably increasing or a decreasing of the drying time. From these results, we can deduce that the moisture content of the okra decreases with its age. On the other hand, the okra dries faster when it is very young or very old. Initial water content is not the parameter that governed the drying process. The reason of such result can proceed from the structure of the product, which changes according to okra ages as we can see in Figure 2. This means that the moisture transport is also controlled by inherent internal factors of maturity.

3.3. Diffusion Coefficient

Figures 5 and 6 show the influence of okra age on its effective diffusion coefficient at 60˚C. It can be seen that  is almost proportional to drying time. We found the equation of this proportionality as reported in Table 1. From the curves plotted from

is almost proportional to drying time. We found the equation of this proportionality as reported in Table 1. From the curves plotted from  versus time, we draw first the equation of the straight-line from which we deduced

versus time, we draw first the equation of the straight-line from which we deduced  then the slope k values.

then the slope k values.

Also, the different constants that permitted Deff calculation are found and recorded in Table 1. The determined

Figure 5. ln(MR) evolution versus okra age at 60˚C.

Figure 6. Okra effective diffusion coefficient evolution with okra age.

Table 1. Data draw from okra draying curve for Deff calculation.

values of Deff for different states of maturity are given in Figure 6. The effective diffusivities of okra were 1.38 × 10−10, 6.09 × 10−11, 1.23 × 10−11, 8.98 × 10−11, and 1.05 × 10−10 m2/s respectively for 2, 3, 4, 5 and 7 days old. The values lie within the general range of 10−11 m2 /s to 10−9 m2/s for food materials [18] . However, lower values were observed in this work than in the previous studies which might be due in part to varietal differences and also to method of sample preparation. Results showed (Figure 6) that okra age can be divided on two parts. For the first period, (2 - 4 days old) okra effective diffusion coefficient decrease with its age. At the second period (4 - 7 days old) okra effective diffusion coefficient increases when okra age increases. A minimum were reached at 4 days old in this study.

4. Conclusions

The influence of maturity of okra in the range of 2 - 7 days old at 60˚C of drying air temperature for okra was studied.

The result allows predicting drying behavior of okra according to its age. Contrary to all expectations, okra drying time does not increase or decrease versus its age. It was found from the experimental results that okra maturity has important influence on its behavior during convective drying. At 2, 3, 4, 5 and 7 days old, the drying effective time was respectively 780, 1000, 1155, 850 and 750 min. Effective diffusivities of the okra in this order of age were 1.38 × 10−10, 6.09 × 10−11, 1.23 × 10−11, 8.98 × 10−11, and 1.05× 10−10 m2/s. The youngest (two days old) and the oldest (seven days old) fruit dried fast, and the middle one (4 days old) retained more moisture. The reason that can explain this situation is to consider the consistence of the matter inside the product. In fact, the younger okras generally had high initial water content while the older okras decrease their initial water content. Whole okra at 2, 3, 4, 5 and 7 days old has respectively 12.27, 9.00, 7.53, 5.97 and 4.92 Kgw/Kgdm of initial water contain. The youngest fruit with high water content reveals soft and breakable. This physical characteristic makes transfers easy. The oldest one has low water content and high fibers content. It weakly withstands to transfers.

Nomenclature