Time-Frequency Entropy Analysis of Arc Signal in Non-Stationary Submerged Arc Welding ()

1. Introduction

The submerged arc welding has been widely used in welding production because of its high effection [1]. But it is hard to realize online inspection of voltaic arc and molten pool state by detection methods of infrared and video, because the arc load burn under the welding fluid and influenced by various uncertainties, and the processes of arc stability, drop transfer and weld formation are changed. Although strongly nonlinear, time-varying load of arc, the changes of arc made energy signals is reflected in time and frequency domain in welding process, so it a significant to achieve online detection and study arc stability and welding quality by sensed current or voltage signals in welding process [2]. Welding current or voltage is a no-stationary signal of submerged arc welding. The time-frequency analysis is the useful method to research no-stationary signal [3]. So it’s no doubt that time-frequency analysis and calculation of arc current and voltage signals of submerged arc welding is a good method to judge stability of arc and welding quality by introducing information entropy into time-frequency distribution [4,5]. In order to quantitatively describe the degree for the energy time-frequency distribution of different operation state of a machine, information entropy theory as a diagnosis criterion has been introduced into the time-frequency distribution by some researchers, and good effect has been obtained in machinery fault diagnosis [6,7]. Therefore, time-frequency analysis method is introduced to analyze the collected arc signal in different conditions of welding process and calculate corresponding energy entropy in this paper. The relationship between arc stability and energy entropy of submerged arc welding is explored to obtain new knowledge of arc characteristic of submerged arc welding, even to get more accurate numerical evaluation of arc stability. It is also provided that a more adequate guidance for welding parameters choice.

2. Time-Frequency Entropy Theory and Algorithm

There are some time-frequency analysis methods such as window fourier transformation, continuous wavelet transformation, wigner-ville distribution and hilbert-huang transformation. The time-frequency window in window fourier transformation is immovable, so it can’t meet the frequency and time resolution at the same time. In the process of wavelet transformation, the choice of wavelet basis has a great impact on analysis result with poor adaptation to the whole signal. Wigner-ville has cross-term disturbance, so it is against to the subsequent time-frequency entropy calculation. Hilbert-huang Transform is a new self-adapting time-frequency analysis method. It has higher time-frequency resolution and time-frequency concentration, which is especially suitable to the analysis of arc current signal. Hilbert-huang transform is introduced to conduct time-frequency analysis of arc current signal.

Hilbert-huang transformation contains empirical mode decomposition and corresponding hilbert spectrum. The signal  is decomposed into summation of lots of internal mode component Intrinsic Mode Function

is decomposed into summation of lots of internal mode component Intrinsic Mode Function  and a residual component rn as expressed in Equation (1),

and a residual component rn as expressed in Equation (1),

(1)

(1)

where rn is an average trend or a constant. Neglecting the residual component , Hilbert transform of every Intrinsic Mode Function

, Hilbert transform of every Intrinsic Mode Function  is performed. Equation (2) can be obtained,

is performed. Equation (2) can be obtained,

(2)

(2)

The analytic signal  is constructed by Equation (2),

is constructed by Equation (2),

(3)

(3)

Where the amplitude function  and phase function

and phase function  are obtained as Equations (4) and (5) respectively,

are obtained as Equations (4) and (5) respectively,

(4)

(4)

(5)

(5)

The instantaneous frequency  can be further obtained by Equation (5) as follows,

can be further obtained by Equation (5) as follows,

(6)

(6)

In this way, the following Equation (7) can be obtained,

(7)

(7)

where RP is real part. Equation (7) is defined as Hilbert spectrum and is written as Equation (8),

(8)

(8)

Equation (8) describes the accurate changing law of time and frequency of signal amplitude in the whole frequency ranges. Signal amplitude is expressed as function of time and instantaneous frequency in the three dimensions space. It also can be expressed as contour line of time-frequency plane.

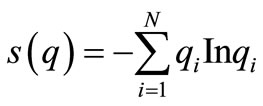

The method of information entropy introduced into time-frequency analysis is to divide time-frequency plane into N equal area blocks. Each block energy is supposed as , the total energy of the time-frequency plane is A. Each block energy is normalized by

, the total energy of the time-frequency plane is A. Each block energy is normalized by , thus

, thus  =1, which corresponds with initial normalization condition of information entropy calculation. Based on the formula of information entropy, formula of time-frequency entropy

=1, which corresponds with initial normalization condition of information entropy calculation. Based on the formula of information entropy, formula of time-frequency entropy  based on Hilbert-huang transformation is written as Equation (9),

based on Hilbert-huang transformation is written as Equation (9),

(9)

(9)

According to the basic property of information entropy, the more uniform is the  distribution, the larger is the value of time-frequency entropy

distribution, the larger is the value of time-frequency entropy , while the less uniform is the

, while the less uniform is the  distribution, and the smaller is the value of time-frequency entropy.

distribution, and the smaller is the value of time-frequency entropy.

3. Time-Frequency Entropy Calculation of Arc Signal

Experiments have been done by submerged arc welding machine ME1000. The material of work piece is low carbon steel with slab thickness of 20 mm, the welding wire trademark is H08A with diameter of 4.0 mm, and welding flux is HJ431. Current and voltage signals are collected by sensor SML1500E/S60 and data acquisition card PCI-1718HGU in the experiments. Under the above experimental condition, experimental program is done as follows: a) Under the given voltage of 38V, current amplitude of 450A, welding wire extension of 22 mm, welding speed of 0.6 m/min, the welding parameter unchanged in the welding process. b) Under the given voltage of 38V, welding wire extension of 22 mm, welding speed of 0.6 m/min, current amplitude changed from 450A to 550A. c) Under the given current amplitude of 450A, welding wire extension of 22 mm, welding speed of 0.6 m/min, the welding voltage changed in the welding process. Technology experiment are done by the above three experiments and record the arc signal in welding process. The frequency of sampling is 20 kHz, sample time is 30 s in each welding process. Time-frequency entropy calculation is done by 200000 points from the whole acquisition data. The waveform of welding arc current and voltage are shown in Figures 1-3.

Each 5000 collected data of currents and voltage is analyzed respectively with Hilbert-huang transformation, 100 time-frequency entropy value in each duty cycle is obtained.

in each duty cycle is obtained.  is the average of

is the average of . The calculation result of time-frequency entropy

. The calculation result of time-frequency entropy is shown in Figure 4.

is shown in Figure 4.

From Figure 1, it can be seen that welding process are stable. It is indicated that physical parameter of current, voltage and inputting energy are unchanged. Figure 2 is

(a) Current signals

(a) Current signals (b) Voltage signals

(b) Voltage signals

Figure 1. the arc signals the arc signals under experimental program (a).

(a) Current signals

(a) Current signals (b) Voltage signals

(b) Voltage signals

Figure 2. The arc signals under experimental program (b).

(a) Current signals

(a) Current signals (b) Voltage signals

(b) Voltage signals

Figure 3. The arc signals under experimental program (c).

the current and voltage signal of suddenly changed arc, there are two steps in the current waveform, and each platform is very stable, the before platform is near the current 450A, the after platform is near the current 550A, the change of the current occurs in a very short time. Figure 3 shows the arc current is always stable, but arc voltage is slightly undulating, which cause the arc energy fluctuations and instability inputting of welding heat.

Table 1 shows that time-frequency entropy calculation result that is big as the arc current and voltage are more

Table 1. Welding parameters and time-frequency entropy in different experiments.

(a) Current

(a) Current (b) Voltage

(b) Voltage

Figure 4. Time-frequency entropy.

stable. The time-frequency entropy is a measure of com plexity, so it should be large as current and voltage are regular. The time-frequency is reduced as arc current and voltage changed. It indicates that the arc current and voltage wave of submerged arc welding is a factor to affect the time-frequency entropy, and is closely related with stability of welding process. Therefore, time-frequency entropy can be used as the stability judgment criteria of submerged arc welding. Furthermore, it is seen form Figure 2 and Table 1 that the welding current can be adjusted to obtain the appropriate weld parameters width, penetration. Figure 3 and Table 1 show that the key factor of inputting weld energy is arc voltage in the conditions of unchanged current. Under certain conditions of welding current, the time-frequency entropy changes larger as arc voltage variation and lead to deterioration of the weld shape.

Figure 4 shows the fluctuations of time-frequency entropy calculation process. It also can be seen from the process of time-frequency entropy calculation that the more stability of submerged arc welding process is, the smaller of fluctuations of current and time-frequency entropy are. The standard deviation  (Sa) is the numerical description of fluctuations of time-frequency entropy calculation process, the smaller is the

(Sa) is the numerical description of fluctuations of time-frequency entropy calculation process, the smaller is the  (Sa), and the smaller is the fluctuations. Table 1 shows that standard deviation of time-frequency entropy is the smallest in experimental program a), which indicates that the fluctuations under these experimental program are smallest and most stability. It is also verified that time-frequency entropy can be used as the stability judgment criteria of submerged arc welding.

(Sa), and the smaller is the fluctuations. Table 1 shows that standard deviation of time-frequency entropy is the smallest in experimental program a), which indicates that the fluctuations under these experimental program are smallest and most stability. It is also verified that time-frequency entropy can be used as the stability judgment criteria of submerged arc welding.

4. Conclusions

The calculation and analysis of time-frequency entropy under three experimental condition show that time-frequency entropy value relates with stability of submerged arc welding process. The more stable is the welding process, the larger is the time-frequency entropy. On the other hand, the more unstable is the welding process, the larger is the fluctuations of time-frequency entropy. It is verified that the larger time-frequency entropy indicates the more stable arc. This research indicates that the timefrequency entropy can be used as stability evaluation criterion for alternating current square wave submerged arc welding.

5. Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51005073), Scientific Research Fund of Hunan Provincial Education Department (No. 10C0682), Ph. D Start Fund (No. E51088), Aid program for Science and Technology Innovative Research Team in Higher Educational Institutions of Hunan Province and Hunan Natural and Science Foundation Project (No. 10JJ8002).