1. Introduction

Industrial production line is one of the most important processes as it is dependent on the quality of products from manufacturing process. Therefore, the machines used in this process should provide good performance. Appropriate machine alignment and also building construction should be prepared for preventing ground subsidence. However, the most common problem would be the error in machine operation caused by the level of land subsidence in the areas where a number of large and heavyload machines are placed. Generally, the angle can be measured by using several methodologies [1-4]. Angular measurement based on magnetic field method using the HES was the alternative methodology to measure and monitor land subsidence. The measured results were in electrical voltage form obtained from output of HES and then transmitted to computer for real time monitoring and maintaining the appropriate position of the machines.

2. Fundamental Method

2.1. Sensing Part and Error Analysis

HES is a small passive transducer (non-contact sensor) which is applicable in several purposes. The output voltage is generated when the constant current transmitting through a semiconductor namely Hall Generator is diverted [5,6]. In this study, the magnetic density (B) generated by sensing module can be analyzed by Lorenzt force (F) of the magnetic field on an electron (q) when changing the relative angle (q) and v is the velocity of electron due to electric field as given in Equation (1) [7].

(1)

(1)

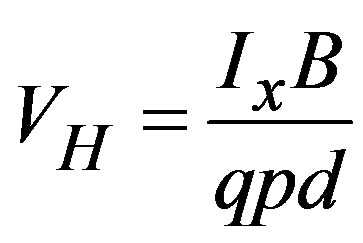

The output voltage from sensing of the HES (VH) as a function of the magnetic density can be calculated by Equations (2) and (3).

(2)

(2)

(3)

(3)

where I is the current flowing through Hall generator on X-axis (A);

is the current flowing through Hall generator on X-axis (A);

B is the density of magnetic field (Tesla);

d is the thickness of Hall generator (mm);

p is the number of holes;

n is the number of electrons.

The evaluation of value from repetitive measurements or random measurements is the estimation of uncertainty in type A standard. The standard deviation (Sd) will be considered as Estimate standard deviation in Equation (4) [8] when n is a great amount, x is the measured value.

(4)

(4)

2.2. Principle of Permanent Magnet

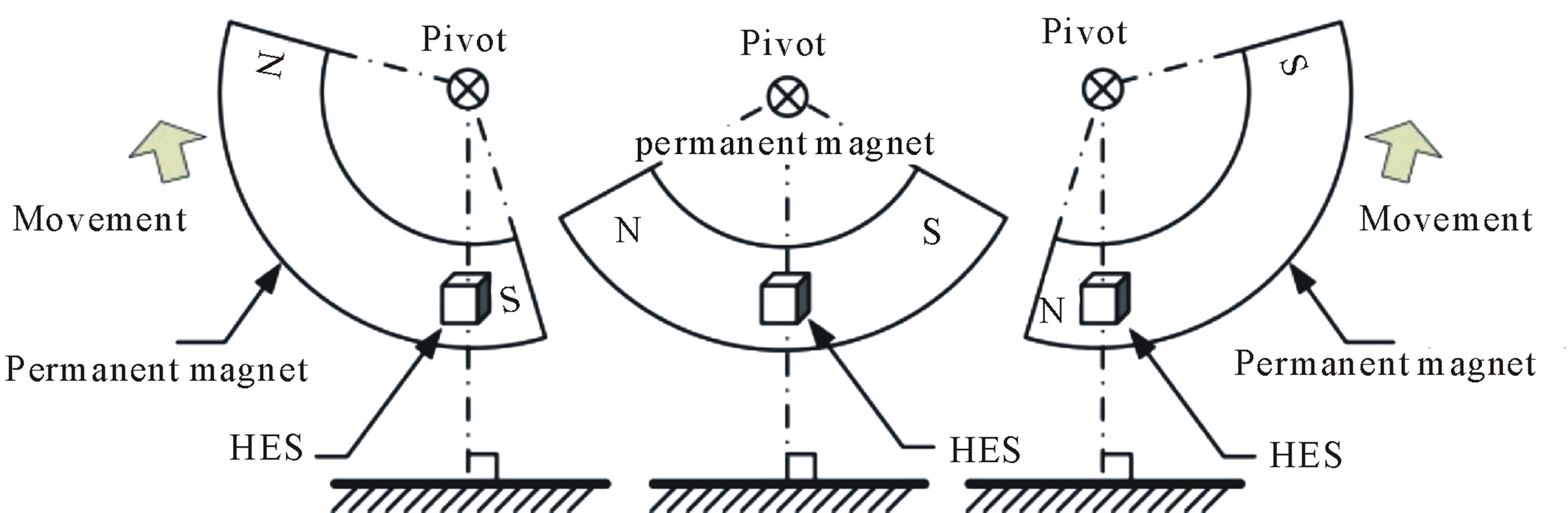

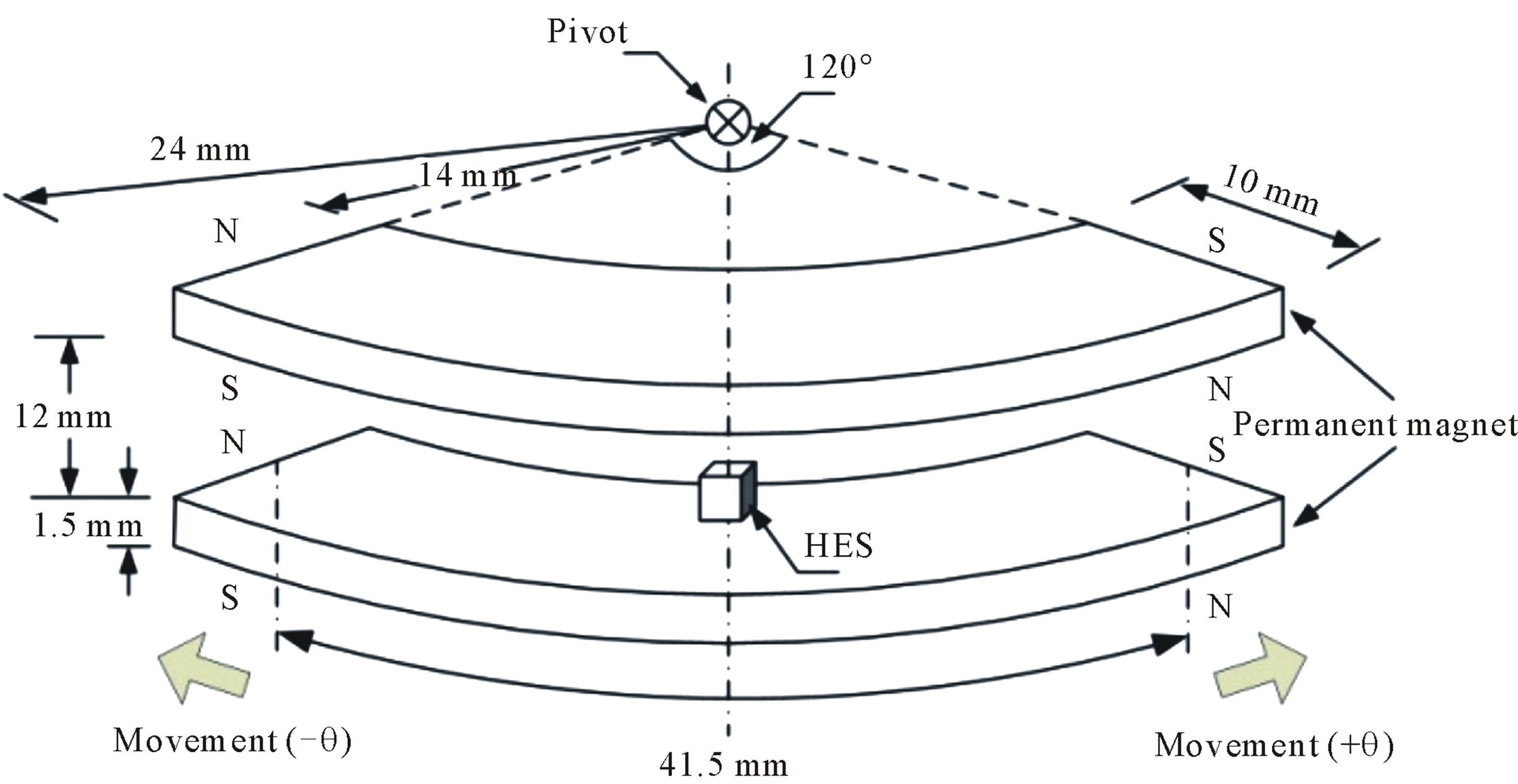

The permanent magnet, ferromagnetic material type, was selected in this study and the maximum magnetic density was 0.25 Tesla. Two flat-curve permanent magnets was 10 mm wide, 1.5 mm thick, and 41.5 mm long. The outer and inner radius was 24 mm and 19 mm, respectively and the plate curve was 120 degree with the distance of 12 mm. The permanent magnet was mounted parallelly and the magnetic poles were placed in position that can generate the magnetic tension force and can provide the widest linearity range of magnetic density field as shown in Figures 1 and 2.

3. Structure of System Developed

The subsidence monitoring system presented in this study was developed by applying magnetic field method. There are three important parts of this system is as following; magnetic Field Generation, measuring system (Land subsidence sensing module) and electrical signal system. Details are as follows:

3.1. Magnetic Field Generation

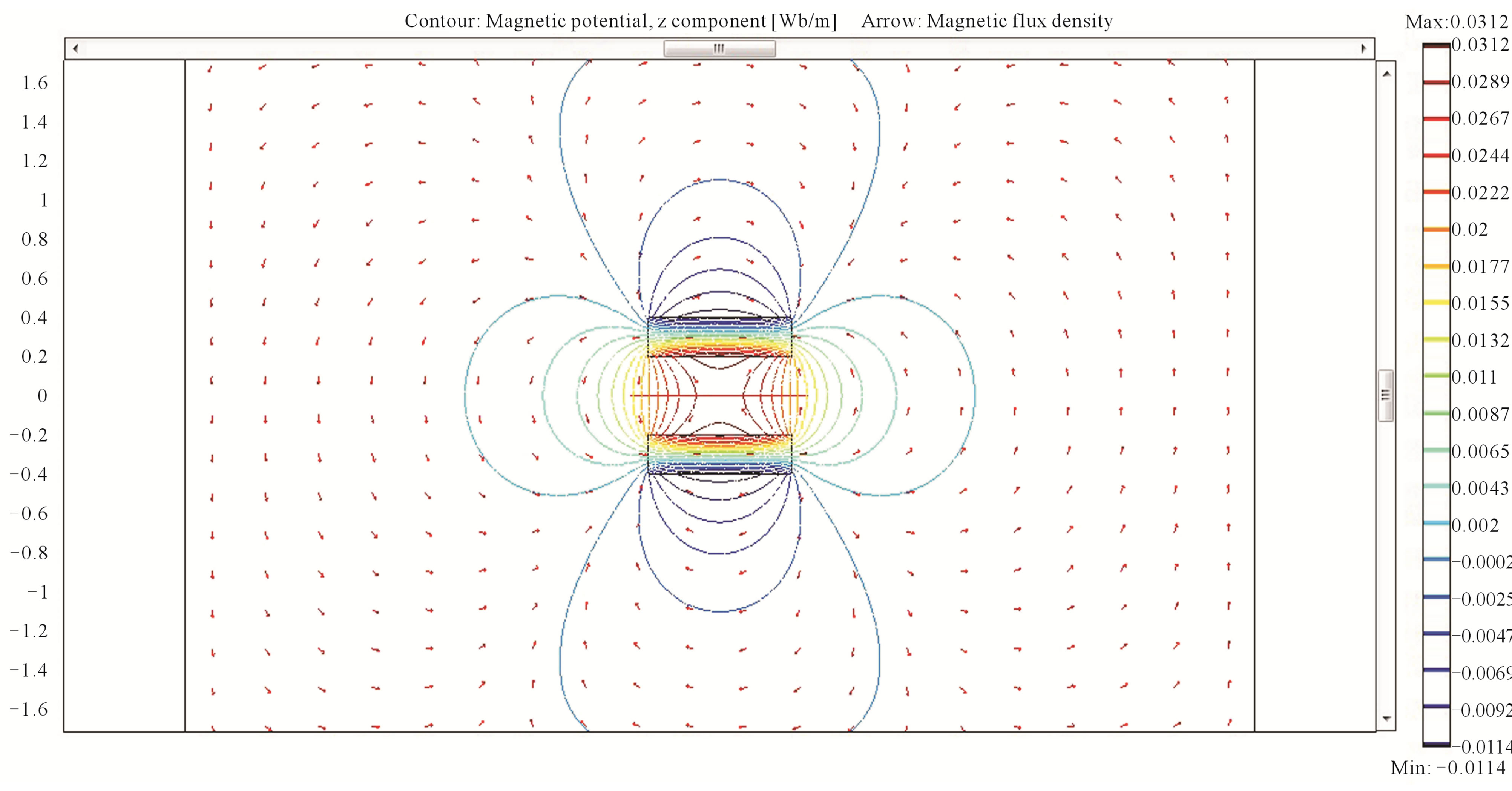

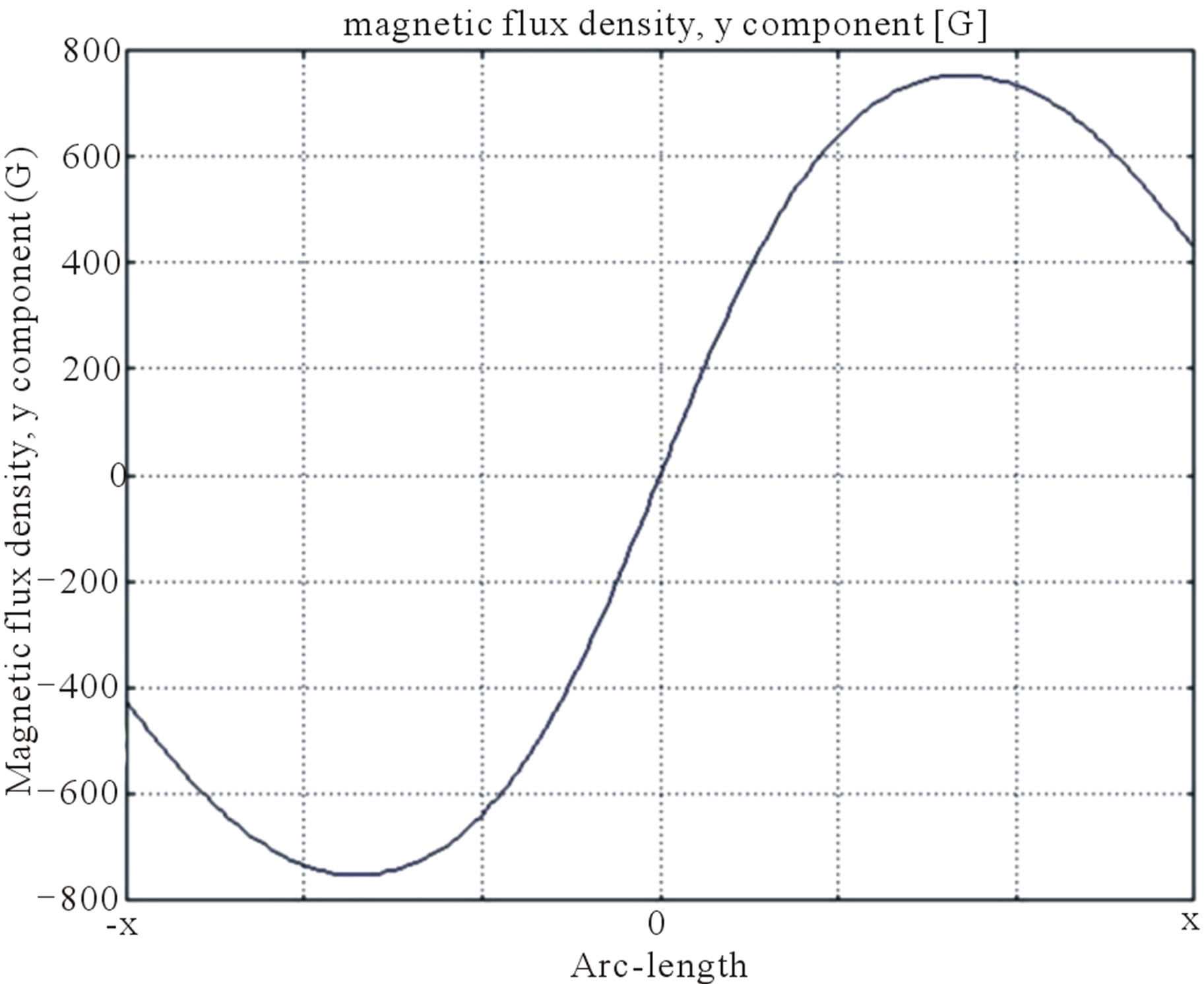

To define the permanent magnet shape for generating the magnetic field, COMSOL software simulation was adopted. The permanent magnets were then positioned to generate magnetic flux in Y-axis direction. Two sets of four magnetic domains (one set consists two domains) were placed alternately in poles as shown in Figure 3. The appropriate gap of two permanent magnets was fixed at 12 mm, which was half the length of the outer radius of permanent magnet (24 mm). The result obtained from simulation is as shown in Figure 4 where Y-axis is the density of the magnetic field and X-axis is the inclination angle within the permanent magnet radius.

Figure 5 shows the direction of the flat-curve permanent magnet movement. The HES was placed at the center of magnets and perpendicular to X-axis. From experiment, the relationship between output voltage from the HES and magnetic field density generated by two flat-curve permanent magnets were observed. The results agree well to the results from calculation using COMSOL software simulation as shown in Figure 6 [9]. It can be noted that when the permanent magnet was moved, the output voltage from HES would be significantly varied

Figure 1. Direction of flat-curve permanent magnet movement.

Figure 2. Structure of permanent magnetic and HES placement.

Figure 3. Characteristic of the magnetic flux was analyzed from the permanent magnet placed alternately in the poles by using COMSOL software simulation.

Figure 4. Wave form of magnetic field using COMSOL software.

at the middle range of permanent magnet. Moreover, it can provide the widest measuring range compared to other different magnet shapes. Therefore, the flat-curve permanent magnet was selected as in this study.

3.2. Land Subsidence Sensing Module

Profile of the measuring system namely Land subsidence sensing module (LSSM) consists of a sensor namely HES [10], placed at the center between two flat-curve permanent magnetic plates with the distance of 12 mm.

At the set point of 0 degree as shown in Figure 7.

Figure 5. Measured range of flat-curve permanent magnet.

Figure 6. Wave form of output voltage and magnetic field from experiment.

From experiment, the Land Subsidence Sensing Module (LSSM) exhibited high accuracy and reliability. The output voltage from inclination of angle experimented was calibrated using high accurate and precious instruments to setup the system developed as shown in Figures 8 and 9.

Figure 9 illustrates the angle calibration due to magnetic field movement. The high accurate and precious instrument (reference scale) for inclined angle adjustment was installed and defines the position of set point at 0 degree.