1. Introduction

Iron and steel industry is to support the basic industries of the national economy. Iron and steel are related to people’s livelihood of the bulk of raw materials. In recent years, with the rapid growth of China’s national economy, steel trade enterprises have developed, and the logistics scale is increasing [1] . China’s apparent consumption of steel was 911 million tons in 2012, and China’s apparent consumption of steel was 935 million tons in 2013. China Steel Association released that the highest social stock reached 19.41 million tons in the end of March 2014, up 43.65% over the beginning.

However, with the increase of China’s steel industry concentration gradually and the continuous expansion of steel production capacity, steel market has become increasingly prominent contradictions. Industrial structure is irrational obviously in steel trade logistics. On the geographical position, various types of iron and steel trading market, and distribution centers are constructed low-level redundant, so some areas have an over-supply problem; in the functional definition, theoretically speaking, because the logistics center can be a better integration of social resources, logistics node function is generally assumed by the logistics center. For a long time, most of the iron and steel plants are mostly self-owned transport vehicles, but the service specification is limited and cannot perform the function of the logistics node. Because the iron and steel enterprises always choose their own logistics and transportation enterprises to distribution or transportation, they are difficult to integrate logistics resources, and they can’t form a scale effect. And because of the iron and steel enterprises in the logistics process in the lack of planning, traffic flow is very uneven, and it is difficult to provide high-quality services [2] . Iron and steel enterprises in the logistics not only can’t achieve the integration of logistics functions and scattered energy, but also can’t focus on core business, which reduce market competitiveness.

As a logistics management and processing base, logistics distribution center can promote the flow of goods to overcome its time and space barriers [3] . Modern distribution center can integrate resources, form scale advantages and flexibility, respond to customer needs quickly, reduce inventory, conduct circulation processing, integrate information, and finish professional distribution finally. The iron and steel enterprises with professional standard can reduce logistics costs, thereby enhancing market competitiveness.

2. Logistics Distribution Status of Wuhan Iron and Steel Company

Wuhan Iron and Steel Company is located in Wuhan, which is a manufacturing company for mine mining, coking, iron making, steelmaking, and steel rolling. The factory produces 0.5 ~ 2 mm specified cold rolled sheet and φ6 mm - φ12 mm wire, and sales to multiple cities of Hunan province, such as Yueyang, Changsha, Xiangtan, Hengyang, Yongzhou, Loudi, Shaoyang, Yiyang, Changde, Huaihua, Loudi. At present, the steel company uses direct delivery model, that is, steel is delivered directly from the company to customer according to customer’s demand. In order to analyze the advantages and disadvantages of the direct distribution model, according to the actual location of steel mills and demand points, using the following methods, steel and customer location diagram are calculated firstly.

Wuhan city is regarded as the coordinate origin, then the Cartesian coordinate system can be established, and the coordinates of the cities in Hunan Province can be calculated as shown in Table 1 and Figure 1. The position coordinate table scale is 1:250,000.

Because the point-of-sale location of cities in Hunan province is scattered as shown in Figure 1, each city can be carried out in accordance with the principle of the nearest clustering [4] . Average annual sales of steel in cities of Hunan province can be calculated integrating previous year’s sales figures. According to the transport routes, the average rate of transport can be got from Wuhan to each city in Hunan province.

![]()

Table 1. Location table of Hunan cities (Unit: cm).

![]()

Figure 1. Coordinate map of each city in Hunan (Unit: cm).

Because cold plate and wire size, shape are different, so they need different shipping space under the same weight. According to the average sales of Hunan cities, the proportion of two steel varieties, and the average transportation rate, the weight of each city can be calculated and shown in Table 2.

In Table 2, the symbols are defined as follows.

: The city’s total sales;

: The city’s total sales;

: Transportation rates of Wuhan to city i;

: Transportation rates of Wuhan to city i;

: The city’s weights;

: The city’s weights;

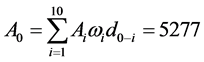

Calculated from Wuhan to Hunan cities of direct transport costs,

million yuan.

million yuan.

3. Location Model and Calculation Results of Wuhan Steel Mills’ Distribution Center in Hunan Province

Because the locations of steel demands in Hunan Province are located in the southwest of Wuhan City, the steel logistics distribution center can be built in Hunan Province to

![]()

Table 2. Annual sales of steel and weights of Hunan cities Inputs and outputs.

reduce the total cost of steel distribution.

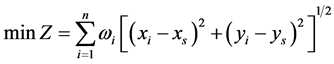

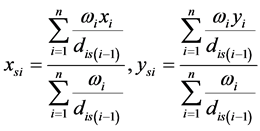

In this paper, the precise center of gravity method is used to determine the location of steel distribution center in Hunan Province. The exact center of gravity method with continuous point location is one of the most widely used models among cities. This method is based on the distance between existing facilities and the quantity of goods transported. The Euclidean distance is used to determine the distance between two cities. The purpose of exact center of gravity method is to minimize the sum of sum of logistics distance, and transportation rate of each city in Hunan province [5] .

From Figure 1 and Table 2, Shaoyang is selected as the initial distribution center. The iterative threshold is set to 10 km.

The decision variables are defined as follows:

: Coordinates of Hunan’s Demand Cities;

: Coordinates of Hunan’s Demand Cities;

: The coordinates of the initial distribution center;

: The coordinates of the initial distribution center;

: The distribution center coordinates for each iteration;

: The distribution center coordinates for each iteration;

,

, : Threshold of the iteration.

: Threshold of the iteration.

In order to minimize transportation costs, the exact center of gravity model is as follows:

(1)

(1)

(2)

(2)

(3)

(3)

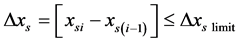

(4)

(4)

(5)

(5)

1) The objective function which minimizes the transportation cost;

2) Iterative expression;

3) Euclidean distance;

4), 5) The condition for terminating the iteration.

The optimal solution of the model can be obtained by using Matlab software. The coordinates of the model are (162.3, 121.4). Considering that each city has its corresponding administrative scope, and the distance from optimal solution coordinates to Loudi is the nearest, so the optimal solution of the corresponding city is in Loudi City. In other words, Loudi City should be chosen as a steel distribution center.

4. Sensitivity Analysis

Steel can be concentrated firstly and then delivery to the Loudi City Distribution Center, and then transported to various demand points from the Loudi City Distribution Center. According to the data in Table 2 and the formula in 3-1, the freight can be calculated after the establishment of distribution centers, and the total freight is 37.31 million yuan corresponding to the transport program. From Wuhan to Loudi steel distribution center cost 21.66 million yuan, and the total freight is 15.65 million yuan from the distribution center to the various points of demand.

Comparing the freight of two transportation strategies between Wuhan steel mills to the cities of Hunan, the following conclusions can be drawn:

1) Transportation cost from Wuhan through the distribution center to the cities of Hunan to reduce the direct transportation costs of 15.46 million yuan, accounting for about 29.30% compared with transportation directly;

2) The establishment of a distribution center in Loudi will help to further integrate the province’s resources, reduce product costs, improve customer service, and thus can broaden the market and enhance overall competitiveness;

3) The distribution from Loudi city to Hunan is conducive to the further development of access to greater scale advantages. At the same time, other additional transactions can be made with the cities and long-term development of cooperative relations, which can effectively reduce the phenomenon of no-load vehicles and achieve long-term green development of steel transport.

The establishment of a distribution center is not only to consider the transport costs, but also a comprehensive consideration of the local macro-policy and internal factors. Such as Loudi city’s macro-policy, infrastructure, environmental factors, traffic conditions and so on. Loudi is located in the middle of Hunan, Hunan Province is the most economically developed central block; also in the Changsha-Zhuzhou-Xiangtan area under the influence of economic integration [6] , industrial land infrastructure is good. Although the initial construction of distribution centers need to invest a lot of money, but after the operation of the payback period is very short, which can be profitable quickly.

5. Conclusion

This paper studies the location of Wuhan Steel Plant Logistics Distribution Center. According to the geographic location of steel company and the demand of steel in Hunan province, the location model of distribution center with minimum total transportation cost was established by using accurate center of gravity method. The iterative solution was carried out by Matlab software. The conclusion can be seen by comparing the transport costs: from the steel mills in Wuhan to Hunan cities, the total transportation costs greatly reduced after the establishment of distribution centers. In the direct transport, Wuhan steel logistics flexibility is poor and can’t fully focus on its core business; the cost is huge whose competitiveness is not good in the market. The establishment of steel logistics distribution center is to meet customer’s needs better and quickly adapt to market changes, and large-scale transportation can reduce costs, so the construction of specialized distribution center has broad prospects. The results of this study can be the decision-making basis for the iron and steel plant construction logistics center.

Acknowledgements

This work was supported by National Natural Science Foundation of China (71540028), High lever scientific research project of Beijing Wuzi University (GJB20164005); the Funding Project of Beijing high level innovation and entrepreneurship program teaching teacher.