Numerical Simulation of Stress-Strain State for Nonhomogeneous Shell-Type Structures Based on the Finite Element Method ()

1. Introduction

Structures in the form of nonhomogeneous shells are common in the priority areas of modern technology (aviation, space technology, oil and gas industry). The main manifestation of nonhomogeneity is the presence of openings of different shapes.

Openings characterize the design features and damage defects that appear in various cases of exploitation or in manufacturing processes. They reduce to concentration of stresses [1,2].

High load levels lead to plastic deformation. This fact is taken into account when using the methods of elastic solutions that reduce the solution of elastoplastic problems to solution of elastic problems [3].

The fields of stresses and strains that arise near openings’ edges have the mutual influence on each other. This influence depends on the openings’ shapes, dimensions, quantities, and spacings. Plastic deformation appreciably changes the pattern of this interaction. Transformation of above-mentioned fields near the openings cause changes to the process of exhausting the carrying capacity.

The plastic deformation zones, stress distributions and loads that correspond to the start of merging and further transformation in the course of loading make it possible to predict load-carrying ability of shell-type structures with openings.

Let us consider shell-type structures in view of cylindrical shell with rectangular openings.

2. Features of Used Solution Methods

The numerical finite element method (FEM) is an efficient method for solution of various complex problems of stress-strain state (SSS) and critical states (carrying capacity, stability) of various structures.

The projective-iterative versions (PIV) of FEM essentially reduces the needed for calculations performed by means of personal computers, which is of importance in simulation of complex nonlinear deformation of shelltype structures with openings of various types.

The theoretical foundations of PIV FEM in [4-8] and in series of works in mathematics problems are presented. The basic idea is as follows.

The problem of finding the minimum of the potential energy functional, defining the SSS of shell structures members is the conditional minimization problem

(1)

(1)

where  is the functional bounded on a set of cinematically possible displacements

is the functional bounded on a set of cinematically possible displacements  of the real Hilbert space

of the real Hilbert space .

.

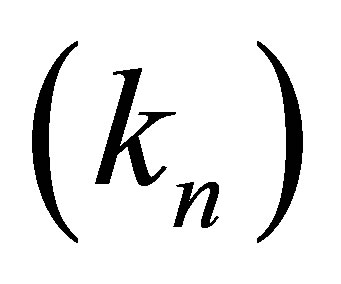

The extremum problem Equation (1) is approximated, through the use of FEM, by a series of discrete extremum problems . Each of the problem is solved via some iterative process, but not completely. Starting from an arbitrary rather rough breakdown of the mesh, one constructs just a few approximations

. Each of the problem is solved via some iterative process, but not completely. Starting from an arbitrary rather rough breakdown of the mesh, one constructs just a few approximations  to the minimum point of the n-th multivariable function. The last approximation is interpolated into a finer finite element mesh and serves an initial approximation to the minimum point of the next function at the (n + 1)-th step of the PIV process that goes on until a present calculation accuracy is achieved.

to the minimum point of the n-th multivariable function. The last approximation is interpolated into a finer finite element mesh and serves an initial approximation to the minimum point of the next function at the (n + 1)-th step of the PIV process that goes on until a present calculation accuracy is achieved.

The PIV FEM models have been applied successfully of elastic boundary value problems, elastoplastic stressstrain state problems for plates with various openings, plane elastoplastic deformation problems for structured media containing assembles of pores, cracks, inclusions [2,8]. Use of this models provides a significant (dozensfold) saving in computation time in comparison to the conventional FEM.

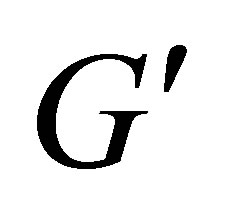

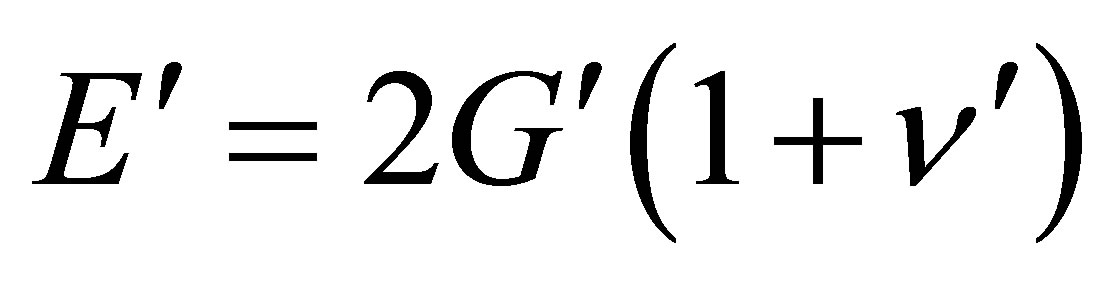

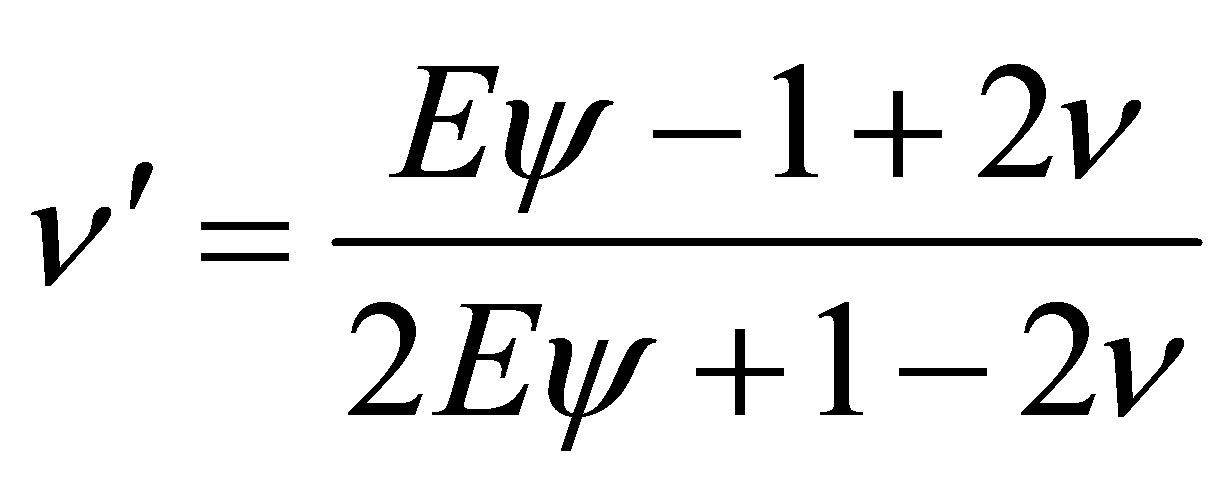

For solution of elastoplastic problems we use the method of variable elastic parameters (VEP)—version of elastic solutions methods [3,8]. The method give construction of iterative process, in each approximation an elasticity problem with variable elasticity and shear modulus ,

,  and Poisson’s ratio

and Poisson’s ratio  is solved. For deformation theory of plasticity we have for each approximation

is solved. For deformation theory of plasticity we have for each approximation

;

;

;

; ;

;

;

; , (2)

, (2)

where  and

and  are the of stresses strains,

are the of stresses strains,  and

and  are the stress and strain intensities,

are the stress and strain intensities,  is the mean stress,

is the mean stress,  is the Kronecker delta.

is the Kronecker delta.

For a first approximation, we have ,

,  and determine

and determine ,

,  ,

,  ,

, . In a second approximation we have

. In a second approximation we have ,

,  obtained from Equation (2) at

obtained from Equation (2) at  and so on. The process is run until two successive approximations coincide to within a given accuracy,

and so on. The process is run until two successive approximations coincide to within a given accuracy, .

.

Corresponding schemes for the flow theory of plasticity may be constructed.

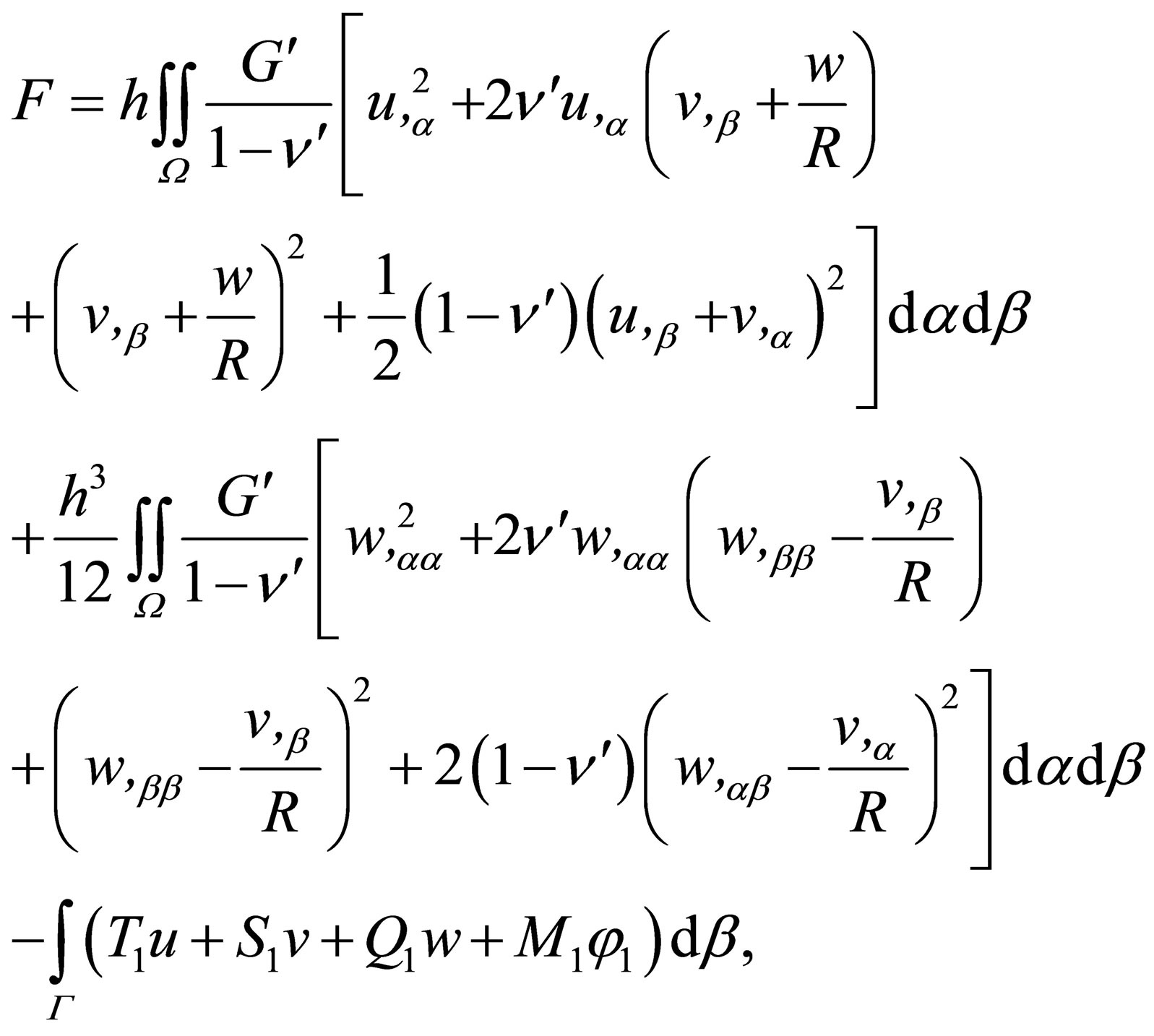

The corresponding minimized energy functional for shell with openings is written as [9]

(3)

(3)

where ,

,  , and

, and  are the displacements of the middle surface,

are the displacements of the middle surface,  and

and —coordinates,

—coordinates,  is the shell thickness,

is the shell thickness,  is the sheet surface,

is the sheet surface,  and

and  are the variable elastic parameters for each method VEP approximation,

are the variable elastic parameters for each method VEP approximation,  ,

,  ,

,  and

and  are the longitudinal, tangential, transverse force and bending moment, respectively which are applied to the shell edges

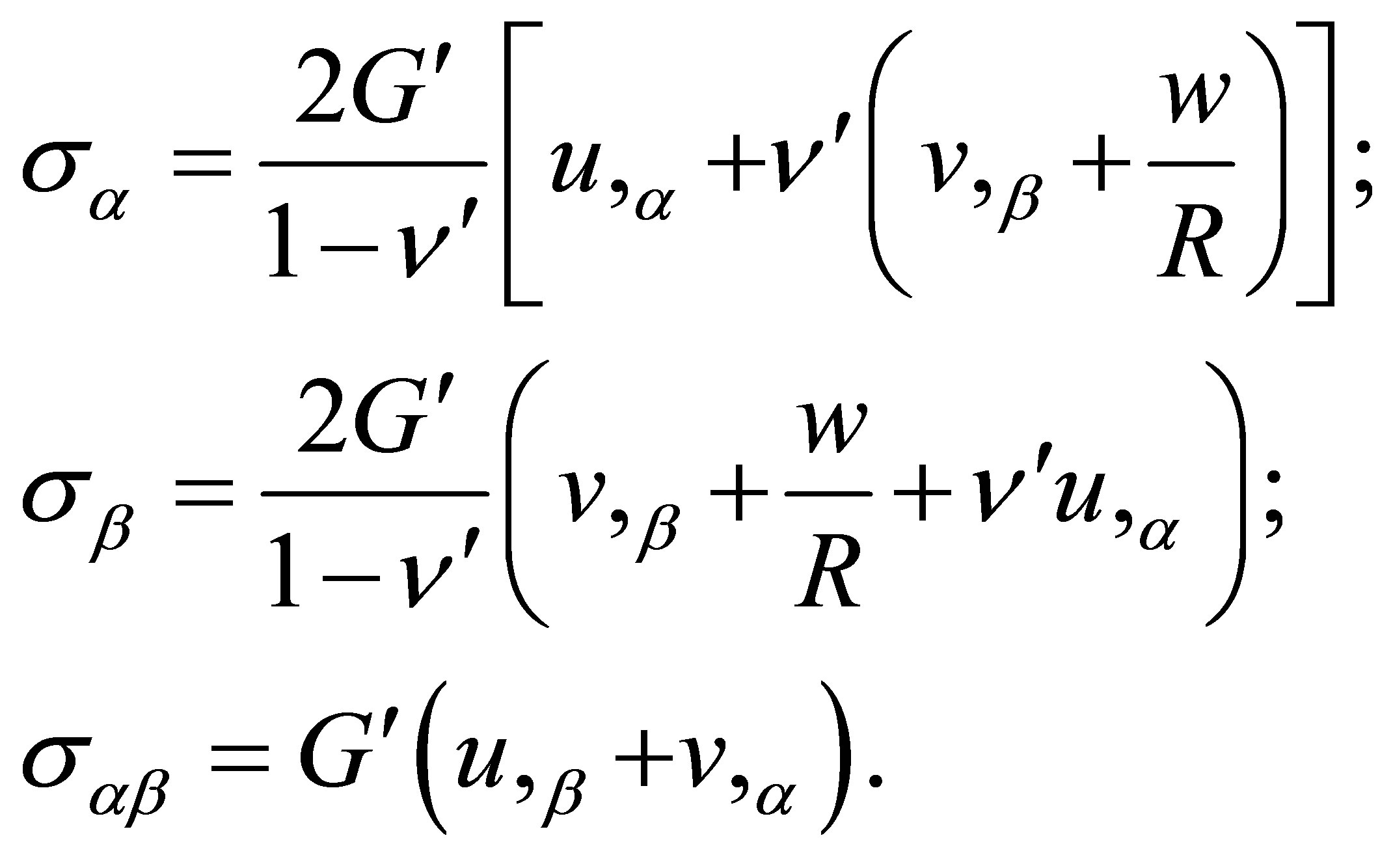

are the longitudinal, tangential, transverse force and bending moment, respectively which are applied to the shell edges , comma denotes differentiation in the coordinate. Stresses in the shell middle surface are given by

, comma denotes differentiation in the coordinate. Stresses in the shell middle surface are given by

(4)

(4)

3. Results of Numerical Analysis

Founded on the PIV FEM procedure, a program in C++ language has been written for the stress-strain state analysis of cylindrical shell with three rectangular openings.

We calculated shells ( ,

, and

and ) of D16T aluminum alloy (Figure 1). The

) of D16T aluminum alloy (Figure 1). The

Figure 1. Scheme of shell structure and loading.

larger openings measures  and the smaller one

and the smaller one . Compressive loads

. Compressive loads  were varied from 55 to 100 MPa. The center-to-center distances:

were varied from 55 to 100 MPa. The center-to-center distances: —between the small opening and the nearest larger opening,

—between the small opening and the nearest larger opening, —between two larger openings were varied. The offset yield stress

—between two larger openings were varied. The offset yield stress  was taken 200 MPa.

was taken 200 MPa.

The PIV FEM has been implemented on eight double-folded FE meshes of rectangular Hermitian elements. The number  of approximations at the n-th step

of approximations at the n-th step  of the PIV process was chosen as the smallest integer k satisfying the condition

of the PIV process was chosen as the smallest integer k satisfying the condition

, (5)

, (5)

where  is the solution to the n-th finite-dimensional problems and

is the solution to the n-th finite-dimensional problems and  is the preset accuracy of computations on the n-th mesh.

is the preset accuracy of computations on the n-th mesh.

Let us consider some results of the numerical analysis.

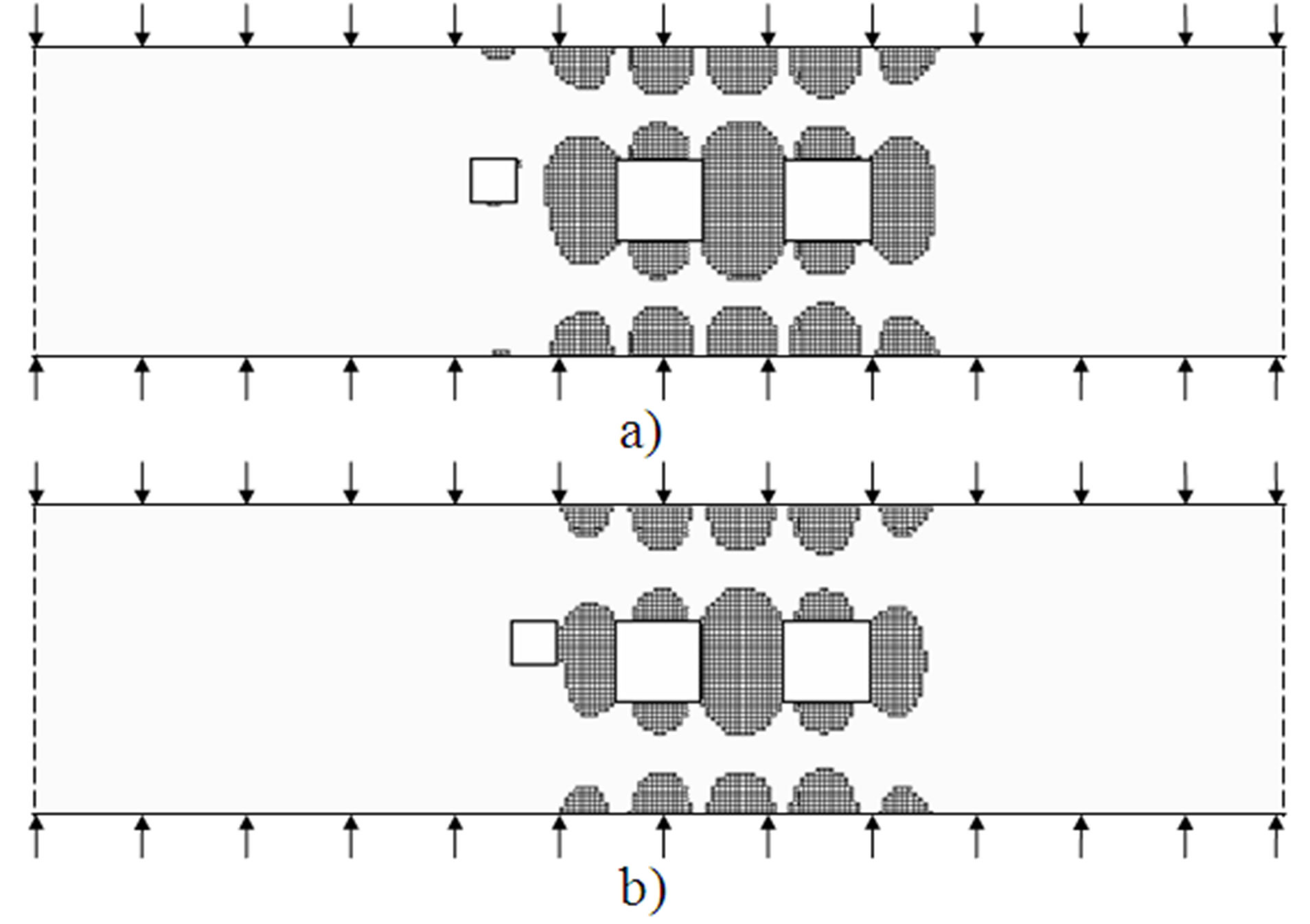

By way of plane projections of the shell evolvent, Figure 2 shows how the plastic strain zones develop in a shell with openings:

,

,

(Figure 2(a));

,

,  ,

,

(Figure 2(b)).

These zones arise locally at the openings edges and at shell ends, merge as the load  grow and

grow and  decreases. The variants of mutual influence of the openings will differ as the shell and openings parameters are changed.

decreases. The variants of mutual influence of the openings will differ as the shell and openings parameters are changed.

Using the computation program we can determine the loads whereby the plastic strain zones start merging to be become integral ones. The use PIV FEM models in these problems has provided a saving of computer time by a factor of 30 to 50 (depending on the class of problems) in comparison to the traditional FEM models (on a single mesh).

Figure 2. Distribution of plastic strain zones in a shell with openings.

The plastic strain zones affect on stiffness. The forma tion of the zones common for the openings considerably impairs the resistance of shall-type structures with openings to effective loads. This finding can be used in predicting their load-carrying capacity.

4. Conclusions

Founded on PIV, FEM models have significantly reduce the computation time (in comparison to the conventional FEM models). Therefore, methods of numerical simulation of strength for elastoplastic shell-type structures containing several rectangular openings are developed. The variation of openings parameters, quantities, and center-tocenter distances allows one to study the formation and transformation of plastic strain zones in the process of loading. Merging of the zones leads to a decrease in stiffness. This fact is used in predicting the load-carrying capacity.

The developed schemes for numerical simulation can be expended to the plate-shell structures members with openings of other shapes (circular, elliptical). This is partly done in [2,8].