Characterization of Egyptian Manganese Ores for Production of High Carbon Ferromanganese ()

1. Introduction

Manganese is an essential alloying element in nearly all types of steel and is used to increase strength, toughness, hardness and hardenability. It is used for deoxidation and desulphurization of ferrous metals and alloys. Manganese is also important in the production of cast iron. Manganese is added to steel or cast iron in the form of manganese ferroalloys such as ferromanganese or silicomanganese alloys [1]. The rapid expansion in the world and Egyptian steel industry in recent years and consequently the increasing demand on the essential ferromanganese necessitated the domestic production of this ferroalloy.

Egyptian Manganese ores are located in Egypt in two major localities beside other several small occurrences. The economic deposits of manganese are Um Bogma in Central Western Sinai and Elba in South Eastern Desert. The reserve of these ores in Um Bogma is about 1.7 million tons. The only processing steps carried out on the manganese ores are crushing and screening [2].

Manganese oxides in manganese ores are reduced to manganese (ferromanganese) by carbon with heat supplied by carbon combustion in Blast Furnace (BF) and electric power in Submerged Electric Arc Furnaces (SAF) [3]. Manganese ore reduction occurs in two stages in the first stage (pre-reduction), gaseous reduction of iron and manganese oxides to FeO and MnO by CO in the solid state. In the second stage, direct reduction of MnO, FeO and SiO2 occurs by carbon producing work has been carried out a metallic Mn, Fe and Si. The completeness of the gaseous reduction, therefore, affects directly the economics of the production process through increasing the efficiency of carbonaceous reducer and decreasing the electric power consumption [1].

As the efficiency of these reactions affects the coke and the energy consumption, the ore reactivity can be considered as the most important parameter during production of ferromanganese [4,5].

There are three main parameters affecting on the manganese ore reactivity [6]:

1) The efficiency of the solid/gas exchange so that the higher the ore porosity the more complete reactions between higher manganese oxides and CO gas.

2) The available oxygen (Av Ox) which is the percentage of oxygen in ore bound to manganese above that associated with MnO and FeO, i.e. the maximum quantity that could be released from reaction with CO gas. As the pre-reduction reactions being exothermic, the higher the available oxygen, the higher the energy will be released. This contributes to heat the burden in the pre-reduction zone and thus favors the reactions occurring in the second stage.

3) Particle size.

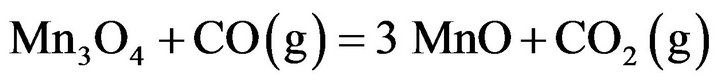

The pre-reduction process of manganese oxides in manganese ore i.e. gaseous reduction can occur according to the following equations [6-8]:

(1)

(1)

(2)

(2)

(3)

(3)

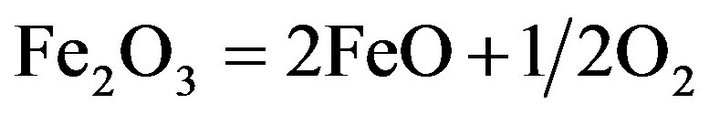

Iron is always present in manganese ores, and the reduction of iron oxides present in manganese ores runs parallel to reduction of the higher manganese oxides. According to the equations:

(4)

(4)

However, the most possible reaction is the indirect reduction of higher iron oxides in the solid state by CO to FeO:

(5)

(5)

(6)

(6)

This work aims at characterization of three grades of Egyptian manganese ores located in Um Bogma in Central Western Sinai, Egypt through studying the reactivity of these ores in the region of the gaseous reduction.

2. Material and Methods

Three grades of manganese ores with different chemical composition from Um Bogma mines were supplied by Sinai Manganese Company. These ores were crushed to small sizes (<25 mm). Representative samples of Mn ores for determination of chemical composition were analyzed by XRF method. Table 1 shows chemical composition of the representative samples of Mn ores.

2.1. X-Ray Diffraction

X-ray diffraction was done to determine the mineralogycal composition of the prepared samples at room temperature and diffraction patterns were obtained by means of a chart recording Philips PW (1790) X-ray diffracttometer using copper (Kα) radiation. The instrument was properly calibrated and adjusted with respect to the X-ray source. A high voltage of 40 kV and a node current of 30 mA were chosen. The connected Geiger Muller tube detector was adjusted to the order of one degree/cm for identification purposes.

2.2. Scanning Electron Microscope

JEOL, JSM-5410 Scanning Microscope was used to ex-

Table 1. Chemical composition of um bogma manganese ores.

amine the morphological structure of the ores before and after the reduction process. The sample to be examined was fixed into an epoxy resin mould, and then examined under JEOL, JSM-5410 Scanning Microscope.

2.3. Density and Porosity

Boiling water method was used to determine sealed pore, true and apparent porosity. Specific gravity bottle method (pycnometer) was used to determine true density for each ores.

2.4. Reactivity Test

The reactivity tests were carried out by gaseous reduction of manganese ores using 60% CO - 40% CO2 gas mixture and the experiments were carried out at temperatures of 900˚C and 1100˚C in a vertical furnace. Nitrogen gas used for removing any gas found in the furnace at the beginning of the experiment and after the experiment also nitrogen gas pass through the furnace to remove CO and CO2 gasses as the sample must be introduced and taken from the furnace in the presence of nitrogen gas.

Figure 1. Schematic diagram of reactivity apparatus.

Reactivity of different Mn ores was measured using the system given in Figure 1. The system mainly consists of three parts. The first part is carbon monoxide, carbon dioxide and nitrogen gas cylinders. The second one is purification unit to purify the gases before their use (E) anhydrous silica gel towers and (F) soda lime granules towers. The third part is the thermo balance which consists of vertical tube furnace (G) wounded by a kanthal wire for attaining a maximum temperature of 1200˚C, a Ni/Ni-Cr thermocouple (L) and the reaction tube (H), which is a fused alumina tube. The samples were placed inside a kanthal wire basket (D) suspended by a kanthal wire (C) attached to the pan of a fully automatic sensitive (0.1 mg) balance (A).

The furnace was heated to the required reduction temperature. After reaching this temperature, oxygen free nitrogen gas was flushed into the furnace to remove any contaminants gas in the reaction tube by rate flow 1liter /min.

A kanthal wire basket (D) was placed in the furnace and was weighed as empty then taken from the furnace and was leaved to be cooled then the sample put in it and then the basket (D) with the sample were introduced into the furnace (G) so as to be in the middle of its constant hot zone, in presence of nitrogen gas flushing, Then the mixture of CO and CO2 gases was flushed into the reaction tube by flow rate 600 ml/min and 400 ml/min, respectively. The weight loss due to oxygen removal from the samples was intervally recorded with time until the weight of the sample becomes constant. At the end of the experiment, the basket and the sample were dropped into pure acetone to save the phases that formed in the reduced sample.

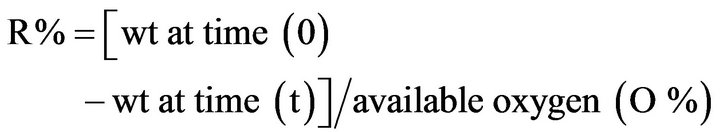

The reduction rate (R%) can be calculated by the following equation:

The available oxygen calculated in this work as the excess or removable oxygen that can be reduced from pyrolusite to reach Manganosite and hematite to reach wustite according to the following equations:

(7)

(7)

(8)

(8)

3. Result and Discussion

The chemical composition of the three selected manganese ores, given in Table 1, indicates that increasing the percentage of manganese in the manganese ore, the iron content decreases and consequently it’s available oxygen for pre-reduction increases. However as the manganese in the high manganese ore highly oxidized, which could lead to an important exothermic effect in the pre-reduction zone of the furnace which will lead to lower electric power consumption.

The examination of the selected ores by XRD showed that, as it is clear from Figure 2, manganese oxide in the ores is mainly in the form of pyrolusite (MnO2) and iron is present as hematite (Fe2O3). It is also clear that with the decrease of the manganese content, the iron content increases.

The results of porosities determination for different ores are given in Table 2. It is clear from the results that the porosity of medium and low manganese ores is nearly similar. The results of measuring densities of ore size of 1mm given in Table 2.

Photos of the three prepared samples of Mn ores examined by SEM are shown in Figure 3. It can be ob-

Figure 2. XRD of Mn ores: (a) High Mn ore; (b) Medium Mn ore; (c) Low Mn ore.

Table 2. True porosity, apparent porosity and sealed pores and true density of the three investigated Mn ores.

served from the examination of the different ores, that the ores particles are agglomerated forming dense grains.

The results obtained from the reduction experiments are represented in Figure 4.

Figure 4(a) indicates that the pre-reduction process of low, medium and high grade Mn ores at 900˚C increases sharply with time at the first stages of reduction for the three ores, then the reduction rate tends to be steady at a certain time. The reduction rate for high grade ore is higher than medium and low grade ores. This may be attributed to the effect of available oxygen as the high grade ore have high available oxygen than the other two grades which significantly affects on the pre-reduction and reactivity. Figure 4(b) indicates that the pre-reduction process of low, medium and high grade Mn ores at 1100˚C has the same behavior as at 900˚C. However, there are small increases in the reduction rate for the