Factors Affecting Fines Flocculation Performance with Cofactor-Polyethylene Oxide ()

1. Introduction

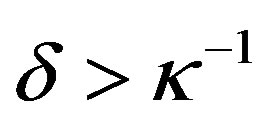

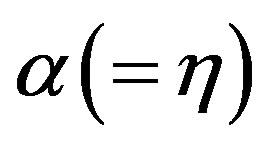

Flocculation process requires retention aid systems of dualor multi-components to retain colloids and fines. The conventional cationic retention aids were found interfered with charged substances in furnishes, and the neutral and high molecular weight of polyethylene oxide (PEO) is used as an alternative [1,2]. PEO was found working at low shear rates [3] efficiently with a cofactor (CF) having phenol groups [1,2,4]. In flocculation and retention processes, the following cofactors: modified phenolic resin (MPR), sulphonated kraft lignin (SKL), tannic acid (TA), phenol formaldehyde resin (PFR) and sodium naphthalene sulphonate (SNS) were used in papermaking applications [5]. In literature, phenol cofactors CF and PEO are not adsorbed on some colloids, fines, and fibers, but their combinations were found effective [6]. Some hypothesis explained the work of retention aids; the most dominant one was the association-induce polymer bridging mechanism by van de Ven and Alince [7], who argued the mechanism of the network [6]. Inassociation-induce polymer bridging, the negative charge CF segments adsorbed on PEO coils expand and stiffen PEO coils to larger size (δ) due to repulsion among CF segments on the coils, making the coils capable to bridge surfaces. This large coil of PEO with CF is a CF-PEO complex, working as a polyelectrolyte capable to overcome the electrostatic double layer thickness ( ) with a thickness

) with a thickness  [8]. When PEO was used alone, the inducing polymer bridging (Figure 1(a)) showed that small PEO coil was not capable to bridge surfaces since

[8]. When PEO was used alone, the inducing polymer bridging (Figure 1(a)) showed that small PEO coil was not capable to bridge surfaces since , but with CF addition (Figure 1(b)), the expanded CF-PEO complex (

, but with CF addition (Figure 1(b)), the expanded CF-PEO complex ( ) bridged the surfaces [7,9].

) bridged the surfaces [7,9].

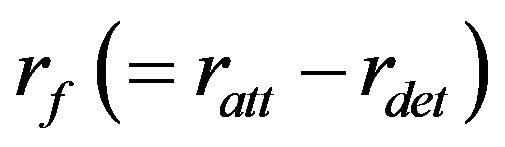

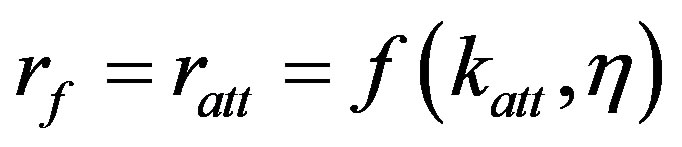

Flocculation processes are either heteroflocculation of dissimilar particles or homoflocculation of similar ones. The rate of flocculation rate  is a net of attachment rate (

is a net of attachment rate ( ) and detachment or deflocculation rate (

) and detachment or deflocculation rate ( ) [3,9,10]. Re-flocculation rate (

) [3,9,10]. Re-flocculation rate ( ) is the rate of the detached particles to form flocs again [11]. Attachment rate

) is the rate of the detached particles to form flocs again [11]. Attachment rate  can be assumed here as comprising

can be assumed here as comprising

(a) (b)

(a) (b)

Figure 1. Schematic of association-induced polymer bridging. Here, (a) No chain adsorption onto surfaces; (b) Polymer adsorption and bridging occur when association stiffens the chain.

. One important parameter enhancing

. One important parameter enhancing  is flocculation efficiency (

is flocculation efficiency ( ), or capture efficiency

), or capture efficiency  as used for polymeric retention aids. When PEO is used with CF forming the CF-PEO complex in a suspension, the efficiency

as used for polymeric retention aids. When PEO is used with CF forming the CF-PEO complex in a suspension, the efficiency  will be a function of the complex, or mainly of factors in PEO and CF. One factor is PEO quantity (

will be a function of the complex, or mainly of factors in PEO and CF. One factor is PEO quantity ( ) added to suspension to maintain the fractional coverage

) added to suspension to maintain the fractional coverage  on the surfaces; here

on the surfaces; here  is the maximum quantity needed to maintain the full coverage [9,12]. The second factor is the CF quantity added, or the CF to PEO ratio (

is the maximum quantity needed to maintain the full coverage [9,12]. The second factor is the CF quantity added, or the CF to PEO ratio ( ) in suspension, which mainly determines the size

) in suspension, which mainly determines the size  of CF-PEO complex and the strength of the bridging bond between the complex and the surfaces [3,11]. The third factor is the shear rate (

of CF-PEO complex and the strength of the bridging bond between the complex and the surfaces [3,11]. The third factor is the shear rate ( ) subjected in flocculation vessel as a stirring rate N (rpm). In previous work [9], since the attachment rate applies

) subjected in flocculation vessel as a stirring rate N (rpm). In previous work [9], since the attachment rate applies , the shear rate

, the shear rate  that enhances the attachment rate constant (

that enhances the attachment rate constant ( ) and affects flocculation efficiency

) and affects flocculation efficiency , will also affect

, will also affect . On the other hand, the shear rate

. On the other hand, the shear rate  that enhances the detachment rate constant

that enhances the detachment rate constant  will cause the detachment rate

will cause the detachment rate to increase [9]. What’s more, the shear rate

to increase [9]. What’s more, the shear rate  effects on flocculation were reported in literature as a breakage of flocs that enhances

effects on flocculation were reported in literature as a breakage of flocs that enhances  [9,13], and as a dissociation of the polyelectrolyte retention aid that causes

[9,13], and as a dissociation of the polyelectrolyte retention aid that causes  to decrease [9]. Long exposure to hydrodynamic forces of similar intensity ought to be able to overcome the binding forces that hold flocs together [14]. The shear rate tends to break fiber flocs into one by eroding fiber from the surface of a floc [15,16] or by splitting a floc into two [17-19]. Macromolecules can be described brittle; agitation to suspension of fiber flocculated by high mass polyelectrolyte tends to cause breakage, reducing the mean molecular mass [20-22]. Addition of cationic starch solution initially caused an extensive flocculation of fibers, which with continued agitation, the induced attachments between fibers were gradually broken resulting in a well dispersed suspension [23,24]. The forth factor is the number of parameters in PEO preparation, causing changes to PEO coil microstates prior to addition to flocculation process, and affecting flocculation efficiency

to decrease [9]. Long exposure to hydrodynamic forces of similar intensity ought to be able to overcome the binding forces that hold flocs together [14]. The shear rate tends to break fiber flocs into one by eroding fiber from the surface of a floc [15,16] or by splitting a floc into two [17-19]. Macromolecules can be described brittle; agitation to suspension of fiber flocculated by high mass polyelectrolyte tends to cause breakage, reducing the mean molecular mass [20-22]. Addition of cationic starch solution initially caused an extensive flocculation of fibers, which with continued agitation, the induced attachments between fibers were gradually broken resulting in a well dispersed suspension [23,24]. The forth factor is the number of parameters in PEO preparation, causing changes to PEO coil microstates prior to addition to flocculation process, and affecting flocculation efficiency  after addition. These parameters are stirring intensity and time in PEO dissolution unit; time in storage tank; dilution in preparation unit; and shear rate of a pump in transportation unit [9,25]. In literature, the first factor was expressed

after addition. These parameters are stirring intensity and time in PEO dissolution unit; time in storage tank; dilution in preparation unit; and shear rate of a pump in transportation unit [9,25]. In literature, the first factor was expressed  [9,12]. The forth factors were parameters in preparation unit prior to PEO addition worked to dissociate the PEO entanglements decreasing their size

[9,12]. The forth factors were parameters in preparation unit prior to PEO addition worked to dissociate the PEO entanglements decreasing their size , causing a drop in flocculation efficiency

, causing a drop in flocculation efficiency  [9,25]. The PEO entanglements were found reformed after PEO granules dissolution in water resulted in a clear solution [26]. Two interacted coils are needed to build up a primary entanglement of a size larger than a single coil, while more coils will reform larger entanglements. In flocculation process, the PEO entanglement has a primary role: when PEO dosage is added as entanglements with CF, the size of the resulted CF-PEO complex will get larger that increases the complex ability to bridge particles [9].

[9,25]. The PEO entanglements were found reformed after PEO granules dissolution in water resulted in a clear solution [26]. Two interacted coils are needed to build up a primary entanglement of a size larger than a single coil, while more coils will reform larger entanglements. In flocculation process, the PEO entanglement has a primary role: when PEO dosage is added as entanglements with CF, the size of the resulted CF-PEO complex will get larger that increases the complex ability to bridge particles [9].

In this work, the second and the third factors become the main subject of this study, and the objectives are to determine the effects of the increases in the ratio  (at moderate values) and shear rate

(at moderate values) and shear rate  on flocculation efficiency

on flocculation efficiency , amplitude (floc size), and fastness. To maintain this study, experiments of flocculation of fines were performed using CF-PEO retention aid at different shear rates

, amplitude (floc size), and fastness. To maintain this study, experiments of flocculation of fines were performed using CF-PEO retention aid at different shear rates  and values of ratio

and values of ratio . Since the detachment rate

. Since the detachment rate  is considered negligible (zero) at initial time of flocculation, the initial rate of flocculation which becomes

is considered negligible (zero) at initial time of flocculation, the initial rate of flocculation which becomes  can be taken as a measure of flocculation efficiency

can be taken as a measure of flocculation efficiency  at constant shear rate

at constant shear rate . The flocculation amplitude can be taken as a measure of floc size. The characteristic time of flocculation can be taken as a measure of flocculation fastness. Fines, the fiber fragments passing the 200 mesh pores of sizes less than 76 µm [27], were used to determine flocculation characteristics with CF-PEO system in a wide range of particle size and a wide range of fines retention applications in papermaking and environment.

. The flocculation amplitude can be taken as a measure of floc size. The characteristic time of flocculation can be taken as a measure of flocculation fastness. Fines, the fiber fragments passing the 200 mesh pores of sizes less than 76 µm [27], were used to determine flocculation characteristics with CF-PEO system in a wide range of particle size and a wide range of fines retention applications in papermaking and environment.

2. Experimentation

2.1. Materials

The fines used were separated by filtration of mixed pulps, taking the particles passed the 200 mesh (76 µm) openings. Flocc 999; the PEO of 7 million molecular weight was used as a flocculent. Interac 1323 the phenolic material was used as a cofactor. Masson Maclaren Mill (Canada) provided the pulps, while I.Q.U.I.P Inc. (Canada) provided Flocc 999 and Intrac 1323.

2.2. Experimental Setup

The experimental setup used in this work (Figure 2) is the one used in previous work [3,9,13]. The fines (0.1% consistency) was added to the beaker where mixed at constant stirring rate N (rpm), and then circulated by a peristaltic pump passing the photo cell of the Photome

Figure 2. Experimental set up of flocculation vessel: 1 = flocculation vessel (Beaker), 2 = mixer, 3 = peristalic pump, 4 = PDA, 5 = recorder.

tric Dispersion Analyzer (PDA) [28]. The PDA output signals, the direct current voltage ( ) and the ratio (

) and the ratio ( ) of the alternating to direct current voltages, were plotted versus time by a recorder. After reaching steady state, CF was added to fines followed by PEO. The

) of the alternating to direct current voltages, were plotted versus time by a recorder. After reaching steady state, CF was added to fines followed by PEO. The  signal, the voltage of the light transmitted the fines suspension, indicates particle concentration. The alternating voltage represents the root mean square (rms) of the transmitted light or the rms of the particle number, while ratio reading

signal, the voltage of the light transmitted the fines suspension, indicates particle concentration. The alternating voltage represents the root mean square (rms) of the transmitted light or the rms of the particle number, while ratio reading  indicates particle size. The change of reading

indicates particle size. The change of reading  with time indicates the flocculation rate taken as a measure of flocculation intensity [28]. In this work, the vertical distance the pen moved in arbitrary unit (AU) was taken as

with time indicates the flocculation rate taken as a measure of flocculation intensity [28]. In this work, the vertical distance the pen moved in arbitrary unit (AU) was taken as  reading. Both

reading. Both  and

and  readings were plotted versus time (

readings were plotted versus time ( ) by a recorder (Figure 3). The slope value of the curve

) by a recorder (Figure 3). The slope value of the curve  at initial time gave initial rate of flocculation

at initial time gave initial rate of flocculation , here,

, here,  is flocculation amplitude at equilibrium, and

is flocculation amplitude at equilibrium, and  is characteristic time of flocculation. Equilibrium time (

is characteristic time of flocculation. Equilibrium time ( ) is the time the flocculation requires to reach equilibrium. Flocculation process was shown transient in all flocculation runs, deflocculating after reaching equilibrium. The slope the

) is the time the flocculation requires to reach equilibrium. Flocculation process was shown transient in all flocculation runs, deflocculating after reaching equilibrium. The slope the  reading decreases at initial deflocculation is taken as initial rate of deflocculation (

reading decreases at initial deflocculation is taken as initial rate of deflocculation ( ). The time required to reach zero amplitude at initial deflocculation rate is the characteristic time of deflocculation (

). The time required to reach zero amplitude at initial deflocculation rate is the characteristic time of deflocculation ( ).

).

3. Results and Discussion

In this work, two flocculation experiments were performed. One was to study the effect of CF to PEO ratio  at moderate values by adding different quantities of CF with constant PEO, keeping the other parameters constants. The second was to study the shear rate effect on flocculation intensity at different stirring rates

at moderate values by adding different quantities of CF with constant PEO, keeping the other parameters constants. The second was to study the shear rate effect on flocculation intensity at different stirring rates  (rpm), keeping other parameters constants. One result of experiment one (Figure 4) show that the flocculation intensity was enhanced when

(rpm), keeping other parameters constants. One result of experiment one (Figure 4) show that the flocculation intensity was enhanced when  was doubled; shown as an increase in the amplitude

was doubled; shown as an increase in the amplitude  and initial rate

and initial rate  which indicates an increase in floc size and flocculation efficiency

which indicates an increase in floc size and flocculation efficiency . Explanation of this increase is related to the increase in the CF segments adsorbed on PEO coils. Since the PEO coils are constant, doubling the CF quantity will double the ratio

. Explanation of this increase is related to the increase in the CF segments adsorbed on PEO coils. Since the PEO coils are constant, doubling the CF quantity will double the ratio  which doubles the CF segments adsorbed on PEO coils. Here the PEO coils will be more stiffened and expanded resulting in larger CF-PEO complex that enhances flocculation efficiency

which doubles the CF segments adsorbed on PEO coils. Here the PEO coils will be more stiffened and expanded resulting in larger CF-PEO complex that enhances flocculation efficiency  and floc size. Furthermore, the number of the bridging bonds between the complex and fines surfaces will be doubled which strengthens the bridging bonds between PEO and surfaces [3,8,9], enhancing flocculation efficiency and floc size. We should notice that we have used moderate values of

and floc size. Furthermore, the number of the bridging bonds between the complex and fines surfaces will be doubled which strengthens the bridging bonds between PEO and surfaces [3,8,9], enhancing flocculation efficiency and floc size. We should notice that we have used moderate values of , the one used in papermaking range to maintain the required specifications. The high values of

, the one used in papermaking range to maintain the required specifications. The high values of , as reported [11] maintain small complexes and produce weak flocculation, are not in the scope of this work. The second result of experiment one was the transient flocculation of fines with CF-PEO system, recorded after equilibrium as a decrease in the ratio reading R with time and estimated as a deflocculation rate

, as reported [11] maintain small complexes and produce weak flocculation, are not in the scope of this work. The second result of experiment one was the transient flocculation of fines with CF-PEO system, recorded after equilibrium as a decrease in the ratio reading R with time and estimated as a deflocculation rate . This

. This

Figure 3. Ratio reading R is a measure of flocculation intensity with time. rf = initial rate of flocculation, Am = amplitude of flocculation at equilibrium, t = characteristic time of flocculation, te = equilibrium time of flocculation, rd = initial rate of deflocculation, td = characteristic time of deflocculation.

transient behavior was also reported in previous work [3] in flocculation processes with PEO alone enhanced by CF addition, where the transition behavior was ascribed to the instable PEO entanglement which dissociates with time. In this work, the deflocculation rate  (Figure 4) is not only enhanced with CF addition, but shows a behavior with increases in

(Figure 4) is not only enhanced with CF addition, but shows a behavior with increases in . This increase in

. This increase in , the increase in CF segments adsorbed on PEO coils, will cause the repulsion intensity among PEO coils in CFPEO complex to increase. This increase in CF repulsion worked, in early flocculation, to expand the CF-PEO complex that enhanced flocculation efficiency

, the increase in CF segments adsorbed on PEO coils, will cause the repulsion intensity among PEO coils in CFPEO complex to increase. This increase in CF repulsion worked, in early flocculation, to expand the CF-PEO complex that enhanced flocculation efficiency , and after flocculation reaching equilibrium, the CF repulsion in the formed flocs works to depart the PEO coils enhancing deflocculation.

, and after flocculation reaching equilibrium, the CF repulsion in the formed flocs works to depart the PEO coils enhancing deflocculation.

Furthermore, the effect of ratio  increase on flocculation fastness (Figure 5) is indicated enhancing to the fastness, shown as a significant decrease in the characte-

increase on flocculation fastness (Figure 5) is indicated enhancing to the fastness, shown as a significant decrease in the characte-

Figure 4. Effect of CF to PEO ratio (f) on flocculation and deflocculation intensities.

Figure 5. Effect of CF to PEO ratio (f) on flocculation and deflocculation fastness.

ristic time of flocculation  with the increase in

with the increase in . The resulted characteristic time of deflocculation

. The resulted characteristic time of deflocculation  is shown about 7.8 to 9.2 times larger than the corresponding

is shown about 7.8 to 9.2 times larger than the corresponding , showing a relatively slow deflocculation, which allows sufficient time to save flocs prior to deflocculation. For more, the increase in ratio

, showing a relatively slow deflocculation, which allows sufficient time to save flocs prior to deflocculation. For more, the increase in ratio  (Figure 5) showed weak effect on deflocculation fastness, since

(Figure 5) showed weak effect on deflocculation fastness, since  was shown constant. The actual values of

was shown constant. The actual values of  (s) at

(s) at  = 1.13 and 2.26 are respectively 145.5 and 143.3. This small effect (deflocculation fastness is increased with the increase in

= 1.13 and 2.26 are respectively 145.5 and 143.3. This small effect (deflocculation fastness is increased with the increase in ) is expected significant at higher values of

) is expected significant at higher values of .

.

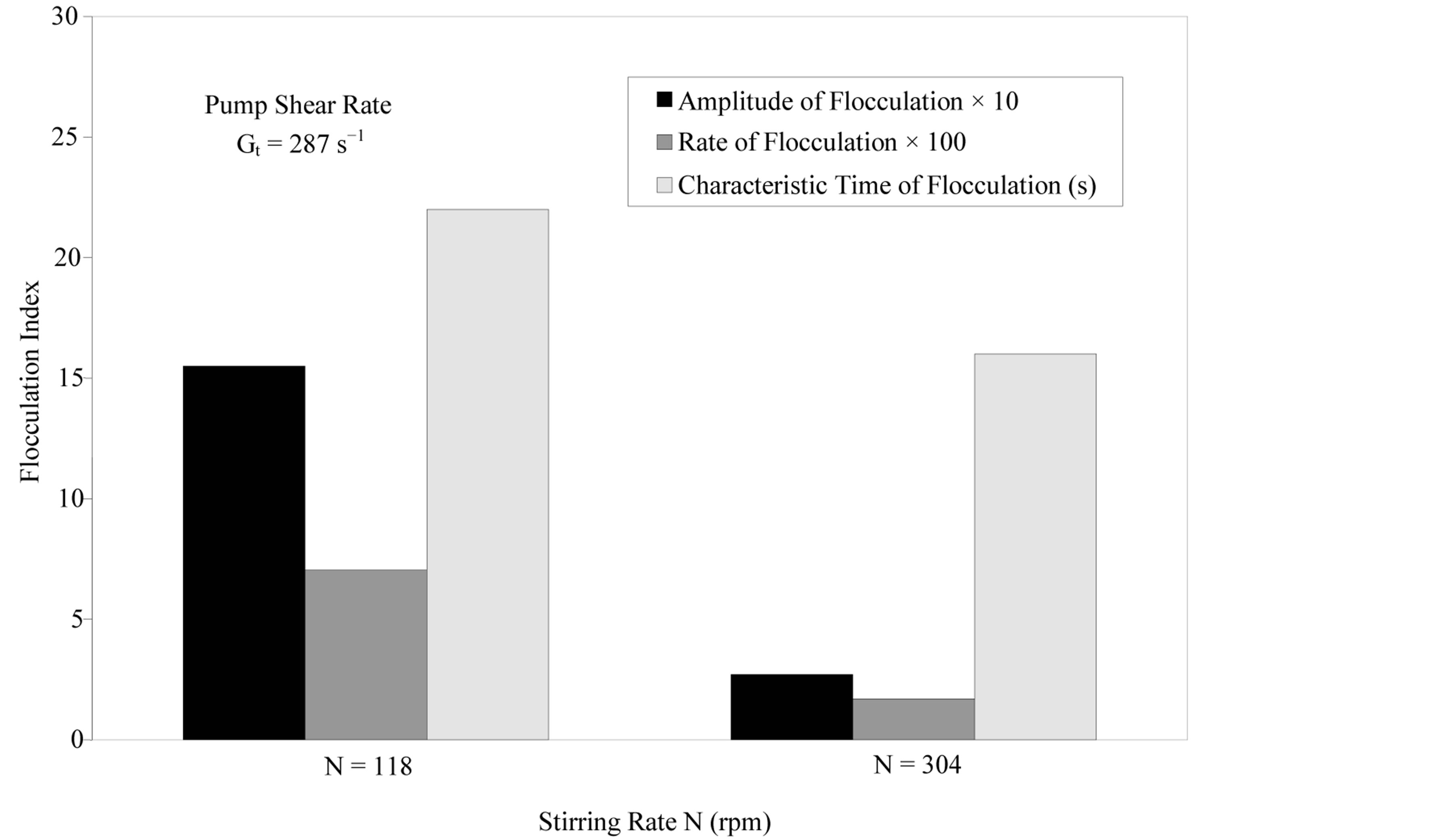

In experiment two, the effect of shear rate on flocculation intensity was studied, where 500 ml of 0.1% fines were flocculated in a beaker at low and high stirring rates  (rpm): 118, and 304. The circulated fines passed the PDA photocell via the transparent tubing by a peristaltic pump at low and constant velocity having a simple shear rate

(rpm): 118, and 304. The circulated fines passed the PDA photocell via the transparent tubing by a peristaltic pump at low and constant velocity having a simple shear rate  (s−1). In each run, CF (0.25 mg/g fines) was added and followed by PEO (0.12 mg/g fines) maintaining a constant and moderate ratio

(s−1). In each run, CF (0.25 mg/g fines) was added and followed by PEO (0.12 mg/g fines) maintaining a constant and moderate ratio  (= 2.1). Results (Figure 6) show that the increase in stirring rate

(= 2.1). Results (Figure 6) show that the increase in stirring rate  caused decreases in the amplitude

caused decreases in the amplitude  and in initial rate of flocculation

and in initial rate of flocculation , indicating decreases in floc size and flocculation efficiency

, indicating decreases in floc size and flocculation efficiency . In other hand, the increase in

. In other hand, the increase in  caused a decrease in the characteristic time of flocculation

caused a decrease in the characteristic time of flocculation , and relatively in equilibrium time

, and relatively in equilibrium time  since

since  (Figure 3), shows faster flocculation.

(Figure 3), shows faster flocculation.

Comparing the effect of the increases in shear rate  and ratio

and ratio  at moderate values on flocculation experiment, results have shown: the flocculation efficiency

at moderate values on flocculation experiment, results have shown: the flocculation efficiency  is increased with the increase in the ratio

is increased with the increase in the ratio  and decreased with the increase in the shear rate

and decreased with the increase in the shear rate ; the floc size is increased with the increase in the ratio

; the floc size is increased with the increase in the ratio  and decreased with the increase in the shear rate

and decreased with the increase in the shear rate ; the flocculation fastness is increased with the increases in both ratio

; the flocculation fastness is increased with the increases in both ratio  and shear rate

and shear rate . This result indicates that the bad selection of the shear rate

. This result indicates that the bad selection of the shear rate  in process will break large flocs resulted by CF, increasing operation cost. Furthermore, excess addition of CF at high

in process will break large flocs resulted by CF, increasing operation cost. Furthermore, excess addition of CF at high  will produce fast flocculation with small flocs [11] and when

will produce fast flocculation with small flocs [11] and when  is increased, the expected destructive effect of

is increased, the expected destructive effect of  on flocs will be added. Furthermore, if floc is required of small size, the high shear rate

on flocs will be added. Furthermore, if floc is required of small size, the high shear rate  with high dosage ratio

with high dosage ratio  are seemingly not recommended, since the required size can be obtained by only increasing the shear rate

are seemingly not recommended, since the required size can be obtained by only increasing the shear rate .

.

4. Concluding Remarks

In this work, increases in CF addition at constant PEO and in a moderate range of CF to PEO ratio caused increases in flocculation amplitude, rate and fastness, making these moderate ratios recommended for use in flocculation and retention processes. All flocculation runs with CF-PEO system were transient, showing deflocculation after equilibrium enhanced by CF to PEO ratio increase. Increases in the shear rate caused a decrease in flocculation amplitude producing small flocs, and a decrease in characteristic time of flocculation causing fast flocculation. Selection of a required floc size and flocculation fastness will be a matter of operation setting of CF to PEO value and shear rate.

Figure 6. Effect of shear rate (stirring rate N) on fines flocculation with CF-PEO in a beaker.

Acknowledgements

1) I like to acknowledge Pulp and Paper Research Center/McGill, where these experiments were performed.

2) Dr. van de Ven T.G.M. and Dr. J. Paris for valuable discussions 3) Maclaren Masson Mill, and E.QU.I.P Inc. for material supply.