Modern Mechanical Engineering

Vol.2 No.1(2012), Article ID:17711,5 pages DOI:10.4236/mme.2012.21001

Research on Lubrication Model of Rock Bit Bearings with Non-Newtonian Medium*

State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation, Southwest Petroleum University, Chengdu, China

Email: #wanggr@swpu.edu.cn, kuenwong@126.com, zhonglin858296@163.com

Received December 3, 2011; revised December 28, 2011; accepted January 8, 2012

Keywords: Journal Bearing; Rock Bit; Lubrication Model; RB Grease

ABSTRACT

Lubrication media of rock bit journal bearing is non-Newtonian fluid, and because of structure limitations, lubricant supply is only from the inside track and its rheological properties are relatively complex. In general studies, the nonNewtonianism of lubrication media of rock bit journal bearing is neglected to simplify the research process. Based on the universal Reynolds equation of non-Newton media, the mathematical model of lubrication analysis was suitable for the rock bit bearing working conditions was established. Then according to the experimental results of rheological properties of RB-type lubricating grease, the equivalent viscosity of the model was established and this model can be solved by the method used in solving the Reynolds equation of Newton fluid.

1. Introduction

In the complicated working conditions and special environment of rock bit bearings, lubricating oil ,which is commonly called Newtonian fluid ,can’t satisfy the need of lubrication. In order to improve the bearing lubrication performance, people added many additives of long-chain polymer materials in base oil. These additives can decreese sliding frication coefficient, reducing heat and wear, increasing oil viscosity and capacity, but it makes lubricant present non-Newtonian characteristic at different degree, and makes rheological property of lubricants become the noticeable factors of lubrication designs. RB grease used in rock bit bearings is a type of non-Newtonian fluid, because of its complicate rheological property ,the non-Newtonian behavior of rock bit lubrication medium is usually neglected in the general study. The Reynolds equations of non-Newtonian fluid and Newton fluid are unified by two equivalent viscosities [1], a dynamically loaded finite journal plastic bearing lubricated with a nonNewtonian fluid, which account for some non-Newtonian characteristics through an equivalent power-law [2]. A power law model is developed for the elastohydrodynamic lubrication regime. The modified Reynolds equations with elasticity equation were formulated for the elastohydrodynamic journal bearings under heavy load conditions [3]. Non-Newtonian Powell-Eyring fluid as lubricant is presented in an infinite lubricated inclined slider bearing [4]. The apparent viscosity and the performance of 1D slider bearings are analyzed and discussed in a porous media model [5,6]. The performance characteristics of bearing operating with micropolar lubricant are presented and compared with that of Newtonian lubricant, for a wide range of non-dimensional load, capillary restrictor design parameter and micropolar parameters [7]. According to the upper documents .It can be seen that non-Newton media has great influence on lubrication and load carrying capacity of the sliding bearings, so the study of Newton’s media with improvement on lubrication of rock bit bearings is of great significance. In order to greatly accord with actual working condition, the nonNewtonian behavior of the grease should be considered during establishing the lubrication equation of rock bit sliding bearings, which is convenient to deeply study the rock bit sliding bearings. Based on common Reynolds equation of non-Newtonian medium, this paper establish a model of the lubrication analysis, which is suitable for the actual working condition of rock bit bearings, and study its solving method.

2. The Determination on Equivalent Viscosity of Rock Bit Sliding Bearings with Non-Newtonian Medium

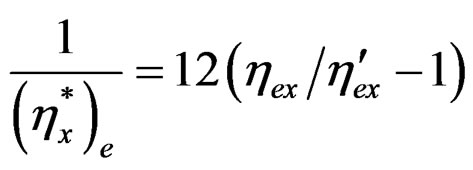

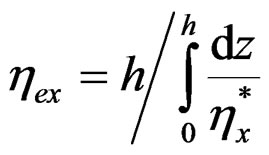

In the lubrication model of rock bit sliding bearings with non-Newtonian medium, the expression of ,

,  and

and  indicates that the final integral results contain clearance function h(x, y), in order to get the expression h(x, y) of clearance function from

indicates that the final integral results contain clearance function h(x, y), in order to get the expression h(x, y) of clearance function from  and

and , the most critical parameters—equivalent viscosity

, the most critical parameters—equivalent viscosity

, the equivalent viscosity under working conditions of rock bit sliding bearings will be confirmed in this paper.

, the equivalent viscosity under working conditions of rock bit sliding bearings will be confirmed in this paper.

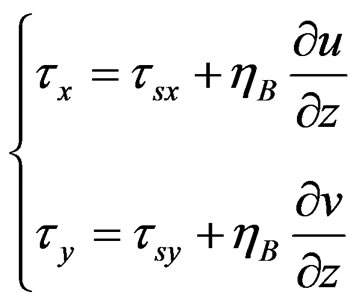

The RB grease constitutive equation of rock bit is:

(1)

(1)

About Equation (1), Thereinto,  is shear stress,

is shear stress,  is Bingham viscosity,

is Bingham viscosity,  is ultimate shear stress.

is ultimate shear stress.

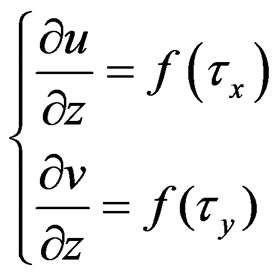

According to the lubrication problem of journal bearing, no matter it is Newtonian rheological model or nonNewtonian rheological model, theirs constitutive equation can be uniformly wrote into the following forms:

(2)

(2)

For Newtonian fluid

(3)

(3)

Therefore, for unifying the flow of non-Newtonian fluid and that of Newtonian fluid, the two equivalent viscosity

only need to be defined:

only need to be defined:

(4)

(4)

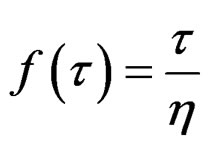

Taking Equation (4) into Equation (2),

(5)

(5)

By Equation (5), equivalent viscosity is equal to the ratio of shear stress and shear velocity with non-Newtonian fluid.

In view of the actual working condition of rock bit, the rheological property of RB grease about rock bit, whose temperature is between 50˚C and 150˚C is carried out the experimental research in the literature [8]. According to the experimental data ,the change rule of shear stress and shear velocity with RB grease was obtained in the above temperature range, for the Bingham law containing two rheological parameters about  and

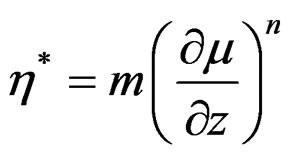

and  Equation (1), in order to simplify the analysis process, applying Newtonian viscous law, showing the viscosity of the nonNewtonian fluid through the ratio of shear stress given shear velocity and shear velocity, it is called the nominal viscosity (or the apparent viscosity) [9], by the parameter estimation method, the fitting equation of nominal viscosity changing with shear velocity, whose temperature ranges from 100˚C to 150˚C, is as follow:

Equation (1), in order to simplify the analysis process, applying Newtonian viscous law, showing the viscosity of the nonNewtonian fluid through the ratio of shear stress given shear velocity and shear velocity, it is called the nominal viscosity (or the apparent viscosity) [9], by the parameter estimation method, the fitting equation of nominal viscosity changing with shear velocity, whose temperature ranges from 100˚C to 150˚C, is as follow:

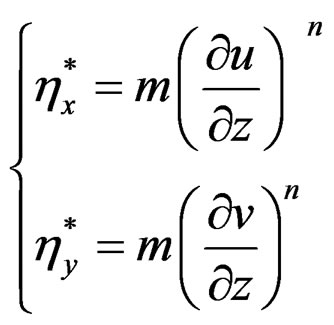

(6)

(6)

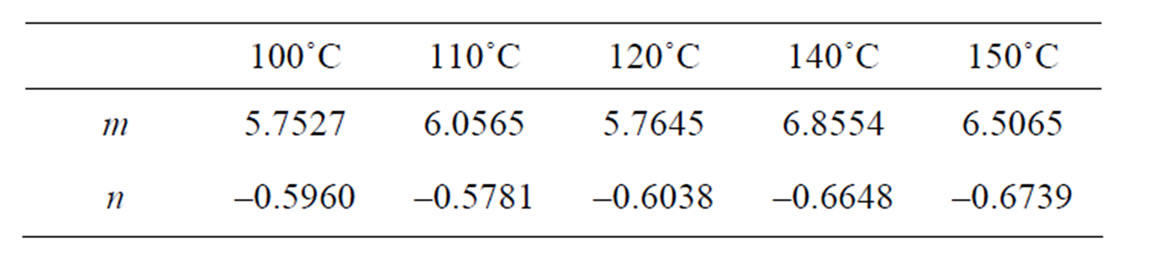

It is known that the nominal viscosity of RB grease and shear velocity become the relation of power exponent in the same temperature,  is the nominal viscosity of RB grease, m n is the fitting parameter, the special data is showed in Table 1.

is the nominal viscosity of RB grease, m n is the fitting parameter, the special data is showed in Table 1.

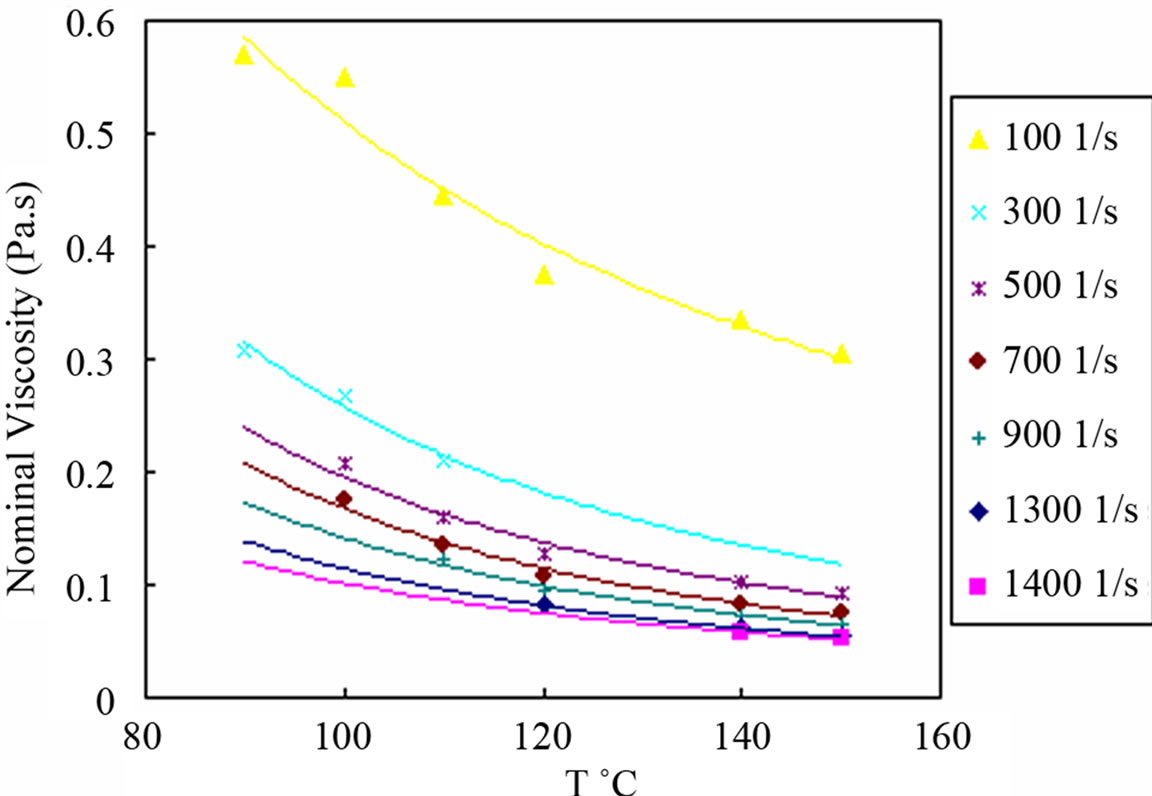

Through the experiment data processing, Regulation that the nominal viscosity of RB grease vary with temperature is as Figure 1, Which show that viscosity of RB grease vary with temperature at different shear rate.

Because the expression of equivalent viscosity is the same as the definition of the nominal viscosity, in order to making the lubrication model more suitable for the actual working condition of rock bit sliding bearing, the nominal viscosity of RB grease is took as equivalent viscosity in this paper, therefore it can be showed in the following:

(7)

(7)

Table 1. The fitting parameters of the relationship between viscosity and shear rate.

Figure 1. The nominal viscosity-temperature curve of RB grease in different shear rate.

The lubrication property under relevant working condition can be analyzed by taking the expression of equivalent viscosity into the lubrication model rock bit sliding bearing with non-Newtonian fluid.

According to the derivation of the lubrication analysis mathematical model of rock bit sliding bearing with nonNewtonian medium, during establishing the model in this paper, it unifies the Reynolds equation with non-Newtonian fluid and the Reynolds equation with Newtonian fluid in the forms, and determines the expression of equivalent viscosity by the previous experimental results, while in solving the lubrication analysis mathematical model of rock bit sliding bearing with non-Newtonian medium, it only need to solve according to the general Reynolds equation with Newtonian fluid.

3. The Lubrication Analysis Mathematical Model of Rock Bit Sliding Bearings with Non-Newtonian Medium

3.1. Hypotheses about Non-Newtonian Medium Lubrication of Rock Bit Sliding Bearings

According to rock bit of special working conditions and RB grease of complicate rheological property, there are some hypotheses about non-Newtonian medium lubrication of rock bit bearings:

1) Ignoring the physical impacts of rock bit and grease. Due to structure limits of rock bit, the size of bearings system is smaller, and the drilling pressure is much bigger during working .Therefore the physical effects can be neglected .

2) Ignoring the influence of grease inertia force. Due to rock bit working in low speed, and viscous force of the grease is smaller than its inertia force, thereby the inertia force can be neglected. These inertia force include the centrifugal force of oil film bend and the force generated by acceleration.

3) The grease flow state is laminar. This paper takes 8 1/2 rock bit for example, its bearing diameter is less than 60 mm, the bearing speed generally ranges from 60 to 200 rpm, its working state is hard to appear the phenomenon of eddy current and turbulence.

4) Ignoring pressure changes along the thickness direction of lubrication film. In the actual working condition of the rock bit, the bearing load of rock bit bearings is bigger, but the magnitude of the oil film thickness is smaller, thereby there are no apparent changes in the thickness direction.

5) There is no sliding about grease on the surface of the rock bit bearings. According to the motion law of general viscous fluid, the surface velocity of rock bit bearings is the same as that of its oil layer in lubrication state.

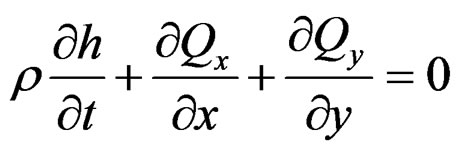

3.2. Mathematical Model of Rock Bit Sliding Bearings with Non-Newtonian Medium

The universal Reynolds equation of non-Newtonian fluid with lubrication mechanics was derived from reference [10], with the boundary conditions of rock bit working conditions’ speed:

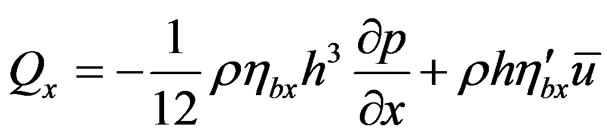

Obtaining that

Obtaining that

(8)

(8)

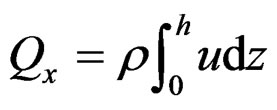

When the rock bit sliding bearings are in work, its pressure are usually less than 300 MPa [11], grease density changes can be neglected in this range, namely the grease is regarded as incompressible fluid in the working conditions of rock bit bearings, the density ρ is constant, fluid mass along X direction can be expressed as

(9)

(9)

Substituted in Equation (8), obtaining that

(10)

(10)

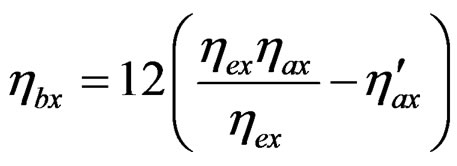

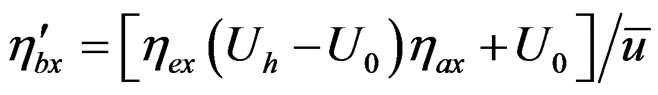

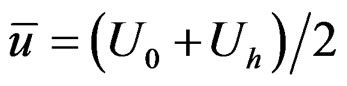

Including

,

,

,

,

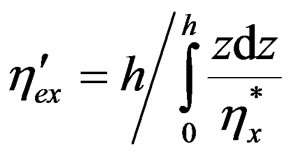

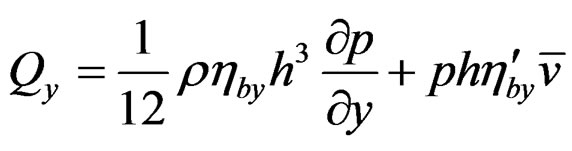

Similarly

(11)

(11)

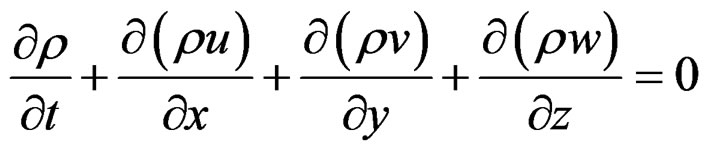

The continuity equation of compressible fluid:

(12)

(12)

Continuity equation of incompressible fluid was obtained as follows:

(13)

(13)

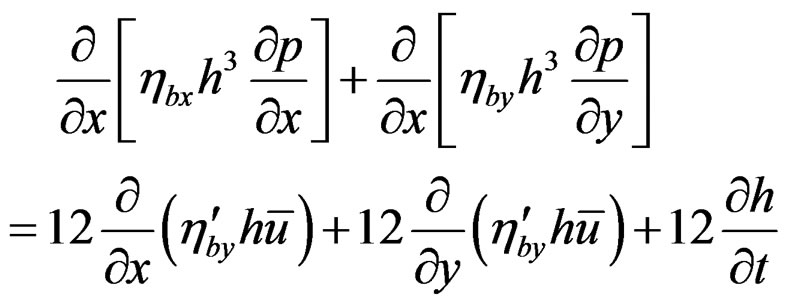

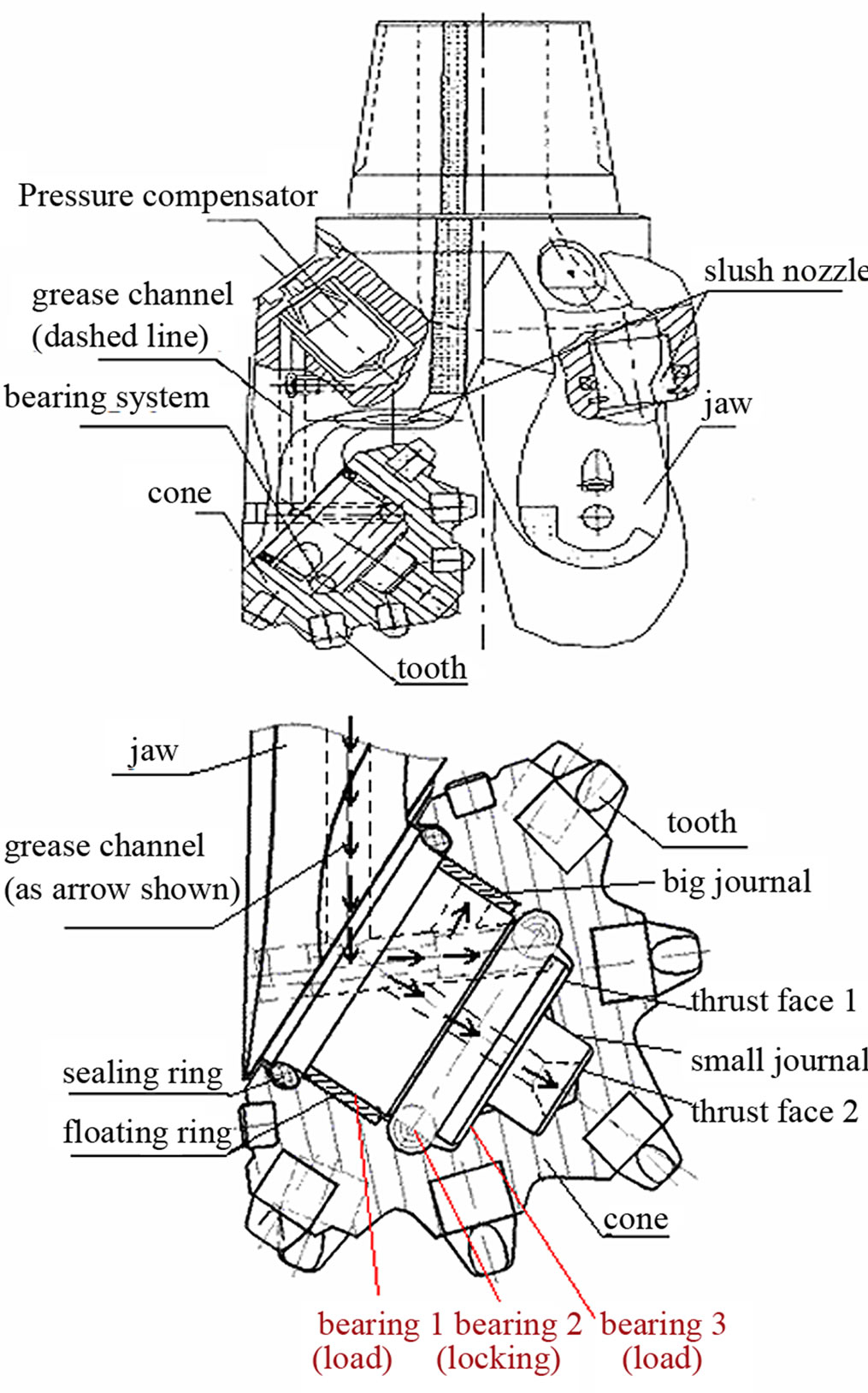

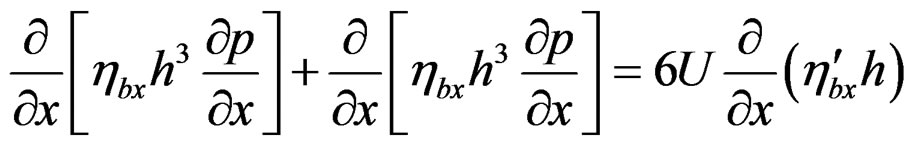

Substituting Equation (10) and Equation (11) into continuation Equation (13), obtaining that

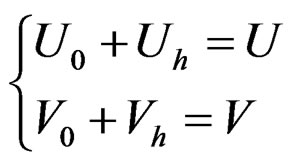

Let be , Then

, Then

(14)

(14)

The Equation (14) is the lubrication analysis mathematical model of rock bit sliding bearings with nonNewtonian medium, for considering the non-Newtonian behavior of lubrication film, involving more parameters with viscosity, making the lubrication model more complex, greatly increasing the solving difficulty. In order to be greatly suitable for the working conditions of rock bit sliding bearings, this paper will simplify the equation.

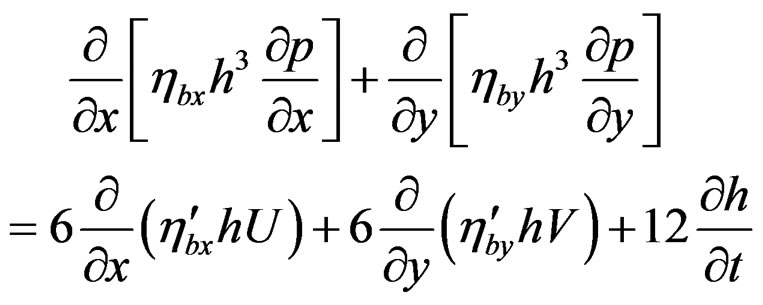

Firstly, according to the structural diagram of rock bit bearing system Figure 2, thrust bearing can prevent the cone from moving in the claw axial, selecting the proper coordinate system, that is, X direction is rotational direction of the bearings; Y direction is the axial direction of the bearings; Z direction is the direction of film thickness, it is considered that velocity is zero along Y direction, simplifying the Equation (14) as follow:

Figure 2. Structural schematic diagram of rock bit and lubrication system of its bearings.

(15)

(15)

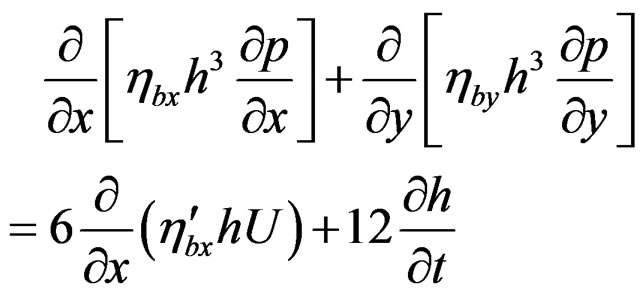

Secondly, the elastic deformation of bearing surface is neglected in this paper, so all the velocity is the same, which is along the rotational direction of bearing surface, that is to say, the circumferential velocity doesn’t vary with X, therefore the Equation (15) is further simplified:

(16)

(16)

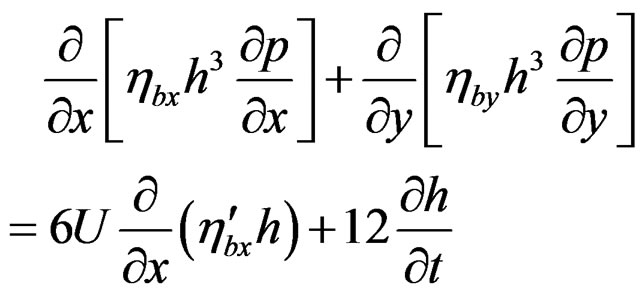

Above the equation, it shows that the force in the oil film thickness direction, which is on the lubrication surface of rock bit sliding bearings, makes the lubrication film thickness thinner, then producing pressure fluxion, it is called extrusion effect. Because the lubrication equation is hard to solve including the extruding terms, the extruding terms is usually not considered in solving, then lubrication analysis mathematical model of rock bit bearings with non-Newtonian medium is finally simplified as:

(17)

(17)

Based on the simplification of the model, the lubricity of rock bit sliding bearings can be analyzed, compared with the result of lubrication model with the general Newtonian medium, through finding the difference between them, it can provide the theoretical basis for structure design of rock bit sliding bearings in the future.

4. Conclusions

1) The studies established the lubrication analysis mathematical model of rock bit sliding bearing with nonNewtonian medium, and the equivalent viscosity of the model was got by the rheological experimental results of RB grease with rock bit, while it simplified the solving process of the equivalent viscosity of lubrication model with the universal non-Newtonian medium.

2) Through unifying the forms about the Reynolds equation with non-Newtonian fluid and the Reynolds equation with Newtonian fluid, the study got a method of solving the lubrication model with non-Newtonian fluid by the Reynolds equation with Newtonian fluid.

5. Acknowledgements

This project was financially supported by the National Natural Science Foundation of China (50905149), and cooperated with CNPC Chuanqing Drilling Engineering Company Limited.

REFERENCES

- Y. L. Fu, P. R Yang and J. Zhu, “A Method and Numerical Simulated Study on the Non-Newtonian Lubrication for Journal Bearing,” Journal of System Simulation, Vol. 15, No. 6, 2003, pp. 902-904.

- T. A. Osman, “Effect of Lubricant Non-Newtonian Behavior and Elastic Deformation on the Dynamic Performance of Finite Journal Plastic Bearings,” Tribology Letters, Vol. 17, No. 1, 2004, pp. 31-40. doi:10.1023/B:TRIL.0000017416.95176.30

- C. Aiumpornsin and M. Mongkolwongrojn, “Influence of Surface Roughness on Elastohydrodynamic Journal Bearings with Non-Newtonian Lubricants,” Advanced Tribology, Part 3, I., 2010, pp. 50-51. doi:10.1007/978-3-642-03653-8_20

- S. Ialam, A. Shah, C. Y. Zhou and I. Ali, “Homotopy Perturbation Analysis of Slider Bearing with Powell-Eyring Fluid,” Zeitschrift für Angewandte Mathematik und Physik, Vol. 60, No. 6, 2009, pp. 1178-1193. doi:10.1007/s00033-009-7034-9

- N. Kousar and S. Liao, “Series Solution of Non-similarity Boundary-Layer Flows over a Porous Wedge,” Transport in Porous Media, Vol. 83, No. 2, 2010, pp. 379-412. doi:10.1007/s11242-009-9450-x

- W.-L. Li, “Derivation of Modified Reynolds Equation: A Porous Media Model with Effects of Electrokinetics,” Journal of Tribology, Vol. 131, No. 3, 2009, Article ID 031701. doi:10.1115/1.3140610

- S. Verma, V. Kumar and K. D. Gupta, “Analysis of Multirecess Hydrostatic Journal Bearing Operation with Micropolar Lubricant,” Journal of Tribology, Vol. 131, No. 4, 2009, Article ID 021103, pp. 1-9.

- G. R. Wang, “Research on Working Mechanism of Rock Bit Floating Ring Journal Bearings,” Southwest Petroleum University, Chengdu, 2004.

- H. P. Jost, “Tribology: The First 25 Years and Byond-Achievements, Shortcomings and Future Tasks,” Industrial Lubrication and Tribology, Vol. 44, No. 2, 1992, pp. 22-27.

- P. R. Yang and S. Z. Wen, “A Generalized Reynolds Equation Based on Non-Newtonian Flow in Lubrication Mechanics,” Acta Mechanica Sinica, Vol. 6, No. 4, 1999, pp. 289-295. doi:10.1007/BF02486885

- K. S. Wu, “Research on Strength of Three-Dimensional Contact Finite Element in Rock Bit Journal Bearing System,” Southwest Petroleum University, Chengdu, 2003.

NOTES

*The project was supported by the National Natural Science Foundation of China (50905149).

#Corresponding author