Empirical study of Logistics Outsourcing practices and Firm Productivity of selected Manufacturing Companies in Nigeria ()

1. Introduction

Productivity is of key interest to any organisational manager. The route to achieving high productivity is always challenging both from operational and strategic perspectives. The drive to reduce operational expenses is usually the same for managers because managers across sectors and companies are faced with the same cost concerns which are context based. The concerns arise from poor roads, high cost of vehicle parts to inadequate power supply given the location of factories in Nigeria (Chete, Adeoti, Adeyinka, & Ogundele, 2021). One proposed solution to these problems is to leverage logistics outsourcing which tends to allow manufacturing firms chance to concentrate on their core functions through partnership arrangement with professional in logistic business. Studies confirmed that such effort can reduce cost of production (McCarthy & Anagnostou, 2004; Meixell, Kenyon, & Westfall, 2014; Zailani, Shaharudin, Razm, & Iranmanesh, 2015).

However, inefficient management of logistical activities owned by manufacturing outfits is posing survival issue to organisation which often cumbers managers with less time to deliver their core function of producing quality goods that meet needs of the market. Customers can no longer cope with rising cost of living due to inflation and depletion in their disposable income. Availability of cheaper products from foreign competitors is placing local producers under pressure to unbundle activities that are not having direct link with their production of goods hence the need for outsourcing of either inbound or outbound logistics activities. This study was intended to achieve the objective of examining the effect of logistics outsourcing practices on firm productivity. It is hypothesized that

CODE: Logistics (L 11), Outsourcing (L 21) and Productivity (L 23).

H01: Logistics outsourcing does not have significant positive effect on the productivity of manufacturing companies in Nigeria.

2. Literature Review

2.1. Conceptual Review

The concept of logistics always attracts attention from both industry and academia. Thomopoulos (2016) established that logistics involves the flow of items from the point of origin to the final destination to satisfy the needs of customers. It adds value to the production process but it comes at costs to customers in terms of high product cost and time constraint for managers during product delivery where it is not well managed. Expectation of Council of Logistics Management Professionals (2003) further lends credence to the fact that logistics is the function that can facilitate organisation’s response to client requirements.

Vallespir and Kleinhans (2001) recognised the strategic decision need to outsource logistics given its relevance to organisations at either short or long term effect in the areas of operating cost reduction and conservation of scarce resources towards delivering values. Ugwu & Okoroji’s (2014) description of outsourcing is when a company, X, hands over a portion of their business operations to another firm, Y, to perform services that could otherwise be performed internally. In the light of this, Company X is not burdened with cost of performing these tasks and can concentrate their main activities. It is revealed in literature that outsourcing logistics can benefit organisations in number of ways among which are cost saving both in capital and operational expenditures, specialization on its main and core tasks and compete more effectively in the market (Opiyo, 2000).

Transportation management involves haulage and distribution of both raw materials and finished good at inbound or outbound service points up to reverse logistics for containers account-related operations or waste drive to incinerate or destroy expired commodities in Health Supply chain. This is a major and important element of logistics outsourcing because it has to occur somehow in the value chain of logistics landscape. It could be on a long distance called haulage or short distance called distribution. Optimization of payload, route optimization and various improvement techniques like trackers, play key role in terms of cost management and process efficiency.

Heung and Gyu (2006) asserted that warehousing accounts for between 2% and 5% of total sales costs, so it must be handled correctly through outsourcing. It consists of provision of storage facilities, inventory control and ancillary services such as invoicing to customers, cash management, routine stock count, stock aging analysis and documentation. Managers in manufacturing outfits can sacrifice the activity to third party organisation to engender efficient and effective utilisation of their managerial time and effort in the production of goods. Apart from that, Material handling equipment involves the provision and use of machines such as forklift, pallets, racks which help in space optimization and speed of delivery through mechanical advantage. It could also be accessed for operational use through outsourcing without having to procure them directly by an organization. The equipment has capacity to reduce human interface in the course of handling materials either inbound or outbound level for finished goods and raw materials.

Petroni & Braglia (2000) subscribed that high incidence of capital outlay to acquire business premises for operational activities could be averted through outsourcing of facilities. Organizations that subscribe to the idea of either operating alone in a leased facility or co-locate with other companies and agree on lease rental cost not treated as balance sheet item to be capitalized and amortized over a period time, but a charge against the company’s profit and loss. This promotes a heathier balance sheet as facilities are not capitalised.

Poluha (2016) defined productivity as the comparison of input and output variables especially, the output quantity in relation to factor input quantity. It is also a measure of effectiveness and efficiency. The measurement of logistics and supply chain costs often represents a region which greatly interests business executives—after all, it often conceals the potential to save on costs. However, it is important to leverage outsourcing logistics to increase firm productivity.

2.2. Theoretical Review

The study was hinged on the transaction cost economics (TCE) by Williamson (1993). He gave a useful direction on the best approach to either be responsible directly for certain jobs within an organisation or seek external inputs from the experts to get the job done. The proponents of the theory advocate that, leveraging on TCE can help an organisation in evaluating the relative distinction and potential benefits between external charge-out cost and “internal production costs. In this way, the choices of outsourcing using TCE as a basis would be based on professional competence of the providers. However, caution was raised by Williamson (1993) which he termed opportunism”, where he pointed out a negative attribute which manifests in a monopolistic situation in which the supplier might seek to take advantage of the client. In this regard, ultimate solution is for the business operatives to closely monitor market trends and pricing dynamics, for occasional renegotiation.

2.3. Empirical Review

Previous empirical studies were reviewed where several observations were noted to further show credence to the relevance of productivity on the need to outsource logistics. Somuyiwa, Odepidan and Dosunmu (2016) investigated the numerous operations that manufacturing firms outsourced in order to satisfy customer demand and satisfaction in Nigeria. According to their research, transportation operations are critical in maintaining high customer satisfaction and repeat purchases. This is due to the relative benefits of lower freight charges, less inventory in transit, and improved production planning due to greater transportation visibility. It was also discovered that companies that engaged in the production of goods or services outsource peripheral or ancillary services at various levels of their operations, with haulage or redistribution of their goods being the most outsourced, indicating that transportation is a critical component of manufacturing firms’ operations since it is required throughout the entire process.

Musau (2016), a case study of Bidco Africa Limited, Kenya, and the study found that cost-driven outsourcing enhances short-term and long-term performance by reducing costs and risks and boosting operational efficiency. Furthermore, the report revealed that innovation-oriented outsourcing enables firms to create, develop and offer value to their consumers faster than their competitors. However, the success of innovation-led outsourcing has depended significantly on cost management and core competence concentration, and should thus be thoroughly examined. Finally, the research showed that focused outsourced services allow a company to free up resources so that its core business may be focused and therefore lead to increased corporate performance.

Companies that export to a medium-sized company may face greater logistics costs than other companies. To validate this conclusion, more investigation would be necessary. Outsourcing does not influence the logistical performance negatively or positively. The more outsourcers, the more in-house and outside, and vice versa they watch and run carefully. The findings demonstrate in a nutshell that management should not assume inevitable benefits from logistical externalisation, but rather look at the company-specific features that support or, under certain situations, prevent the decision of externalisation.

In Lin, Pekkarinen and Ma (2015), description analyses were carried out to examine the consequences of logistics outsourcing for the company's performance in Finland. In order to check the data validity, field visits and secondary documentation were used. It was found that three degrees of interface interaction are the design interface between goods and logistics, the interface between manufacturing and service providing companies and the information connection of manufacturing information systems and logistic systems. The conclusions implied that these interfaces may be created and maintained utilising eleven fundamental S-D logic premises, in particular service-oriented, customer-oriented and streamlined perspectives. In order to study logistical outsourcing and performance in Malaysia, Zailani, Shaharudin, Razm and Iranmanesh (2015) employed primary data from the structured questionnaire, analysed using the regression techniques.

There has been a lack of knowledge in human and physical assets as well as transaction uncertainty in the implementation of different outsourced logistics methods. The four logistics outsourcing strategies investigated in the study, especially the strategic emphasis, have a positive influence on the outsourcing of logistics performance. Although companies may think that the implementation of a logistics outsourcing strategy will save costs, this study shows that this is not the case since one of the four logistic outsourcing strategies evaluated has only contributed favourably to the financial benefit.

Using the data from 2004-2007, Westfall et al. (2014) investigated outsourcing in the USA. The data were obtained from the US production plant MPI census of manufacturer’s survey and used in cross- and longitudinal studies. Research shows that production outsourcing tends to shift costs across cost categories for sold products (COGS) but does not consistently lower COGS overall. Bali (2013) highlighted the job of third-party logistics (3PL) providers and its quantifiable advantages in his research work. In the study, the accomplishments of 3PL providers influence operations manager to dispassionately evaluate different suppliers’ quotations through data analysis and proper reference checks with a view to prequalifying the ideal providers.

Bajec (2013) carried out a study amongst Slovenian logistics suppliers and discovered that they were not developed enough for progressively keen methods of complex logistics solutions. Yet, he proposed a more scientific and transparent logistics outsourcing solutions that relief’s manufacturer from the pains of insourcing. He also acknowledged that what truly affect logistics outsourcing most times, is quality of logistics partners to engage and the use of technological innovations that would ease the process of achieving deliverables in logistics outsourcing.

Rahman’s (2011) research was also carried out from an Australian viewpoint on outsourcing of 3PL services. This study is based on an Australian questionnaire survey. The sample was selected from the 500 biggest Australian companies, according to Dun and Bradstreet. A total of 210 firms were found for this study after banks and other financial institutions, insurance companies and real estate enterprises were removed from the list. Statistics suggest that warehouse management, order fulfilment and fleet management are the most often used logistics services. The top three reasons why companies outsource are cost reductions, lower investment in capital and more operational flexibility. 3PL service providers are highly satisfied with 86 percent of these services saying that they will continue to utilise them in the future. On the other side, employee morality in 50% of 3PL customers was negatively affected.

Hilletofth and Hilmola’s (2010) study focused on standard logistics processes, supply chain strategy and management. They examined the influence on supply chain management and strategy of logistics outsourcing. The research has used and analysed primary data utilising the method of regression analysis. As far as the results are concerned, outsourcing of storage, IT and customs offices will have an influence on a number of supply chains’ management and strategy (SC). Consequently, no statistically significant of the differences identified were detected. Integrated IT production and logistics systems, reverse logistics approaches and reengineering logistics operations might affect supply chain strategy and management. In-house IT services and perhaps outsourced storage, according to research, play an important role in purchases outside the country.

3. Conceptual Framework

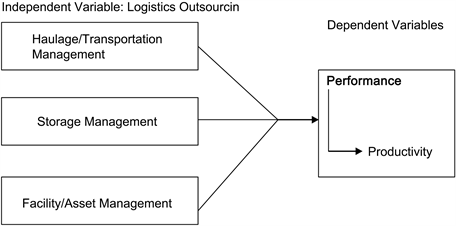

The conceptual framework adopted for this study was conceived after thorough reviews of both theoretical and empirical studies have been examined. It was established that outsourced logistics could help organisations reduced cost and meet customers’ demand more efficiently. In the light of this, more empirical evidence will provide clearer perspective to the benefits of logistical outsourcing to manufacturing firms and also foster 3PLs the opportunity to underscore their role in the value chain management.

Conceptual Framework:

Source: Authors’ conceptualisation, 2021.

4. Methods

The study used cross-sectional research design. The population consisted of 620 senior managers, middle level officers and supervisors who have direct knowledge of the four (4) fast moving consumer goods companies operations. These companies are: Nigerian Bottling Company (NBC) Ltd, a bottling partner of Coca-Cola Company, Friesland Campina WAMCO Nigeria Plc, thirdly, CHI Ltd, and lastly, Rite foods Ltd. The distribution of these staff is depicted respectively: 260, 144, 119 and 97. Proportional stratified sampling technique was used to select both the participating companies and the respondents.

The study adopted proportional stratified sampling technique to select both the participating companies and the respondents. The sample size of the participants was determined using Taro Yamane formula since the study has a definite population which is more appropriate when little or no information is known about population behaviour. Yamane formula is presented below:

where:

n = Sample size required N = Population size e = level of precision (0.05)

Yamane formula gave 243 respondents; however, the sample size was increased to 260 respondents to compensate for the non-response rate which is common with survey studies. NBC shared 101 respondents, 56 for WAMCO, 48 for CHI and the remaining 38 was for Rite. Primary data were sourced through designed questionnaire. The questionnaire was used to gather data from the respondents who were mainly staff with logistics and supply chain departments of the four companies, including managers and supervisors.

The questionnaire has two components (Sections A and B). Section A comprises biodata of the respondents such as age, gender, etc. Section B captured data on the effect of logistics outsourcing on productivity of the selected manufacturing companies in Southwestern Nigeria. Five-point rating scale was used for Sections B. The instrument was validated through experts and seasoned managers in logistics and supply chain operations of some manufacturing outfits in Lagos State. Reliability of the instrument was obtained using pilot test which considered 10% of the total copies of the questionnaire. The Cronbach alpha (α) of the constructs is stated thus: 5 items of transportation management, Storage Management, and Facility/Asset Management with α = 0.821, 0.874 and 0.936 respectively. The dependent variable (Productivity) with 4 items has α = 0.873. These statistics confirmed the reliability of the instrument since all of them satisfied the 0.6 threshold.

The model specification for the study to regress the effect of the independent variables on the dependent variable is stated thus:

(1)

where:

PROi = Productivity.

TRM = Transportation/haulage management.

STM = Storage Management.

FM = Facility/Asset Management.

β0 = constant and β1- β3 = slopes which is the coefficients of each variable while ε = Error term.

Apriori expectation is that a negative relationship is expected between the variables.

5. Results

Bio-data Descriptions of the Respondents

Table 1 presented the bio-data description of the respondents based on their demographic characteristics. The demographic variables considered were gender, age, educational qualification, years of experience and position. The analysis showed that majority of the respondents were male (81.9%) while female was (18.1%). This concluded that more male responded to the questionnaire than female, also considering the fact that the questionnaire was administered to those in managerial positions; this established that males were much more than female in the managerial cadre in manufacturing companies. With regards to the age group, majority of the respondents were within a very active and productive age; those between the age of 41 and 50 years were 48.8%, 31 - 40 years were 27.7%, 51 - 60 are 19.2% while 20 - 30 years were 4.2%. This concluded that all the respondents were mature and able to give sound ethical judgement and standards with reference to answering the research questions.

The highest educational qualification of majority of the participants was master’s degree (76.9%), followed by HND/B.Sc. (21.2%) and (1.9%) had Ph.D. Thus, all the respondents were well educated and therefore understood the contents, construct and importance of supplying honest answers to the research question which further justified the validity and reliability of the gathered data. Regarding the respondent’s years of service experience majority had over 16 years of experience (44.6%), followed by 11 - 15 years (26.2%), 6 - 10 years (25%) and 1 - 5 years with (4.2%) years of experience. Also, 56.5%, 33.5%, and 10%, upper management cadre, middle management cadre, and lower management cadre respectively. This further strengthened the reliability and validity of the data gathered because all the respondents appeared to be responsible individuals with reasonable years of service experiences; who were expected to have a clear knowledge of the research questions. (Table 1)

Effectiveness of Logistics Outsourcing Practices on Productivity of Manufacturing Companies

Table 2 reveals the effectiveness of logistics outsourcing practices among manufacturing companies in Southwestern Nigeria. The practices were summarized into three sub class, these are; the transportation management practices, storage management practices and the facility/asset management practices. On the transportation management practices, (49.6%) and (29.2%) agreed and strongly agreed respectively that the third-party transportation contracting saved cost. Likewise, the on-time and in-full deliveries has improved tremendously as attested by (47.3%) and (33.5%) who agreed and strongly agreed respectively. This was also true about stock shortage and road accidents where (27.3%) and (34.2%) agreed and strongly agreed respectively that stock shortage and road accidents have reduced. Also, as agreed by (84.7%), vehicle scheduling and availability has improved. Finally, (80.8%) agreed that the customer service index has improved. Thus, the overall transportation management practices among manufacturing companies in Nigeria has been very effective (

= 4.00).

![]()

Table 1. Bio-data description of the respondents.

Source: Field survey, 2021.

![]()

Table 2. Effectiveness of logistics outsourcing among the manufacturing companies.

Source: Field survey, 2021.

With regard to storage management, proper storage has led to less damage to materials/stock as attested by (70.8%) majority of the respondents. The study also established (82.7%) that good housekeeping practices have been achieved. Also, warehouse business loss has reduced (78.5%). In the same direction, the study also established that warehousing has reduced cost (76.5%) and wastages (93.13%). Therefore, with logistics outsourcing, effective storage management practices have been achieved (

= 4.11).

Finally, with regard to facility/asset management, proper equipment handling enhanced its lifespan (94.4%). There has been easy monitoring of stock movement (93.7%). Availability of material handling equipment reduced in-depot/in-plant congestions (88.5%). Good facility management enhanced good service delivery (96.1%), and proper management of equipment improved production (96.2%). Also, effective management of facilities/assets by third party has been very effective (

= 4.39) to manufacturing companies in Nigeria.

In addition, the grand mean value (4.08) depicts an overall perceived high effectiveness in the logistics outsourcing practices in terms of transportation management, storage management, and facility/asset management. By implication, these practices were found to be, generally, very effective in the selected manufacturing companies in the Southwestern Nigeria. The grand mean value further emphasises that outsourcing logistics occupies a critical position in the engendering high productivity in the manufacturing organisations. Importantly, proper equipment management requires more attention since analysis in Table 2 depicts that such effort will lead to improved production compared to other practices.

Effect of Efficiency of Logistics Outsourcing Practices on Productivity of Manufacturing Companies

Multicollinearity Test

The study checked for multicollinearity among the independent variables as one of the assumptions of classical linear regression.

Table 3 shows the effect of logistics outsourcing practices on productivity and was achieved using differing measures of the constructs using both multiple regression using variance covariance estimate of the standard error of the coefficients of the variables which is robust to serial correlation and potential residual misnomer (model 1) and ordered generalized linear models (models 2 - 7) as displayed in Table 4. Preliminary analysis adopted sum score approach which was used to extract each measure of productivity from the group of items explaining them. In essence, the average scores of the responses from each group of items measuring each performance proxies.

![]()

![]()

Table 3. Showing the correlation matrix.

*Shows significance at the 0.05 level; Source: Authors’ Compilation, 2021.

Source: Authors’ compilation, 2021.

![]()

Table 4. Multiple regression model of logistics outsourcing practices and productivity of manufacturing companies in the southwestern, Nigeria

Robust seeform in parentheses; *p < 0.01, **p < 0.05, ***p < 0.1; Source: Researcher’s Computation, 2021.

The analysis tested the hypothesis of the study which states that “Logistics outsourcing does not have significant positive effect on the productivity of manufacturing companies in Nigeria”. The focused factors were summarized into three main divisions: transportation management (TRM), storage management (STM), and facility/assets management (FM), while the dependent variable was the productivity of manufacturing companies in the Southwestern, Nigeria. It can therefore be noted that the coefficients and the standard errors are not varying. For the purpose of this study, the model will be used to interpret the relationship between the variables.

The results showed that although the independent variables were positively related to productivity, only facility/assets management (FM) was statistically significant to productivity of the manufacturing companies (t = 5.78, p < 0.05). The beta (β) weights of individual variable showed that facility/assets management (FM) has the strongest impact (41.9%) on productivity; followed by storage management (STM) with 15.3% impact, and transportation management (TRM) with the least impact (14.4%) on productivity.

Furthermore, the findings showed that the independent variables put together had significant effect on the productivity of the manufacturing companies (F = 36.72,p < 0.05). Thus, the model fitness was highly reliable as it explained 27.3% variation in the companies’ productivity (see R2). Based on aforementioned results, the Hypothesis One was rejected and concluded that logistics outsourcing practices had significant effect on the productivity of the selected manufacturing companies.

6. Conclusion and Recommendations

It is concluded in the study that manufacturing companies should give more attention to storage facility management practices given that its contribution to organization productivity is high. The study recommended that effort needs to be honed to mitigate the challenges around the transportation management practices. Government should invest more in infrastructure development such as roads construction and maintenance in order to reduce current problems of bad roads and scale up activities on the maintenance of those in deplorable conditions. Apart from that, policy should be developed that will promote industrial storage facilities such that there will be secured and conducive environment for their activities and operations which will engender investment in the area.

7. Contribution to Knowledge

The study contributed to the frontier of knowledge in the area on supply chain management with emphasis in logistic outsourcing. It further confirms that logistics outsourcing can enhance productivity of manufacturing companies in Nigeria. Further studies can consider companies in the telecommunication sector of the economy among others. The findings of the study may not be generalized because of the fact that its study area was only the manufacturing sector of the economy and that it covered four companies in the sector.

8. Limitation of Research

The study focused on determining the effect of Logistics outsourcing on productivity of manufacturing companies in food and beverages in Lagos, Oyo and Ogun states of southwestern states of Nigeria, this limits the scope of researcher, hence, further studies could be explored in other sectors of manufacturing companies.

In addition, manufacturing companies are located in all the states of Nigeria, this can further stimulate research interests with a wider geographical spread in Nigeria.