New Trends in Non-Destructive Evaluation of Surface Hardened Layers and Coatings ()

1. Introduction

Due to the particular location, the surface layer of the material is in a specific state, and has properties that are often different from those of a base material. Common causes of this condition are well known:

- weakened condition of atomic bonds;

- interaction with the environment, characterized by oxidizing, hydrogen saturation, or other properties;

- defects of treatment appearance: mechanical, thermal, radiation, or other;

- segregation of impurities and defects, as in the case of fatigue or wear;

- the presence of tensile stress concentration zones, as in the case of grinding burns, etc.

Therefore, the surface material is always of particular concern to developers of products and designs. Structural and economic arguments add up to the need to provide at least equal strength and equivalence properties of the surface material and the substrate. This is achieved in two principal ways: a special coating or surface treatment. Application technology and processing have long turned to the independent industry, objecting to improve the operating characteristics of the articles by giving to their surface layers special properties like strength, resistance to wear, oxidation or fatigue, providing thermal stability, radiation and corrosion resistance, the ability to absorb or reflect light of certain wavelengths, etc. up to imparting to products the disinfecting or antibacterial features.

The important parts of surface treatment industry are diagnostic methods of surface layers and coatings, determination of their geometric, physical and chemical characteristics by a variety of NDT methods. It is clear that any one single method of treatment or coating is not complete without the development of technology and means for measuring or assessing the full range of properties of layers and/or coatings: thickness, hardness, stress, chemical composition and optical properties, thermal conductivity, surface roughness, fatigue strength and wear resistance, the presence of surface nonuniformity, etc. In now-a-day experts arsenal for surface layers diagnosis (SLD) there are instruments and methods of non-destructive testing: magnetic, eddy current, ultrasonic, radiation, thermal, magnetic noise, microwave, optical probe microscopy, etc. As I know, one of the first instruments for surface testing in mass production, was magnetic Akulov thickness meter (ATM) (Figure 1), based on the principle of the ponderomotive interaction of a permanent magnet with a ferromagnetic substrate. The instrument is able to measure within a few microns accuracy the thickness of non-magnetic materials (copper, tin, zinc, chromium, titanium) on steel, the thickness and properties of ferromagnetic nickel coatings on the same base material, the content of the ferromagnetic α-phase in stainless steel, etc. The device had full metrological

Figure 1. Akulov magnetic thickness gage.

support, including methods of certification, verification and measurement, and came with a set of calibration and control samples. Despite the fact that the device has been patented worldwide and put into production in 1963, still no one device in its class can compete with ATM in terms of accuracy, ease of use, reliability and portability.

Since that together with the emergence of a large number of methods for applying layers and surface treatment, the demands to SLD became more sophisticated. There is a need to measure the thickness of layers with the accuracy from nanometers (nano-layers) to a few millimeters (clad layers), the parameters of multilayer coatings, layers treated with concentrated (laser, plasma) sources of heat, cover the diagnosis of new materials (such as graphite), properties of coatings and layers with a depth resolution (for example, after surface plastic deformation (SPD)), to identify defects in nanoscale coatings and more.

The conventional market offers a large number of non-destructive and low-damaging devices for the diagnosis of layers and coatings: eddy current, ultrasonic, magnetic, microwave, micro-X-ray spectral and others. The set of measured parameters is usually reduced to the thickness, hardness and chemical composition. This article does not aim to describe all existing methods of traffic police. It attempts to present some, from the point of view of the author, significant trends in SLD and some nearest prospects of this development.

1.1. Evaluation of Coatings and Layers with Depth Resolution. Multilayer Coatings

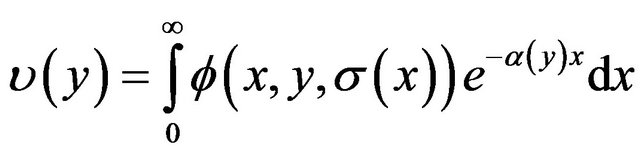

Evaluation of coatings and layers with depth resolution or layer-by-layer (LbL) analysis of surface layers (SL) in the mathematical formulation is classified as significantly ill-posed inverse problem. For the first time in this form the problem was formulated in [1,2] for the LbL analysis of hardened layers on ferromagnetic materials by magnetic noise in the following form:

, (1)

, (1)

where —effective voltage of Barkhausen Noise (BN) in the overhead Barkhausen transducer (BT), depending on a varied during the experiment parameter

—effective voltage of Barkhausen Noise (BN) in the overhead Barkhausen transducer (BT), depending on a varied during the experiment parameter  (for example, magnetization current or BN frequency range);

(for example, magnetization current or BN frequency range); —the contribution of the unit layer to the BN signal;

—the contribution of the unit layer to the BN signal; —parameter under test e.g. stress value, dependent on the depth

—parameter under test e.g. stress value, dependent on the depth ;

; —the damping factor of the BN in ferromagnet, which generally depends on the parameter

—the damping factor of the BN in ferromagnet, which generally depends on the parameter . If the reconstructed function is the distribution of internal stresses in depth (after SPD), the task of stress value reconstruction with depth resolution can be expressed as the following integral equation:

. If the reconstructed function is the distribution of internal stresses in depth (after SPD), the task of stress value reconstruction with depth resolution can be expressed as the following integral equation:

(2)

(2)

where f—the ultimate depth of the informative layer.

Equation (2) is ill-posed Fredholm equation of the 1st kind and can be solved by traditional Tikhonov regularization technique [3]. Based on this approach, the authors in the Institute of Applied Physics in Minsk developed hardware and software system INTROMAT for Industrial implementation of LbL on-line analysis of elastic stresses in the surface layers subjected to the SPD, or hardness after surface heat treatment like cementation. Figure 2 (solid line) shows the stress profiles obtained for samples of steel 300M after SPD by solving the Equation (2). For comparison, Figure 2 also shows the stress distribution on the same sample, but measured by an independent destructive method comprising of LbL by a known electro polishing technique. The figure shows that both methods are in good agreement. The error, which provides a reconstruction method does not exceed 20%, which is sufficient for many practical applications.

The strong micro-magnetic BN characteristics dependence of internal stress or other SL properties is the physical basis of this technique. The situation is much more complex for nonmagnetic conductive materials, which conductivity is weakly dependent on stress. For most structural materials, these changes do not exceed 3% of the usual material conductivity. In this case, the use of the frequency spectrum change with stress variation is more reasonable. American researchers [4] developed technique for eddy current signals frequency spectra inversion for the reconstruction of the stress function

Figure 2. Layer-by-layer stress profiles σ(x), acquired for steel 300M specimens by the solution of Equation (2) (dashed line) and measured by Davidenko method (electrolytic etching) (solid line) [2].

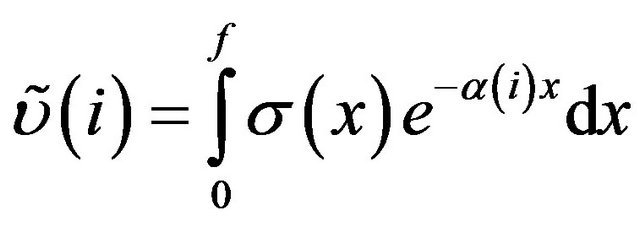

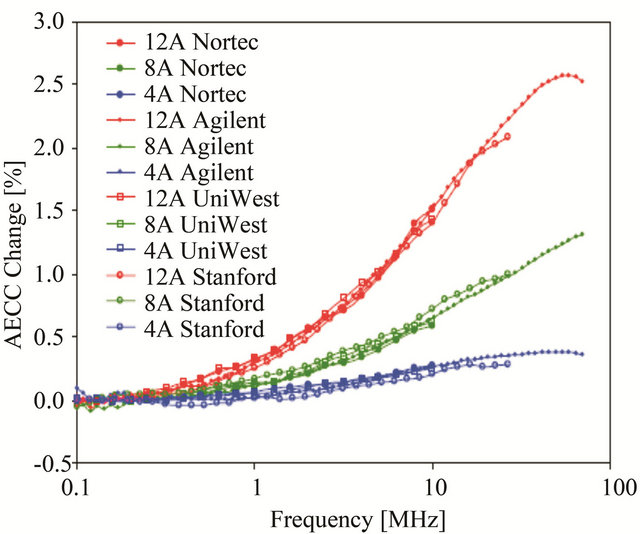

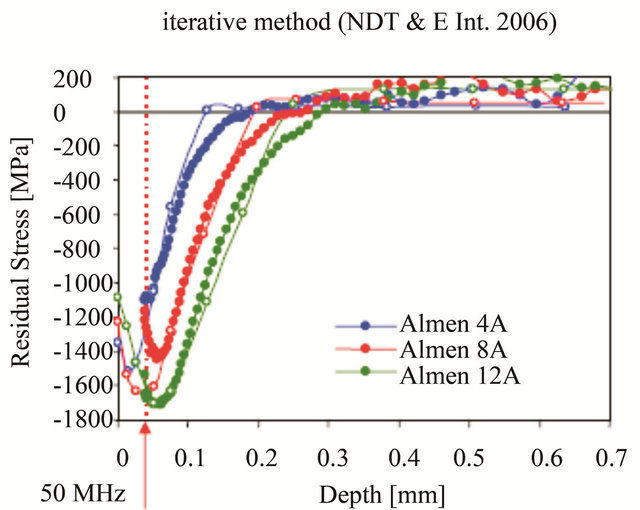

changes with depth resolution. The problem is central to space and aviation industry, where almost all the bearing components are subjected to surface hardening. Figure 3 shows an example of the imaginary part of the surface conductivity spectra variation (Apparent Eddy Current Conductivity, AECC) for samples of Inconel. As can be seen in a wide frequency range spectral characteristics vary by only 2.5%. Therefore, a high-precision measurement of conductivity in the monitoring process is necessary. Figure 4 shows the results of the reconstruction of LbL function of stress distribution obtained by inverting AECC spectra with the simplified and iterative methods, respectively.

The need to solve the inverse problem (without restriction to a method of solution) for the reconstruction of LbL properties of SL was later independently confirmed and developed in many analysis. The use of methods of data inversion to study the properties of SL has been applied successfully, for example, to magnetic [5,6], eddy current [7], and ultrasonic [8] methods. The list can be repeatedly extended. One of the most impressive application of inverse problems described in Several papers by G. Sabbah to reconstruct the multilayer coating properties of shuttles thermal protection [7] (Figure 5) by eddy current method. Left shows the compositions of layers,

Figure 3. Apparent Eddy Current Conductivity (AECC) spectra in the INCONEL after surface plastic deformation treatment of the specimens with different Almen indexes, manufactured in different USA laboratories [4].

(a)

(a) (b)

(b)

Figure 4. Reconstruction results of layer-by-layer stress distribution in the Inconel IN718 specimens with different Almen indexes, manufactured in different USA laboratories [4]. Reconstruction left-by simplified method, right-by iterative technique. Dotted lines-direct stress measurement results.

and on the right shows the results of the reconstruction of their thickness. Stratified analysis is as well implemented in the framework of the thermal, X-ray and microwave methods.

1.2. Magnetic Meander Magnetometers

The meander Magnetic Winding Magnetometers

(MWMTM) created first in Massachusetts Institute of Technology (MIT, USA) and then elaborated by Jentek Sensors Inc., are flexible film eddy current sensors for investigation the properties of conductive materials SL [9-11]. The uniqueness of the new technology is also in the use of so-called grid diagrams, actually the type of tetra-parameter hodograph chart, enabling to invert the measured amplitude and phase of the electromagnetic impedance values in to electric conductivity and magnetic permeability (Figure 6). Used up to temperatures 120˚C, MWM sensors are manufactured on a thin flexible substrate, making them adaptable to almost any surface. Intelligence surface depth depends on the excitation frequency and varies in the range from a part of a micron to a few parts of a millimeter. Sensors produced by planar technology, provide excellent reproducibility and resolution. MWM sensors and MWM-matrix are calibrated in air, they can be used as a high-precision measuring instruments of the absolute conductivity values. The equipment allows for a parallel interrogation of all the inputs, avoiding multiplexing and many times speeding up the measurement process as well as allowing the color imaging of the measured conductivity at large surfaces within a time close to real. Technology developerthe company JENTEK Sensors Inc., activated large number of applications to Non-Destructive Evaluation and diagnosis of the SL.

Figure 7 shows the distribution of the normalized permeability at the surface of the low-alloy steel plate in the process of tensile strain to failure. Images were obtained [12] by MWM matrix at 1 MHz (a) and (b), and 158 kHz—(c) and (d). Orientation of the coils with respect to the sample loading direction is shown on the right. Similar images have been obtained for electric conductivity distribution at different frequencies for other types of SL in conductive materials.