Enhanced Photocatalytic Properties of Pure and Cr-Modified ZnS Powders Synthesized by Precipitation Method ()

1. Introduction

The reactive dyes are wide consumed in the dye market that due to have a high ability for forming strong covalent bonds with cellulosic fibers via the hydroxyl groups under highly alkaline conditions that leads to a high fastness. Moreover, they have a low cost, highly soluble in water as anionic electrophiles and wide range of color can be given bright colors [1] [2] [3] [4] [5] . There are many types of these dyes that have a general formula structure S-F-T-X, where, S is solubilizing group like SO3 group, F is chromophore group like azo or aromatic ring groups, T is Bridge group such as sulphide, imino, oxide, ethyl & methyl groups and X is reactive group such as vinylsulfone and dichlorotriazine that are accountable to bound with cellulosic fibers [5] [6] . In general the chromophore groups in these dyes are determined the kind of the absorbed light area, so, in a visible light area the azo bond has absorption, while in the UV light area the aromatic ring has absorption [7] . In the manner, reactive dyes are mainly employed in dying paper and textile industries that release large flows from colored wastewater [8] . Many triers to remove the wastewater in different physical, chemical and biological methods were done such as photocatalytic decolorization [8] [9] [10] , adsorption [11] [12] [13] , bio-removal [14] [15] , photo fenton and fenton-like [16] [17] extraction [18] , Coagulation [19] [20] and using dielectric barrier discharge [21] .

In this study, the work focused on the optimal conditions for photocatalytic decolorization of reactive black 5 dye with ZnS powders bare and doped with chromium, perform by precipitation method. This study was described the effects of dose of catalyst, initial pH of solution, concentration of K2S2O8 and temperature on photoreaction rate.

2. Practical Part

2.1. Chemicals

In this photocatalytic experiments, all chemicals were used without any further purification. Commercial Zinc sulfide and Thiourea were supplied by Fluka. Other chemicals such as Chromium (III) chloride, Zinc sulphate hepta hydrate and poly ethylene glycol (PEG-4000) were purchased from Merck. NaOH, NH4OH and HCl were supplied by BDH. The textile dye (reactive black 5 dye) was supplied by the Hilla textile factory in Babylon city in Iraq, and the characteristics of it are summarized in Table 1.

2.2. Preparation of Bare ZnS and (1:1)% Cr-ZnS Nanopowder

All prepared solutions were dissolved in distill water then shaking by ultrasonic

![]()

Table 1. The main characteristics of reactive black 5 dye [13] [18] [21] .

(FALC) for 10 min to ensure getting for homogenous solution. The Bare ZnS and metal loaded ZnS procedure were modified from procedure in reference [22] . 0.5 M from ZnSO4 was used as starting material. The equal volume from 0.5 M thiourea was taken in a burette and added drop by drop into ZnSO4 solution with vigorous stirring (Labtech-magnetic stirrer) for 25 minutes to get ZnS solution, and simultaneously 0.05 M from CrCl3 was added to this solution as droping agent using burette for 25 min to create the Cr loaded ZnS. This final formed solution was followed by drop wise addition of 1% of poly ethylene glycol-4000 (PEG-4000) as neutral capping agent solution under vigorous stirring for 1 hour. Afterwards, 0.1 M from ammonia solution was added slowly to solution of metal until the pH reached to range between 10 and 12, that necessary to generate the metal complex. Finally the metal complex solution was filtrated under vacuum using Büchner’s funnel. The precipitate was twice times by using distill water then used absolute ethanol to remove the impurities. The produced precipitate for ZnS and Cr/ZnS were white and grey color as seen as Figure 1, both catalysts were dried overnight by desiccator then dried in oven at less 100˚C for 2 h to obtain powder sample.

The suggested chemical equations were investigated from the following equations.

(1)

(2)

(3)

and

(4)

(5)

![]() (a)

(a) ![]() (b)

(b)

Figure 1. Images for prepared (a) ZnS nanopowder and (b) Cr loaded ZnS nanopowder.

2.3. Photocatalytic Experiments

Appropriate grams of photocatalysts (ZnS or Cr-ZnS) were added to 100 mL of 25 ppm from reactive black 5 dye solution. The produced suspension solutions were subjected to UV-A light flux at intensity equal to 1.45 × 10−7 Einstein s−1, which calculated by chemical actinometer [23] . At different time intervals, 3.5 mL was taken out with using syringe and then carried out double separated processes by using centrifuge for 10 min and 4000 rpm. The produced filters were studied by reading the absorption at 595 nm to find the residue concentration of dye after irradiation.

3. Results and Discussion

3.1. Characterisation of Bare and Cr-ZnS

3.1.1. XRD Analysis

From XRD spectra in Figure 2, the observed diffraction peaks are broadening that confirmed the crystallites were nanosized [24] . The XRD patterns display the generated of ZnS nanoparticle, the (111), (200) and (311) planes (JCPDS Card No. 65-9585) were confirmed the ZnS nanoparticles is prepared at 2θ equal to 27.76˚, 32.98˚ and 58.6˚ respectively [25] [26] . A small and broadening peaks were noticed at around 2θ values of 13˚ - 26˚ for both samples, that due to organic moiety PEG that used as capping agent [27] [28] . The diffraction peak of (111) at 27.76˚ is slightly shifted to higher angles at 27.88˚ for dispersed Cr ions into the ZnS matrix. This may be assigned to the small ionic radii of Cr3+ (0.63 Å) that will interact with Zn2+ (0.74 Å) in ZnS lattice [29] [30] . Further, after loaded Cr on ZnS surface, the (0010) plane at 6.82˚ was shifted and become sharp at 8.14˚. In (220) plane, the peak was reduced at 41.68˚ with loading the chromium ion. From XRD data, the mean crystal size of ZnS nano and Cr/ZnS nano are calculated which depended onto Deby-Scherrer formula [31] and found to equal to 19.986 nm and 16.21 nm respectively.

![]()

Figure 2. XRD patterns of Bare and Cr3+ loaded on ZnS nanopowders.

3.1.2. AFM Analysis

The roughness of ZnS nanopowder is more than that roughness for Cr loaded ZnS nanopowdr, which appear in Figure 3. The agglomeration is the most dominated in the nanoparticles. The shapes of prepared samples are having semi spherical shape with low agglomeration. This result is in agreement with the reported in reference [32] . The particle sizes for ZnS nano and Cr loaded ZnS nano are measured to be 51.02 nm and 82.33 nm respectively.

3.1.3. Band Gap Energy Measurements

The band gaps for the above prepared samples were investigated by measuring the fluorescence spectra in Figure 4.

The band gaps (Eg) were calculated employed the following expression in Equation (6) for optical absorption of the above prepared photo-catalysts [33] .

(6)

![]() (a)

(a)![]() (b)

(b)

Figure 3. AFM 2-dimensions Image of (a) bare ZnS nanopowder and (b) Cr Loaded on ZnS nanopowder.

![]() (a)

(a) ![]() (b)

(b)

Figure 4. Fluorescence spectra of (a) bare ZnS nanopowder and (b) Cr Loaded on ZnS nanopowder.

The absorption edge for ZnS nanopowder and Cr loaded on ZnS nanopowder were found to be at 348.5 nm and 347.1nm respectively. The bang gaps were found to be 3.558 eV and 3.572 for bare and Cr loaded ZnS nanopowder respectively. The slight blue shift in the absorption edge for Cr loaded on ZnS nanopowder is related to the calculated bang gap increase when Cr loaded on ZnS.

3.2. Effect of the Metal Loading on Photocatalytic Activity

Figure 5 illustrates, that the metalized process of photo-semiconductor (ZnS) by Cr leads to increase the rate constant for decolorization of reactive black 5 dye. The rate constant (kapp.) can be calculated by depended on the Langmuir-Hinshelwood kinetic expression to determine Equations (7) and (8) [34] . This reaction is found to be obeyed the pseudo first order.

(7)

where: Ct is a concentration of the reactive black 5 dye at t time of irradiation. C = is an initial concentration of same studied dye at (dark reaction) in 0 min as the time of irradiation. The apparent first order equation can be investigated from Equation (8) [34] [35] :

(8)

The % Efficiency (% E) of decolourization for reactive blue 5 dye was calculated using the following relationship that reported in reference [35] .

(9)

This result assigns to rise the charge carrier space distance that leads to increase the hole life time and inhibits the recombination process. Moreover, the metal acts as collector of electron by forming a Schottky’s barrier [36] [37] [38] .

![]()

Figure 5. Rate constant of photo reaction as Function of bare ZnS nano and 1:1 Percentage of Cr loaded on ZnS nano Surface, Used (1 g from catalysts), under Purged environment O2.

The probability for generating this barrier is depended upon the value of work functions fcc (111) for both Cr and Zn in ZnS. Hence, the large value for work function of Cr at fcc (111) 4.5 enhances the interaction between Cr and Zn fcc (111) 4.22 in ZnS photocatalyst [39] .

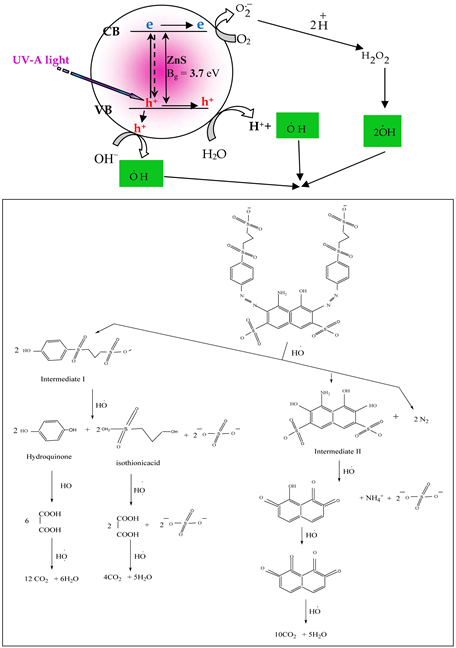

3.3. Suggested Mechanism

The proposed mechanism for photodecolorization of reactive blue 5 dye (RB5) is occurred in when UV-A light focused on suspension solution of bare ZnS nanopowder or Cr loaded on ZnS nanopowder, that perform as system (Dye/sem-iconductor/UV light). The more accepted mechanism is outlined in Scheme 1. In outset, azo bond is oxidative cleavage either C-N or N-N cleavage by attaching the hydroxyl radical that generated via photocatalysis process [40] [41] in presence the prepared photocatalysts. The intermediate I and intermediate II were formed with liberated N2. After that the C-S bond is cleavage in series steps to generate CO2 and H2O [41] .

4. Conclusions

On basis on produced data in this work, the main conclusion can be epitomized:

1) The XRD analysis was evidenced the bare and Cr loaded on ZnS nanopowder surface. The mean crystal size for bare ZnS nanopowder is less than that for Cr loaded ZnS nanopowder.

2) AFM analysis was indicated the prepared nanopowder shapes are semi-spherical.

3) From the florescence spectra, the calculated band gaps for the bare ZnS nanopowder were more than that value for Cr loaded ZnS nanopowder.

4) The photo-decolorization of reactive blue 5 dye is clearly followed the pseudo first order kinetics by depended on Langmuir-Hinshelwood Kinetic Expression at low concentration.

The nanopowder Cr-ZnS powder has more activity for decolorization of

Scheme 1. Schematic diagram for more accepted proposed mechanism as system (Dye/ semiconductor/UV light) (modified from reference [41] [42] [43] ).

reactive black 5 dye under ultraviolet light than that for using prepared ZnS nanopowder to almost 94% and 59 % in 160 min respectively.