Study of Material Evaluation Probe Using a Longitudinal Wave and a Transverse Wave ()

1. Introduction

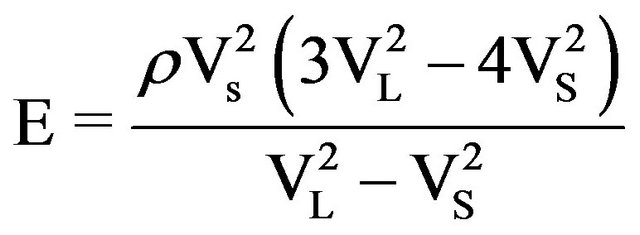

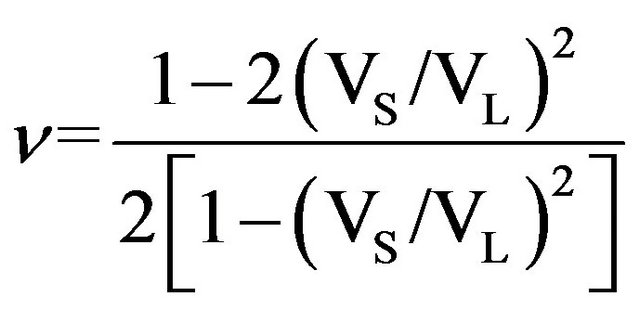

For the NDT and SHM in the composite material industry, it is crucial to know the elastic properties such as Young’s modulus, shear modulus, Poisson’s ratio anisotropy, texture or stress. Ultrasonic techniques are often used to evaluate or nondestructively characterize such properties. Since many parts or structures are subject to high temperature, it is of interest and sometimes even mandatory to characterize their properties at high temperature [1-3]. Thus ultrasonic testing at high temperature has become important. The Young’s modulus E, shear modulus μ and Poisson’s ratio v of an isotropic material can be obtained knowing the longitudinal wave velocity VL and transverse wave velocity VS. Their relations are given in Equations (1)-(3), respectively.

(1)

(1)

(2)

(2)

(3)

(3)

Where E, Young’s modulus, is the ratio of the applied longitudinal stress to the longitudinal strain when a rod is subjected to a uniform stress over its end planes and its lateral surface is free to expand. Where μ, the shear modulus, is the ratio of the transverse stress to transverse strain. Where v, Poisson’s ratio, is the ratio of the lateral contraction (expansion) to the longitudinal extension (contraction) of the rod.

2. Concept of Trial Ultrasonic Probes Using a Bar Wave and a Transverse Wave

Figure 1 shows the generating principle of a bar-wave. If a biased magnetic field by a magnet and high frequency induced magnetic field by an electromagnetic-induced

(a) (b)

(a) (b)

Figure 1. robe using bar wave. (a): Drive principle; (b): Outline the Probe.

coil is produced in the long direction of the shaft part of a trial probe, an induce vibration by a Magnetostrictive effect on the surface is introduced. It will be converted into a bar wave, which is a kind of ultrasonic wave, if the diameter is enough small. The vibration of this bar wave serves as a compressional wave and converts into a longitudinal wave at the step part of the trial ultrasonic probe, and it crosses the probe [4]. An EMAT for the traverse wave was installed on the top surface of the trial ultrasonic probe and injects a transverse wave into the probe. It crosses the probe.

Finally, the simultaneous transmission and reception of the longitudinal wave and transverse wave is performed by combining the two kinds of generating procedures.

Figure 2 shows the generating principle of a transverse wave which crosses a specimen in the thickness direction by an electromagnetic acoustic wave transducer (EMAT). An EMAT consists of a magnet and an electromagnetic induction coil. It generates a magnetic field and high frequency electric current on the surface of the specimen. It then generates a Lorentz force in the horizontal direction on the surface which changes the direction according to the high frequency electric current in the induction coil. It converts to a transverse wave which crosses the specimen in the thickness direction [5,6].