Open Journal of Energy Efficiency

Vol.04 No.01(2015), Article ID:54339,13 pages

10.4236/ojee.2015.41001

Electric Vehicles Analysis inside Electric Mobility Looking for Energy Efficient and Sustainable Metropolis

Miguel Edgar Morales Udaeta*, Carolina Attas Chaud, André Luiz Veiga Gimenes, Luiz Claudio Ribeiro Galvao

Energy Group of the Electrical Power and Automation Engineering, Department of the Polytechnic, University of São Paulo―GEPEA/EPUSP, São Paulo, Brazil

Email: *udaeta@pea.usp.br

Copyright © 2015 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 7 February 2015; accepted 25 February 2015; published 28 February 2015

ABSTRACT

This paper aims to study and evaluate electric mobility over time, focusing on the development of the electric car. Methodologically, in order to accomplish this intent, the characterization of the electric vehicle (EV) is made based on the variables which determine its performance, such as: assessment of speeds, distance traveled, analysis of facts related to the energy source (electro- chemical accumulators) and analysis of the determining system of electric mobility (the electric engine as a function of power (W) and voltage (V)). This way, to demonstrate the effects of time, this process will be analyzed from the beginning of the 20th century (1930s) to the present (the first decade of the 21st century), methodologically structured in 4 cycles that show the performance of the EV. The results show the existence of vulnerabilities and of electric mobility potential, as well as the nuances of the development of the electric vehicle along the years and along the transformations in what is considered state-of-the-art. Thus, in the case of batteries, it is evident that the lithium-ion type used nowadays reveals better results due to its higher specific efficient energy, which maximizes energy autonomy to 200 km. In the beginning, the insertion of the electric vehicle was commercially harmed by the fundamental limitations of batteries as a power source. Conclusively, on certain occasions there have been improvements in the aerodynamics, engines, weight and size of the batteries, demonstrating the maturity of EVs.

Keywords:

Electric Vehicle, EV Development, Electric Mobility, Energy Analysis, Metropolis, Sustainability

1. Introduction

Urban mobility in the 21st century comes with a series of constraints―ranging from problems in availability of essential resources to difficulties in the disposal of waste by average speed in the transportation of goods and people―all of which leading to considerations about the future role of the automobile in the cities. This is an opportunity to think and implement fundamental changes in concepts and models of the last century’s standardized transport. Even though cars, trucks and other mobility machines have been synonymous with urbanization development, nowadays these machines are partially responsible for the collapse of metropolises [1] . From numerous negative factors relating to urban mobility in the full sense, the biggest target for the minimization of effects is local pollution, simply because humans need well-being. In this sense, electric mobility seems as a part of a solution known to the cities since―on the contrary of what it may seem―the first electric vehicles have emerged in the turn of the twentieth century, preceding the invention of the combustion engine gas (by Daimler Benz in 1885’s Germany). In fact, before the internal combustion engine imposed itself as synonymous with mobility, the history of western socioeconomic development demonstrates that the electric vehicles industry was thriving, with electric buses lines, for example, which earned space on the streets of London around 1886. This has occurred because of the supremacy of the research conducted in France by Gustave Trouvé in 1881, which has made it possible to recharge batteries.

Regular use of electric vehicles has endured a long time, the proof of which being the remarkable advances in this area, such as the construction of the electric car that reached the incredible speed, for those days, of 100 km/h (by the Belgian Camille Jenatzy in 1899). The same way, in 1918, the electric buses line between Praça Maua and the then existing Monroe Palace in the city of Rio de Janeiro was inaugurated, known as the comfortable bus battery―powered electric traction―with solid rubber wheels, no noise, no vibration and without smo- ke or the hassle of gasoline (Peres, 2003).

The entrance of the Ford T in the market in 1909, along with its subsequent improvements such as the electric start, meant at the time the fall of the electric car―even with the advances recharge time and autonomy. Thus, like T Ford, urban mobility initiated its way to the current days. More than that, in the consumer society the automobile has become an indispensable asset. The following well-known step, in the case of the internal combustion engine, was the investment in oil refinery fields and their availability primarily in the U.S., which has determined the necessary support fuel. It is important to recall that the diesel engine [2] had been invented in the late 19th century but the use of fossil fuels like diesel in general transportation is not well seen due to the serious pollution and GHG emissions that result from it.

In this sense, environmental initiatives have favored in recent times the technological evolution of the electric power train, such as the Kyoto protocol, which especially concerns the burning of petroleum in powered internal combustion engine vehicles. Additionally, these vehicles in large population centers are a significant source of contaminating emissions, contributing often in 100% with the emission of pollutants into the atmosphere [3] [4] . Therefore, electrical and urban mobility are inserted in a new context due to the increase in the availability and use of electric vehicles in the world.

It is interesting to evidence that the relative emission of urban mobility―fueled by petroleum derivatives― while added to the combustion products of local industries becomes lethal when the case involves temperature inversions that prevent the dispersion of pollutants [5] .

Therefore, to foster the construction of an eco-economy towards a sustainable socioeconomic development that includes mobility in large cities seems irreversible in the 21st century. This means we live in a world where energy comes from clean sources such as wind turbines and not from coal mines, where recycling industries replace mining industries and where cities are planned for people and not for cars. A sustainable economy includes the welfare of future generations [1] .

As a premise, the electric vehicle proves itself to be conducive to environmental issues of urban mobility, since emissions are significantly reduced, which should also include a decrease in noise. Since recharging batteries (neuralgic point of the inclusion of electric mobility) incorporates new concepts into the commercial power grid, the inclusion of the electric vehicle should be planned within the power generation mix of each country. In any case, with respect to Brazil―given that the electric energy is hydroelectric―electric mobility is a significant option for sustainable urban mobility in megacities such as São Paulo [2] .

Relevant Aspects of the Electric Vehicles

At first, an electric vehicle in its basic meaning can be understood as being an automobile with an electric motor connected to the front wheels through a gearbox with one or two speeds, but there are several other possible variations of the propulsion system architectures. Thus, for example, a significant variation of this techonology is the use of four small motors for each wheel, in exchange for only one drive motor, as originally designed in the beginning of the electric car [6] .

Moreover, in the context of this work, electrical mobility aims at the driving of people, objects or a specific load. However, the electric vehicle in this case, independently from other technological variants, is generally understood as a system whose only power source is the battery charged with the task of activating one or more of the automobile’s electric motors. Even because, in this specific case of electric mobility, it is generally assumed that the availability of power supply determines the type of vehicle so that, for example, a subway or trolley follows a predetermined route by rail or electrical distribution network [7] .

Given the diversity―in the modern world―of electric mobility among existing systems for electric vehicles, this work focuses on cars and utility vehicles for loads. In this sense, the study considers electric vehicles throughout time, in an analysis divided by the phases of its evolution, considering also the technology employed and socioeconomic importance of the period.

2. Technical Evolutionary Context of Electric Vehicles

In essence, the electric mobility’s technology is based on the joint implementation of energy accumulators and of the electric motor as drive system. Two researchers stand out in this context: Alessandro Volta for the precursor of the battery in 1800 (“Battery Back”) and Michael Faraday, who developed the homopolar motor in 1821.

In this sense, the predominance of the electromagnetic induction since 1831 has led to the consolidation of the electrical and electronics technologies, including engines and electrical generators. From this assumption, all findings related to the operation of an electric motor have supported the conjunction of the battery and of the electric motor connected to the wheels of a light vehicle. The first electric vehicles appear in the 1830s using non-rechargeable batteries.

In 1859 Gaston Plante introduced the rechargeable lead-acid, which is the technology currently used in acquiescence in most applications requiring energy storage. Following that, Aphonse Camille Faure improved the ability of such batteries, leading to industrial scale production, in such a way that in 1881 the autonomous electric vehicles proliferated the cities’ streets. That way, it is important to mention that in the late 20th century, with the rechargeable batteries, electric cars entered the commercial market [8] . Thus, it can be said that the predominance of the accumulation of electrical energy and its conversion to mechanical energy has enabled a new, quiet and clean method for urban mobility.

As for the accumulators, other batteries have been developed―for example, the iron-zinc battery. Even Thomas Edison, interested in the potential of electric vehicles in the early 1900s, developed the nickel-iron battery, with a storage capacity 40% greater than that of the battery lead, but with a much higher cost of production. Thus, the 19th century saw the development of batteries such as the nickel-zinc and the zinc-air [9] .

Thus, electrical mobility starts when the first electric vehicle (tricycle) to use lead-acid (developed by Planté) as a source of energy was demonstrated in France by Mr. Trouvé in 1881. In this period, other electric tricycles with lead batteries were also in the U.S. and UK. In this context, it is worth remembering that only in 1885 did the German Karl Benz demonstrate the first combustion powered vehicle: the Pantentmotorwagen [10] .

Moreover, in 1837, Robert Davison Aberdeen built in England the first electric carriage, powered by a rustic iron-zinc battery and driven by an electric motor, but containing all the basic elements used in modern electric vehicles. In France, experiments were performed by Charles Jeantaud Raffard while, at the same time, Werner Siemens, in Germany, perfected the electric motor. Even though the mobility steam prevailed at the time―es- pecially in the area of public transport―the electric vehicle showed itself ideal for urban traffic, not having made noises and having had a drive system that did not pollute the environment [7] .

Anyway, since its inception electric mobility has gained significance, seeing that the electric motor, by not involving any combustion, was free of soot and grease, therefore being very clean. More than that, the electric vehicle with graduations for three, four and up to nine speeds was not required to carry a paraphernalia command, which is a fundamental characteristic of petrol and steam cars [11] .

3. First Cycle of Electric Vehicles (1837-1912)

Schiffer [12] points out that the electric car powered by rechargeable batteries seemed to have a great future about a century ago. Twenty-eight percent of the 4192 cars produced in the U.S. in 1900 were electric. Some of the most prestigious inventors, including Thomas Edison, promoted electric cars or the participation in its development. And the first industries to produce cars in series were manufacturing electric cars. In the early twentieth century, electric, steam and gasoline cars competed more or less on equal terms. Many analysts at the time believed that each type of car would find its own “performance space” and that they would coexist indefinitely. However, by the late 20s the electric car was a product in decline when considering the commercial sphere. The gasoline-powered car had conquered all spaces with its impressive speed, performance and finish. “Tripping A spectacular”, from “The electric automobile in America”. Table 1 presents schematically an analysis of the performance achieved each year by the respective electric vehicles, parameterized in speed, range, battery voltage and power, in the golden period related to the 1st cycle, which it set between 1837 and 1912.

Occasionally, around 1905 the gasoline-powered vehicle began to stand out when compared to the electric vehicles in question. The autonomy of the 63 miles (about 100 km) reached by vehicle combustion more than doubled the range of an electric car (30 miles or approximately 50 km), as seen in the table. The initial investment and the operating cost of electric cars were higher than the gasoline-powered. The available figures indicate that the 1900s petrol cars cost between $1000.00 and $2000.00, while an electric car cost U.S. $1250.00 to U.S. $3500.00. The cost of operating a gasoline car was $0.01/mile while for an electric car it was $0.02 to 0.03/mile. In 1901 big oil fields were discovered in Texas, which drove down petrol’s costs in a way that it gained a sustainable competitive advantage.

Still, according to Larminie and Lowry [8] , early in the development of electric vehicles, an internal combustion engine that flipped a generator was used together with one or more electric motors, called hybrid vehicle.

According to Schiffer [12] , electricity best fulfills the requirements of a traction system than steam engines or even internal combustion engines.

However, in 1912, the fleet of electric cars in the United States reached its peak of 30,000 units and the amount of petrol cars was already thirty times larger, to the verge of 900,000 units [13] . Given this background, in the same period, between 1900 and 1912, there were initiatives in the pursuit of improving distance and performance of electric vehicles through the adoption of the hybrid configuration.

Based on the assumptions presented above, the trajectory of electric cars has continued in eversion. Among the main factors that have since contributed to the decline of electric cars [14] , the following can be cited:

・ The competitive advantage achieved by the development of the production system in series, applied by Henry Ford, has allowed an increase in the manufacture of combustion-powered cars, as shown in Table 2.

・ Elimination of the crank used to drive vehicles powered combustion. Invention of the electric starting, in 1912 [15] ;

・ In the mid-1920s, the highways in the United States interconnected several cities, which demanded vehicles capable of traveling long distances [14] ;

Table 1. Evolution of electric vehicles from 1837 to 1912.

Source: own compilation.

Table 2. Number of vehicles built in USA in the beginning of the century.

Source: own adaptation from [7] .

・ Oil discoveries in Texas have reduced the price of gasoline, making it an attractive fuel for the transportation sector [16] ;

・ Development of distillation techniques in continuous and consequent cheapness of petroleum products resulting in the expansion of the technological development of the automobile industry headed for gasoline- powered vehicles [7] .

4. Second Cycle of Electric Vehicles (1912-1973)

After the discovery of oil fields, gasoline vehicles and, later, diesel quickly reached levels of performance that resulted in greater speed, greater acceleration and lower weight compared to electric vehicles. The oil industry had developed into such a supreme point that virtually all of its derivatives started to present cost advantage because of its growing consumption.

Sales were minimal even in England, where Brougham (by Partridge Wilson ) was marketed, powered by a battery of 60 V and 34 Ah, which enabled a speed of 51.5 km/h and a radius of 97 km per battery charge [7] .

Based on the assumptions presented above, having the 2nd cycle started around 1909, the production of electric cars dropped considerably, reaching about 4.4% of the number of combustion-powered cars. In 1913, as aforementioned, Ford began producing gasoline cars in series in the first industrial assembly line in Highland Park plant. In 1912 with the advent of the electric starter motor vehicles, the explosion made these cars even more attractive.

Obviously, by 1912 there was renewed enthusiasm for the electric car with the emergence of a few technical developments. Thomas Edison had perfected and carried out the first tests using the nickel-iron battery, which had a 35% increase in storage capacity between 1910 and 1925. The lifespan of these batteries has also increased whereas the maintenance costs decreased.

However, this resurgence was most striking for small delivery trucks in companies that owned fleets of around 60 vehicles and that could have their own central recharge batteries.

The advent of the First World War in 1914 caused an increase in oil prices and also in optimism about electric cars. But despite the commercial and marketing efforts, the number of electric trucks fell from 10% in 1913 to only 3% - 4% in 1925 according to Schiffer [12] .

However, the years between 1920 and 1970 were a time of steady decline in electric cars. On a global scale, the depression of the 1930s, followed by World War II, harmed a possible resurgence of electric vehicles and new experiments with alternative fuel vehicles. At that time, few studies and scientific research have been developed for electric vehicles. Even in the postwar period of economic prosperity, the electric vehicle projects remained stored in a context of small concern for energy security, due to the existence of abundant and cheap fuel and vehicles with internal combustion engine (MCI), the largest and fastest [15] .

In the United States, a meager revival of electric vehicles happened in the 60s. Car technology was basic, with DC motors with brushes. However, in terms of energy accumulators there was some variety beyond the normal lead-acid: the lead-cobalt and the nickel-cadmium.

Specifically, the electric traction technology began again to be shyly explored, its development returning only from the 60s on, when the electric vehicle was seen as a way to overcome the environmental problems caused by emissions from the combustion powered vehicles. It is noteworthy that most of the electric vehicles produced in the 60s emanated from the conversion of conventional vehicles.

We observe, however, that from the 1970s on, with the emergence and worsening of the oil crisis, discussions on environmental issues in urban centers have become a worrying factor for government leaders. The electric vehicle has been considered as an energy alternative, mainly in countries with a lot of hydroelectric generation or coal-based thermal power. In this period, there were several initiatives aiming to insert them back into the market, but neither the pure electric cars nor the hybrids were able to compete in the market with conventional cars, which had a sustainable competitive advantage [9] .

Thus, the performance achieved each year by the respective electric vehicles parameterized in speed, range, battery voltage and power on the 2nd cycle (between 1912 and 1973) are summarized in Table 3.

Because of its importance and relevance to this study, as a kind of complementary measure, the table shows one of the striking points in time due to short range (50 to 100 km) and low average speed (on average, 50 to 100 km/h). Somehow, these factors affected the introduction of electric vehicles on a large scale. Moreover, the delay on the recharging of the battery (about 8 hours) and the lack of infrastructure in use service became a concomitant factor.

Meanwhile, according to Valle Real and Balassiano [17] , there are basically two paths to be taken. The first would make them more efficient vehicles from the point of view of energy consumption (as well as of the amount of emissions); and the second, by means of restrictions and adoption of specific rates, would make the user reduce the utilization of motor vehicles, particularly the car.

5. Third Cycle of Electric Vehicles (1973-1996)

Apart from being cleaner (depending on the type of energy used), electric cars manufactured and converted in the late 60s used certain conservation techniques in an attempt to increase their autonomy and maximum speed. The priority was in guaranteeing that these vehicles reached the level of performance offered by combustion powered cars, whose development had been significant throughout the century.

Interest in electric vehicles had increased considerably until the late 80s, when the problem of air pollution from large cities began to be discussed more often [6] . With respect to Brazil, for example, the fundamental importance of engineer John Augustus Conrado do Amaral Gurgel (1926-2009) cannot be forgotten, since he pro-

Table 3. Evolution of electric vehicles from 1912 to 1973.

Source: own compilation.

duced the first Brazilian electric car in 1974, with a range of 60 km―called Itaipu.

Generically speaking for this period, it is noteworthy that by the year 1973 the crisis associated with the embargo imposed by the OPEC (Organization of Petroleum Exporting Countries) brought new prospects for electric cars. However, the United States depended significantly on oil from the Arab countries and the U.S. Congress at the time was determined to reduce this dependence. There was also an economic motivation given by the U.S. trade balance. Environmental issues were not actually critical, therefore, it was not generally considered that only the use of electric cars would improve air quality, according to Schiffer [12] .

Objectively, as stated before about the 80s, the government interests turned to the advantages derived from powered electric vehicle propulsion vehicles, mainly because of environmental issues. Thus, it is observed that government policy measures were introduced worldwide in the pursuit of reducing urban vehicle emissions. The prime example was the California Air Resources Board’s (CARB) that implemented, in 1990, the first regulatory standards for zero-emission vehicles in California.

A number of modern vehicles was introduced by automakers between the 1980s and 1990. Along with the selling of the top vehicles, such as the General Motors EV-1, the Toyota RAV4-EV and the Ford Ranger EV, several studies about the cost of batteries have been developed in order to assess the commercial prospects of these vehicles [12] . Although they were more efficient than conventional cars, this advantage had little value at the time when the oil price was the lowest in history [18] .

Based on the performances achieved each year by its respective electric vehicles, parameterized in speed, range, battery voltage and power and in comparison to previous cycles, Table 4 shows the variables from the 3rd cycle, between 1973 and 1996.

6. Fourth Cycle of Electric Vehicles (1997 to the Present)

Within the different stages of live cycles, currently the hybrid, the electric and the plug-in vehicles emerge

Table 4. Evolution of electric vehicles from 1973 to 1996.

Source: own compilation.

as instruments to solve flagship-oriented issues such as energy security and climate impact. According to Anfavea [19] , the Brazilian Chain of Automotive Supplies brings together a spectrum of ethnic diversity in the nationalities of their manufacturers, so that automakers are gathered here from no less than nine different countries: Germany, Brazil, South Korea, United States France, India, Italy, Japan and Sweden. This ethnic diversity has no record in any other major producer of vehicles on the planet [19] .

Most of these automakers that help compose the chain of the automotive segment conduct research with universities in order to develop integrated models of hybrid and electric cars format. The first major step in this recent movement arose in 1997, when Toyota, the Japanese automaker, launched the Prius in Japan―a hybrid four-door sedan―followed by Honda, the first to launch a hybrid in the U.S. market―the Insight in 1998 [20] .

Since the launch of the Toyota Prius in 1997, 1.9 million HEVs (Hybrid Electric Vehicles) vehicles and 60.0 thousand PHEVs (Plug-in Hybrid Electric Vehicles) and BEVs (Battery Electric Vehicles) vehicles have been sold in the North-American market [15] . This fact can be attributed in large part to the encouragement of the U.S. government to manufacturers and consumers of hybrid and electric vehicles. Worldwide, over the last decade, many HEVs, PHEVs and BEVs have been sold, totaling more than 2.5 million vehicles. In early 2011, the penetration of these technologies in the market is of 2% in the U.S. and 9% were sold in Japan [21] . A descriptive approach to the start of the 4th cycle will be presented below.

Although it is necessary to prioritize the previously mentioned variables that portray each historical cycle, at first, it is noticed that the electric motor is the ideal drive propulsion. Due to the strong competition and the growing consumer demand, companies in the area of transport and logistics attempt to reduce operating costs, while seeking to improve services. The electric vehicle meets those needs, since it has compatible attributes such as: it is quiet, it is highly efficient, it has excellent torque characteristics × speed and it does not pollute. However, the Mercedes-Benz CL600 has a 367 hp of 12-cylinder engine and can accelerate its 2380 kg 0 - 60 miles/h (about 100 km/h) in 6.3 s. To increase efficiency there is a mechanism that disables 6 cylinders when there is no need for high torque, according to Dettmer [22] . Table 5 shows the variables portrayed in the 4th cycle, starting in 1997 until today.

With the new developments in batteries, electric vehicles now have their storage capacity between 20 and 60 kWh, allowing its interconnection with the electric distribution network through the consumption of energy. Plus, in the very near future, this will provide energy according to the needs of network functionality through the Vehicle Connected to the Network (VLR), according to Kempton and Tomic [23] .

Figure 1 shows a partial configuration of the components of an electric vehicle that properly uses the electricity from the public distribution system to recharge the battery installed in the vehicle (battery bank). The re-

Table 5. Evolution of EVs between 1996 and the present.

Source: own compilation.

Figure 1. Evolution of batteries.

ceived energy is stored in the battery, in electrochemical format. This stored energy is converted into electrical energy that is transported to the Electric Motor (M/G), which will make its conversion into mechanical energy and thus provide the movement of the vehicle without generating emissions or noise. Also, if a Regenerative Breaking System (TR) is implemented in the electric vehicle, it is also possible to store the energy produced when breaking or slowing down, by converting the kinetic energy into electrical energy through the M/G, which will be stored in the battery [24] .

7. Potentialities and Limitations Highlighted in the LV Development

The importance of batteries is irrefutable in an electric vehicle. That way, the main characteristics of an accumulator of energy are the specific energy, specific power and lifetime. Specific energy is the energy amount stored by the battery per unit weight; the specific power is the supplied power per unit mass; and the lifetime is the number of charge/discharge that may be required.

In Graph 1, it is possible to check, on a timeline, the progress in size and weight of the various types of batteries. The batteries of the Pb-SO4, Ni-Cd, Ni-MH type are stagnant in terms of specific energy and density.

Thus, it can be defined as energy density the ratio between the maximum amount of energy that can be stored securely in an energy storer element body and the volume of that body. The higher the energy density―which can be measured in Wh/l (watt/h per liter) or MJ/l (megajoules per liter)―the more energy can be stored or transported in one body with the same volume. As for the specific energy, it also relates to the maximum amount of energy that can be stored, but with the mass of the containing body element. Specific energy can be quantified in Wh/kg (watt-hours per kilogram).

Peças Lopes, Soares, Almeida and Moreira da Silva [11] point out that, with the new developments of batteries, vehicles powered by electric traction have the storage capacity of between 20 and 60 kWh, allowing its interconnection with the power grid distribution through the energy consumption. In the very near future, this will provide power according to the needs of the network through the functionality of a Vehicle Connected to the Network (VLR).

On the face of it, the technical requirements demanded by the energy accumulators are different for each type of vehicle. Electric vehicles require batteries with higher energy densities, which limits them due to the masses and volumes associated, contributing to the low range of these types of vehicles. Since in pure electric vehicles batteries are the only energy source, these end up suffering deeper discharges, demanding more robust batteries with long life and the acceptance of a high number of charge and recharge cycles. However, increasing the autonomy of electric vehicles requires larger batteries, greatly increasing the vehicle mass. Inversely, reducing the range of electric vehicles enables higher effective energy efficiency. In Graphs 2-5 we can see the evolution of the range and speed before 4 cycles, taking into account previously shown factors that were considered essential for the development of these vehicles.

It is worth noting that the lead-acid (Pb) batteries are the best-known being used in cycles 1, 2 and 3, having the largest implementation in 2012. These batteries are the most inexpensive and they require little maintenance; however, they have limited power and specific energy, 40 Wh/kg and 350 W/kg respectively. The average lifespan of these batteries is one of its limitations, being it about 500 charge/discharge cycles.

Faia [25] discusses that the type of battery which has appeared most promising in recent years has been the

Graph 1.Evolution of batteries.

Graph 2. 1st cycle―electric vehicles (1837-1912).

Graph 3. 2nd cycle―electric vehicles (1912-1973).

Graph 4. 3rd cycle―electric vehicles (1973-1996).

Graph 5.4th cycle―electric vehicles (1996 to present).

lithium (Li-ion) ion. This battery, used intrinsically in the 4th cycle, has a specific energy of over 150 Wh/kg and specific powers that can go up to 2000 W/kg. Its lifespan is about 1200 charge/discharge cycles. The disadvantages of this type derive from the fact that batteries require a precise charging system due to its low tolerance for peak power and are still relatively expensive for pure electric vehicles.

A solution to the inflexibility of the batteries’ autonomy has been presented by Andersen et al. [26] , being implemented in Israel. The core of this proposal is the separation of the properties of the car and of the battery. A company would be responsible for assuming the risk of ownership of the batteries, which would be leased. The consumer would be charged for the energy they consume over the kilometers traveled. This is analogous to the collection of minutes used by mobile phone operators. Consumers would have a number of “packages” available, which will depend on the battery usage profile.

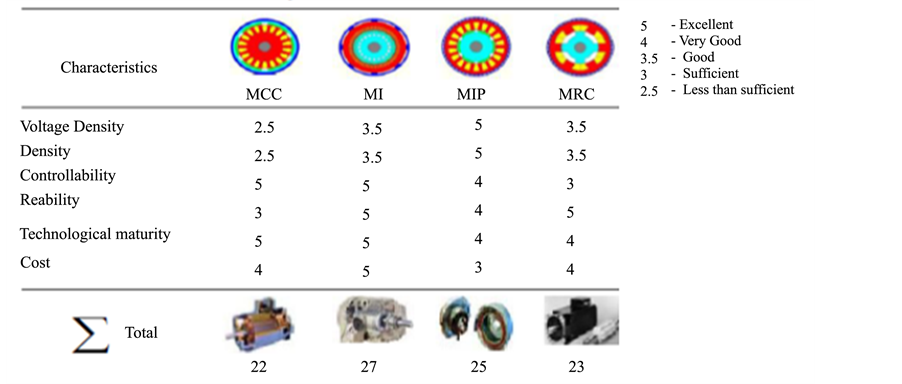

In this aspect, the main types of motors used in electric vehicles are: Continuous Current Motor (MCC), or Asynchronous Induction Motor (IM), Permanent Magnet Synchronous Motor (IPM) and Switched Reluctance Motor (MRC). In Figure 2 one can see the qualitative assessment of various engine characteristics, with the objective of identifying the technologies that would have the best performance in the electric car applications according to Zeraoulia, Benbouzid and Diallo [27] .

It is possible to compare the total ratings of the characteristics of the different propulsion systems listed in Figure 2, allowing us to infer that the MI OE MIP are the most suitable for electric vehicles. Thus, from the 4th cycle to the IPM motor cycle, this type of vehicle has currently become more solicited because of its gains in density, its efficiency and its cost.

Figure 2. Matters of electric motor selection drive for HEV propulsion systems: a comparative study.

8. Conclusions and Final Thoughts

The analysis in the context of this study points to the vulnerabilities and potentialities that derive from the introduction of electric vehicles (EV) in a timeline. In essence, the lithium used properly in the fourth cycle ion shows better results due to its higher specific energy and high energy efficiency maximizing autonomy of 200 km. Moreover, there have been improvements in aerodynamics, engines, and the weight and size of batteries, demonstrating the technical and marketing maturity of the EVs. That is why studies about the logistics of such vehicles in terms of autonomy become intrinsically relevant.

Accordingly, for the first two cycles, specifically in the context of a car, all variables described by means of Tables 1-3 show that the inclusion of these commercially electric vehicles is hindered by the fundamental limitations of batteries as a power source.

Also in relation to energy accumulators, known as batteries, it is valid to emphasize the significant time (6 - 12 pm) they take to be recharged. In contrast, a gasoline tank takes about 2 - 3 minutes to be completed, which means a power flow of an order of 20 - 30 MW during its supply in a gas station―an issue addressed by Hermance and Sasaki [28] .

Undoubtedly, gasoline has become an ideal fuel, but it also has its adversity such as very low efficiency and, in low rpm conditions, the available torque is low. Torque is what determines the acceleration capability; for a conventional car, the combination of the gearbox and the oversizing of the combustion engine―which carries an even greater inefficiency―is what defines this acceleration.

Once again, the main changes that took place, especially in the 3rd and 4th historical cycles of electric vehicles, should be emphasized. They range from the break-up of new technologies to the development of new motors, power converters, battery chargers and energy accumulators.

It is evident that the specific properties of electric vehicles vary according to the battery size and type of vehicle. The same way electric cars need higher specific energy per volume, hybrid vehicles in return require batteries that provide maximum power in the smallest possible size [25] .

In a simplified way, after the energy crisis of 1970 and 1980, and with the significant increase in emissions of Greenhouse Gases (GHG), the revival of the interest in electric vehicles based on energy sources alternative to oil arose, as is corroborated by Tomic and Kempton [23] .

In this sense, the reason why the production of electric cars remains static is related to some indicators such as high production costs―which translate into low penetration―, lack of logistics networks for the vehicles to refuel and unsatisfactory autonomy. This is undoubtedly a worrying factor for the countries, manufacturers and end customers throughout the automotive supply chain.

To firm the findings and considerations of this work, it is important to highlight the studies done by Hall, Reis and Junior [29] -[31] , which have proved that the lithium ion is expected to occupy a prominent place in electric vehicles in the present days. This is due to its higher specific energy in terms of volume and mass, its high energy efficiency (near 100%), its long life cycle (approximately 3000 cycles with a discharge depth of 80%), its low rate of self-discharge, and its lack of memory effect, which decreases battery capacity when it is recharged. Mass production and development of nanostructured materials provide considerable scope for cost savings. We observed their use in large scale from the year of 1996, during the fourth and last cycle analyzed.

Based on the factors put in evidence throughout this work, we point out that the disadvantages of electric vehicles are associated with deficiencies of electrochemical energy storage. Compared to conventional fuels, the battery of electric cars has low specific energy in terms of volume and mass and low rate of refueling/recharging. These questions are well evaluated by Bradley e Frank [32] .

Additional considerations need to be brought up with respect to another aspect that should receive attention in EVs. One of them is associated with the use of electricity by the transportation sector. The introduction in scale of EVs comes with an increase in electricity demand and the possible need for increased capacity to generate electricity. More than that, the penetration of electric vehicles in the electrical system can cause overload on transformers and distribution lines, as well as―mainly depending on the timing and form of clearance―over- shoot in the electrical system. These aspects of the electrical system are also put in evidence by Kiviluoma and Meibom, Hadley and Tsvetkova, Green II et al., Lin et al. [33] -[36] , among others.

Finally, it is concluded from the results, based on the four cycles presented here, that the inverters have improved over the years. We highlight that in old electric vehicles’ DC, there was the need for a transmission to enable reverse driving (rear gear), but this is no longer needed.

References

- Brown, L.R. (2003) Eco-Economy: Building and Economy to Earth. Publicado no Brasil pela Universidade Livre da Mata Atlântica (UMA), Primeira Edição, 368 p.

- Pecorelli Peres, L.A. (2003) Electric Vehicles: Environmental and Energy Benefits. Rio de Janeiro and Cultural Research Noel Rosa.

- Ministry of the Environment (MMA) (1999) Inspection Program Evaluation and Maintenance of Vehicles in Use in Rio de Janeiro. Document Prepared by the partnership LIMA (Interdisciplinary Laboratory Ministry of the Environ- ment (MMA). COPPE/UFRJ as Part of the Project “Air Quality Management in Major Metropolises Brasileiras” under the Third Amendment to the Agreement MMA/Foundation COPPETEC 1999-CV-000054.

- Campi, T.M., Rutkowski, E. and Lima Jr., O.F. (2004) Sustainability of Transportation Techniques. UNICAMP, Campinas.

- Braga, A., Pereira, L.A.A. and Saldiva, P.H.N. (2002) Pollution and Its Effects on Human Health. Seminar on Sustainability in Energy Generation and Use, UNICAMP, Campinas, 20 p. http://www.bibliotecadigital.unicamp.br/

- Delucchi, M.A. and Lipman, T.E. (2010) Lifetime Cost of Battery, Fuel-Cell, and Plug-In Hybrid Electric Vehicles, Chapter 2. In: Pistoia, G. and Elsevier, B.V., Eds., Electric and Hybrid Vehicles: Power Sources, Models, Sustainability, Infrastructure and the Market, Elsevier, Amsterdam, 19-60.

- Bottura, C.P. and Barreto, G. (1989) Electric Vehicles. UNICAMP, Campinas.

- Larminie, J. and Lowry, J. (2003) Electric Vehicle Technology Explained. John Wiley and Sons Ltd., Chichester.

- Baran, R. and Legey, L.F.L. (2011) Electric Vehicles: History and Prospects in Brazil. BNDES, 33, 207-224.

- Hoyer, K.G. (2008) The History of Alternative Fuels in Transportation: The Case of Electric and Hybrid Cars. Utilities Policy, 16, 63-71. http://dx.doi.org/10.1016/j.jup.2007.11.001

- Peças Lopes, J.A., Soares, F.J., Almeida, P.M. and Moreira da Silva, M. (2009) Smart Charging Strategies for Electric Vehicles: Enhancing Grid Performance and Maximizing the Use of Variable Renewable Energy Resources. EVS24, Stavanger.

- Schiffer, M.B. (2010) Taking Charge―The Electric Automobile in America. Smithsonian Institution Press, Washing- ton DC.

- Struben, J.R. and Sterman, J. (2006) Transition Challenges for Alternative Fuel Vehicle and Transportation Systems. MIT Sloan Research Paper. http://ssrn.com/abstract=881800

- DOE (2012) Department of Energy, Energy Efficiency and Renewable Energy. History of Electric Vehicles. http://www1.eere.energy.gov/vehiclesandfuels/avta/light_duty/fsev/fsev_history.html

- Anderson, C.D. and Anderson, J. (2010) Electric and Hybrid Cars: A History. 2nd Edition, McFarland & Company, Inc., Jefferson.

- Yergin, D. (1991) The Prize: The Epic Quest for Oil, Money, and Power. Free Press, Nova Iorque.

- Valle Real, M. and Balassiano, R. (2002) Identify Priorities for Aadoção Mobility Management Strategies: The Case of Dobrio City January. Proceedings of the 10th Congress of Research and Training in Transportation, ANPET, Natal. http://www.ivig.coppe.ufrj.br/ivig/Paginas/teses-dissertacoes-artigos.aspx

- Faia, S.M.R. (2006) Optimization of Vehicle Propulsion Systems for Fleet. Thesis of M.Sc., Instituto Superior Técnico, Lisboa.

- ANFAVEA (2011) National Association of Automobile Manufacturers, Statistical Yearbook of the Brazilian Automotive Industry.

- Dijk, M. and Yarime, M. (2010) The Emergence of Hybrid-Electric Cars: Innovation Path Creation through Co-Evo- lution of Supply and Demand. Technological Forecasting and Social Change, 77, 1371-1390. http://dx.doi.org/10.1016/j.techfore.2010.05.001

- IEA (2011) International Energy Agency, Technology Roadmap: Electric and Plug-In Hybrid Electric Vehicles.

- Dettmer, R. (2001) Hybrid Vigour. IEE Review, 47, 25-28. http://dx.doi.org/10.1049/ir:20010109

- Tomic, J. and Kempton, W. (2007) Using Fleets of Electric-Drive Vehicles for Grid Support. Journal of Power Sources, 168, 459-468. http://dx.doi.org/10.1016/j.jpowsour.2007.03.010

- Kramer, B., Chakraborty, S. and Kroposki, B. (2008) A Review of Plug-In Vehicles and Vehicle-to-Grid Capability. National Renewable Energy Laboratory, 1617 Cole Blvd., Golden, CO 80401, USA.BEV-HEV-PHEV-FCEV.

- Broussely, M. (2010) Chapter 13―Battery Requirements for HEVs, PHEVs, and EVs: An Overview. In: Pistoia, G. and Elsevier B.V., Eds., Electric and Hybrid Vehicles: Power Sources, Models, Sustainability, Infrastructure and the Market, Elsevier, Amsterdam, 305-345. http://dx.doi.org/10.1016/B978-0-444-53565-8.00013-0

- Andersen, P.H., Mathews, J.A. and Rask, M. (2009) Integrating Private Transport into Renewable Energy Policy: The Strategy of Creating Intelligent Recharging Grids for Electric Vehicles. Energy Policy, 37, 2481-2486. http://dx.doi.org/10.1016/j.enpol.2009.03.032

- Zeraoulia, M., Benbouzid, M.E.H. and Diallo, D. (2010) Electric Motor Drive Selection Issues for HEV Propulsion Systems: A Comparative Study. http://hal.inria.fr/docs/00/53/33/62/PDF/IEEE_VPPC_2005_ZERAOULIA.pdf

- Hermance, D. and Sasaki, S. (1998) Hybrid Electric Vehicles Take to the Streets. IEEE Spectrum, 35, 48-52. http://dx.doi.org/10.1109/6.730520

- Hall, P.J. (2008) Energy Storage: The Route to Liberation from the Fossil Fuel Economy? Energy Policy, 36, 4363- 4367. http://dx.doi.org/10.1016/j.enpol.2008.09.041

- Reis, N.A.O. (2008) The Hybrid Car as a Supplier-Consumer Element of Electricity-Battery Modeling. M.Sc. Thesis, IST University, Lisbon.

- Junior, A.R.P. (2002) Regulation of Energy Demand in a Propulsion System for a Hybrid Electric Vehicle Series. M.Sc. Thesis, UFRGN, Natal.

- Bradley, T.H. and Frank, A.A. (2009) Design, Demonstrations and Sustainability Impact Assessments for Plug-In Hybrid Electric Vehicles. Renewable and Sustainable Energy Reviews, 13, 115-128. http://dx.doi.org/10.1016/j.rser.2007.05.003

- Kiviluoma, J. and Meibom, P. (2011) Methodology for Modelling Plug-In Electric Vehicles in the Power System and Cost Estimates for a System with Either Smart or Dumb Electric Vehicles. Energy, 36, 1758-1767. http://dx.doi.org/10.1016/j.energy.2010.12.053

- Hadley, W.S. and Tsvetkova, A. (2008) Potential Impacts of Plug-In Hybrid Electric Vehicles on Regional Power Ge- neration. UT-Battelle, Oak Ridge National Laboratory, Oak Ridge.

- Green II, R.C., Wang, L. and Alam, M. (2011) The Impact of Plug-In Hybrid Electric Vehicles on Distribution Networks: A Review and Outlook. Renewable and Sustainable Energy Reviews, 15, 544-553. http://dx.doi.org/10.1016/j.rser.2010.08.015

- Lin, S., He, Z., Zang, T. and Qian, Q. (2010) Impact of Plug-In Hybrid Electric Vehicles on Distribution Systems. International Conference on Power System Technology (POWERCON), Hangzhou, 24-28 October 2010, 1-5. http://dx.doi.org/10.1109/POWERCON.2010.5666508

NOTES

*Corresponding author.