Finite Element Modelling of Insulation Thicknesses for Cryogenic Products in Spherical Storage Pressure Vessels ()

1. Introduction

The combination of higher natural gas prices, rising natural gas demand, and lower liquefied natural gas (LNG) production costs, is setting the stage for increased LNG trade in the years ahead. Estimates are that worldwide LNG trade will increase 35 percent by 2020. In the United States, Energy Information Administration (EIA) projects that natural gas imports will more than double over the next 20 years. Nearly all the projected increase is expected to come from LNG, requiring an almost 28-fold increase in LNG imports over 2002 levels, [1]. The need for reduced weight, in combination with good insulating properties for long term storage provides a new challenge for cryogenic tank design. These new designs provide an opportunity to apply advanced materials, structural concepts and finite element method in an effort to reduce the overall weight of the tank, reduce the boil off, and keep the volume at an acceptable and practical level. Although, the design of a cryogenic storage tank, involves many challenges, the most dominant ones include geometry and temperature.

In the present study we performed temperature gradient study on a double-walled, insulated jacketed, field fabriccated spherical cryogenic tank wherein determine insulation thickness.

2. Literatures Review

[2], in their paper verified that commercially available pressure vessels could be safely used to store liquid hydrogen. The use of commercially available pressure vessels significantly reduces the cost and complexity of the insulated pressure vessel development effort. This paper describes a series of tests that have been done with aluminum-lined, fiber-wrapped vessels to evaluate the damage caused by low temperature operation.

A Seismic post elastic behavior of LPG spherical storage tanks study was performed by [3] for an existing equipment with a volume of 1000 m3 containing 85% of LPG. The middle diameter of the sphere is 12.50 m; its thickness varies from 36.2 mm to 36.8 mm taking into account the corroded thickness. [4], gave a description of a fatigue analysis method based on the S-N curve and crack propagation method. The presentation of the method is based on an application to a practical example taken from Ship building, i.e., the analysis of details of membrane LNG carriers of the Gas Transport system type. [5] carried out research on the technology development and alternate fuel foundation technologies that will greatly reduce or even eliminate environmentally harmful emissions. Because of this, liquid hydrogen has emerged as a propellant to supply the fuel needs for future aircraft due to its high energy per unit mass. Durable, lightweight cryogenic propellant storage and feed systems are required to enable the development of hydrogen-fueled aircraft. As a result, there is a need for hydrogen tank storage systems for these aircraft applications, which are expected to provide sufficient capacity for flight durations ranging from a few minutes to several days [6].

3. Finite Element Methodology

In this analysis, finite element is adopted in solving a partial differential equation in one-dimensional steadystate heat equation.

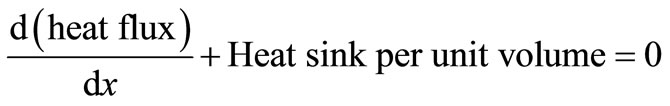

Rate of change of heat flux = heat source per unit volume

(1.0)

(1.0)

where u = The nodal temperature in ˚C;

k = Thermal conductivities in Watts/m/˚C;

q = Heat sink per unit volume in Joules/m3;

x = Distance from the inner wall of inner spherical shell to the outer wall of outer spherical shell in metres.

3.1. Model Assumptions

1) The heat gradient to be in radial direction only;

2) The stored cryogenics product are assumed as sink;

3) The atmospheric surrounding as the heat source;

4) Thermal conductivity, k (Watts/m/˚C) is not temperature or position dependent.

To solve Equation (1.0), weighted residual analysis is applied to give for of Equation (2.0)

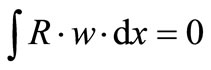

(2.0)

(2.0)

where R is the residual taking from Equation (1.0) and w is the weighting function.

(3.0)

(3.0)

If u and x are exact solutions over the whole domain, the residual R would be zero everywhere. Substituting Equation (3.0) into Equation (2.0) gives

(4.0)

(4.0)

This formulation of the governing equation can be thought of as forcing the residual to be zero in a spatially averaged sense.

Solving Equation (4.0) above, thus gives

(5.0)

(5.0)

3.2. Finite Element Approximation

The domain is divided into three different length elements and replaces the continuous field variable within each element by the parametric finite element approximation.

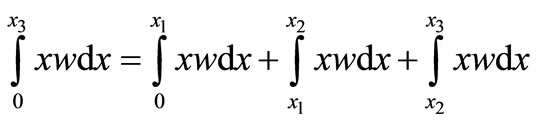

The domain integral in Equation (5.0) can now be replaced by the sum of integrals taken separately over the three elements—inner spherical shell, insulating material and outer spherical steel shell as showing in Figure 1.

(7.0)

(7.0)

and each element integral is normalizing to  -space

-space

(8.0)

(8.0)

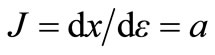

where  the Jacobian of the transformation from x coordinates to

the Jacobian of the transformation from x coordinates to  coordinates.

coordinates.

The element integrals arising from the LHS of Equation (5.0) then have the form

(9.0)

(9.0)

where  and

and  since

since  and

and  are both functions of

are both functions of .

.

But

(10.0)

(10.0)

Figure 1. Showing element divisions of spherical storage pressure vessel.

(11.0)

(11.0)

Substituting Equations (10.0) and (11.0) into Equation (9.0) then

(12.0)

(12.0)

un is taken outside the integral in the equation above because it is not a function of ε.

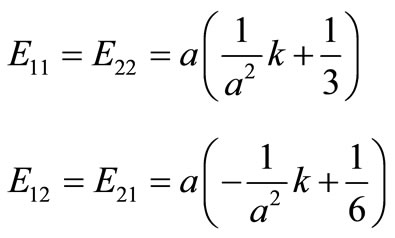

The term multiply un in Equation (12.0) above is term as stiffness matrix. Therefore, stiffness matrix Emn is

(13.0)

(13.0)

3.3. Element Stiffness Matrix

Equation (13.0) gives the element stiffness matrix. The indices m and n in the equation can only take values of 1 or 2. To solve stiffness matrix for element 1, finite element relation between x and ε coordinates is taken as .

.

a = thickness of element measured in metre.

Therefore, .

.

Jacobian, .

.

Substituting for Jacobian, J in Equation (13.0) leads to

(14.0)

(14.0)

where the indices m and n are 1 or 2. To evaluate Emn, we substitute the basic functions 1, 2

(15.0a)

(15.0a)

(15.0b)

(15.0b)

(16.0)

(16.0)

Substitute Equation (15.0) into the Equation (16.0) and integrate.

(17.0)

(17.0)

The above equations give the stiffness matrix for element 1; this can be written in a matrix form

3.4. System Stiffness Matrix

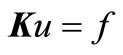

The three element stiffness matrices calculated elements 1, 2 and 3 are assembled into system global matrix.

(18.0)

(18.0)

f = is the heat flux (joules/m2).

K = System stiffness matrix.

f is the heat flux corresponding to the first term of the RHS of Equation (5.0). To solve the integral part of the second terms of Equation (5.0) which is the source term, replacing the domain integral for the x-source term by the sum of three element integrals

(19.0)

(19.0)

Normalizing Equation (19.0) to ε coordinates as it was done in Section 3.2, and then solving the element integral as it is done in Section 3.3. The solved x-source terms are assembled and added to the right hand term of the system matrix Equation (18.0). Therefore, the system matrix equation becomes

(20.0)

(20.0)

s = assembled matrix representing source term.

3.5. Boundary Conditions

Essential Boundary Conditions

The boundary conditions u(0) = T1 and u(1) = T4 are applied directly to the first and last nodal values where

T1 is the temperature of the cryogenic product stored inside the spherical storage tank (˚C);

T4 is the maximum ambient temperature (˚C).

Flux Boundary Conditions

The flux terms in the right hand side of Equation (5.0)

(21)

(21)

For node 1 w1 is obtained from the basis function  associated with the first node of element 1 and therefore,

associated with the first node of element 1 and therefore, .

.

Also, since w1 is identically zero outside element 1, .

.

Thus Equation (20) for node 1 reduces to

(22)

(22)

Similarly, for nodes 2 and 3

and for node 4

4. Results and Discussions

Case 1

In order to validate the finite element procedure used, below are the conditions under which the simulation was carried out to determine the temperature profile across the thickness of spherical shell divides into 3 equal elements.

Thickness of each element of Carbon Steel spherical shell = 0.3333 m;

Carbon steel thermal conductivity = 1.0 W/m ˚C;

Stored product (LNG) temperature = 0.0˚C;

Ambient temperature = 1.0˚C.

It can be seen from the Table 1 above that FEA exact values are in good agreement.

Case 2

Optimum insulation thicknesses are determined for different insulating materials for a spherical storage pressure vessel containing liquefied natural gas (LNG). Below are the conditions under which the simulation to determine different insulation thicknesses were carried out:

Thickness of carbon steel inner shell = 0.024 m;

Thickness of carbon steel outer shell = 0.006 m;

Carbon steel thermal conductivity = 43.0 W/m ˚C;

Stored product (LNG) temperature = –162˚C;

Ambient temperature = 45.0˚C.

Table 2 shows the required insulating material thickness for spherical storage vessel stores Liquefied Natural Gas (LNG).

Case 3

Optimum insulation thicknesses are determined for different insulating materials for a spherical storage pressure vessel containing liquefied hydrogen (H2(l)). Below are the conditions under which the simulation to determine different insulation thicknesses were carried out:

Thickness of carbon steel inner shell =0.024 m;

Thickness of carbon steel outer shell = 0.006 m;

Carbon steel thermal conductivity = 43.0 W/m ˚C;

Stored product (liquefied hydrogen, H2(l));

Temperature = –252.87˚C;

Ambient temperature = 45.00˚C.

Table 3 shows the required insulating material thickness for spherical storage vessel stores Liquefied Hydrogen.