Simple General Purpose Ion Beam Deceleration System Using a Single Electrode Lens ()

1. Introduction

Low energy ion implantation became very important nowadays, either on microelectronics technology, thin film studies or plasma-wall studies in fusion reactors. Traditional ion deceleration uses a system that includes an electrostatic Einzel lens to focus and a target disk to decelerate the ion beam [1] - [3] . The objective of the described work was to develop a system to focus and decelerate a positive ion beam, keeping magnetic scanning of the beam possible. With this system the high-current ion implanter installed at the Nuclear and Technological Campus, can make implantation from less than 5 to 210 keV.

2. System Description

To produce ion implantations at low energies it is necessary to decelerate the beam, keeping it focused. Positive beam deceleration is performed by applying a positive voltage to the target (VA), in order to create an axial electric field in the opposite direction of propagation of the ion beam (E). This is the method (Figure 1) used in most of ion implanters.

The difficulty in the deceleration process is the creation of a uniform axial field in order to decelerate the beam without defocus. The most common method is to use Einzel lenses [4] - [6] to focus the beam in the lens axis. This method restricts the implantation area to a small region. In a general purpose system where multiple samples of different dimensions and large beam scanning has preference over a sharp focus, a single electrode lens can be more useful.

In order to correct the dispersion of the ion beam allowing magnetic scanning to run continuously it was necessary to study the behaviour of a positive ion beam in two aspects: in front of a charged target and in the region inside a charged ring.

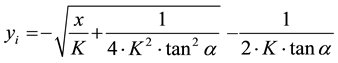

This study, using simple electromagnetism theory, showed that a positive ion beam deflection of length yi due to a uniform electric field with opposite direction of the beam can be described by [7] - [9]

(1)

(1)

where

(2)

(2)

being Eco the initial beam energy and α the incident angle and Ex the electric field on the x direction, given by

(3)

(3)

where Va is the voltage applied to the target, Ca the self-capacitance and Ra the target radius.

As the field is non-uniform, the final deflection yf is given by the sum of elementary regions of uniform fields as in

(4)

(4)

being n the number of considered uniform regions.

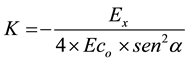

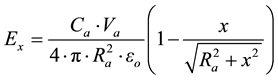

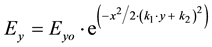

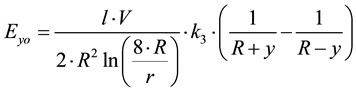

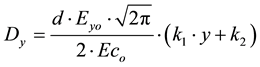

On the other hand, the study of a charged ring showed that the electric field in the y direction inside the ring, that forms the single electrode lens, can be given by

(5)

(5)

![]()

Figure 1. Deceleration method for a positive ion beam.

where

(6)

(6)

being V the voltage applied to the ring, l the ring length, R the ring radius, r the electrode radius and k1, k2 and k3 geometrical constants of the system.

Thus the beam deflection due to a charged ring is given by

(7)

(7)

where d is the distance between the target and the lens.

Thus, using Equations (4) and (7) was possible to determine the voltage to apply to the electrostatic lens to compensate for the deflection of the ion beam caused by the charged target. The theoretical approach was also useful to determine the best overall geometry of the system.

To confirm these results, the simulation software Simion 3D 8.0 was used to simulate the performance of the electrostatic lens, enabling to verify the best target and lens dimensions and gap in between to subsequently build the system [5] .

In Figure 2 the non-charged target is showed, the lines in blue represent the various possible trajectories for a positive ion beam of 15 keV energy.

In Figure 3 is represented one simulation with the same conditions but with a target potential of 10 kV (beam energy of 5 keV). In this situation deflection exists, as predicted in the theoretical study. The red lines represent the electric field equipotentials.

Through this figure is also possible to verify that the deflection increases as the target is biased at higher potentials, as expected i.e. as final energy becomes smaller, the beam becomes defocused.

For subsequent simulations a lens was introduced. As shown in Figure 4, the simulation confirms the theoretical prediction that, using a charged lens with only one electrode with a given potential, it is possible, for most trajectories, to compensate the deflection caused by the target, relaying the path of the beam to its original position. It is also shown that the outmost trajectories are over-deflected.

Table 1 and Figure 5 shows the theoretical and simulated values for the potential applied to the lens (VL) for which the most significant trajectories are better compensated for various values of the target potential (VA), using the same geometry in both cases.

![]()

Figure 2. Ion beam simulation with a non-charged (grounded) target.

![]()

Figure 3. Ion beam simulation with target biased at 10 kV.

![]()

Figure 4. Ion beam simulation at VA = 10 kV and VL = 15.5 kV.

![]()

Figure 5. VL = f(VA) theoretical and simulated.

![]()

Table 1. VL = f(VA) theoretical and simulated.

The equation for the deflection caused by the electric field (7), is in general terms in agreement with the simulations, as long it is applied to flat samples to avoid changes in the geometry of the target and consequently in the electric field.

3. Experimental Results

In Figure 6 is showed the circuit used for deceleration and focusing of the beam.

In this circuit, two high voltage (20 kV) power supplies are used, one to bias the lens (VL) and the other to bias the target (VA). Resistors R1 and R2 are used to improve voltage stability, while the resistor R3 is intended to measure the beam current [10] .

Three sets of tests were performed in order to proof homogeneity of implantations using the studied system. Each test consists of an implantation of four samples of silicon with an Argon beam with final energy of 5 keV. The implantation area was 10 × 10 cm2 and beam current of 100 μA (Figure 7). The first test consists of an implantation without target bias and without lens (beam of 5 keV directly from source). The second test consists of an implantation with target bias but without lens (beam of 15 keV and target bias at 10 kV). The third test consists of an implantation with target bias and lens (beam of 15 keV, target bias at 10 kV at lens bias at 15.5 kV).

Figure 8 shows the obtained values. The first test shows that it is not possible to have implantation homogeneity without deceleration, a beam with initial energy of 5 keV suffers too much dispersion along the beam line [11] - [13] . Second test, with deceleration but without electrostatic lens, shows that, as predicted by simulation, implantation fluence is higher in the sample located far from the target edge.

![]()

Figure 7. Position arrangement of the silicon samples.

![]()

Figure 8. Comparing fluences implanted in the different samples.

Only the third test, with deceleration and lens, shows homogeneity. Notice that, again as predicted by simulation, the fluence is a bit higher for the outmost samples due to beam over-deflection. With this experimental result it was observed that there is a greater homogeneity in the samples 9 to 12 with the largest difference between fluences of the order of 14% while in samples 1 to 4 and 5 to 8 are about 42% and 38% respectively.

Through this test, and taking into account the theory the simulation and the results, it is possible to confirm that the maximum limit that each sample can be within the edge of the target is about 6 cm (sweeping amplitude of 16 cm ). This can be verified in Figure 7 where sample 9 is distant 3 cm from the edge, which clearly overcomes the limitations of the system. This test also permits to verify that the trajectory correction due to the use of the lens is concentrated in the center of the target in an area of about 8 cm in radius, which allows implantations of about 15 × 15 cm2 with acceptable homogeneity.

4. Conclusions

Using the developed system was possible to perform implantations at 5 keV energy continuously scanning of the ion beam over an area of 10 × 10 cm2 with accuracy for a general purpose low-energy implantation system. In addition it was possible to compare the differences between ion implantation based on energy and beam focus.

In this paper the results obtained for implantations at low energies (below 15 keV) were presented. These results were achieved based on the system developed with an electrostatic lens of a single electrode, allowing performing implantations at low energies with a focused beam using the magnetic beam scanning over a large area, gaining versatility for research involving ion implantation.

The system developed and applied to the CTN implanter can be used in other implanters, for general purpose low energy implantations where a very high homogeneity and/or very high fluence control is not an issue.