1. Introduction

While global warming and green house gas effect correspond to a part of issues in the green environmental topics of worldwide. Biodiesel takes a significant role in reducing the accumulation of green house gas and maintain a globally benign environmentally. As vehicle fuel, biodiesel has some benefits due to domestic and renewable resources, also its application without requiring a major modification of engine. In terms of clinical aspects, biodiesel is suitable for environmentally friendly fuels because of there are not any toxic compounds produced during the period of combustion. In this matter, Demirbas [1] reported that the advantages of biodiesel is better quality of exhaust gas emissions, its biodegradability and its contribution to the reduction in carbon dioxide (CO2) emissions.

Most researchers have selected the cheapest and simplest technique of biodiesel production. The others have applied the expensive methods once the untreated oil was used as feedstock of biodiesel. Even though, the economical aspect is highly associated with the technique of biodiesel production. However, the quality of biodiesel should be taken into account when one of techniques is applied as reported by Jain and Sharma [2]. It is due to the process may take place either with catalysts such as alkaline [3], acid [4] and enzyme [5,6] or without catalysts [7]. In an industrial scale, the alkaline catalyst is the most prefer way due to low cost, easy to install and above all, its high reaction rate without requiring a large reactor volume and save the capital of production [8].

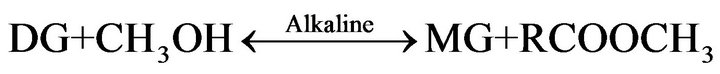

As a rule, the methanolysis process proceeds under three step wise reactions as indicated in Scheme 1. Based on the reaction stoichiometry, one mole of triglyceride requires three moles of methanol to produce three moles of fatty acid methyl esters and one mole of glycerol as shown in Scheme 2.

The nowadays serious problem for biodiesel production is the high price of vegetable oil which leads to a highly expensive of biodiesel product price compared to that of petroleum based diesel product. For anticipating such that situation, many researchers have started to utilize the waste resource based oils as reaction feedstock.

Scheme 1.

Scheme 2.

As Berrios et al. [8] reported that waste cooking oils are good raw material because of their low cost and the environmental advantage of the residue valorisation. Another feedstock which corresponds to bio-based oils is the slaughterhouse waste.

The objective of this study is to synthesize the oil waste into biodiesel and investigate the physicochemical properties of biodiesel product for engine application such as kinematic viscosity, density, flash point, water content, calorific value, iodine value, total acid number (TAN), pour point, and cetane index. The analysis of those properties refers to the standards of ASTM D 6751 [9], where TG, DG, MG, GL, and R denote triglyceride, diglyceride, monoglyceride, glycerol and long hydrocarbon chain.

2. Materials and Methods

2.1. Material

The feedstock employed in this work is waste frying oils that are collected from restaurants and houses. Isopropanol, phenolphthalein and potassium hydroxide are utilized for determining acid values of waste frying oil and the oil after treating. While the sulphuric acid is used for the pre-treatment process, sodium methoxide is used as catalyst in the methanolysis process and methanol is applied for both pre-treatment and methanolysis processes. Ethyl acetate and BSTFA are for gas chromatography sample preparation. The equipments involved are three neck flask, oil bath, graham condenser, thermometer, hot plate complete with stirrer, and other related glass wares.

2.2. Acid Pre-Treatment Process

In this work, the steps of acid pre-treatment (esterification) are carried out. Initial step, the high free fatty acid waste frying oil is poured into the three neck flask (reactor) and heated. The mixing solution of methanol with catalyst (sulphuric acid) is also heated prior to be added into the reactor. After the reaction completing, the products are allowed for 2 h settling down in a separation funnel and then, the methanol-water fraction at the top layer is removed.

2.3. Methanolysis

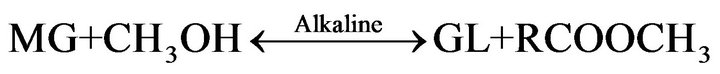

The treated oil is used as the feedstock. Fatty acid composition of the waste frying oil is given in Table 1. The oil needs to be heated after pouring into the reactor prior to the excess reactant and catalyst are added. The reactor is filled up with 150 g of treated oil and heat until 60˚C. Then, the mixture of methanol with catalyst is added at which the reaction is assumed to commence. The flow sheet of completed biodiesel production process is shown in Figure 1.

2.4. Analytical Procedure

The free fatty acids content of the waste frying oil and treated oil is determined using acid base titration technique. A standard solution of 0.1 N alkali solution is used. The titration method is as follows. The specified weight of oil sample is measured in a flask, add 50 ml of isopropanol and thus, shake it gently while titrating with standard alkali to the first permanent pink colour. The colour must persist for 30 seconds.

2.5. Gas Chromatography Analysis

GC (gas chromatography) analysis is performed for identifying the hydrocarbon compounds such as fatty acids and methyl esters. The separation is carried out by using capillary column Rtx-5MS 30 m × 0.25 mm ID, 0.25 μm with helium at 137.7 ml/min as a carrier gas and 1:100 of split ratio.

Table 1. Fatty acid composition of waste frying oils.

Figure 1. Process flow diagram of biodiesel production.

3. Results and Discussion

3.1. Biodiesel Synthesis

The production of biodiesel from triglyceride of waste frying oil takes place slowly at the lower mixing speed (350 rpm). This phenomenon is happened because of the mechanical nature which contributes to the process that is going on ineffectively. However, at higher mixing speeds, the yield of biodiesel increases significantly, in particular at higher of reaction time as shown in Figure 2. It proves that the methanolysis process is extremely affected by the rpm. Also, it can be seen that the reaction is slow during the initial reaction time due to the mixing and excess reactant dispersion with triglyceride (Figure 2). Nevertheless, the reaction yield increased steadily from 30 min of reaction. Especially, at both 400 rpm and 450 rpm of mixing speeds, the yield of methyl ester enhances proportionally. The conversion of waste frying oil triglyceride into valuable methyl ester reached the maximum yield at 50 min of reaction time. The highest yield of biodiesel product obtained in this work is 99%. The similar study has been done by Wang et al. [10] which attained 97% of biodiesel conversion from waste cooking oil. Also, Zhang et al. [11] have conducted the assessment on the technological and process for biodiesel production from oil waste.

3.2. Study on Kinematic Viscosity

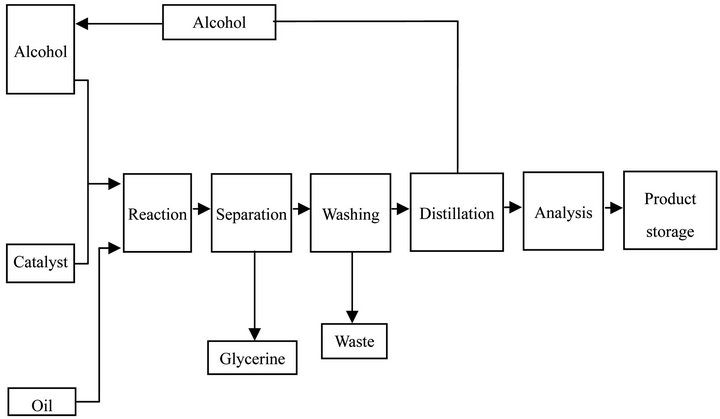

Kinematic viscosity is one of the most effecting parameters on the performance of engine and the emission characteristics [12]. Also, according to Bhale et al. [13], kinematic viscosity is the property of a fluid by virtue of which it offers resistance to flow. In this work, the inves-

Figure 2. The yield of biodiesel at various mixing speeds (rpm).

tigation on kinematic viscosity of biodiesel over rpm is carried out. The findings are reported that the kinematic viscosity of biodiesel declines exponentially at every selected rpm for whole reaction times. Above all, at 30 until 90 min, the slopes appear to be the same (Figure 3), except for 60 min of reaction time, there is a slightly difference of slopes in particular after 350 rpm. In the reality, the kinematic viscosity decreases with increase in rpm of mixing intensity. Therefore, at low rpm, the unsuccessful reaction has caused the biodiesel viscosity still remains at high level. As the engine fuel, according to Heywood [14] and Coulson & Richardson [15], the higher viscosity results in the mixture to burn lean in the engine as fuel moves slowly through the fuel filter and fuel lines. In addition, the higher viscosity of biodiesel fuel causes inadequate atomization and incomplete com-

Figure 3. Effect of rpm on the kinematic viscosity.

bustion.

Although, the mixing intensity is surely increased until 450 rpm, from Figure 3 it can be observed that at 400 rpm and 60 min of reaction time, the feasible kinematic viscosity of biodiesel (4.21 mm2/s) is obtained. The similar study has been carried out by Tesfa et al. [16] using corn oil, rapeseed oil and waste oil as the reaction feedstock. Their findings report revealed that the kinematic viscosity of biodiesel is in the range of 3.55 - 5.48 mm2/s.

3.3. Study on Biodiesel Density

Density of biodiesel is one of specified quality parameters which closely relates to the kinematic viscosity and affects the engine performance. More viscous of biodiesel, higher the density of biodiesel is produced. The density of biodiesel depends on the composition of fatty acid compounds, as Tat and Gerpen [17] reported that densities of biodiesel will vary with the fatty acid composition and their purity. Thus, it leads to a problem for engine combustion which results in coking and trumpet formation on the injectors, carbon deposits, oil ring sticking, thickening and gelling of the lubricating oil [18]. In present study, the correlation between density and rpm is investigated. From Figure 4, it can be seen that the change of biodiesel density at every rpm is significant. However, between 400 to 450 rpm (6.7 - 7.5 Hz), there is not any major change of density for all reaction times. On the other hand, at 300 rpm, especially for 30 min of reaction time, the density of biodiesel is almost close to the density of feedstock. This condition shows that the reaction is not happened completely due to the time constraint.

Many previous works have been done by other researchers on the biodiesel density [19]. But, their find-

ings showed that the density change is linier with the increase of pressure and inversely to the decrease of temperature. The similar study also has been performed by Alptekin and Canakci [12] which obtained that the density of biodiesel is between methanol and fatty acid densities.

3.4. Study of Flash Point

The aim of flash point analysis is to identify the temperature degree of oil to be flammable with air. It is only one of properties which must be considered in assessing the overall flammability hazard of a material [20]. This analysis is very important for the fuel transportation and storage purposes.

The flash point of biodiesel corresponds to both the percentage amount of hydrocarbon saturated compounds and the residual of alcohol. As Jorge et al. [21] reported the high sensitivity of the flash point with respect to the residual alcohol content of the biodiesel is very clear. This study is performed to investigate the effect of viscosity on the flash point of biodiesel. The correlation of viscosity with flash point of biodiesel can be explained by using Figure 5. The results of observation (Figure 5) showed that the flash point increases considerably with enhance the viscosity. The bond appears to be linier. It means that higher the percentage of saturated hydrocarbon compounds, lower the flash point of biodiesel. In terms of safety, the lowest the flash point, a higher cost is necessary for storage system. In this work, a moderate flash point is obtained on the acceptable value of biodiesel viscosity as indicated in Table 2. The similar work has been conducted by Mejía et al. [22], which used the blending of vegetable oil biodiesel with fossil based die-

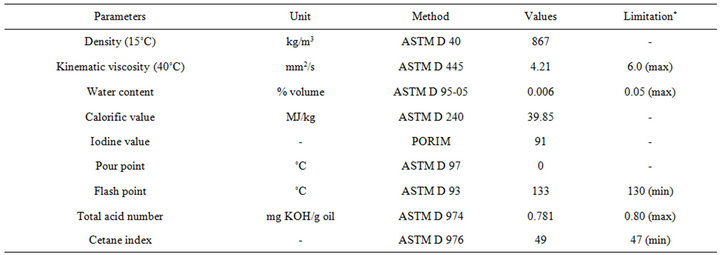

Table 2. Physicochemical properties of waste frying oils based-biodiesel (ASTM D 6751).

*[9].

Figure 5. Flash point of biodiesel over kinematic viscosity.

sel as the analyzed matter.

3.5. Analysis of Physicochemical Characterization of Biodiesel

Since biodiesel as fuel for the engine application, it should meet the standard quality of International specifications. In this work, some physic chemical properties of waste frying oil-based biodiesel are analyzed using ASTM method as shown in Table 2.

Most studies in biodiesel application have been focused on the blending with petroleum-based diesel. In terms of emulsifying, biodiesel is also potentially prone to hydrolytic degradation which is caused by the presence of water [23]. Biodiesel contaminated with water can result in engine corrosion. To avoid this negative effect, ASTM D 6751 set the maximum allowable content of 0.05% for water in biodiesel [24]. Anyway, in this study, the value of water content of biodiesel is very low compared to the minimum standard limitation. In terms of TAN, Fan et al. [24] also reported that TAN is used as a guide in the quality control as well as monitoring oil degradation during storage period. Other physicochemical properties comply with the values of standards specification.

4. Conclusion

This research work, however, employs the optimum condition for methanolysis process namely 1% wt of catalyst, 50 min of reaction time, and a hundred percent of stoichiometric excess of methanol to oil, which is equal to 6:1 molar ratio to obtain the maximum percent conversion of biodiesel production under various reaction temperatures. The highest yield of biodiesel is 99%. The similar condition is also achieved for the kinematic viscosity, density, and flash point studies. The entire analyzed physicochemical properties of product showed that the biodiesel properties favour the commercial requirements, in particular for diesel engine application.

5. Acknowledgements

The authors acknowledged all parties which contributed in this research work, and a special thank for PT. Arun NGL management which has allowed the authors for using the lab facilities in conducting some analysis of biodiesel properties.

NOTES