1. Introduction

As stated by reference [1] some years ago, Industrial Ecology provides the technological and scientific basis for being considered a path toward sustainability. This has been the case mainly in European countries, particularly in The Netherlands, where the concept is disseminated due to its influence on the positive ecological results from the industrial symbiosis at the Kalundborg industrial park in Denmark [2] . In order to create an industrial symbiosis, Boons and Spekkink [3] found the mobilization capacity, which was the ability of actors within the industrial park to activate relevant firms and other parties to develop symbiotic linkages, to be critical.

Life Cycle Assessment (LCA) is another key concept in Industrial Ecology that is used as analytical tool to address the environmental impacts of products and services [4] . In recent years, LCA has been useful for decision makers in business and policy [5] .

From its beginning to present day, LCA has been used for different environmental purposes in several settings such as: cement manufacture [6] ; wood production [7] ; carbon nanotube products [8] ; renewable resources [9] ; industrial waste [10] ; fisheries [11] ; organic waste [12] and many other applications. Most of these, along with other LCA-case studies found in the literature, were unsurprisingly conducted in Europe thus proving the institutionalization of the concept in that continent. The fact that it is not possible to find literature on LCA studies in Mexico in the most prestigious sustainability journals indicates there is a lack of institutionalization of Industrial Ecology, pertaining to LCA, in Mexico.

Thus, one of the goals of this study was to test this premise and explore the degree of institutionalization of LCA in northwestern Mexico by conducting a life cycle analysis case study at the slaughtering stage of the beef production system of Mexico Supreme Quality, official brand, in a Federally Inspected Type (TIF for its Spanish acronym) Slaughterhouse within the state of Sonora, Mexico.

Beyond the technical difficulties, the study also aimed at analyzing the current role played by the Mexican academia in increasing the degree of institutionalization of the LCA in northwestern Mexico.

2. Methodology

2.1. Case Study Profile

The life cycle analysis study was conducted according to the standards ISO14040: 2006, NMX-SAA-14040- IMNC-2008NOM in a Federally Inspected Type (TIF by Spanish acronym) Slaughterhouse in the state of Sonora in Northwest Mexico. The Slaughterhouse was built in 2007 covering an area of 21,000 square meters in a suburb of the capital city of Hermosillo. The average daily cattle slaughter is 200 bovines, including cows, bull, calves, heifers, and bullocks, from several farms. Eighty-seven workers are employed in the slaughterhouse covering two shifts.

The slaughter process was characterized by observing the production tasks during several walkthroughs the production lines and by having short interviews with workers, supervisors, and the manager.

2.2. Functional Unit (FU)

A mass balance for the slaughterhouse process was required to get the functional unit of the system under examination. The average weight of livestock, the average weight of bovine meat, and the average weight of the organic waste generated in three days were calculated.

2.3. Inputs and Outputs Inventory

The rate of livestock slaughtered per day, the water and natural gas consumption per day, and the electricity consumption per month were all considered. The hazardous substances used for housekeeping were also included in the inputs inventory. The emission inventory included the production of methane (CH4) calculated from the enteric fermentation, manure, and the natural gas emissions from the boiler. Additionally, emissions of carbon dioxide (CO2), carbon monoxide (CO), nitrous oxide (N2O), nitrogen oxide (NOX), sulfur dioxide (SO2), and the volatile organic compounds (VOC’s) from the use of natural gas were calculated as well. Furthermore, the CO2 emissions from electricity generation were also taken into account.

2.4. Data Calculations

a) CH4 emissions from enteric fermentation

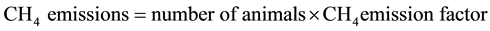

The CH4 emissions were calculated using the guidelines suggested by the Intergovernmental Panel on Climate Change [13] , whose formula for enteric fermentation is shown in Equation (1):

(1)

(1)

where the CH4 emissions factor is equivalent to 56 kg/animal/year.

b) CH4 emissions from manure

It was considered for the tier 1, emissions factors with high uncertainty, from the 2006 IPCC guidelines.

c) CO2, N2O, NOX, CO, SO2 emissions and VOC’s from natural gas

Emission factors for criteria pollutants and greenhouse gases from natural gas combustion were taken from the U.S Environmental Protection Agency guidelines [14] .

d) CO2 emissions from electricity generation

The CO2 emissions from electricity generation were obtained by using a Mexican Calculator of CO2 [15] created by the National Institute of Ecology, a Mexican governmental agency, Pronatura Mexico, and a private organization called “Reforestemos Mexico”.

e) Wastewater

Wastewater was analyzed, taking into account the Mexican Official Norm (NOM for its Spanish acronym) NOM-001-SEMARNAT-1996, at a certified laboratory of the National Water Commission in Mexico (CONAGUA). The water quality parameters analyzed were phosphate (PO4-P), total suspended solids (TSS), the biochemical oxygen demand (BOD), the chemical oxygen demand (COD), and the total Kjeldahl nitrogen (TKN).

f) Environmental impacts

Environmental impacts such as water depletion, water eutrophication, global warming potential, human toxicity, air acidification, and the photochemical ozone creation potential were evaluated with the GaBi Education Software, version 4.

3. Results

a) Boundary system

Figure 1 shows the boundaries of the slaughterhouse production system, indicating inputs and outputs per work station.

b) Mass balance

Table 1 indicates the mass balance with a functional unit of 299.5 kg, which was calculated as described in the methodology section.

![]()

Table 1. The slaughter process―mass balance.

![]()

Figure 1. Characterization of the slaughter process.

c) Inputs inventory

The consumption of resources in relation to the functional unit is shown in Table 2. The time period is presented on a monthly base.

d) Hazardous inputs

Chemicals are also used in the slaughter process, Table 3 presents these inputs. In addition, products for cleaning and disinfection of facilities are also considered in Table 4.

e) Emissions to environment

Table 5 shows the sources of the emissions per functional unit (FU) associated to the production process as well as the potential impact on the environment.

f) Organic waste

Table 6 depicts the organic waste generated per functional unit.

g) Potential environmental impacts

The assessment of the potential environmental impact was done using the method CML 2001 of the Center of Environmental Science of Leiden University and taking into consideration the slaughter average rate per month of 4333. Table 7 shows the numbers.

4. Discussion

The present LCA case study revealed opportunities for improving the environmental performance of the slaughterhouse by taking measures such as the reduction of CH4 from enteric fermentation since methane is one of the main greenhouse gases responsible for climate change. The LCA showed that CH4 contributes to about 99%, 215,566 CO2-equivalent kilograms, of the total emission in the slaughterhouse.

According to the Greenhouse Gas (GHG) emission inventories and forecasts report (I & Fs) of the state of So-

![]()

Table 2. Inventory of inputs used in the slaughterhouse.

![]()

Table 4. Products for cleaning and disinfection of facilities.

![]()

Table 5. Emissions to the environment and potential impact per functional unit.

GWP = Global Warning Potential, EP = Eutrophication Potential, AP = Acidification Potential, POCP = Photochemical Ozone Creation Potential, HTP = Human Toxicity Potential, EF = Enteric Fermentation, M = Manure. NGC = Natural Gas Combustion, EP = Electric Power, EF (EPA) = Emission Factors (Environmental Protection Agency), WS = Wastewater Samples.

![]()

Table 6. Organic waste per functional unit.

nora [16] , 52.6% of total greenhouse gas emissions in 1990 was generated from enteric fermentation in the state’s farms, and it has been forecasted that by 2020 enteric fermentation will account for 53.3% of the total greenhouse gas emission in the state. These data rank the agriculture sector and the energy supply conjointly as the main sources of GHG emission in the state.

Another environmental concern is wastewater due to its high contents of blood, air, fats, and chemicals that increase the biochemical oxygen demand (BOD) and the chemical oxygen demand (COD) that consequently cause, the eutrophication of water. There is strong evidence that water crisis worsens as climate change increases [17] . In spite of the water scarcity in homes, the agricultural sector concentrates almost 80% of world water consumption [18] ; additionally, important amounts of water are also consumed in the production of meat and dairy products [19] . For those reasons, wastewater treatment is vital nowadays in order to avoid water shortages that have prevented economic growth in many countries around the world [20] .

From the academic perspective, the case study was a success because it was possible to collect data for conducting the LCA, despite of the lack of interest of administrators in this methodology. Since a basic tenet of business is generation profits, when thinking about sustainability, administrators are expected to be not only green but also cutting costs. Although, the LCA generated reliable information in terms of climate change or water eutrophication, it is true that decision makers at the slaughterhouse were more interested in production process data that could cut costs and protect the environment at a local level. For this reason, the chances of implementing sustainable initiatives are unlikely because the benefits to reduce the impacts to climate change or to

![]()

Table 7. Environmental impacts-CML2001.

reduce the water crisis would be unnoticeable and unaffordable for companies.

Now, the challenge is to transfer LCA from academia to public or private organizations. In Europe, this tool has been more deeply-rooted in scientific settings with less degree of institutionalization among business and lesser among consumers [21] perhaps due to the complicated math behind the methodological steps of this tool; mainly, in the allocation methods for the life cycle inventory analysis, which have been debated in numerous articles about LCA [22] .

Institutionalization has been studied from many perspectives, but many coincided in defining this concept around values, norms, traditions, routines, interactions, and relationships within organizations [23] .

According to Cohen and Howard [24] the degree of institutionalization of a concept is determined by the following conditions: professional legitimacy, viable clientele, entrepreneurial acumen, and prospective occupational opportunities.

The first condition deals directly with the academic field; one of the most important proactive efforts in northwestern Mexico to promote Life Cycle Assessment came from the Sustainable Development Certificate (SDC) at Engineering College of the University of Sonora. The SDC is considered by the Mexican Council of Science and Technology (CONACYT) as a Graduate Program of excellence with international recognition. This is the highest rank granted to a graduate program in Mexico by CONACYT; only 1% of all Mexican graduate programs reach this level. As an international competence graduate program, faculty have been influenced by peers in foreign institutions, mainly in Holland, Sweden, and Germany. Consequently, Industrial Ecology is part of the SDC curricula and students are taught to conduct LCA studies.

Viable clientele refers to the existence of a need that establishes the demand for LCA studies. This was not the case in this study, external drives for adopting and implementing Industrial Ecology tools such as LCA do not exist in Mexico. The main driver to conduct the LCA study was academic; therefore, it was done for free.

The third condition is entrepreneurship, which is inherently risky because it implies changes to organization’s structures [25] . Perhaps for this reason, it was easier to get access to a small business than to larger companies. Although, permission was granted, the absence of philosophies, techniques, procedures, and rules in the slaughterhouse made the development of the LCA study more difficult. Gibb [26] also noted that entrepreneurial behaviors are less evident in larger companies than in small businesses, confirming another obstacle for the institutionalization of LCA in Mexico; the lack of adequate managerial and engineering skills in small businesses.

The last indicator to prove the institutionalization of a concept is the labor market. Labor market refers to information about what jobs and skills employers looking for. In other words, the number of jobs available, demand, and number of people with the competence for these jobs, supply.

A survey conducted in the state of Sonora at six manufacturing plants that import and assemble duty-free electronic components for export found that none of the participants in the survey claimed to perform material and energy balance or other tool of Industrial Ecology [27] . This survey suggests that there is no demand for industrial ecologists; despite that there are people having a set of skills needed to be competent in LCA.

5. Conclusions

By mimicking European LCA experiences in a slaughter house in northwestern Mexico, it was possible to confirm the premise that there was a low degree of institutionalization of LCA in this country.

In the case study here presented, LCA was not known by the administrators of the slaughterhouse; however, they accepted to grant access to slaughterhouse’s facilities as long as data could cut costs and protect the environment at a local level. Although this was not the case, it was important to conduct the LCA in order to institutionalize the concept among private enterprises.

This LCA study identified two major opportunities to improve the environmental performance in the slaughterhouse: the CH4 emissions from enteric fermentation and its wastewater. Beyond technical limitations to conduct the study; the LCA has proven to the administrators of the slaughterhouse that preventive measures can be taken particularly on these two pollution sources in order to reduce its environmental load. However, the consequences of these pollution sources resulted in global impacts making it unattractive to administrators to invest in projects that would have no direct benefits for the slaughterhouse.

Findings in this study also confirmed the importance of Mexican universities for promoting and conducting more LCA studies among private and public organizations in order to guide firms towards this tool.

As a closing insight, it is necessary to remark the potential of LCA as a viable alternative to help organizations to be more sustainable.

Acknowledgements

Authors would like to thank Dr. Leo Baas professor of Industrial Ecology from Linkoping, University in Sweden, for sharing his wisdom on Industrial Ecology with students and professors at the University of Sonora in Mexico and also for providing the inspiration for incorporating Industrial Ecology and LCA to curricula and research.