R. B. XU ET AL.

247

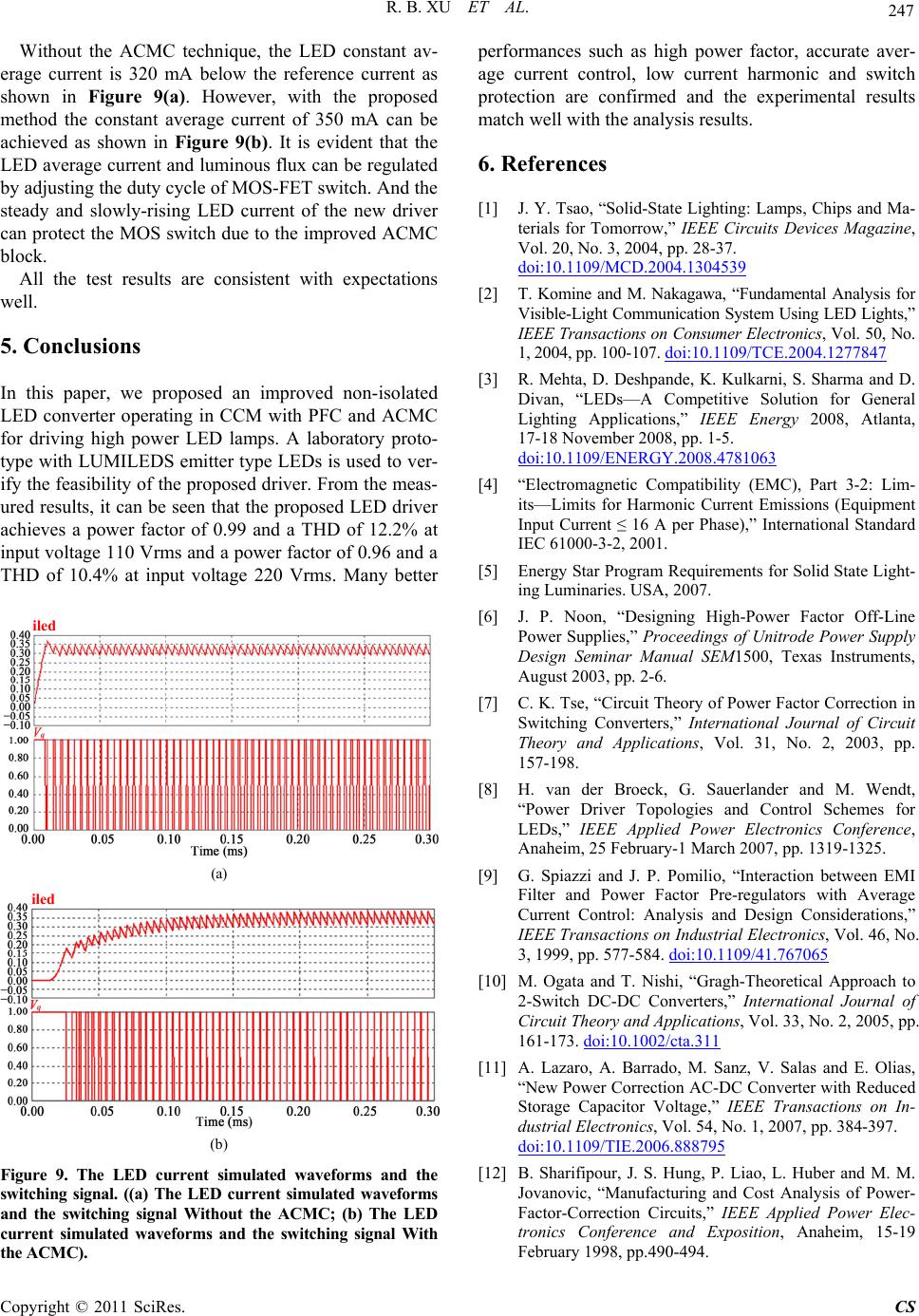

Without the ACMC technique, the LED constant av-

erage current is 320 mA below the reference current as

shown in Figure 9(a). However, with the proposed

method the constant average current of 350 mA can be

achieved as shown in Figure 9(b). It is evident that the

LED average current and luminous flux can be regulated

by adjusting the duty cycle of MOS-FET switch. And the

steady and slowly-rising LED current of the new driver

can protect the MOS switch due to the improved ACMC

block.

All the test results are consistent with expectations

well.

5. Conclusions

In this paper, we proposed an improved non-isolated

LED converter operating in CCM with PFC and ACMC

for driving high power LED lamps. A laboratory proto-

type with LUMILEDS emitter type LEDs is used to ver-

ify the feasibility of the proposed driver. From the meas-

ured results, it can be seen that the proposed LED driver

achieves a power factor of 0.99 and a THD of 12.2% at

input voltage 110 Vrms and a power factor of 0.96 and a

THD of 10.4% at input voltage 220 Vrms. Many better

(a)

(b)

Figure 9. The LED current simulated waveforms and the

switching signal. ((a) The LED current simulated waveforms

and the switching signal Without the ACMC; (b) The LED

current simulated waveforms and the switching signal With

the ACMC).

performances such as high power factor, accurate aver-

age current control, low current harmonic and switch

protection are confirmed and the experimental results

match well with the analysis results.

6. References

[1] J. Y. Tsao, “Solid-State Lighting: Lamps, Chips and Ma-

terials for Tomorrow,” IEEE Circuits Devices Magazine,

Vol. 20, No. 3, 2004, pp. 28-37.

doi:10.1109/MCD.2004.1304539

[2] T. Komine and M. Nakagawa, “Fundamental Analysis for

Visible-Light Communication System Using LED Lights,”

IEEE Transactions on Consumer Electronics, Vol. 50, No.

1, 2004, pp. 100-107. doi:10.1109/TCE.2004.1277847

[3] R. Mehta, D. Deshpande, K. Kulkarni, S. Sharma and D.

Divan, “LEDs—A Competitive Solution for General

Lighting Applications,” IEEE Energy 2008, Atlanta,

17-18 November 2008, pp. 1-5.

doi:10.1109/ENERGY.2008.4781063

[4] “Electromagnetic Compatibility (EMC), Part 3-2: Lim-

its—Limits for Harmonic Current Emissions (Equipment

Input Current ≤ 16 A per Phase),” International Standard

IEC 61000-3-2, 2001.

[5] Energy Star Program Requirements for Solid State Light-

ing Luminaries. USA, 2007.

[6] J. P. Noon, “Designing High-Power Factor Off-Line

Power Supplies,” Proceedings of Unitrode Power Supply

Design Seminar Manual SEM1500, Texas Instruments,

August 2003, pp. 2-6.

iled

[7] C. K. Tse, “Circuit Theory of Power Factor Correction in

Switching Converters,” International Journal of Circuit

Theory and Applications, Vol. 31, No. 2, 2003, pp.

157-198.

[8] H. van der Broeck, G. Sauerlander and M. Wendt,

“Power Driver Topologies and Control Schemes for

LEDs,” IEEE Applied Power Electronics Conference,

Anaheim, 25 February-1 March 2007, pp. 1319-1325.

[9] G. Spiazzi and J. P. Pomilio, “Interaction between EMI

Filter and Power Factor Pre-regulators with Average

Current Control: Analysis and Design Considerations,”

IEEE Transactions on Industrial Electronics, Vol. 46, No.

3, 1999, pp. 577-584. doi:10.1109/41.767065

iled

[10] M. Ogata and T. Nishi, “Gragh-Theoretical Approach to

2-Switch DC-DC Converters,” International Journal of

Circuit Theory and Applications, Vol. 33, No. 2, 2005, pp.

161-173. doi:10.1002/cta.311

[11] A. Lazaro, A. Barrado, M. Sanz, V. Salas and E. Olias,

“New Power Correction AC-DC Converter with Reduced

Storage Capacitor Voltage,” IEEE Transactions on In-

dustrial Electronics, Vol. 54, No. 1, 2007, pp. 384-397.

doi:10.1109/TIE.2006.888795

[12] B. Sharifipour, J. S. Hung, P. Liao, L. Huber and M. M.

Jovanovic, “Manufacturing and Cost Analysis of Power-

Factor-Correction Circuits,” IEEE Applied Power Elec-

tronics Conference and Exposition, Anaheim, 15-19

February 1998, pp.490-494.

Copyright © 2011 SciRes. CS