The Effect of Using Nano ZrO on the Properties of W-ZrC Composite Fabricated through Reaction Sintering5

2

asibility of fabricating W/ZrC com-

Table 4 Comparing to prior ZrC-W composites [2] these

values for mechanical properties are acceptable. Anyway

the variances might be because the reaction between

ZrO2 and WC did not go to completion and because of

the effect that the un-reacted components have on the

properties of the composite.

4. Conclusions

In this study the fe

posite through reaction sintering was studied and the

differences of composite made from nano and micron

ZrO2 were investigated. The W/ZrC composite was pro-

duced by mixing WC and ZrO2 powders, gel casting the

mixture to produce a green body and then sintering at

2100˚C. The XRD patterns and SEM images indicate that

W/ZrC composite has been fabricated successfully by

this method, although some extra compounds have been

formed. Moreover the XRD pattern of nano sample

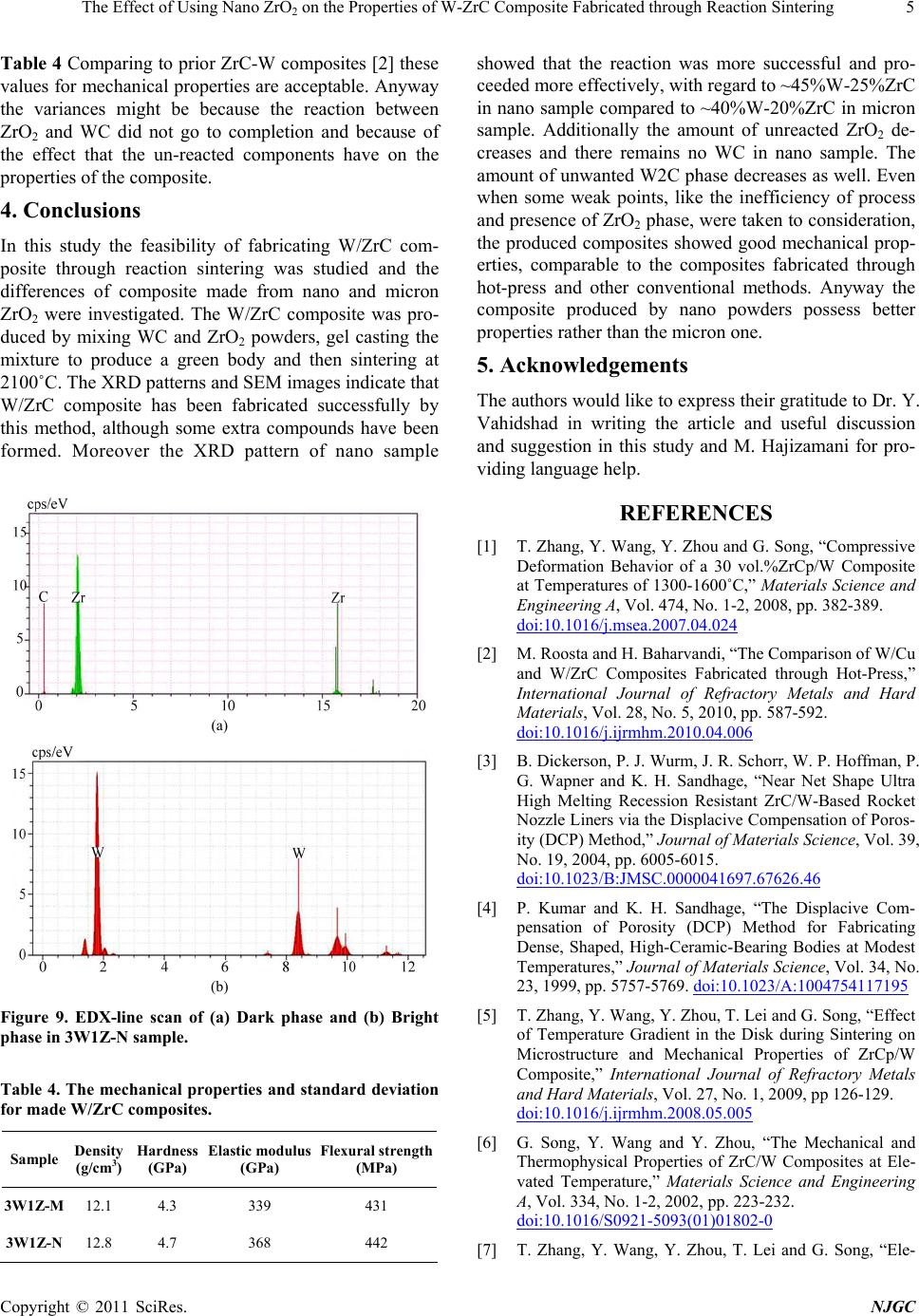

(a)

(b)

Figure 9. EDX-line scan of (a) Dark phase and (b) Bright

phase in 3W1Z-N sample.

ties and standard deviation

r made W/ZrC composites.

(g/cm ) (GPa)

astic modulus

(GPa)

Flexural strength

(MPa)

Table 4. The mechanical proper

fo

Sample Density

3Hardness El

3W1Z-M 12.1 4.3 339 431

showed th rean was m successfu pro-

ceeded more effectively, with rega45%WrC

acomd to ~4-20%ZrC in micron

useful discussion

and M. Hajizamani for pro-

, Y. Zhou and G. Song, “Compressive

Deformation Behavior of a 30 vol.%ZrCp/W Composite

at Temperaturterials Science and

Engineering A, , pp. 382-389.

at thectioore

rd to ~

l and

-25%Z

in nano smple pare0%W

sample. Additionally the amount of unreacted ZrO2 de-

creases and there remains no WC in nano sample. The

amount of unwanted W2C phase decreases as well. Even

when some weak points, like the inefficiency of process

and presence of ZrO2 phase, were taken to consideration,

the produced composites showed good mechanical prop-

erties, comparable to the composites fabricated through

hot-press and other conventional methods. Anyway the

composite produced by nano powders possess better

properties rather than the micron one.

5. Acknowledgements

The authors would like to express their gratitude to Dr. Y.

d Vahidshad in writing the article an

and suggestion in this study

viding language help.

REFERENCES

[1] T. Zhang, Y. Wang

es of 1300-1600˚C,” Ma

Vol. 474, No. 1-2, 2008

doi:10.1016/j.msea.2007.04.024

[2] M. Roosta and H. Baharvandi, “The Comparison of W/Cu

and W/ZrC Composites Fabricated through Hot-Press,”

International Journal of Refractory Metals and H

Materials, Vol. 28, No. 5, 2010, pp. 587-592

ard

.

doi:10.1016/j.ijrmhm.2010.04.006

[3] B. Dickerson, P. J. Wurm, J. R. Schorr, W. P. Hoffman, P.

G. Wapner and K. H. Sandhage, “Near Net Shape Ultra

High Melting Recession Resistant ZrC/W-Ba

Nozzle Liners via the Displacive Co

sed Rocket

mpensation of Poros-

ity (DCP) Method,” Journal of Materials Science, Vol. 39,

No. 19, 2004, pp. 6005-6015.

doi:10.1023/B:JMSC.0000041697.67626.46

[4] P. Kumar and K. H. Sandhage, “The Displacive Com-

pensation of Porosity (DCP) Method for Fabricating

Dense, Shaped, High-Ceramic-Bearing Bodies

Temperatures,” Journal of Materials Science, V

at Modest

ol. 34, No.

23, 1999, pp. 5757-5769. doi:10.1023/A:1004754117195

[5] T. Zhang, Y. Wang, Y. Zhou, T. Lei and G. Song, “Effect

of Temperature Gradient in the Disk during Sintering on

Microstructure and Mechanical Properties of ZrCp/W

Composite,” International Journal of Refractory Metals

and Hard Materials, Vol. 27, No. 1, 2009, pp 126-129.

doi:10.1016/j.ijrmhm.2008.05.005

[6] G. Song, Y. Wang and Y. Zhou, “The Mechanical and

Thermophysical Properties of ZrC/W Composites at Ele-

vated Temperature,” Materials Science and Engineering

A, Vol. 334, No. 1-2, 2002, pp. 223-232.

doi:10.1016/S0921-5093(01)01802-0

[7] T. Zhang, Y. Wang, Y. Zhou, T. Lei and G. Song, “Ele-

3W1Z-N 12.8 4.7 368 442

Copyright © 2011 SciRes. NJGC