Fatigue Crack Growth on Double Butt Weld with Toe Crack of Pipelines Steel

Copyright © 2012 SciRes. MSA

599

0

2

4

6

8

10

020000 4000060000 80000100000

N ( number of Cycles )

Crack length (m m)

API 5L X60

API 5L X70

[8] T. N. Nguyen and M. A. Wahab, “The Effect of Weld

Geometry and Residual Stresses on the Fatigue of Welded

Joints under Combined Loading,” Journal of Materials

Processing Technology, Vol. 77, No. 1-3, 1998, pp. 201-

208.

[9] J. A. M. Ferreira and C. M. Branco, “Influence of Weld

and Plate Geometry on the Fatigue Strength of Cruciform

Joints,” Theoretical and Applied Fracture Mechanics,

Vol. 9, No. 1, 1988, pp. 23-32.

doi:10.1016/0167-8442(88)90044-4

[10] S. J. Maddox, Met. Construct., Vol. 2, No. 8, 1970, pp.

327-335.

[11] J. A. M. Ferreira and C. M. Branco, “Influence of the

Radius of Curvature at the Weld Toe in the Fatigue

Strength of Fillet Welded Joints,” International Journal

of Fatigue, Vol. 11, No. 1, 1989, pp. 29-36.

doi:10.1016/0142-1123(89)90044-3

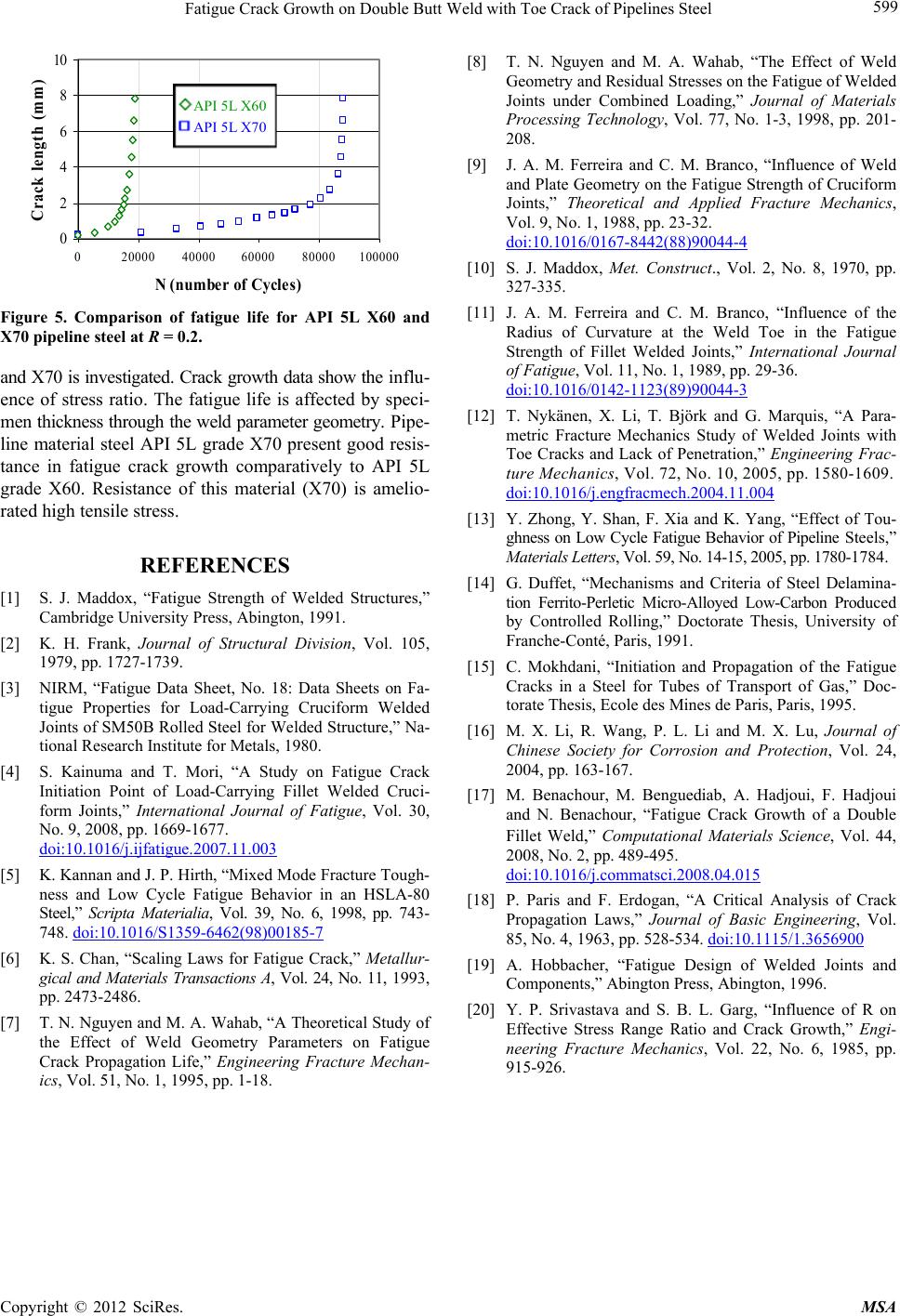

Figure 5. Comparison of fatigue life for API 5L X60 and

X70 pipeline steel at R = 0.2.

and X70 is investigated. Crack growth data show the influ-

ence of stress ratio. The fatigue life is affected by speci-

men thickness through the weld parameter geometry. Pipe-

line material steel API 5L grade X70 present good resis-

tance in fatigue crack growth comparatively to API 5L

grade X60. Resistance of this material (X70) is amelio-

rated high tensile stress.

[12] T. Nykänen, X. Li, T. Björk and G. Marquis, “A Para-

metric Fracture Mechanics Study of Welded Joints with

Toe Cracks and Lack of Penetration,” Engineering Frac-

ture Mechanics, Vol. 72, No. 10, 2005, pp. 1580-1609.

doi:10.1016/j.engfracmech.2004.11.004

[13] Y. Zhong, Y. Shan, F. Xia and K. Yang, “Effect of Tou-

ghness on Low Cycle Fatigue Behavior of Pipeline Steels,”

Materials Letters, Vol. 59, No. 14-15, 2005, pp. 1780-1784.

REFERENCES [14] G. Duffet, “Mechanisms and Criteria of Steel Delamina-

tion Ferrito-Perletic Micro-Alloyed Low-Carbon Produced

by Controlled Rolling,” Doctorate Thesis, University of

Franche-Conté, Paris, 1991.

[1] S. J. Maddox, “Fatigue Strength of Welded Structures,”

Cambridge University Press, Abington, 1991.

[2] K. H. Frank, Journal of Structural Division, Vol. 105,

1979, pp. 1727-1739. [15] C. Mokhdani, “Initiation and Propagation of the Fatigue

Cracks in a Steel for Tubes of Transport of Gas,” Doc-

torate Thesis, Ecole des Mines de Paris, Paris, 1995.

[3] NIRM, “Fatigue Data Sheet, No. 18: Data Sheets on Fa-

tigue Properties for Load-Carrying Cruciform Welded

Joints of SM50B Rolled Steel for Welded Structure,” Na-

tional Research Institute for Metals, 1980. [16] M

. X. Li, R. Wang, P. L. Li and M. X. Lu, Journal of

Chinese Society for Corrosion and Protection, Vol. 24,

2004, pp. 163-167.

[4] S. Kainuma and T. Mori, “A Study on Fatigue Crack

Initiation Point of Load-Carrying Fillet Welded Cruci-

form Joints,” International Journal of Fatigue, Vol. 30,

No. 9, 2008, pp. 1669-1677.

doi:10.1016/j.ijfatigue.2007.11.003

[17] M. Benachour, M. Benguediab, A. Hadjoui, F. Hadjoui

and N. Benachour, “Fatigue Crack Growth of a Double

Fillet Weld,” Computational Materials Science, Vol. 44,

2008, No. 2, pp. 489-495.

doi:10.1016/j.commatsci.2008.04.015

[5] K. Kannan and J. P. Hirth, “Mixed Mode Fracture Tough-

ness and Low Cycle Fatigue Behavior in an HSLA-80

Steel,” Scripta Materialia, Vol. 39, No. 6, 1998, pp. 743-

748. doi:10.1016/S1359-6462(98)00185-7

[18] P. Paris and F. Erdogan, “A Critical Analysis of Crack

Propagation Laws,” Journal of Basic Engineering, Vol.

85, No. 4, 1963, pp. 528-534. doi:10.1115/1.3656900

[6] K. S. Chan, “Scaling Laws for Fatigue Crack,” Metallur-

gical and Materials Transactions A, Vol. 24, No. 11, 1993,

pp. 2473-2486.

[19] A. Hobbacher, “Fatigue Design of Welded Joints and

Components,” Abington Press, Abington, 1996.

[20] Y. P. Srivastava and S. B. L. Garg, “Influence of R on

Effective Stress Range Ratio and Crack Growth,” Engi-

neering Fracture Mechanics, Vol. 22, No. 6, 1985, pp.

915-926.

[7] T. N. Nguyen and M. A. Wahab, “A Theoretical Study of

the Effect of Weld Geometry Parameters on Fatigue

Crack Propagation Life,” Engineering Fracture Mechan-

ics, Vol. 51, No. 1, 1995, pp. 1-18.