Z. T. AL-MALKI ET AL. 103

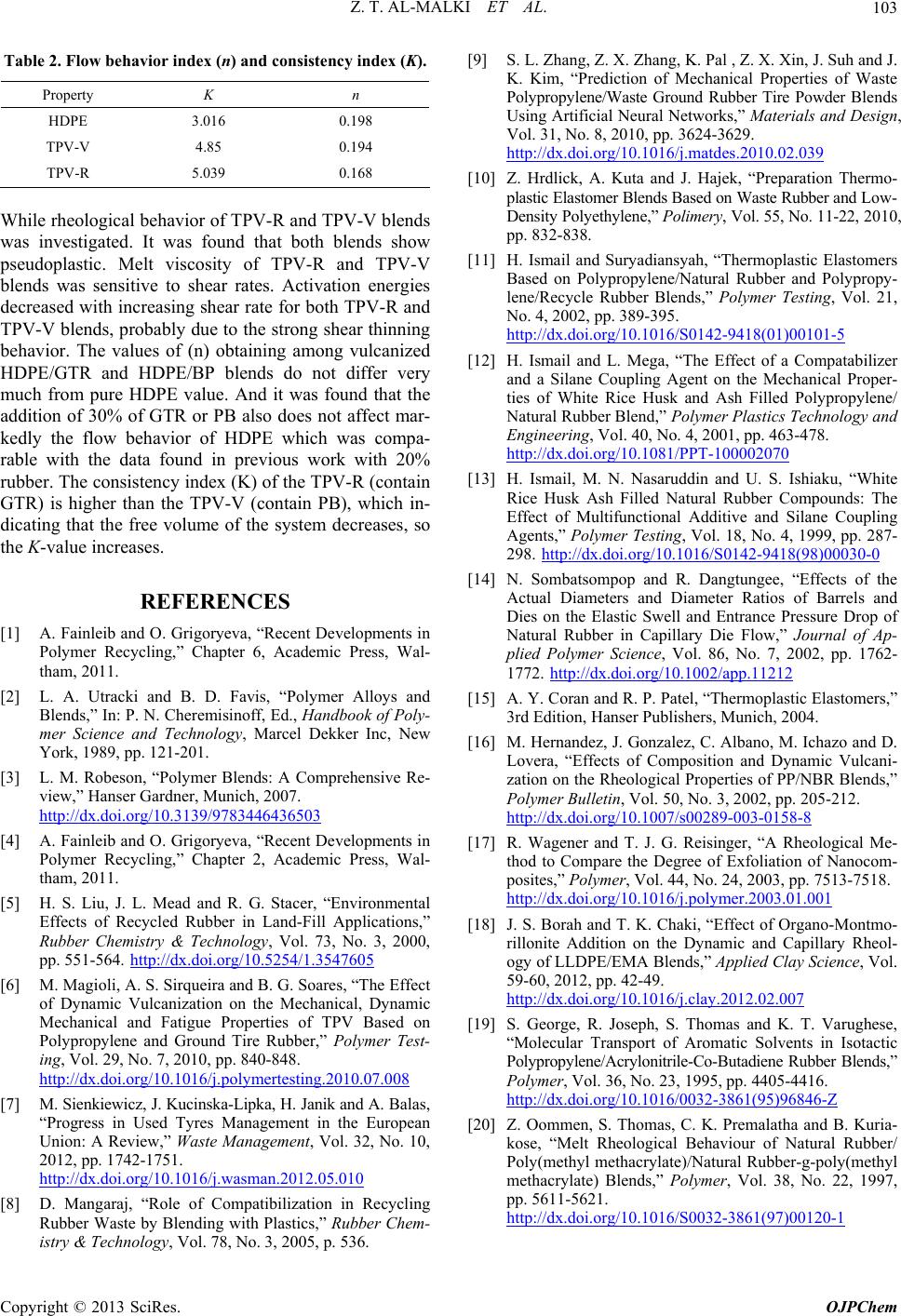

Table 2. Flow behavior index (n) and consistency index (K).

Property K n

HDPE 3.016 0.198

TPV-V 4.85 0.194

TPV-R 5.039 0.168

While rheological behavior of TPV-R and TPV-V blends

was investigated. It was found that both blends show

pseudoplastic. Melt viscosity of TPV-R and TPV-V

blends was sensitive to shear rates. Activation energies

decreased with increasing shear rate for both TPV-R and

TPV-V blends, probably due to the strong shear thinning

behavior. The values of (n) obtaining among vulcanized

HDPE/GTR and HDPE/BP blends do not differ very

much from pure HDPE value. And it was found that the

addition of 30% of GTR or PB also does not affect mar-

kedly the flow behavior of HDPE which was compa-

rable with the data found in previous work with 20%

rubber. The consistency index (K) of the TPV-R (contain

GTR) is higher than the TPV-V (contain PB), which in-

dicating that the free volume of the system decreases, so

the K-value increases.

REFERENCES

[1] A. Fainleib and O. Grigoryeva, “Recent Developments in

Polymer Recycling,” Chapter 6, Academic Press, Wal-

tham, 2011.

[2] L. A. Utracki and B. D. Favis, “Polymer Alloys and

Blends,” In: P. N. Cheremisinoff, Ed., Handbook of Poly-

mer Science and Technology, Marcel Dekker Inc, New

York, 1989, pp. 121-201.

[3] L. M. Robeson, “Polymer Blends: A Comprehensive Re-

view,” Hanser Gardner, Munich, 2007.

http://dx.doi.org/10.3139/9783446436503

[4] A. Fainleib and O. Grigoryeva, “Recent Developments in

Polymer Recycling,” Chapter 2, Academic Press, Wal-

tham, 2011.

[5] H. S. Liu, J. L. Mead and R. G. Stacer, “Environmental

Effects of Recycled Rubber in Land-Fill Applications,”

Rubber Chemistry & Technology, Vol. 73, No. 3, 2000,

pp. 551-564. http://dx.doi.org/10.5254/1.3547605

[6] M. Magioli, A. S. Sirqueira and B. G. Soares, “The Effect

of Dynamic Vulcanization on the Mechanical, Dynamic

Mechanical and Fatigue Properties of TPV Based on

Polypropylene and Ground Tire Rubber,” Polymer Test-

ing, Vol. 29, No. 7, 2010, pp. 840-848.

http://dx.doi.org/10.1016/j.polymertesting.2010.07.008

[7] M. Sienkiewicz, J. Kucinska-Lipka, H. Janik and A. Balas,

“Progress in Used Tyres Management in the European

Union: A Review,” Waste Management, Vol. 32, No. 10,

2012, pp. 1742-1751.

http://dx.doi.org/10.1016/j.wasman.2012.05.010

[8] D. Mangaraj, “Role of Compatibilization in Recycling

Rubber Waste by Blending with Plastics,” Rubber Chem-

istry & Technology, Vol. 78, No. 3, 2005, p. 536.

[9] S. L. Zhang, Z. X. Zhang, K. Pal , Z. X. Xin, J. Suh and J.

K. Kim, “Prediction of Mechanical Properties of Waste

Polypropylene/Waste Ground Rubber Tire Powder Blends

Using Artificial Neural Networks,” Materials and Design,

Vol. 31, No. 8, 2010, pp. 3624-3629.

http://dx.doi.org/10.1016/j.matdes.2010.02.039

[10] Z. Hrdlick, A. Kuta and J. Hajek, “Preparation Thermo-

plastic Elastomer Blends Based on Waste Rubber and Low-

Density Polyethylene,” Polimery, Vol. 55, No. 11-22, 2010,

pp. 832-838.

[11] H. Ismail and Suryadiansyah, “Thermoplastic Elastomers

Based on Polypropylene/Natural Rubber and Polypropy-

lene/Recycle Rubber Blends,” Polymer Testing, Vol. 21,

No. 4, 2002, pp. 389-395.

http://dx.doi.org/10.1016/S0142-9418(01)00101-5

[12] H. Ismail and L. Mega, “The Effect of a Compatabilizer

and a Silane Coupling Agent on the Mechanical Proper-

ties of White Rice Husk and Ash Filled Polypropylene/

Natural Rubber Blend,” Polymer Plastics Technology and

Engineering, Vol. 40, No. 4, 2001, pp. 463-478.

http://dx.doi.org/10.1081/PPT-100002070

[13] H. Ismail, M. N. Nasaruddin and U. S. Ishiaku, “White

Rice Husk Ash Filled Natural Rubber Compounds: The

Effect of Multifunctional Additive and Silane Coupling

Agents,” Polymer Testing, Vol. 18, No. 4, 1999, pp. 287-

298. http://dx.doi.org/10.1016/S0142-9418(98)00030-0

[14] N. Sombatsompop and R. Dangtungee, “Effects of the

Actual Diameters and Diameter Ratios of Barrels and

Dies on the Elastic Swell and Entrance Pressure Drop of

Natural Rubber in Capillary Die Flow,” Journal of Ap-

plied Polymer Science, Vol. 86, No. 7, 2002, pp. 1762-

1772. http://dx.doi.org/10.1002/app.11212

[15] A. Y. Coran and R. P. Patel, “Thermoplastic Elastomers,”

3rd Edition, Hanser Publishers, Munich, 2004.

[16] M. Hernandez, J. Gonzalez, C. Albano, M. Ichazo and D.

Lovera, “Effects of Composition and Dynamic Vulcani-

zation on the Rheological Properties of PP/NBR Blends,”

Polymer Bulletin, Vol. 50, No. 3, 2002, pp. 205-212.

http://dx.doi.org/10.1007/s00289-003-0158-8

[17] R. Wagener and T. J. G. Reisinger, “A Rheological Me-

thod to Compare the Degree of Exfoliation of Nanocom-

posites,” Polymer, Vol. 44, No. 24, 2003, pp. 7513-7518.

http://dx.doi.org/10.1016/j.polymer.2003.01.001

[18] J. S. Borah and T. K. Chaki, “Effect of Organo-Montmo-

rillonite Addition on the Dynamic and Capillary Rheol-

ogy of LLDPE/EMA Blends,” Applied Clay Science, Vol.

59-60, 2012, pp. 42-49.

http://dx.doi.org/10.1016/j.clay.2012.02.007

[19] S. George, R. Joseph, S. Thomas and K. T. Varughese,

“Molecular Transport of Aromatic Solvents in Isotactic

Polypropylene/Acrylonitrile-Co-Butadiene Rubber Blends,”

Polymer, Vol. 36, No. 23, 1995, pp. 4405-4416.

http://dx.doi.org/10.1016/0032-3861(95)96846-Z

[20] Z. Oommen, S. Thomas, C. K. Premalatha and B. Kuria-

kose, “Melt Rheological Behaviour of Natural Rubber/

Poly(methyl methacrylate)/Natural Rubber-g-poly(methyl

methacrylate) Blends,” Polymer, Vol. 38, No. 22, 1997,

pp. 5611-5621.

http://dx.doi.org/10.1016/S0032-3861(97)00120-1

Copyright © 2013 SciRes. OJPChem