Apparent Viscosity of a Skim Milk Based Dessert: Optimization Through Response Surface Methodology ()

1. Introduction

Consumption of foods containing saturated fat is considered to contribute to the development of heart diseases and colon cancer [1,2]. In addition, reduction in the release of flavors, a severe technological limitation, has been associated with the presence of high fat contents in foods such as ice creams and custards, which are semi-solid, typically whole or semi-skimmed milk dairy desserts [3-5]. Therefore, new food systems presenting lower saturated fat content have been proposed [6-8]. Semi-solid dairy desserts are foods with high sensory appeal, usually containing fat milk, thickeners, sucrose and a flavoring agent [9,10].

Recent studies have investigated the rheological behavior of combinations of semi-solid polysac-charide mixtures and dairy products. For example, the addition of λ- carrageenan resulted in an increment in viscosity of semi-solid dairy desserts, and, most of the resulting products presented a clear gel-like behavior [11].

Creaminess, a sensory feature also known as creamy mouthfeel, is a very important attribute of semi-solid dairy desserts [12]. And, for model caramel creams containing various levels of dairy fat and xanthan gum, a positive quadratic relationship between creaminess and apparent viscosity was demonstrated [13]. In addition, in starch-based custard desserts, creaminess has been demonstrated to be determined by its lubricant properties, homogeneity and apparent viscosity [14]. Furthermore, a sensory panel aimed at evaluating butter-in-water emulsions confirmed that apparent viscosity strongly influences the consumer perception of creaminess. When seen together, data from rheological and sensory analysis suggest that the viscosity of the continuous phase is the dominating attribute controlling the perceived creaminess [15]. These findings demonstrated that rheological parameters might be useful for initial screening of custards for better texture [16].

In this work, we describe the use of response surface methodology to optimize the apparent viscosity of a semi-solid skim milk-based dessert, aiming to improve creaminess, a key-sensory attribute of dairy desserts.

2. Materials and Methods

2.1. Materials

The following ingredients were used for the preparation of the semi-solid dairy dessert: UHT (Ultra High Temperature) skim milk (Parmalat, Carazinho, Brazil); sucrose, (Copersucar, São Paulo, Brazil); cross-linked waxy maize starch (Amysol® 700, Corn Products International, Westchester, IL, USA), κ-carrageenan and guar gum (Doce Aroma Comercial Ltda, São Paulo, Brazil). Citric acid and sodium bicarbonate (Labsynth, Diadema, Brazil) were used for pH adjustment and potassium sorbate (SigmaAldrich, Saint Louis, MO, USA) was used as a food preservative.

2.2. Methods

2.2.1. Dessert Preparation

Carrageenan, guar gum, sucrose, citric acid and sodium bicarbonate (for pH adjustment) were used according to the experimental design, reported below. Modified starch and potassium sorbate concentrations were set, for all formulations, at 3.25% (w/w) and 0.04% (w/w), respectively [11]. After stirring the ingredients until complete homogeneity, citric acid or sodium bicarbonate was added to the mixture in order to reach the desired pH. The formulations were individually pasteurized at 74 ± 2˚C for 15 s. Then, the desserts were stored at 4 ± 1˚C, for six hours, before the apparent viscosity measurements.

2.2.2. Apparent Viscosity Measurements

The apparent viscosity of the desserts was measured at 4 ± 1˚C through the use of a rotational viscometer (DV II + LV, Brookfield, Middleboro, MA, USA), equipped with a LV4 spindle. Measurements were carried out at fourteen angular speeds of the viscometer spindle, ranging from 1.5 to 100.0 rpm.

The angular speeds of 2.5, 5.0, 10.0, 20.0, 50.0 and 100.0 rpm were used together with the correspondent apparent viscosity measurements in order to generate the values of shear rate, shear stress and flow behavior index of the formulations. A fixed volume (300 mL) of each sample was used for the apparent viscosity measurements in a 600 mL beaker [17].

2.2.3. Experimental Design

A four factors-five levels response surface Central Composite Design, which resulted in twenty six formulations, was used in this trial. The response surface methodology was chosen in order to optimize the levels of the independent variables (factors) that provided the desired values for the dependent variable (response) [18]. The chosen factors were carrageenan, guar gum and sucrose concentration, and pH. The levels of the factors were chosen according to the recommendations of the manufacturers, in the case of the two gums, and according to previously reported studies on dairy desserts, in the case of sucrose and pH [19,11,4]. The average apparent viscosity found in this study for regular (whole or semi-skimmed milk-based) commercially available semi-solid dairy desserts (Table 2) was used as a target to be achieved for our dairy dessert. Table 1 shows the five levels chosen for each of the four independent variables of the Central Composite Design.

The effect of the factors used in this work on the apparent viscosity were fitted by polynomial models. In order to describe the effects of the several factors on the apparent viscosity, response surfaces were developed

Table 1. Description of the factors used in this work, along with their respective levels.

Table 2. Apparent viscosity and thickeners used in commercial samples used as a reference for the optimization of the apparent viscosity of the formulated dessert.

considering two of the independent variables constant at the central level of the central composite design. The generated mathematical model was submitted to analysis of variance and effects estimation using a 5% confidence level (Statistica version 7.0, Statsoft, Tulsa, OK, USA).

3. Results and Discussion

The apparent viscosities of eight commercially available semi-solid dairy desserts and their respective thickening agents were evaluated (Table 2). The apparent viscosity of these desserts ranged from 15.4 to 68.9 Pa.s, with an average of 44.4 ± 17.6 Pa.s. This average value was used as target for apparent viscosity for our dessert. Five out of eight of the commercially available semi-solid dairy desserts evaluated were gelified/thickened by a combination of modified starch, carrageenan and guar gum. The addition of modified starches to semi-solid foods, in combination with other types of thickeners, has been widely used because the enzymatic breakdown of starch by salivary amylase has been demonstrated to reduce creaminess of semi-solid foods [20,12]. Guar gum is a cheap, broadly used source of food thickener. It consists of a commercial hydrophilic polymer, structurally described as l-4-linked β-D-mannopyranosyl backbone partially substituted at O-6 with α-D-galactopyranosyl side groups, obtained from seeds of Cyamopsis tetragonolobus L. Taub. Guar gum is essentially a galactomannan with a mannose/galactose ratio of 1.6:1 [21]. Carrageenan, another hydrocolloid, is typically used as a thickener in dairy desserts, in combination with starch. Carrageenan consists of a linear sulphated polysaccharide, namely O-β-D-galactopyranosyl-4-sulfate-(1-4)-O3,6-anhydro-α-D-galactopyranosyl-(1-3), obtained from red seaweeds [9,11,4,5]. Upon heating and subsequent cooling, κ-carrageenan forms thermoreversible gels in the presence of gel-promoting cations [22]. In dairy desserts, κ-carrageenans complex with κ-casein micelles of milk generating a thickening effect of 5 to 10 times greater than its effect in water. Carrageenan is a good substitute for fat in dairy products, once it maintains softness in these food systems [23,24].

Figure 1 shows the relationship between the calculated shear rate and shear stress for the twenty six desserts formulated in this work. All of the formulations prepared in this trial presented behavior typical of non-Newtonian fluids, i.e., the relationship between shear rate and shear stress was not linear [25]. This finding agrees with previously reported studies in which whey-enriched [26] and semi-solid [27] dairy desserts showed features of non-Newtonian fluids. In addition, our desserts presented a shear-thinning or pseudoplastic nature, as it had been previously observed for corn starch-galactomannan combinations, where the observed pseudoplasticity was at

Figure 1. Shear rate versus shear stress for the 26 formulated desserts.

tributed to the waxy nature of the employed starch [28]. Recently, the apparent viscosity of combinations of starch and fenugreek, another source of galactomannan, was also shown to present shear-thinning behavior [29].

In this work, the response surface methodology was used to predict the effects of the four studied factors, namely carrageenan, guar gum and sucrose concentrations, and pH on the apparent viscosity of the skim milk dessert. The general form of the second-order mathematical model that provided the best fit, based on the R2 value, was

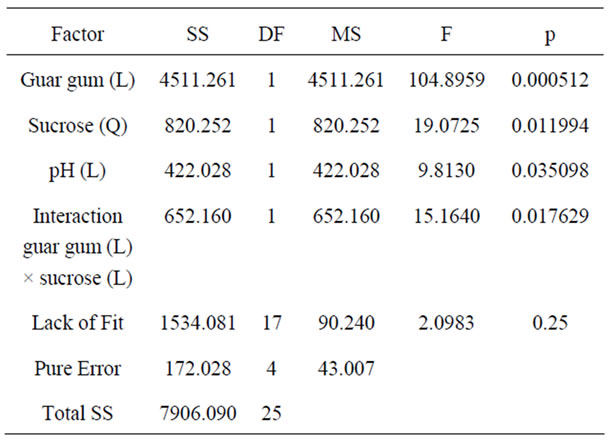

where Y is the dependent variable; β0 is a constant value; X1, X2, X3 and X4 represent the levels of the factors; β1-β14 represent the estimated coefficients; and ε is a random error. The model was associated with an R2 of 0.784. The best fit for the influence of the factors on the response was observed for the apparent viscosity measured at the angular speed of the viscometer spindle of 4 rpm. Analysis of variance for the model is shown on Table 3. Except for the carrageenan concentration, all of the factors investigated were found to be significant at p = 0.05, i.e., guar gum and sucrose concentration and pH, all affected the apparent viscosity of the dessert.

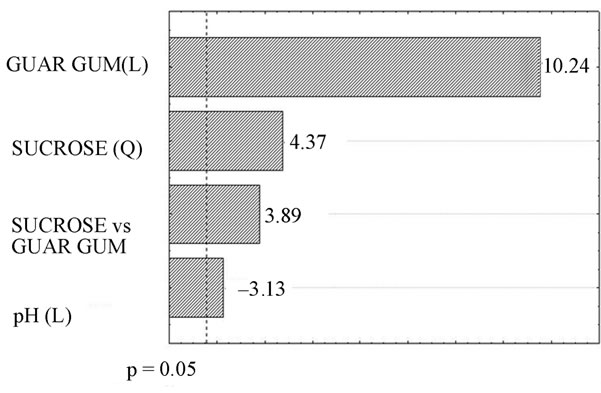

Figure 2 shows the estimates for the effects of the carrageenan, guar gum and sucrose conce-trations, and pH on the apparent viscosity of the skim milk dessert, according to the mathematical model. The positive, linear relationship found for the apparent viscosity and guar

Table 3. Analysis of variance for the model used to describe the effect of carrageenan, guar gum and sucrose concentrations, and pH on the apparent viscosity of the skim milk dessert.

Figure 2. Pareto chart for the influence of carrageenan, guar gum and sucrose concentrations, and pH on the apparent viscosity of the skim milk based desserts.

gum concentration is likely due to the thickening capacity of the guar and also to the significant influence of the guar gum on the pasting properties of corn starch [28]. The negative relationship found for apparent viscosity and pH in this work is similar to what has been previously reported for modified starch pastes, where the apparent viscosity can be controlled by changing pH [23]. A decrease in pH has been reported to increase the initial stiffness (G’ at 1 Hz) in β-lactoglobulin/κ-carrageenan mixed gels, and initial stiffness has been shown to be positively correlated with creaminess in commercial custards [30,12].

Figure 3 shows the response surface of the apparent viscosity values as influenced by guar gum and sucrose concentrations. The carrageenan concentration and pH were kept at their respective center points (0.02% w/w and 6.50, respectively). Under these conditions, the optimal viscosity range (26.8 to 62.0 Pa.s) is achieved when

Figure 3. Effects of guar gum and sucrose concentration on the apparent viscosity of the skim milk based desserts.

guar gum is used at concentrations between 0.0 and 0.315% (w/w) in combination with sucrose at concentrations within the 5.000 to 8.615% (w/w) range. The same figure shows that adding guar gum at concentrations between 0.109% - 0.315% (w/w) and sucrose ranging from 5.000 to 11.000% (w/w) also yields optimal apparent viscosity. Even though the presence of guar gum, a low cost food additive [23], in the formulation is not a requirement to achieve the optimal viscosity, its incorporation into starch pastes causes a synergistic increase in viscosity [28], improving creaminess in the dessert.

4. Conclusions

Data in this work demonstrate that the response surface methodology can be effectively used to optimize the apparent viscosity of formulated semi-solid skim milk-based desserts through the management of the carrageenan, guar gum and sucrose concentrations, along with the pH of the desserts. According to the fitted mathematical model, the optimal apparent viscosity range found for commercially available semi-solid dairy desserts (26.8 to 62.0 Pa.s) can be achieved in our formulated dessert when: guar gum is used at the 0.0 to 0.315% (w/w) range; sucrose is used at the 5.000 to 8.615% w/w range; carrageenan is used at a concentration of 0.02% (w/w) and pH is 6.50. In addition, the optimal apparent viscosity can also be achieved when: guar gum is used at the 0.109 and 0.315% (w/w) range; sucrose is used at the 5.000 to 11.000% (w/w) range; carrageenan at 0.02% (w/w) and pH at 6.50.

Our results demonstrate that it is possible to produce a healthier dairy dessert without jeopardize creaminess, an important sensory attribute of dairy desserts. Further studies are under way in order to provide a proper flavor to the various possible formulations for the skim milk dessert described in this report and also to analyze their sensory features.

5. Acknowledgements

We would like to thank the Brazilian Government (CAPES) for providing a fellowship to the senior author and to Corn Products International and Doce Aroma Ltda for providing part of the ingredients used in this work.