Paper Menu >>

Journal Menu >>

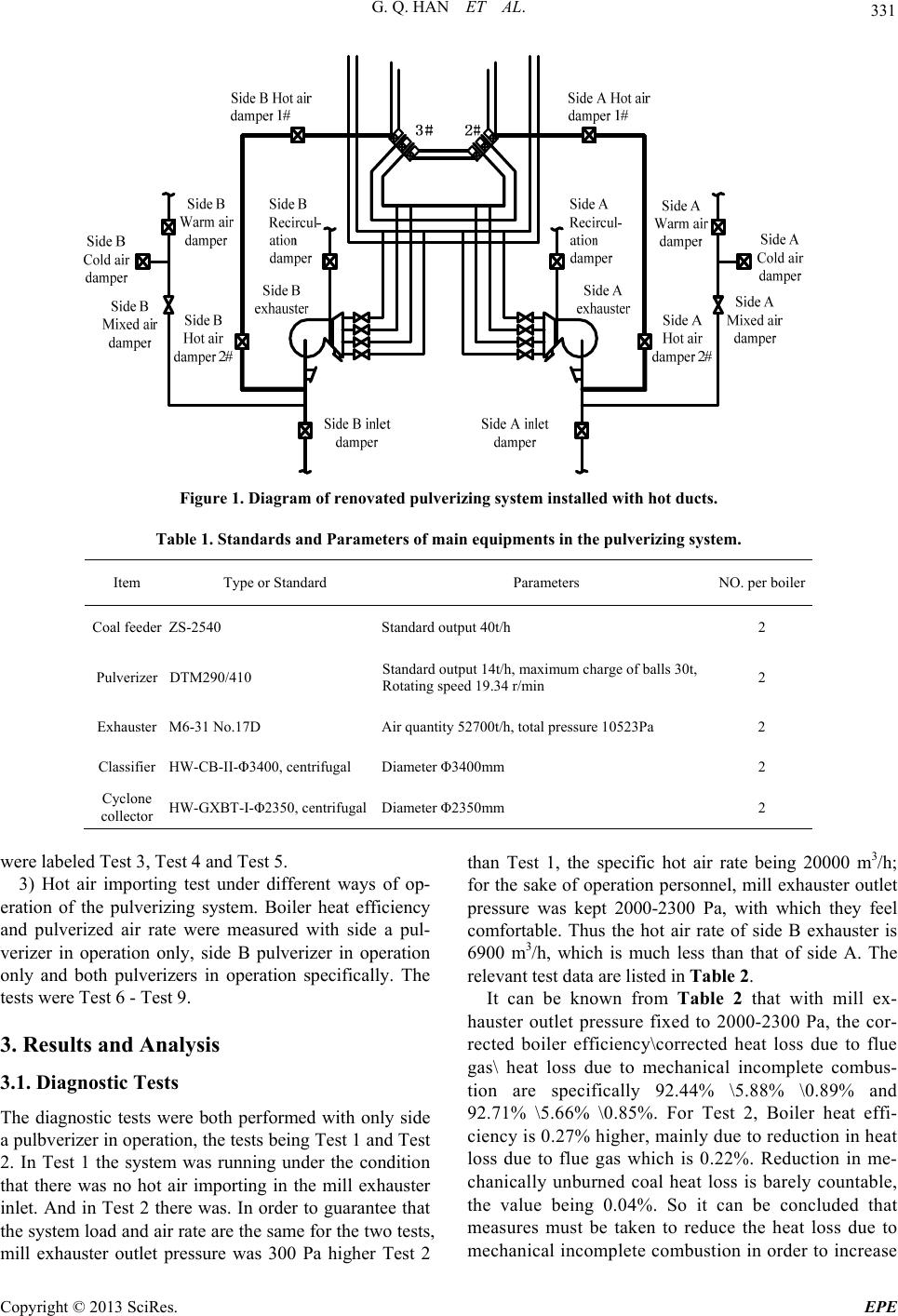

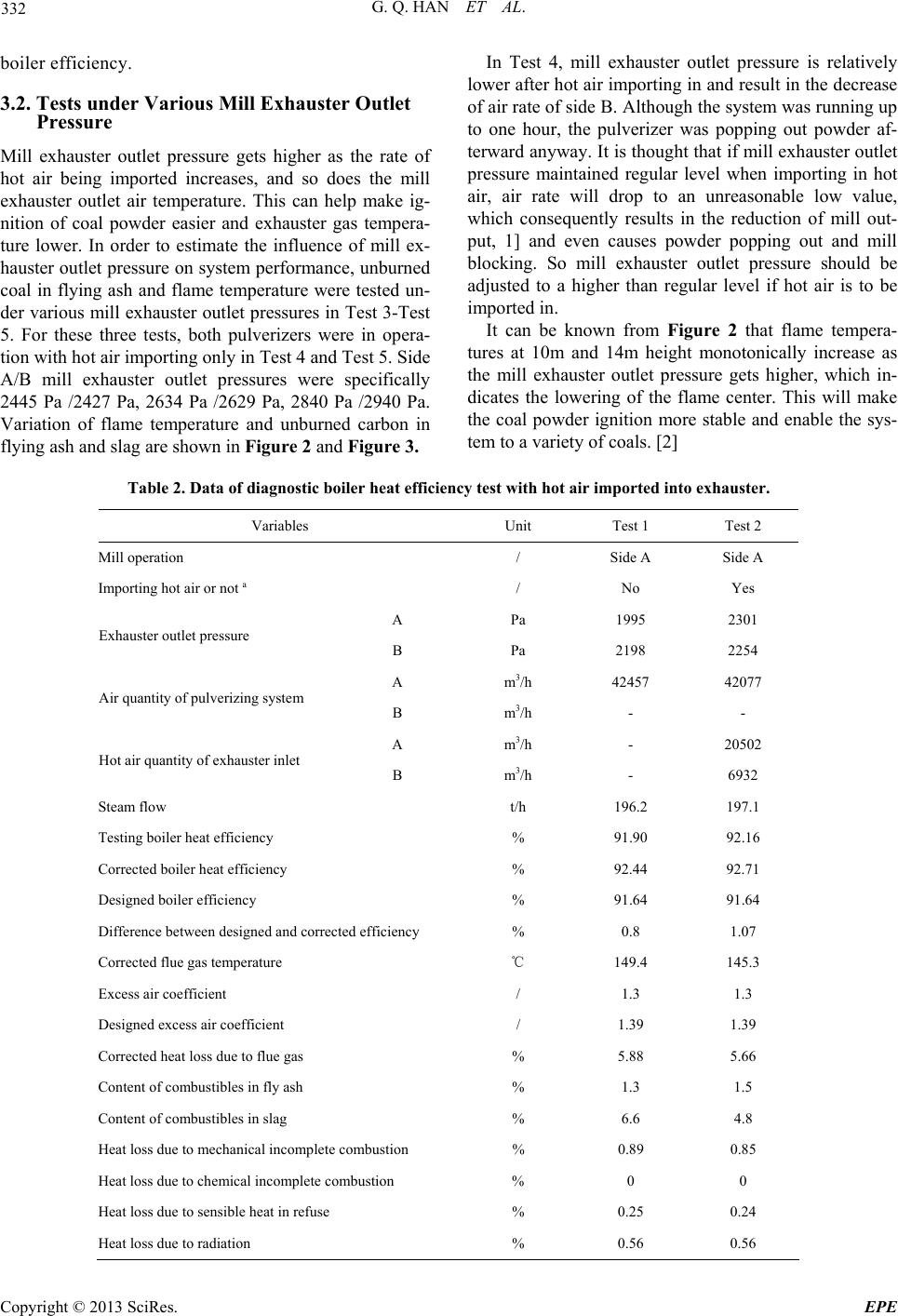

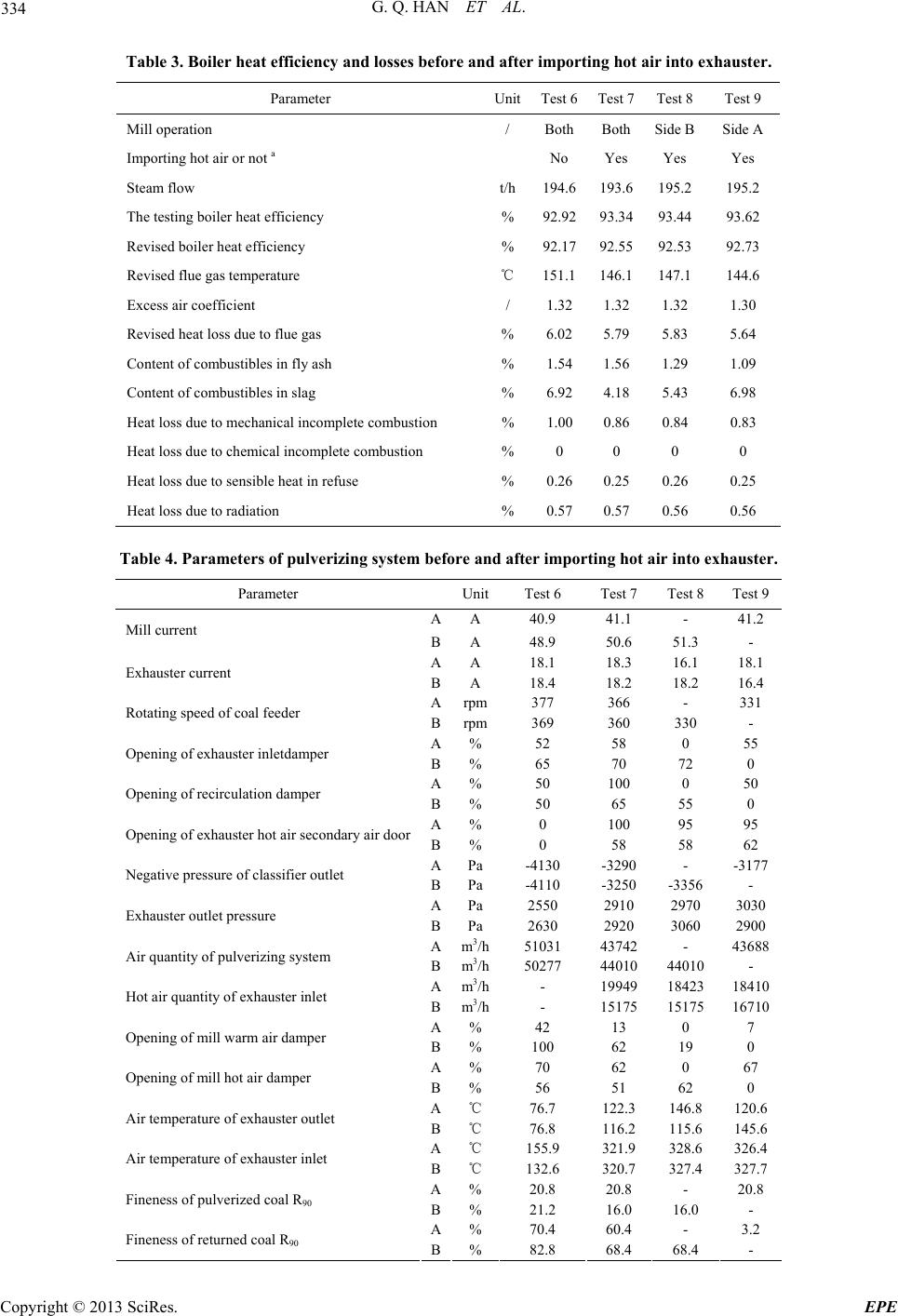

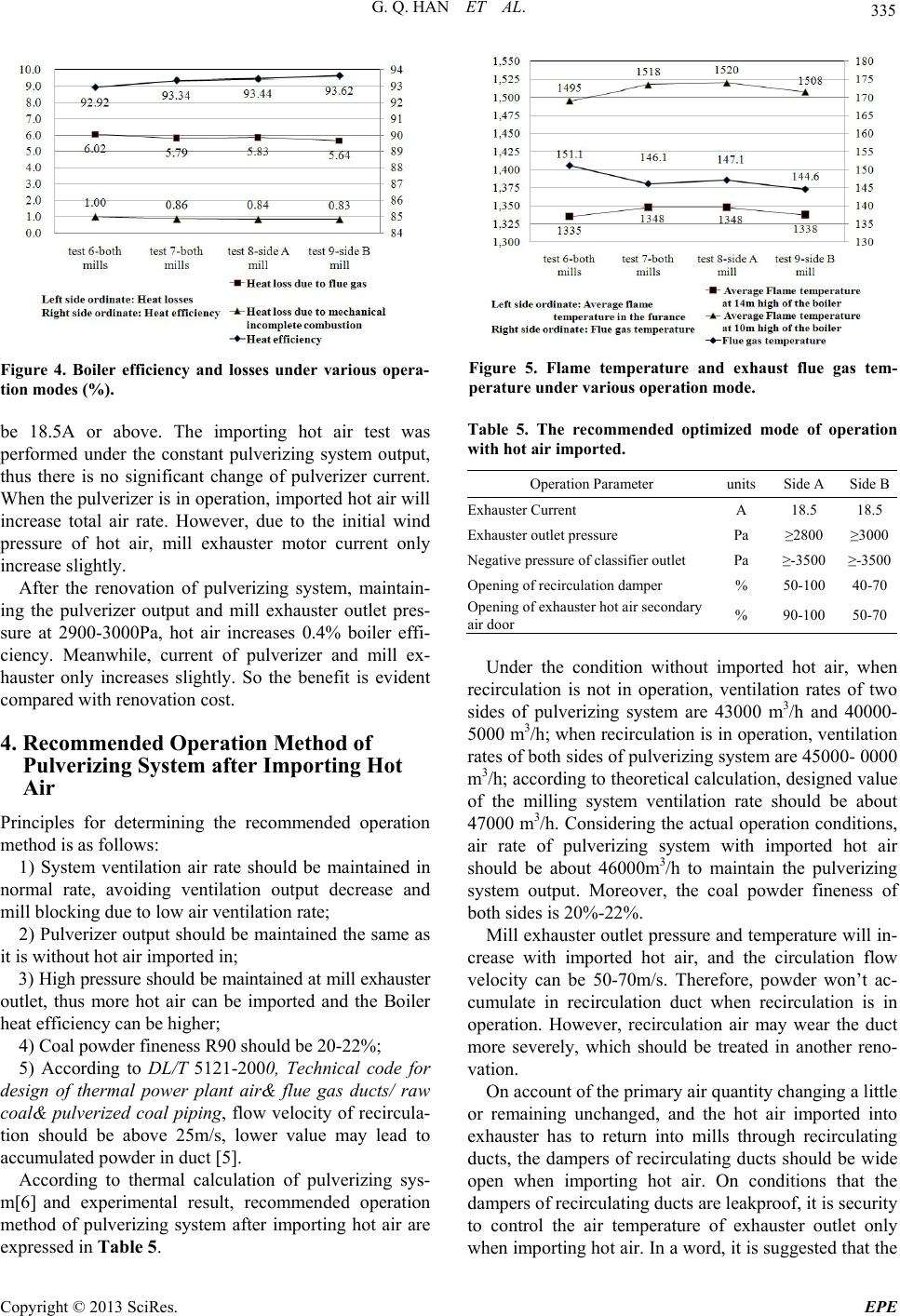

Energy and Power Engineering, 2013, 5, 330-336 doi:10.4236/epe.2013.54B065 Published Online July 2013 (http://www.scirp.org/journal/epe) An Experimental Study on the Performance of Storage Pulverizing System after Renovation of Importing Hot Air Guoqing Han1, Hongqi Wei1,*, Chang-zheng He2, Ying-hui Li1 1School of Energy and Environment, Southeast University, Nanjing, China 2Nanjing Bowo Science and Technology Co. Ltd., Nanjing, China Email: *weihongqi@vip.sina.com Received April, 2013 ABSTRACT A thermal power plant of Sinopec has 9 boilers, which generally have problems of high exhaust gas temperature and high flying ash carbon content. In order to improve the adaptability of coals, the stability of coal powder ignition, the burn-off rate of pulverized coals and the boiler efficiency, a series of renovation projects about importing hot air into mill exhauster are proposed. For the sake of verifying the renovation effects, an efficiency performance test is con- ducted on the renovated #5 boiler. The test result shows that the boiler heat efficiency has improved by 0.4% and it op- erates more safely and reliably after the renovation. At last, this paper recommends an optimized operation mode. Keywords: Storage Pulverizing System; Importing Hot Air Renovation; Performance Test; Operation Optimization 1. Introduction #1-8 boilers(8×220 t/h) in a thermal power plant of Sinopec are designed to equip the storage pulverizing systems with exhaust air used as primary air. And coals are pulverized by ball mills. Each boiler is equipped with 2 pulverizing systems. The air temperature of exhauster inlet is about 80-100℃ when the pulverizing systems use warm air as primary air, and about 65-75℃ when the exhaust air is used as primary air, which helps the inferior coals to burn steadily and burn off to some extent. In order to improve the adaptability of coals, the sta- bility of pulverized coals ignition, the burn-off rate of pulverized coals and the boiler efficiency, the plant takes #5 boiler as a pilot to renovate the pulverizing system with hot air being imported into the exhausters. The #5 boiler is renovated with 2 hot-air ducts, hot-air dampers, observation points, testing points and so on. The diagram of renovated pulverizing system is shown in Figure 1. The #5 boiler is manufactured by Harbin Boiler Fac- tory Co.Ltd. Its type is HG-220/100-10. And it is a natu- ral circulation drum boiler, which was built and operated in August, 1998. The rated evaporation of the boiler is 220t/h, the rated main-steam pressure is 9.8 MPa, the rated main-steam temperature is 540℃, designed feed-water temperature is 215℃, designed supply air temperature is 30℃, designed flue gas temperature is 138 ℃ and designed Boiler heat efficiency is 91.64%. Bitu- minous coal from Shanxi Liujialiang is the designed coal for the boiler. For the pulverizing system, the main equipments’ standards and parameters are shown in Ta- ble 1. 2. Testing Contents and Method The test is aiming at mastering the influence of the aforementioned renovation on pulverizing system and boiler’s performance indexes. Also it will help to ensure the system’s safe operation, improve the Boiler heat effi- ciency and optimize the operation mode. The test was performed according to the standards of GB10848-88(Performance test code for utility boiler) and DL/T 467-2004(Performance test for pulverizers and pulverizing systems of power station) and with a steam capacity of 200t/h. During the test pulverized air rate, flame temperatures were measured and samples of pow- ders and ashes were taken, which were analyzed after- ward. Besides, the combustion condition inside the fur- nace was observed and important variables of the boiler system and pulverizing system were recorded. The schedule of the whole test is as follows: 1) Diagnostic test under the running condition of im- porting hot air in mill exhauster inlet. Boiler heat effi- ciency and pulverized air rate were measured with only side a pulverize in operation. The tests were labeled Test 1 and Test 2. 2) Hot air importing tests under various mill exhauster outlet pressures. The tests were performed under three different mill exhauster outlet pressure specifically and *Corresponding author. Copyright © 2013 SciRes. EPE  G. Q. HAN ET AL. 331 Figure 1. Diagram of renovated pulverizing system installed with hot ducts. Table 1. Standards and Parameter s of main equipme nts in the pulve rizing system. Item Type or Standard Parameters NO. per boiler Coal feeder ZS-2540 Standard output 40t/h 2 Pulverizer DTM290/410 Standard output 14t/h, maximum charge of balls 30t, Rotating speed 19.34 r/min 2 Exhauster M6-31 No.17D Air quantity 52700t/h, total pressure 10523Pa 2 Classifier HW-CB-II-Φ3400, centrifugal Diameter Φ3400mm 2 Cyclone collector HW-GXBT-I-Φ2350, centrifugal Diameter Φ2350mm 2 were labeled Test 3, Test 4 and Test 5. 3) Hot air importing test under different ways of op- eration of the pulverizing system. Boiler heat efficiency and pulverized air rate were measured with side a pul- verizer in operation only, side B pulverizer in operation only and both pulverizers in operation specifically. The tests were Test 6 - Test 9. 3. Results and Analysis 3.1. Diagnostic Tests The diagnostic tests were both performed with only side a pulbverizer in operation, the tests being Test 1 and Test 2. In Test 1 the system was running under the condition that there was no hot air importing in the mill exhauster inlet. And in Test 2 there was. In order to guarantee that the system load and air rate are the same for the two tests, mill exhauster outlet pressure was 300 Pa higher Test 2 than Test 1, the specific hot air rate being 20000 m3/h; for the sake of operation personnel, mill exhauster outlet pressure was kept 2000-2300 Pa, with which they feel comfortable. Thus the hot air rate of side B exhauster is 6900 m3/h, which is much less than that of side A. The relevant test data are listed in Table 2. It can be known from Table 2 that with mill ex- hauster outlet pressure fixed to 2000-2300 Pa, the cor- rected boiler efficiency\corrected heat loss due to flue gas\ heat loss due to mechanical incomplete combus- tion are specifically 92.44% \5.88% \0.89% and 92.71% \5.66% \0.85%. For Test 2, Boiler heat effi- ciency is 0.27% higher, mainly due to reduction in heat loss due to flue gas which is 0.22%. Reduction in me- chanically unburned coal heat loss is barely countable, the value being 0.04%. So it can be concluded that measures must be taken to reduce the heat loss due to mechanical incomplete combustion in order to increase Copyright © 2013 SciRes. EPE  G. Q. HAN ET AL. 332 boiler efficiency. 3.2. Tests under Various Mill Exhauster Outlet Pressure Mill exhauster outlet pressure gets higher as the rate of hot air being imported increases, and so does the mill exhauster outlet air temperature. This can help make ig- nition of coal powder easier and exhauster gas tempera- ture lower. In order to estimate the influence of mill ex- hauster outlet pressure on system performance, unburned coal in flying ash and flame temperature were tested un- der various mill exhauster outlet pressures in Test 3-Test 5. For these three tests, both pulverizers were in opera- tion with hot air importing only in Test 4 and Test 5. Side A/B mill exhauster outlet pressures were specifically 2445 Pa /2427 Pa, 2634 Pa /2629 Pa, 2840 Pa /2940 Pa. Variation of flame temperature and unburned carbon in flying ash and slag are shown in Figure 2 and Figure 3. In Test 4, mill exhauster outlet pressure is relatively lower after hot air importing in and result in the decrease of air rate of side B. Although the system was running up to one hour, the pulverizer was popping out powder af- terward anyway. It is thought that if mill exhauster outlet pressure maintained regular level when importing in hot air, air rate will drop to an unreasonable low value, which consequently results in the reduction of mill out- put, 1] and even causes powder popping out and mill blocking. So mill exhauster outlet pressure should be adjusted to a higher than regular level if hot air is to be imported in. It can be known from Figure 2 that flame tempera- tures at 10m and 14m height monotonically increase as the mill exhauster outlet pressure gets higher, which in- dicates the lowering of the flame center. This will make the coal powder ignition more stable and enable the sys- tem to a variety of coals. [2] Table 2. Data of diagnostic boiler heat efficiency test with hot air imported into exhauster. Variables Unit Test 1 Test 2 Mill operation / Side A Side A Importing hot air or not a / No Yes A Pa 1995 2301 Exhauster outlet pressure B Pa 2198 2254 A m3/h 42457 42077 Air quantity of pulverizing system B m3/h - - A m3/h - 20502 Hot air quantity of exhauster inlet B m3/h - 6932 Steam flow t/h 196.2 197.1 Testing boiler heat efficiency % 91.90 92.16 Corrected boiler heat efficiency % 92.44 92.71 Designed boiler efficiency % 91.64 91.64 Difference between designed and corrected efficiency % 0.8 1.07 Corrected flue gas temperature ℃ 149.4 145.3 Excess air coefficient / 1.3 1.3 Designed excess air coefficient / 1.39 1.39 Corrected heat loss due to flue gas % 5.88 5.66 Content of combustibles in fly ash % 1.3 1.5 Content of combustibles in slag % 6.6 4.8 Heat loss due to mechanical incomplete combustion % 0.89 0.85 Heat loss due to chemical incomplete combustion % 0 0 Heat loss due to sensible heat in refuse % 0.25 0.24 Heat loss due to radiation % 0.56 0.56 Copyright © 2013 SciRes. EPE  G. Q. HAN ET AL. 333 Figure 2. Flame temperature under different mill exhauster outlet pressure (℃). Figure 3. Unburned carbon under different mill exhauster outlet pressure. It can be known from Figure 3 that unburned carbon in both flying ash and slag decrease as the mill exhauster outlet pressure gets higher, causing a reduction in heat loss due to mechanical incomplete combustion up to 0.12%, which is noticeably higher than that during the diagnostic test. To summarize up, after the renovation of importing hot air into the mill exhauster inlet, the more mill ex- hauster outlet pressure is, the more hot air will be im- ported, improving the rigidity of the mixture flow of powder and air, increasing the primary air temperature and making the primary flow rush into the furnace in a better pattern. Besides, the lowering of the combustion center and the increasing of the flame temperature can make the ignition more stable and thus enable the system to a variety of coal with low heat loss due to mechanical incomplete combustion. So it is recommended that mill exhauster outlet pressure should be maintained high (2900-3000 Pa) to get the improvement mentioned above. 3.3. Hot Air Importing Test under Different Ways of Operation of the Pulverizing System Maintaining mill exhauster outlet pressure at 2900- 3000Pa, Boiler heat efficiency and pulverized air volume rate were measured with side A pulverizer in operation only, side B pulverizer in operation only and both pulverizer in operation specifically. In Test 6 no hot wind was imported in mill exhauster inlet. And hot air was imported to both side pulverizers in Test 7-9. Test results are shown in Table 3, Table 4, Figure 4 and Figure 5. Influence of hot air in mill exhauster inlet to performance indexes is as follows: Heat loss due to flue gas Corrected exhaust heat loss of Test 7-9 are 5.79%, 5.83% and 5.64% respectively, which are all less than Test 6 when no hot air imported in mill exhauster inlet. Considering the different excess air ratio in Test 9, if the same excess air ratio can be maintained as other Tests, heat loss due to flue gas may approximately increase 0.1% [3] considering influence of both excess air ratio and exhaust gas temperature. So the heat loss due to flue gas should be about 0.3% in Test 9. Therefore, when mill exhauster outlet pressure is 2900-3000Pa, importing hot air to mill exhauster inlet can decrease about 0.24%. Moreover, importing hot air in Pulverize a working me- thod can achieve a comparatively high efficiency. Heat loss due to mechanical incomplete combustion In Test 7-9, when hot air was imported in mill exhaust inlet, the 14m and 10m average flame temperature was increased compared with without hot air. The heat loss due to mechanical incomplete combustions were 0.86%, 0.84% and 0.83% respectively in Test 7-9, lower than in Test 6 and the average reduction is 0.16%. Analysis ex- pressed the decreased heat loss due to mechanical in- complete combustion was related with high mill ex- hauster outlet pressure and flame temperature in the fur- nance. Boiler heat efficiency In Test 7-9, mill exhauster outlet temperature is 50oC higher than Test 6, which will lead to earlier ignition of primary air. Meanwhile, importing of primary air and coal powder will lead to more moisture precipitate from coal powder, which increases void fraction of it. Large void fraction makes it easier for excess oxygen to diffuse to internal voids. Thus coal powder can easily ignite and burnout. Corrected Boiler heat efficiency in Test 7-9 is 92.55%, 92.53% and 92.73%, average higher 0.4% than Test 6 without imported hot air. The result is better than diagnostic tests, mainly due to the positive influence of high mill exhauster outlet pressure and temperature on mechanically unburned carbon. Mill exhauster motor current Normal mill exhauster motor current is 16.5-18.5A, considering the effect of flue gas recirculation, feed coal quantity, primary wind pressure etc., the average mill exhauster motor current should be about 17.5A. With imported hot air the mill exhauster motor current should Copyright © 2013 SciRes. EPE  G. Q. HAN ET AL. 334 Table 3. Boiler heat efficiency and losses before and after importing hot air into exhauster. Parameter UnitTest 6Test 7Test 8 Test 9 Mill operation / BothBothSide B Side A Importing hot air or not a No Yes Yes Yes Steam flow t/h 194.6193.6195.2 195.2 The testing boiler heat efficiency % 92.9293.3493.44 93.62 Revised boiler heat efficiency % 92.1792.5592.53 92.73 Revised flue gas temperature ℃ 151.1146.1147.1 144.6 Excess air coefficient / 1.32 1.32 1.32 1.30 Revised heat loss due to flue gas % 6.02 5.79 5.83 5.64 Content of combustibles in fly ash % 1.54 1.56 1.29 1.09 Content of combustibles in slag % 6.92 4.18 5.43 6.98 Heat loss due to mechanical incomplete combustion % 1.00 0.86 0.84 0.83 Heat loss due to chemical incomplete combustion % 0 0 0 0 Heat loss due to sensible heat in refuse % 0.26 0.25 0.26 0.25 Heat loss due to radiation % 0.57 0.57 0.56 0.56 Table 4. Parameters of pulverizing system before and after importing hot air into exhauster. Parameter UnitTest 6 Test 7Test 8 Test 9 AA 40.9 41.1 - 41.2 Mill current BA 48.9 50.6 51.3 - AA 18.1 18.3 16.1 18.1 Exhauster current BA 18.4 18.2 18.2 16.4 Arpm377 366 - 331 Rotating speed of coal feeder Brpm369 360 330 - A% 52 58 0 55 Opening of exhauster inletdamper B% 65 70 72 0 A% 50 100 0 50 Opening of recirculation damper B% 50 65 55 0 A% 0 100 95 95 Opening of exhauster hot air secondary air doorB% 0 58 58 62 APa -4130 -3290 - -3177 Negative pressure of classifier outlet BPa -4110 -3250 -3356 - APa 2550 2910 2970 3030 Exhauster outlet pressure BPa 2630 2920 3060 2900 Am 3/h51031 43742- 43688 Air quantity of pulverizing system Bm 3/h50277 4401044010 - Am 3/h- 1994918423 18410 Hot air quantity of exhauster inlet Bm 3/h- 1517515175 16710 A% 42 13 0 7 Opening of mill warm air damper B% 100 62 19 0 A% 70 62 0 67 Opening of mill hot air damper B% 56 51 62 0 A℃ 76.7 122.3 146.8 120.6 Air temperature of exhauster outlet B℃ 76.8 116.2 115.6 145.6 A℃ 155.9 321.9 328.6 326.4 Air temperature of exhauster inlet B℃ 132.6 320.7 327.4 327.7 A% 20.8 20.8 - 20.8 Fineness of pulverized coal R90 B% 21.2 16.0 16.0 - A% 70.4 60.4 - 3.2 Fineness of returned coal R90 B% 82.8 68.4 68.4 - Copyright © 2013 SciRes. EPE  G. Q. HAN ET AL. 335 Figure 4. Boiler efficiency and losses under various opera- tion modes (%). Figure 5. Flame temperature and exhaust flue gas tem- perature under various opera tion mode . be 18.5A or above. The importing hot air test was performed under the constant pulverizing system output, thus there is no significant change of pulverizer current. When the pulverizer is in operation, imported hot air will increase total air rate. However, due to the initial wind pressure of hot air, mill exhauster motor current only increase slightly. After the renovation of pulverizing system, maintain- ing the pulverizer output and mill exhauster outlet pres- sure at 2900-3000Pa, hot air increases 0.4% boiler effi- ciency. Meanwhile, current of pulverizer and mill ex- hauster only increases slightly. So the benefit is evident compared with renovation cost. 4. Recommended Operation Method of Pulverizing System after Importing Hot Air Principles for determining the recommended operation method is as follows: 1) System ventilation air rate should be maintained in normal rate, avoiding ventilation output decrease and mill blocking due to low air ventilation rate; 2) Pulverizer output should be maintained the same as it is without hot air imported in; 3) High pressure should be maintained at mill exhauster outlet, thus more hot air can be imported and the Boiler heat efficiency can be higher; 4) Coal powder fineness R90 should be 20-22%; 5) According to DL/T 5121-2000, Technical code for design of thermal power plant air& flue gas ducts/ raw coal& pulverized coal piping, flow velocity of recircula- tion should be above 25m/s, lower value may lead to accumulated powder in duct [5]. According to thermal calculation of pulverizing sys- m[6] and experimental result, recommended operation method of pulverizing system after importing hot air are expressed in Table 5. Table 5. The recommended optimized mode of operation with hot air imported. Operation Parameter units Side A Side B Exhauster Current A 18.5 18.5 Exhauster outlet pressure Pa ≥2800 ≥3000 Negative pressure of classifier outlet Pa ≥-3500 ≥-3500 Opening of recirculation damper % 50-100 40-70 Opening of exhauster hot air secondary air door % 90-100 50-70 Under the condition without imported hot air, when recirculation is not in operation, ventilation rates of two sides of pulverizing system are 43000 m3/h and 40000- 5000 m3/h; when recirculation is in operation, ventilation rates of both sides of pulverizing system are 45000- 0000 m3/h; according to theoretical calculation, designed value of the milling system ventilation rate should be about 47000 m3/h. Considering the actual operation conditions, air rate of pulverizing system with imported hot air should be about 46000m3/h to maintain the pulverizing system output. Moreover, the coal powder fineness of both sides is 20%-22%. Mill exhauster outlet pressure and temperature will in- crease with imported hot air, and the circulation flow velocity can be 50-70m/s. Therefore, powder won’t ac- cumulate in recirculation duct when recirculation is in operation. However, recirculation air may wear the duct more severely, which should be treated in another reno- vation. On account of the primary air quantity changing a little or remaining unchanged, and the hot air imported into exhauster has to return into mills through recirculating ducts, the dampers of recirculating ducts should be wide open when importing hot air. On conditions that the dampers of recirculating ducts are leakproof, it is security to control the air temperature of exhauster outlet only when importing hot air. In a word, it is suggested that the Copyright © 2013 SciRes. EPE  G. Q. HAN ET AL. 336 air temperature and exhauster outlet pressure should be controlled at 140-150℃ and 2900 Pa around on conven- tional operation. 5. Conclusions and Suggestions Based on the diagnostic test, when only the mill of side A operates and the outlet pressure of exhauster is holding within the conventional range of 2000-3000Pa, the results show that the corrected Boiler heat efficiency is 92.71% after importing hot air into the exhauster. It is 0.27% higher than before. The improvement lies mainly in the heat loss due to flue gas. It decreases by 0.22%, while the decline of heat loss due to mechanical incom- plete combustion falls only 0.04%. By comparing between the tests of different outlet pressures of exhauster, it is found that more hot air can be imported into the exhauster as the pressure increases. It is beneficial for promoting the rigidity of air flow and the temperature of primary air. Also the organization of pulverized coal and air flow will be strengthened. In ad- dition, the furnace temperature raises and the flame ker- nel drops with more hot air imported. In a word, it is sig- nificant to improve the adaptability of coals, the stability of pulverized coals ignition and the burn-off rate of pul- verized coals. Thus it is suggested that when more hot air is imported under the situation of conventional air quan- tity in the pulverizing system, high outlet pressure of exhauster within 2900-3000 Pa is appropriate and useful to reduce the heat loss due to mechanical incomplete combustion. Under the test conditions of two mills operation al- together, one mill of side A and one mill of side B each running alone, hot air is controlled to import into the ex- hauster, while the outlet pressure of exhauster maintained within 2900-3000 Pa. After importing hot air, the air temperature of exhauster outlet and the flame tempera- ture in furnace raises significantly. So the combustion condition is better. The test results shows that the cor- rected heat loss due to flue gas and mechanical incom- plete combustion is less than the operation of two mills without hot air importing. The average decreasing am- plitude is 0.24% and 0.16% respectively. Also the cor- rected boiler heat efficiency is 0.4% higher equally, bet- ter than the diagnostic test as well. The main reason is that higher air pressure and temperature of exhauster outlet is beneficial to reduce the heat loss due to me- chanical incomplete combustion. When the output of mills is stable and the exhauster outlet pressure is maintained within 2900-3000 Pa, there is not much increase in the amount of exhauster current. For this reason, the renovation benefits obviously out- weigh the costs. In order to achieve the optimized operation after the renovation of the pulverizing system, a recommended mode of operation is presented, which is shown in Table 5. REFERENCES [1] H. X. Jia, “Design and Operation for Coal Milling Sys- tem,” Beijing, China Water Power Press, 1995. [2] H. X. Ding and J. B. Zhao, “To Solve Combustion Stabil- ity Problems Using Exhauster Air/Hot Air Pulverized Coal Feeding System,” Electric Power, No. 10, 1995, pp. 41-43. [3] D. Q. Wei, “Analysis of the Existed Problems before and after the Designed Reform of Hot-draft Coal Powder Feeding System in Laibin Thermal Power Plant A, Guangxi,” Guangxi Electric Power, No. 2, 2007, pp. 59-70. [4] C. Z. Fan, “Principles of Boiler,” Beijing, China Water Power Press, 1986. [5] Y. C. Wang, “Study on the Influence of Air Leakage into Boiler upon Exhaust Gas Temperature and Exhaust Gas Loss,” Thermal Power Generation, No. 8, 2007, pp. 19-22. [6] Z. H. Zhao, A. G. Zhang and W. Y. Wang, “Design and Calculation Method for Thermal Power Plant Pulverizing System,” Beijing, China Electric Power Press, 1999. Copyright © 2013 SciRes. EPE |