Hygienic Production and Post-Harvest Handling Practices of Raw Camel Milk in Degahbour District of Jarar Zone, Somali Regional State, Ethiopia ()

1. Introduction

Milk is the lacteal secretion of the mammary glands of a mammal and plays an important role in human nutrition throughout the world where it promotes growth and maintenance of body tissue [1]. It is the most complete food product of animal origin providing more essential nutrients (protein, energy, vitamins and minerals) in significant amounts than any other single food [2]. Milk for human consumption is obtained from cattle, camels, goats, sheep and buffalo. among which, cattle and one-humped dromedary camel play a significant role in providing milk for pastoralist and agro pastoralist in sub-Saharan Africa including Ethiopia [3].

Camel milk, so called white gold of the desert, is more similar to human than any other milk and differs from other ruminant milk because it contains low cholesterol, low sugar, high minerals (sodium, potassium, iron, copper, zinc and magnesium), high vitamin C (three times more than cow milk) [4]. Moreover, camel milk contains protective proteins like as lactoferrin, lactoperoxidase, Immunoglobulins, lysozyme which have potential effect on the treatment of infectious disease [5]. It also contains insulin-like protein which is a potential treatment for diseases like diabetes [6]. According to [7] camel milk contains low level of β-casein and no β-lactoglobulin which cause allergic reaction in lactose intolerant person.

The risk of milk contamination with harmful contaminant agent is high for milk for milk produced in developing countries like Ethiopia as their milk production practices is traditional type which lack appropriate hygienic measures [8]. The potential risk is high in lowland regions. This is mainly due to high ambient temperatures prevalent in the area combined with lack of cooling facilities, scattered distribution of producers, long distance to markets and lack of transportation [9].

To overcome the problem of milk contamination with harmful contaminant agents, the availability of documented information on hygienic milk production and postharvest handling practices is highly important. This is because such information may be important for governmental, non-governmental and other developmental organizations to undertake relevant development interventions, which make milk producers to have clear understanding on the hygienic practices essential for safe milk production and handling. This understanding may be important to ensure safety and suitability of raw camel milk for its intended use. However, currently there is no well documented information available on hygienic camel milk production and post-harvest handling practices in the study area where camel milk is highly consumed in its raw form. Therefore, this study was designed to assess hygienic camel milk production and post-harvest handling practices in Degahbour district of Jarar zone, Somali Region, Ethiopia.

2. Materials and Methods

2.1. Study Area

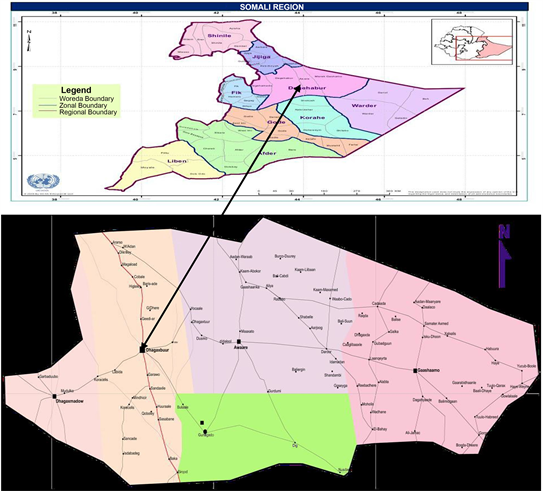

The study was conducted in Jarar Administrative Zone of Somali Regional State, specifically in Degahbour district. The district is located at 8˚13'N latitude and 43˚34'E longitude at 777 km east of Addis Ababa. The altitude of the district ranges from 1044 meters above sea level (m.a.s.l.). It has mean annual minimum and maximum temperature of 5˚C and 38.5˚C, respectively. The mean annual rainfall the area ranges from 300 - 400 mm. The two prevailing agricultural production systems in the district are pastoral and agro-pastoral production systems [10]. According to [11] the district has a total population of 115,555; out which about 65,081 and 50,474 are men and women, respectively. Of the total human population of the district, about 74.015% and 25.98% are rural and urban dwellers, respectively. The average family size for rural and urban areas is 6.7 and 6.8 persons, respectively.

2.2. Study Design

This research was conducted survey work to collect relevant information on hygienic production and post-harvest handling practices of raw camel milk in the study area.

2.3. Sampling Targets

Degahbur district was selected for this study due to its potential of camel milk production. The district was stratified into pastoral and agro-pastoral production systems. Each production system was further stratified into kebeles. Thus, a total of four kebeles (2 from pastoral and 2 from agro-pastoral production systems) with high camel milk production potential were purposively selected for this study. The lists of camel milk producer households were taken from their respective administration. Eventually, 30 milk producer households from each rural kebele (RK) were selected randomly. Thus, the total number of milk producers selected to study hygienic camel milk production and postharvest handling practices in Deghabur district was 120 (2 production systems * 2RK* 30 households).

2.4. Data Collection Procedures

After stratification and identification of camel milk producer households, focused group discussions were held with key informants (such as milk producers having good experience on the subject under study, community leaders and experts) in each production system to generate information on hygienic camel milk production practices and milk postharvest-handling practices of producers in Degahbour district. The resulting information was then used for the development of a survey questionnaire which was pre-tested before administration, and this was followed by questionnaire survey. Moreover, field observations were made to collect some data which were not properly described during the questionnaire survey.

2.5. Data Analysis

The data collected using questionnaire survey and field observations were analyzed using SPSS (version, 20). Descriptive statistics were used to quantitatively express the responses of the study participants with respect to their demographic characteristics as well as the factors responsible for raw camel milk contamination with harmful microorganisms during production and postharvest handling in the study area. Chi-square test was employed to examine the differences among categorical variables and Fisher’s exact test was employed to examine if the cells less than five digits. The differences were considered to be significant at the level P < 0.05.

3. Result and Discussion

3.1. Demographic Characteristics of the Households

Majority of the respondents in pastoral (85%) and agro-pastoral (88%) production systems were male headed households (Table 1). Across all the sampled households in the respective rural kebeles, it was observed that the number of males exceeds that of females. Most of the respondents in pastoral (68.3%) and agro-pastoral (16.7%) production systems belonged to the age group of 46 - 60 years; this indicates that the strongest and active age groups were carrying out camel herding activities in the study area.

The result of this study indicated that majority of the respondents in pastoral (93.3%) and agro-pastoral (76.6%) production systems were illiterate (Table 1). Moreover, none of the respondents in both production systems didn’t get any training on hygienic milk production practices. The finding is in agreement with

![]()

Table 1. Sex, age, educational level and family size of the households in the study area.

Means in the same column are significantly different at (P < 0.05), N = Number of respondents, SE = Standard Error.

the result reported in many pastoral areas of Ethiopia [12]. Similarly; Wendimu [13] reported a higher proportion of illiteracy and religious schools education for Gode and Adadile districts of Somali region. Lack of education and training on hygienic milk production practices exacerbates the risk of milk contamination with spoilage and pathogenic microorganisms at farm level.

3.2. Purpose of Camel Keeping

The result of the study indicated that farmers in the study area keep camel mostly for milk (ranked 1st), meat (ranked 2nd), social and cultural (ranked 3nd) income (ranked 4rd) by selling live animals and their products and/or both, ritual ceremony (marriage) (ranked 5nd) (Table 2). This finding is in line with Chabeda [14] who stated that majority of pastoralist in Kenya keep camel mostly for milk production followed by meat production and social and cultural.

Pastoralists keep camel due to its higher volume of milk which is six times higher than that of indigenous cattle kept in the dry areas [15]. On the other hand, the Somali region has been considered to have one of the largest camel herds, and people living there strongly rely on camel milk and meat [16].

3.3. Housing and Cleaning Practices

All respondents in the study area indicated that calves and mature camels were housed separately. Mature camels were housed in the open field around their

![]()

Table 2. Purposes of keeping camel in the study area.

Index = [(5 for rank 1) + (4 for rank 2) + (3 for rank 3) + (2 for rank 4) + (1 for rank 5)] divided by the sum of all weighed purposes of camel keeping mentioned by the respondents, R = Rank.

home. Camel calves were housed in well-protected enclosures inside their home which was constructed from wood (like Acacia Abyssinica) and fenced by available piece of thorn wood (like Prosopis julifora) and different bush plants.

The result of the study revealed that the majority of respondents in pastoral (53.3%) and agro-pastoral (75%) production system clean the barn once per week (Table 3). Moreover, none of the observed “kraals” were provided with bedding material. This is in lined with Debela [17] who reported that, the farmers in Yabello district of Borena zone do not use bedding material for their animals and 56.7% of them clean the barn once a week.

According to Tassew [18] maintaining the sanitary condition of barn is critically important for the production of good hygienic quality of milk; for example, properly cleaning the barn as well as providing clean dry and comfortable bedding materials to barn minimize the contamination of milk with harmful microorganisms. Moreover, proper and clean housing environment is a prerequisite to produce milk and milk products of acceptable quality [18].

3.4. Milking and Hygienic Practices during Milking

All respondents in the study area camels are milked in the kraals where there is no roof and wall (Table 4). This is in line with Tamirat et al. [19] who reported that milking in different parts of Ethiopia was done in the open air in grazing field and in front of homestead, which were unclean for clean milk production.

The result of the current study indicated that all respondents in both production systems were not washing udder before milking (Table 4). The finding agrees with Muli et al. [20] who also reported that not cleaning of udder of lactating animals as well as hands of milkers before milking were the major problem of pastoralists in Isiolo district in Kenya. The finding also agrees with Yagil [21] who reported that udder of milking camel was not washed prior to milking. Failure to wash udder before milking undoubtedly expose milk for microbial contamination [22].

The study showed that the majority of pastoralists (93.3%) and agro-pastoralists (75%) in the study area did not wash their hands before milking (Table 4). The

![]()

Table 3. Cleaning practices of camel house in the study area.

N = Number of respondents.

![]()

Table 4. Milking and hygienic practices during milking in the study area.

Means within a row are significantly different at (P < 0.05), N = Number of respondents.

finding is comparable with Bashir and Ahmed [23] who reported that half (50%) of the respondents in Afar zone didn’t wash their hand before milking. [8] and [24] indicated that milk producers should properly wash udders and their hand before start milking as such practices highly minimizes milk contamination with harmful microorganisms.

3.5. Milk Equipment, Smoking and Cleaning Practices

All respondents in pastoral and agro-pastoral production system were using plastic containers for raw milk handling. Similar findings were reported by Lumadede et al. [25] as the use of plastic containers dominated the milk market in Dollo, Somali region of Ethiopia especially for milk transportation and storage purpose. Moreover, the finding also agrees with Mattias [26] who reported that the majority of milk producers used plastic jerry-cans for milk handling in Kiambu County in Kenya. The use of plastic container for milk handling is not advisable as such practice highly contributes raw milk for microbial contamination [27] Stainless steel equipment is mostly preferred [28].

The result of the study indicated that all respondents in both production systems were fumigatingwith smoke from burning stems of specific plant species such as Maygaag (Bosciaminimifolia), Sogsog (Acacia ethaica) and Kadi (Blanitesgalabra) (Table 5). The finding agreed with Eyassu [29] who reported that

![]()

Table 5. Milk equipment, smoking and cleaning practices in the study area.

Means within a row are significantly different at (P < 0.05), N = Number of respondents.

woods of tree species of Kadi (Blanitesgalabra), Sogsog (Acacia ethaica) and Wigir (Olea africana), used for smoking milk containers by nomadic pastoralists in Shinile and Jigjiga zones of Somali region.

Majority of the respondents in pastoral (73.6%) and agro-pastoral (72.2%) production system were using smoking to improve taste and flavor as well as to increase shelf life of milk (Table 5). This agrees with the finding of Abebe et al. [30] who reported that the purpose of smoking was to improve the taste and flavor of milk products, as well as to increase the shelf life of the product in Ezha district of Guragezone. Moreover, the finding also in line with the finding of Fikireneh et al. [31] who reported that about 93.3% of respondents smoked their milk handling equipment to improve flavor and aroma of milk and milk products in mid rift valley of Ethiopia. Other studies have also reported on the use of smoke fumigation in the pastoral system [32] [33].

The result of the study revealed that the majority of respondents in pastoral (45%) and agro pastoral (81.6%) production system were regularly cleaning milk vessels with cold water without soap (Table 5). The finding is contradictory with the finding of Haile et al. [34] who reported about 85.6% of respondents in Hawassa City were using hot water to clean milk handling equipment. This variation may be due to lack of any training given to pastoralist and agro-pastoralist on hygienic milk production and post-harvest handling practices in the study area. However, it is highly recommended to use detergents and good quality water for cleaning the equipment as such practices can remove milk remains, including microorganisms, and thereby improve the microbiological quality of the milk [35].

Most losses of dairy products occur because of a combination of poor production and handling practices and lack of technical knowledge. Among others, lack of knowledge on clean milk production, use of unclean milking equipment coupled with lack of potable water for cleaning purpose probably contributed to the poor hygienic quality of dairy products produced in Ethiopia [36].

3.6. Water Sources Used for Hygienic Practices

The majority of the respondents in pastoral (55%) and agro-pastoral (36.6%) production systems were using water from wells and ponds, respectively for hygienic practices (Table 6). This finding agrees with Bereda et al. [37] who reported majority (64.4%) of respondent in Ezha district, Ethiopia were using water from non-tap sources for hygienic practices.

Using water obtained from non-tap sources for hygienic practices during milk production and postharvest handling may leads to milk contamination with spoilage and pathogenic microorganisms [38]. If it is difficult to get potable (safe to drink) water for cleaning practices, water obtained from river, stream, spring and hand dug well should be treated prior to use [28] [39]. However, none of the respondent in the study area was treating water from non-tap sources prior to use for hygienic practices. Thus, it is highly important to heat or chemically treat water from non-tap sources prior to use for hygienic practice.

3.7. Major Constraints to Hygienic Camel Milk Production

The majority of respondents in pastoral (with an index value of 0.24) and agro-pastoral (with an index value of 0.22) production system ranked poor barn hygiene as the 1st most important problem contributing for contamination of milk in the study areas (Table 7). This is in line with Ruegg [40] who reported that practices that expose teat end to wet and muddy pens increase the risk of occurrence of mastitis, and hence milk contamination with microorganisms.

![]()

Table 6. Source of water used for hygienic practices in the study area.

N = Number of respondents.

![]()

Table 7. Ranking of major camel milk hygienic constraints in the study area.

Index = [(5 for rank 1) + (4 for rank 2) + (3 for rank 3) + (2 for rank 4) + (1 for rank 5)] divided by the sum of all constraints of camel production mentioned by the farmers, R = Rank.

Poor hygienic production of milk (unclean udder due to lack of washing the udder before milking, unclean hands, poor personal hygiene and health status, unclean milking containers due to lack of clean water, unclean milking sites) is more likely to cause milk-borne diseases and the natural antimicrobial factors can only provide a limited protection against specific pathogens for a short period. This is in line with Mohammed et al. [22] who reported milk-borne disease is higher when the milk is consumed in its raw state as commonly practiced by the local producers.

Poor hygienic was also ranked one of the major constraints of camel production in the study area (Table 7). The finding is comparable with that of Worku et al. [41] who reported poor handling practices for instance unclean milking equipment as one of the major constraints of camel milk commercialization in Ethiopia.

4. Conclusions and Recommendation

The study indicated that the majority of respondents in both production systems in Degabur district were illiterate. Keeping mature and camel calves were in traditionally prepared house called kraals and Edeg respectively, which is lacking roof, constructed on earthen floor, and contaminated with mud and dung especially during wet season. Barn hygienic was the most important problem contributing for contamination of the milk. Moreover, traditional hand milking was also the commonly used milking practice, followed by not properly washing udder and teats before milking using water from non-tap sources for hygienic practices. The most common used milking and milk handling equipment were plastic equipment and wooden materials which are difficult to clean, and the most common used washing practice was the use of cold water without detergents. In general, it could be concluded that, the milk production practices performed in the study area were unhygienic which could be mainly due to the lack of capacity to produce hygienic milk. Therefore, the following sets of recommendations are made to address the challenges:

● Provision of training to pastoralists and ago-pastoralists on hygienic milk production and postharvest handling practices in the study area is highly recommended.

● Concerned governmental and non-governmental organizations should provide clean water supply to producers as the use clean water highly improve the microbiological quality milk.

Acknowledgements

The authors would like to acknowledge Jigjiga University and capacity building and public service bureau of Somali Regional State, Ethiopia for the financial support.