Keywords:Bulk Metallic Glasses; DSC; XRD Method; HTX; Magnetic Properties

1. Introduction

Magnetic materials have undoubtedly played a central role in the process of rapid technological innovation and evolution. However, there are still limitations, related to non-optimal properties and use of electro-magnetic materials in various devices and appliances. In particular, in the last decades, the electrical utility industry has dramatically increased the monetary value placed on transformer losses as a part of an overall effort to increase electric power generation and distribution efficiency. To meet this challenge, transformers manufactures have introduced new transformer designs and have investigated new transformer core materials aimed at reducing core losses to replace silicon steel. To this aim, metallic glasses, because of their low core loss have received considerable attention for use as a core material in high frequency transformers [1,2]. These have been observed to have unique electronic and mechanical properties arising from a lack of long-range crystallographic order. High cooling rates (above 105 K/s) are required for glass formation to produce amorphous alloys leading to samples in the form of thin sheets with thickness limited to hundreds of µm. Among these systems, a great role has been played by the ferromagnetic Fe-, Coand Ni-based amorphous presently widely exploited in core transformers [3,4].

The major reason for the low-core losses of these systems can be basically ascribed to large electrical resistivity and low magnetic coercivity. However, the quest for advanced engineering materials having simultaneously high glass forming ability, superhigh strength and excellent magnetic properties is always very stringent due to the need of saving energy.

After the discovery that multicomponent alloys could be cast from the liquid state in a fully amorphous state at cooling rate of ≈10 K/s, it has stimulated intensive research due to perspective applications [5,6]. In particularmagnetic bulk metallic glasses (BMG) have been widely investigated despite the non-excellent magnetic properties, due to the possibility of directly casting the materials with different shapes having predefined dimensions. The first room temperature ferromagnetic BMG have been synthesized in 1993. In 1995, Inoue et al. produced Fe-based bulk magnetic systems displaying soft magnetic properties containing a very large number of elements [7]. Since then a variety of Fe-based, Co-based and Ni-based bulk glassy alloys have been produced [8].

The present study has been carried out to synthesize a ribbon amorphous Fe40Ni40B20 alloy of 5 mm width and about 30 µm thickness which was prepared using a single-roller, melt spinning technique under a vacuum atmosphere. The stability of the glassy matrix and the crystallization (formed phases, kinetic…) have been studied by different methods (DSC, HTX-ray diffraction). Magnetic properties of Fe40Ni40B20 were measured at room temperature.

2. Experimental

An ingot of the Fe40Ni40B20 alloy (composition is given in nominal atomic percentages) was prepared by arc-melting mixtures of Fe 99.99 mass % purity, Ni 99.8 mass % purity and B 99.9 mass % purity in an argon atmosphere purified using Ti-gettering. From the master alloy ingot, a ribbon of 5 mm width and about 30 µm thickness was prepared using a single-roller, melt spinning technique under a vacuum atmosphere. The structure of the samples was examined by X-ray diffraction (XRD) with Cu Kα ( Å) radiation. The thermal stability associated with the glass transition, supercooled liquid region and crystallization of the glassy alloys was investigated by differential scanning calorimetry (DSC) at a heating rate of 10˚C/mn. The hysteresis loops of the alloys with different Hf contents were recorded with a superconducting quantum interference device (SQUID) under an applied magnetic field of maximum 1 kOe at room temperature.

Å) radiation. The thermal stability associated with the glass transition, supercooled liquid region and crystallization of the glassy alloys was investigated by differential scanning calorimetry (DSC) at a heating rate of 10˚C/mn. The hysteresis loops of the alloys with different Hf contents were recorded with a superconducting quantum interference device (SQUID) under an applied magnetic field of maximum 1 kOe at room temperature.

3. Results and Discussion

Figure 1 shows the X-ray diffraction pattern for the melt-spun ribbon Fe40Ni40B20 alloy. The pattern consists of a broad diffused maximum without diffraction peaks corresponding to crystalline phases. Consequently, the formation of a single glassy phase for the Fe40Ni40B20 alloy is confirmed.

The critical cooling rate for glass formation, Rc, is an important characteristic parameter for predicting the ease or difficulty of glass formability. It is defined as the minimum cooling rate necessary to keep the melt amorphous without detectable crystallization upon solidification. A slower Rc indicates a greater glass-forming ability of an alloy system.

Figure 2 shows the DSC trace for the ribbon Fe40Ni40B20 metallic glass obtained at the constant heating rate of 10˚C/mn. As shown in Figure 2, a distinct endothermic reaction associated with glass transition can be observed over the temperature Tg is 281˚C. At temperatures above glass transition, the alloy exhibits a wide supercooled liquid region defined as the temperature interval  = 105˚C, where

= 105˚C, where  is the onset temperature of crystallization, Tg the temperature of glass transition. This indicates that the Fe-based ribbon glassy alloy has a high thermal stability, which allows the mechanical spectroscopy measurement to be performed in deeply supercooled liquid region. Thus, for Fe-based alloy, two crystallization events are visible following the supercooled liquid region: the first one is characterized by a sharp and large exothermic peak, associated with the

is the onset temperature of crystallization, Tg the temperature of glass transition. This indicates that the Fe-based ribbon glassy alloy has a high thermal stability, which allows the mechanical spectroscopy measurement to be performed in deeply supercooled liquid region. Thus, for Fe-based alloy, two crystallization events are visible following the supercooled liquid region: the first one is characterized by a sharp and large exothermic peak, associated with the

Figure 1. X-ray diffraction pattern on the melt-spun ribbon Fe40Ni40B20 alloy.

Figure 2. DSC curves of Fe40Ni40B20 alloy ribbon.

crystallization of the amorphous matrix. In contrast, the second is a relatively smaller one, which may be induced by the secondary crystallization of the remaining supercooled liquid or the transformation of the primary metastable phase.

The structural evolution during heating was investigated by XRD. The diffraction patterns of melt-spun ribbon heated to different temperatures are shown in Figure 3, together with the pattern of the as-prepared sample. The ribbon broad maxima characteristic for amorphous materials and no trace of crystalline phases indicate that they are in the amorphous state for temperatures between 200˚C and 350˚C. The phase formation reflects at the (T = 400˚C). Obviously, the first step of devitrification is mostly linked with the formation of quasicrystalline phase, as other crystalline phase (orthogonal Fe3Ni3B, FeNi) only exist in between 449˚C and 600˚C.

Figure 3. XRD scans of annealed sample of Fe40Ni40B20 alloy ribbon.

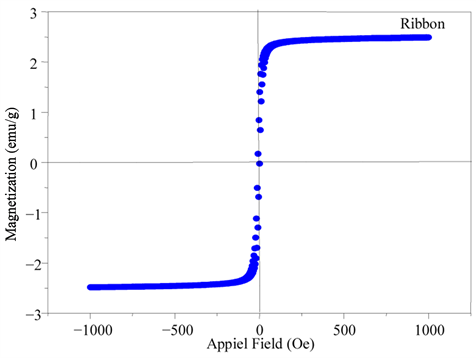

Figure 4. Magnetization curves (M-H loops) of Fe40Ni40B20 alloy ribbon measured at room temperature.

The hysteresis M-H loops Fe40Ni40B20 alloy ribbon is illustrated in Figure 4. Magnetization rises sharply with saturated under the higher applied field for Fe40Ni40B20 alloy, which is the evidence of ferromagnetism. The saturation magnetization is 2.5 emu/g at room temperature, and displays typical features of a soft magnetic material.

4. Conclusion

In conclusion, the stable crystalline phases include cubic orthogonal Fe3Ni3B, fcc FeNi after complete crystallization of ribbon only existing between 449˚C and 600˚C. In addition, the ribbon BMG also shows good magnetic properties with high saturation magnetization of 2.5 emu/ g, demonstrating promising applications in magnetic industry.

Acknowledgements

The authors are grateful to INRIM-Torino of the Univerity of Torino for providing experimental facilities. We thank supports of Prof. M. Barrico for the synthesis of the samples and SEM pictures, XRD analysis.

NOTES