A Solute Pinning Approach to Solute Drag in Multi-Component Solid Solution Alloys ()

1. Introduction

It is well known that segregated impurity atoms can drastically reduce the mobility of grain boundaries in pure metals. The phenomenon is considered to be a general effect and is usually referred to simply as “solute drag”. Cahn [1] and Lücke and Stüwe [2] suggested a quantitative treatment of the solute drag, which has been the basis of following works on solute drag. The latter works have mainly focused on extending their approach to a migrating phase boundary into a multi-component system [3-9]. One achievement of the Cahn-Lücke-Stüwe theory (CLS theory) was to demonstrate that the grain boundary velocity is inversely proportional to the solute concentration in the high solute content/low driving force regime.

However this theory presents some major drawbacks. Firstly, while the basic physical idea behind the solute drag theory is principally simple, where the motion of a grain boundary is slowed down by solute atoms which exert a drag force on the boundary, the analytical treatment becomes rather involved: the solute profile around the moving grain boundary must be established by solving Fick’s first law in a moving frame and then the solute drag is determined from this profile. Secondly, few works have tackled the issue of the influence of different types of solute atoms on a moving grain boundary [10,11]. This issue is of industrial relevance because industrial alloys are generally not high purity alloys with only one type of impurity but in most cases made up of different major additions. The last decades have seen the advent of computer aided material science and engineering and so a solute drag approach taking simply into account the effect of different additions should be of great help to achieve more realistic simulations.

2. The Solute Pinning Approach

Recently a new solute drag model has been proposed based on a solute pinning approach [12]. The grain boundary is pinned by the solute atoms along the boundary, which will induce a local cusping of the boundary at the solute atoms (Figure 1). Stress concentration will arise promoting thermal activation of solute atoms out of the boundary. Compared to the CLS theory, the main benefit of this approach is to be computationally simpler. The present treatment aims to generalize this approach to different types of solute atoms in the high solute content/ low driving force regime. Then let us consider two solutes A and B in a matrix forming an ideal solid solution.

2.1. Establishment of the Equations to Solve

In steady state conditions the concentration of each type of solute atoms adsorbed at the grain boundary remains constant, which means that the rate per unit area at which the solute atoms leave the boundary  is equal to the rate at which the solute atoms arrive

is equal to the rate at which the solute atoms arrive :

:

(1)

(1)

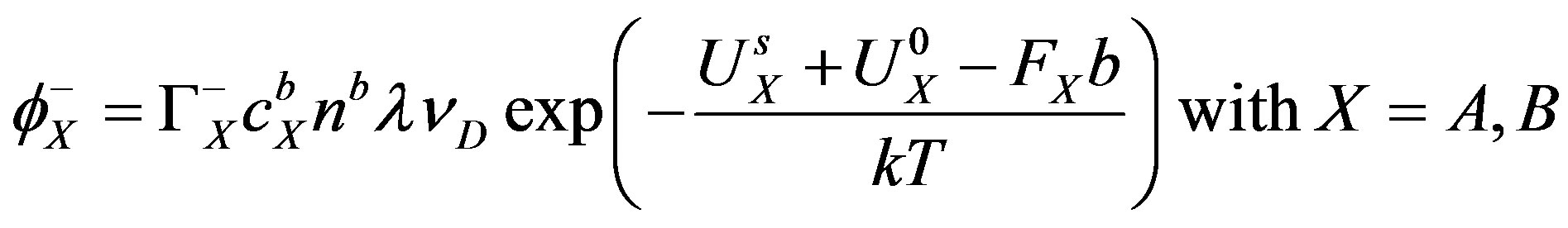

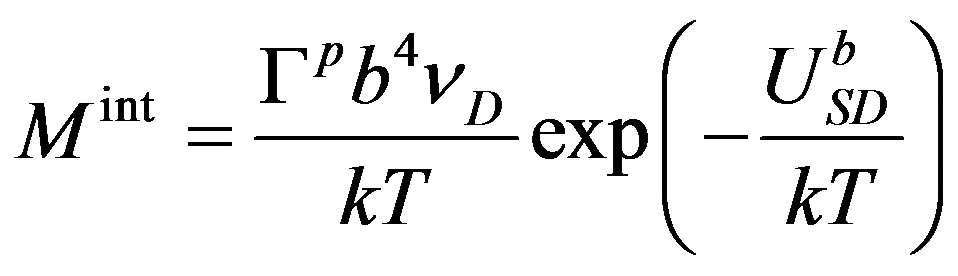

In terms of thermal activation, following [12], the leaving rate  can be expressed as follows:

can be expressed as follows:

(2)

(2)

where  is a constant,

is a constant,  the boundary concentration of the solute X given in terms of atomic fraction,

the boundary concentration of the solute X given in terms of atomic fraction,  the number of atomic sites per unit volume inside the boundary,

the number of atomic sites per unit volume inside the boundary,  the boundary thickness,

the boundary thickness,  the Debye frequency,

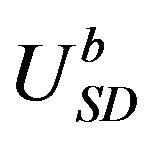

the Debye frequency,  the diffusion activation energy for the solute X,

the diffusion activation energy for the solute X,  the cusping force on each solute atom of type X exerted by the boundary reducing thus the activation barrier out of the boundary by the energy

the cusping force on each solute atom of type X exerted by the boundary reducing thus the activation barrier out of the boundary by the energy  and b the close packed spacing in the matrix. Some parameters are pictured in Figure 1.

and b the close packed spacing in the matrix. Some parameters are pictured in Figure 1.

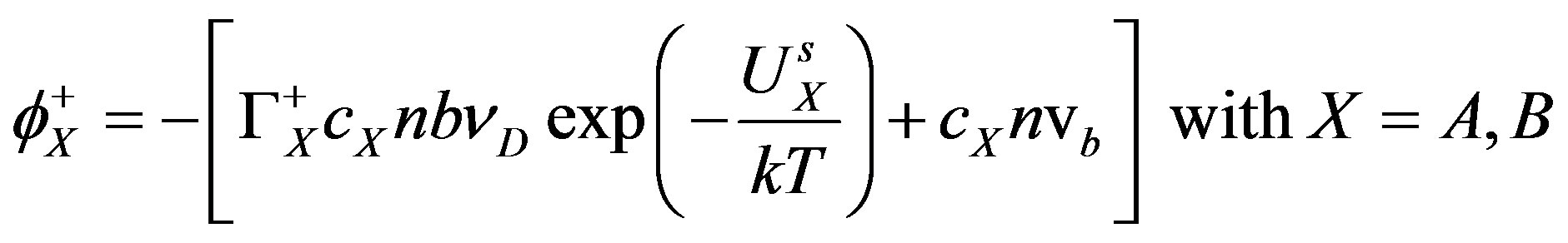

The arrival rate  can be written as follows:

can be written as follows:

(3)

(3)

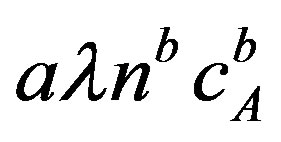

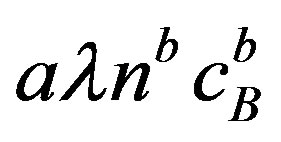

where  is a constant,

is a constant,  is the bulk solute concentration in atomic fraction of the solute X, n the number of atomic site per unit volume in the bulk of the material. The arrival rate

is the bulk solute concentration in atomic fraction of the solute X, n the number of atomic site per unit volume in the bulk of the material. The arrival rate  is made of two terms: the first term represents the diffusion contribution to the arrival rate

is made of two terms: the first term represents the diffusion contribution to the arrival rate  and the second term a convective contribution (i.e. sweeping up of solute atoms ahead of the moving boundary). Introducing the expressions for

and the second term a convective contribution (i.e. sweeping up of solute atoms ahead of the moving boundary). Introducing the expressions for  and

and  in Equation (1) makes possible to calculate the boundary concentration

in Equation (1) makes possible to calculate the boundary concentration  provided an expression for the migration rate

provided an expression for the migration rate  is obtained.

is obtained.

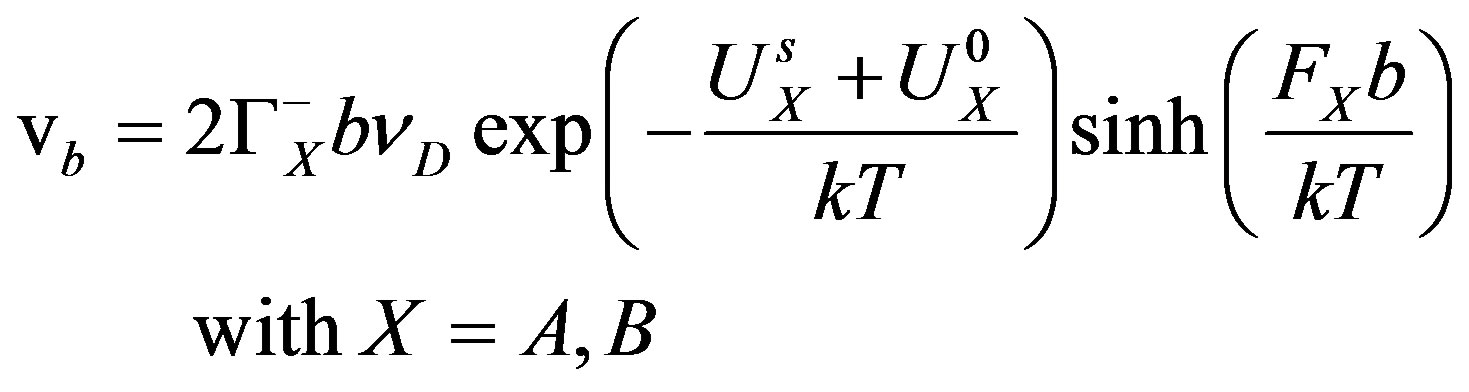

By statistical considerations of the probability that a solute atom leaves the boundary, the boundary velocity  has been established in [12] as equal to

has been established in [12] as equal to

(4)

(4)

By combining the expressions obtained for ,

,  and

and  with Equation (1) and by assuming

with Equation (1) and by assuming  to be approximately of the same size of

to be approximately of the same size of  (represented by a common symbol

(represented by a common symbol  in the following), the following expressions for the boundary solute concentrations are obtained:

in the following), the following expressions for the boundary solute concentrations are obtained:

(5)

(5)

Further in the paper it will be assumed that the number of atomic sites per unit area of the boundary  is nearly equal to the number of atomic sites per unit area inside the matrix

is nearly equal to the number of atomic sites per unit area inside the matrix .

.

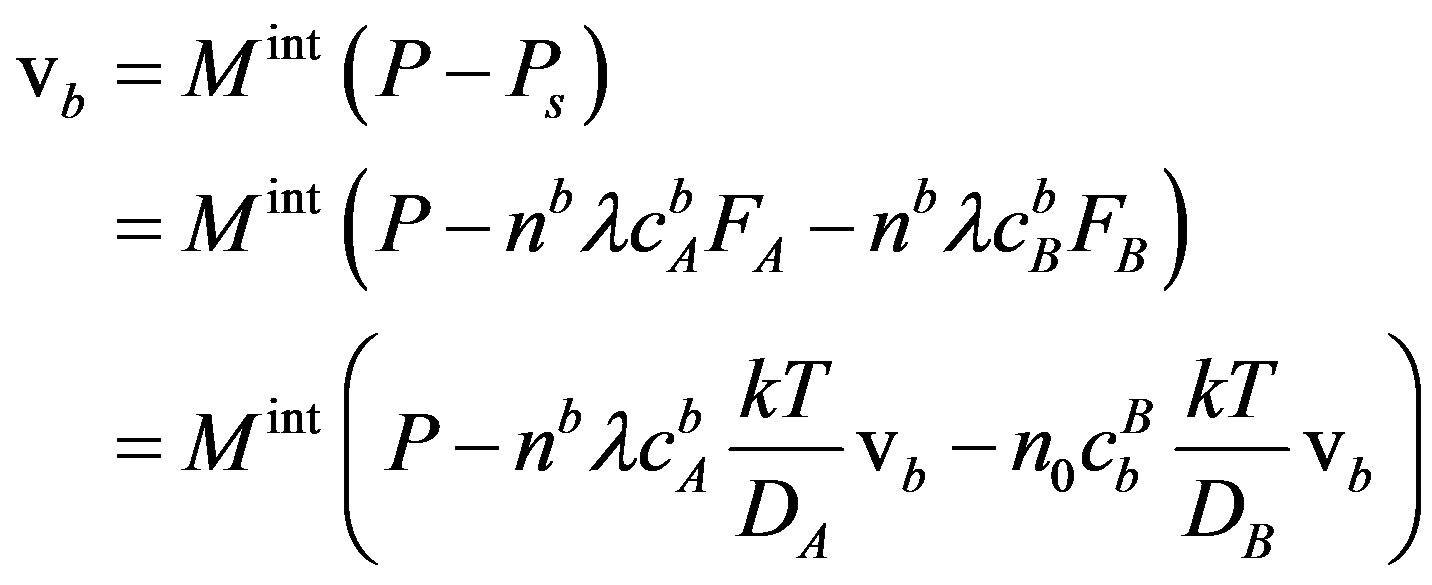

The boundary velocity can also be expressed in terms of mobility. In pure materials, grain boundary migration theory predicts that the boundary velocity  can be expressed as the product of two terms—the intrinsic mobility

can be expressed as the product of two terms—the intrinsic mobility  of the pure grain boundary and the driving pressure P:

of the pure grain boundary and the driving pressure P:

(6)

(6)

Based on the probability of jumps forward and backward through the grain boundary,  can be written as [13]

can be written as [13]

(7)

(7)

In this equation  is a constant and

is a constant and  is an activation energy associated with boundary migration. This activation is typically found to have a value half that of self-diffusion.

is an activation energy associated with boundary migration. This activation is typically found to have a value half that of self-diffusion.

However for metals containing solute atoms the above linear relationship Equation (6) can still be applied to determine the velocity of the grain boundary regions free of solute atoms if P is replaced by a new driving pressure which is the difference between the driving pressure P and the restraining pressure  resulting from the interactions between the solute atoms and the grain boundary

resulting from the interactions between the solute atoms and the grain boundary

(8)

(8)

In the latter expression, the pressure coming from grain boundary curvature is neglected, which assumes that the grain boundary remains macroscopically planar during its migration.

The atoms A and B respectively in number  and

and  exert a force

exert a force  and

and  on a grain boundary of area a. Thus the restraining pressure

on a grain boundary of area a. Thus the restraining pressure  can be determined as

can be determined as

(9)

(9)

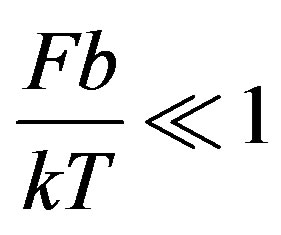

In the special case of a low driving pressure/high solute content, i.e. , it appears that the grain boundary moves with a velocity proportional to the driving pressure. The proportionality factor is determined by the solute content in solid solution. So an extrinsic mobility

, it appears that the grain boundary moves with a velocity proportional to the driving pressure. The proportionality factor is determined by the solute content in solid solution. So an extrinsic mobility  can be defined:

can be defined:

(10)

(10)

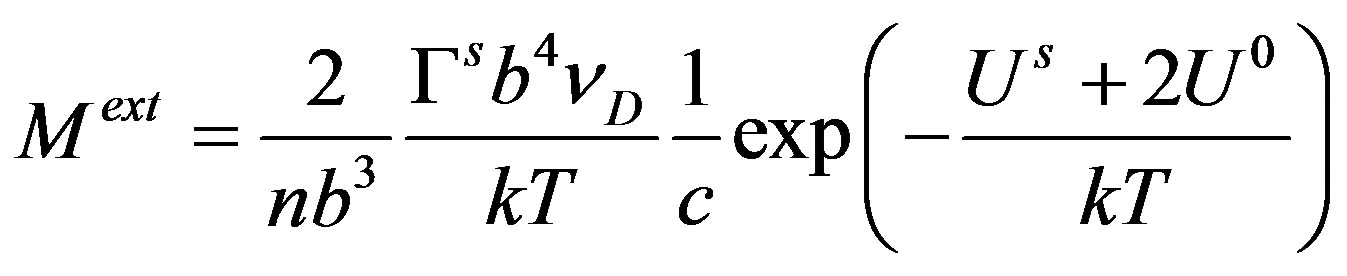

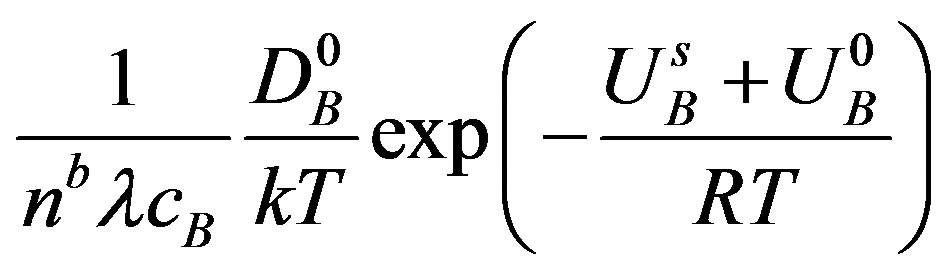

The solute pinning approach gives an expression of this extrinsic mobility in terms of the relevant parameters at the atomic scale [12]:

(11)

(11)

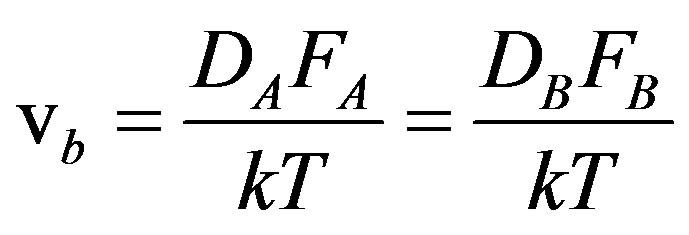

Finally two more relations can be obtained by pointing out that the grain boundary velocity must be independent on which elements used to determine the velocity:

(12)

(12)

By introducing the expressions for the intrinsic mobility  (Equation (7)) and the restraining pressure

(Equation (7)) and the restraining pressure  (Equation (9)) the following non-linear system can be obtained:

(Equation (9)) the following non-linear system can be obtained:

(13)

(13)

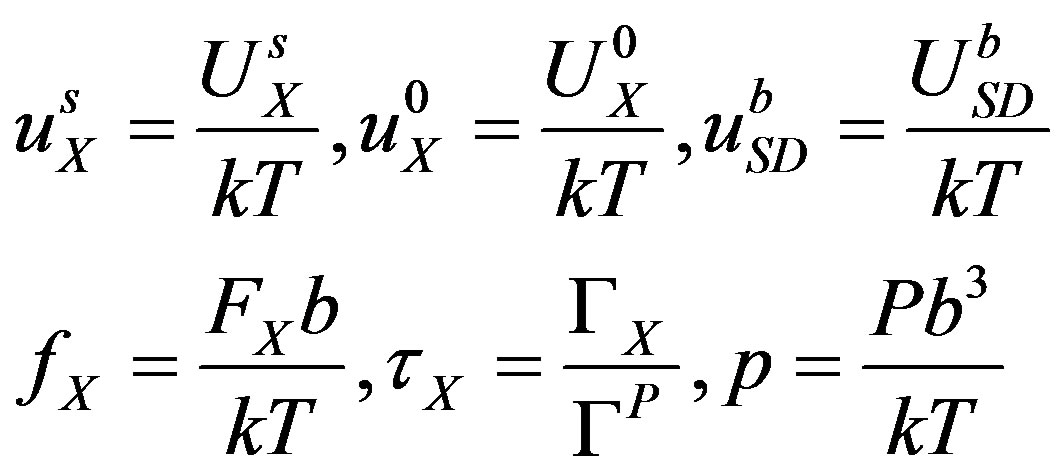

To simplify the notations the following normalized variables are introduced:

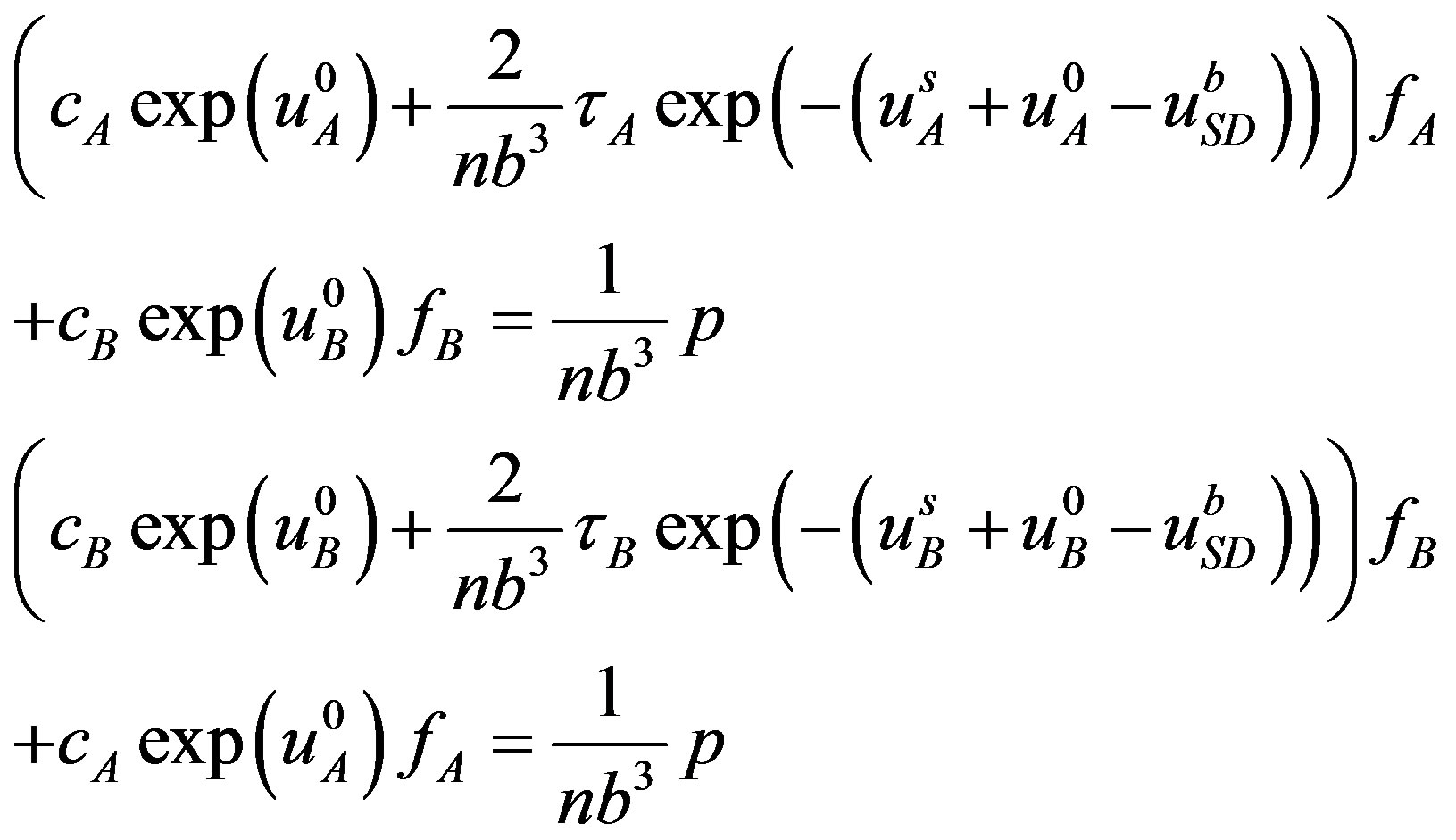

The system becomes then:

(14)

(14)

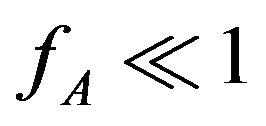

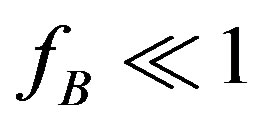

Solving this system for any conceivable case may be quite challenging because of its non-linearity and the coupling between the cusping forces  and

and . In the present paper we will therefore only solve this system for the case of

. In the present paper we will therefore only solve this system for the case of  and

and . These assumptions imply that the solute content is high enough to impede the grain boundary motion.

. These assumptions imply that the solute content is high enough to impede the grain boundary motion.

2.2. Linearization of the System

The system can in this case be linearized as follows:

(15)

(15)

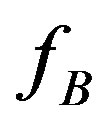

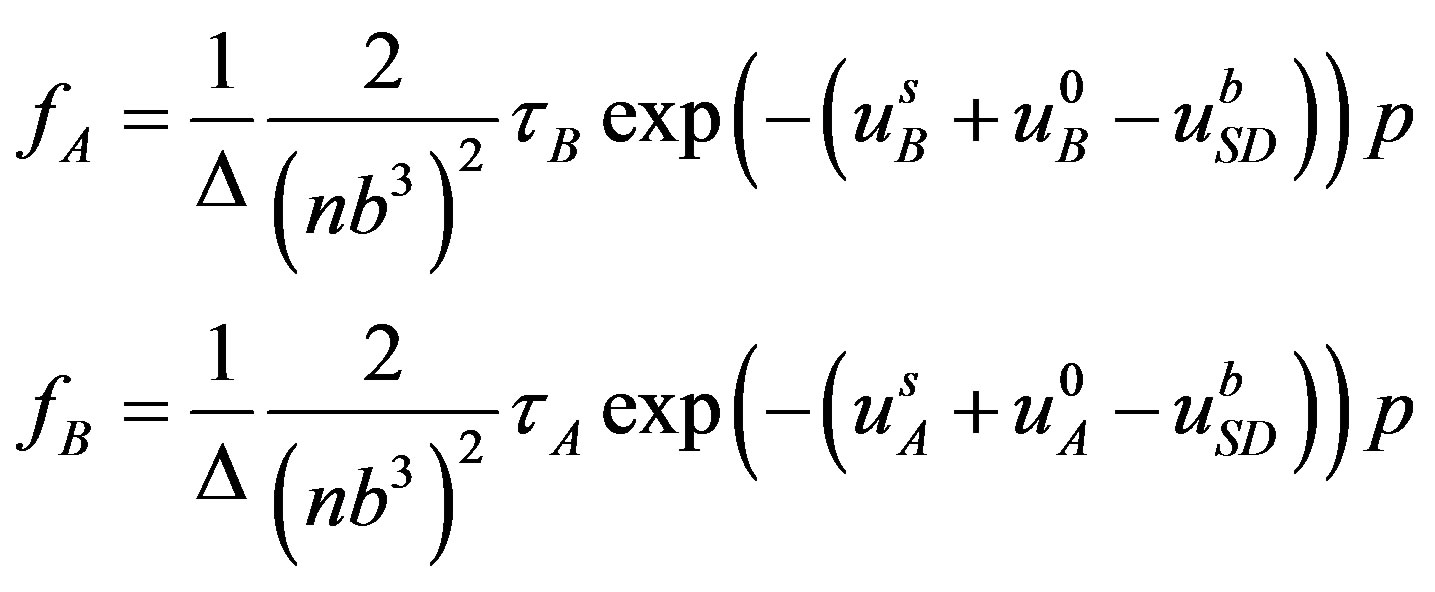

By using the Crammer’s formula for the solutions of a linear system, the expressions for  and

and  could be easily obtained:

could be easily obtained:

(16)

(16)

with  the system determinant whose expression is

the system determinant whose expression is

It should be noted that the expression for  and

and  as given by Equation (16) are symmetrical. To obtain an expression of the boundary velocity independent of the element considered, the grain boundary velocity has to be written as

as given by Equation (16) are symmetrical. To obtain an expression of the boundary velocity independent of the element considered, the grain boundary velocity has to be written as

(17)

(17)

By linearizing the expressions for the boundary velocity  (Equation (4)) and inserting them in Equation (17), the boundary velocity

(Equation (4)) and inserting them in Equation (17), the boundary velocity  can finally be expressed as

can finally be expressed as

(18)

(18)

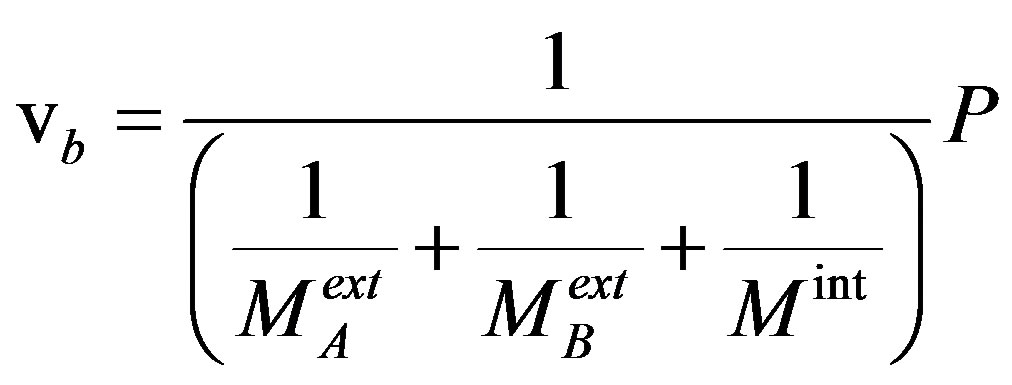

By writing the latter expression with the help of the intrinsic and extrinsic mobilities, respectively Equation (7) and Equation (11), the relation between the boundary velocity  and the driving pressure P takes the form

and the driving pressure P takes the form

(19)

(19)

The present solute pinning approach thus permits to find a very compact and convenient formula for the extrinsic mobility of a grain boundary in the case of different types of solute in solid solution in the high solute content/low driving force regime. The demonstration done for two different types of solute can easily be generalized for n different types of solute by using the expressions of the solutions of a linear system in terms of the determinant.

3. Discussion

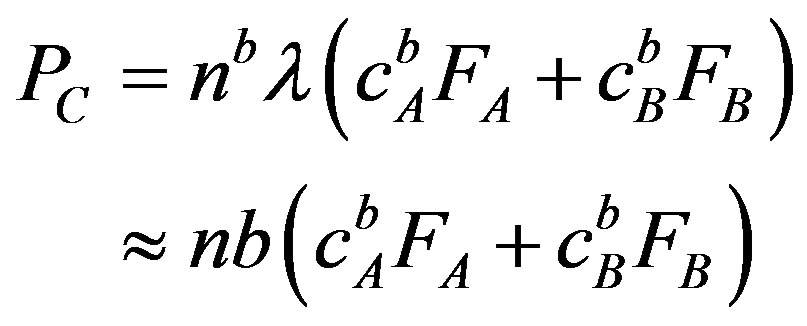

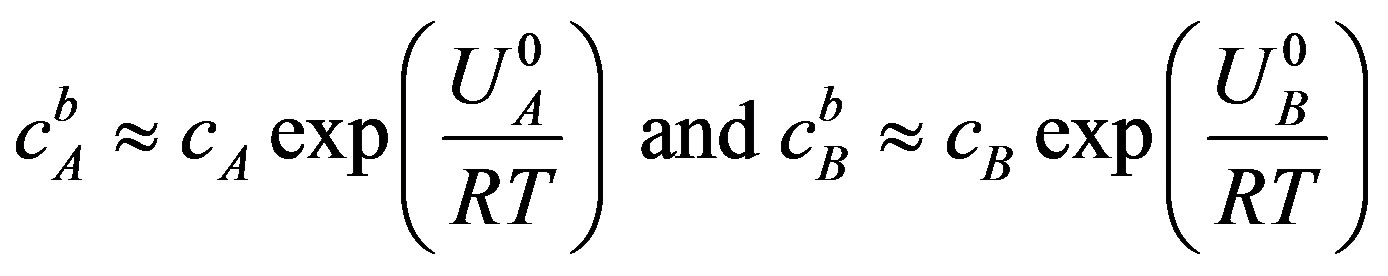

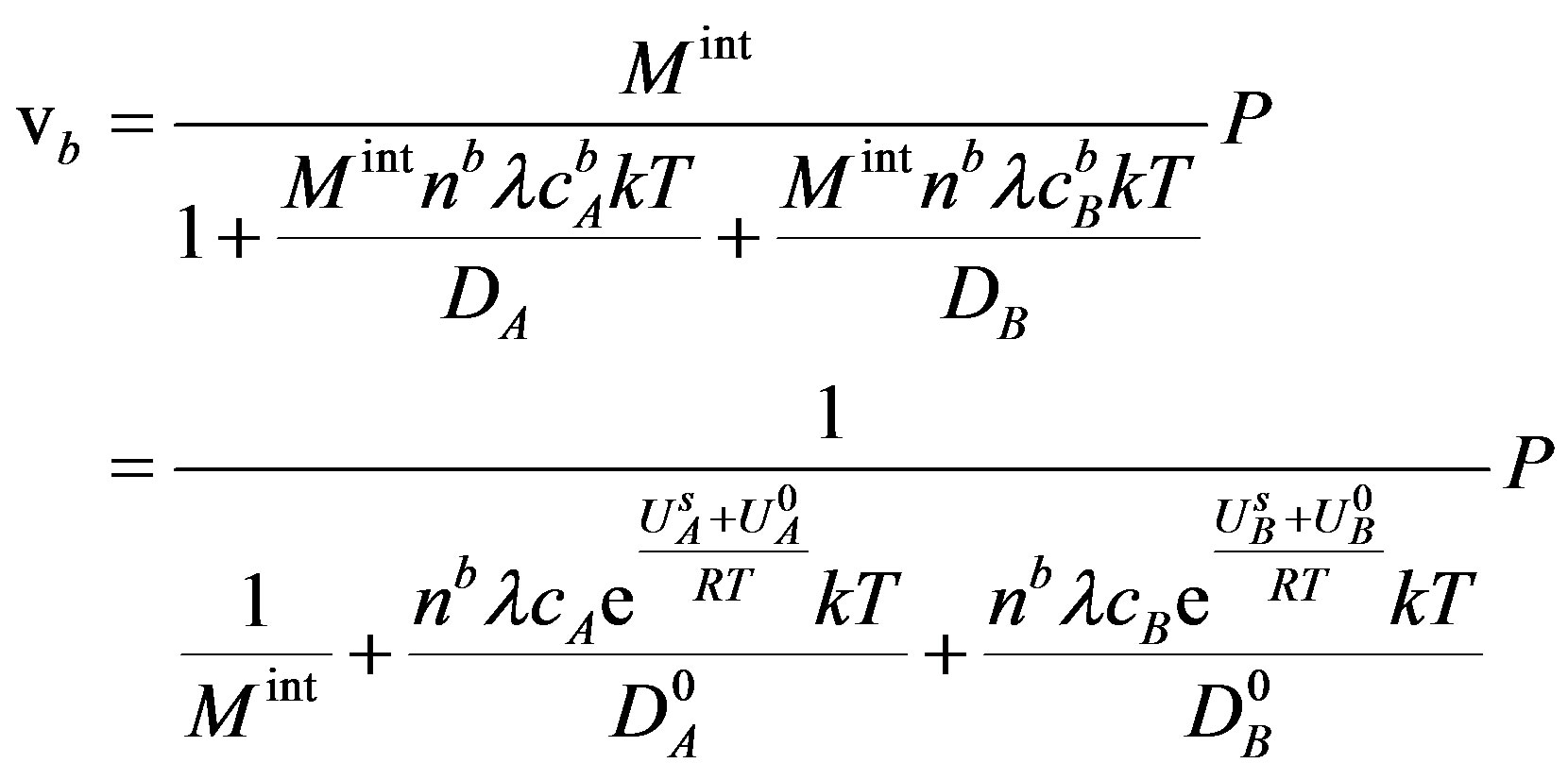

The Equation (19) is actually consistent with an analogous one that can be derived by following Lücke and Detert’s original demonstration of solute drag [14] (the CLS theory has been developed later to overcome the shortcomings of this simple approach but do not change fundamentally the result). Indeed, in their approach it is assumed that a slow moving boundary will drag along its migration a number of solute atoms A and B close to their equilibrium values, which is equal to

(20)

(20)

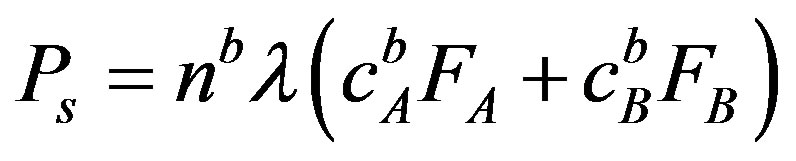

and therefore exert a drag pressure

(21)

(21)

It should be noted that in their demonstration  and

and  are not determined by the cusping of the boundary but by the Einstein’s equation

are not determined by the cusping of the boundary but by the Einstein’s equation

(22)

(22)

where  and

and  are the bulk diffusion coefficient of the solute atoms:

are the bulk diffusion coefficient of the solute atoms:

The boundary will move then with the velocity

(23)

(23)

and therefore,

(24)

(24)

In their approach, the quantities

and

and

are respectively the mobility of the boundary when it is fully loaded either with solute atoms of type A

are respectively the mobility of the boundary when it is fully loaded either with solute atoms of type A  or B

or B . Finally, the boundary velocity could be expressed as

. Finally, the boundary velocity could be expressed as

(25)

(25)

i.e. the same formula as the one in Equation (19), although the explicit expressions for the mobility terms are slightly different (see also [12]). The agreement between the solute cusping approach and the most accepted theory on solute drag can be understood by the fact that in the slow driving pressure/high solute content regime the solute cusping approach predicts a boundary which is nearly flat due to the large number of solute atoms pinning it [12], consistent with the original assumptions made by Lücke and Detert [14].

It is also interesting to note that a similar expression, although simpler, for solute drag effects in multi-component alloys was introduced as a phenomenological approach already by Vatne [15], to account for solute effects in the softening model Alsoft [16-18]. Here an effective concentration of solutes as derived from a summation of the solute concentration of the individual alloy elements, weighted by their activation energy for diffusion, is introduced into an equation analogous to Equation (11) [15].

However, although more stringently derived, it should be noted that some limitations also apply to the formula (Equations (19) and (25)). Firstly, interactions between the two types of solute have been neglected. The consequences of their interactions have been studied in [10,11]. Without considering site saturation in the boundary, it has been demonstrated that the solute drag in the presence of solute-solute interactions could either be increased or reduced depending on the nature of their interactions, attractive or repulsive [10]. It has also been proved that co-segregation of solutes competing for the boundary sites but not interacting with each other can lead to a complex behaviour where an impurity addition increases the boundary mobility [11]. Secondly, this formula only apply for the migration of a grain boundary in a dilute solid solution and do not tackle the problem of interphase migration into a multi-component system, which is at the time being out of the reach of this approach.

4. Conclusion

Despite the limitations mentioned before, and it still remains to be validated against real experiments, it is believed that the establishment of this formula (Equations (19) and (25)) has the potential of more accurate simulations of microstructure evolution (e.g. recrystallisation and sub-grain/grain growth) where solute drag effects are of importance, and thus in computer aided design of industrial processes and alloys. In particular, as compared to simpler approaches, it may be important in alloys where different solute has significantly different diffusion rates and/or boundary segregation tendencies (as expressed by the activation energy )

)

Acknowledgements

This research work has been supported by a KMB project (project number: 193179/I40), in Norway. The financial support by the Research Council of Norway and the industrial partners, Hydro Aluminium and Sapa Technology is gratefully acknowledged.