I. CEYLAN 193

Table 3. Evaluation of heat pump dryer performance.

Fruit COPws

SMERws

(g/kWh)

Drying time

(min)

Initial and final

moisture content

(g water/ g dry matter)

Mean air

velocity

(m/s)

Drying air temperature

(oC)

Kiwi 2.49 81.5 360 4.31 - 0.59 0.37 40

Avocado 2.41 58.8 360 1.51 - 0.24 0.37 40

Banana 2.47 87.9 360 4.71 - 0.39 0.37 40

culated from Equation (9) and given in Figure 6. Energy

utilization ratio of banana was high, whose moisture

content was also high. Energy utilization ratio in drying

chamber decreased as the moisture content in fruits de-

creased, similar to the utilized energy.

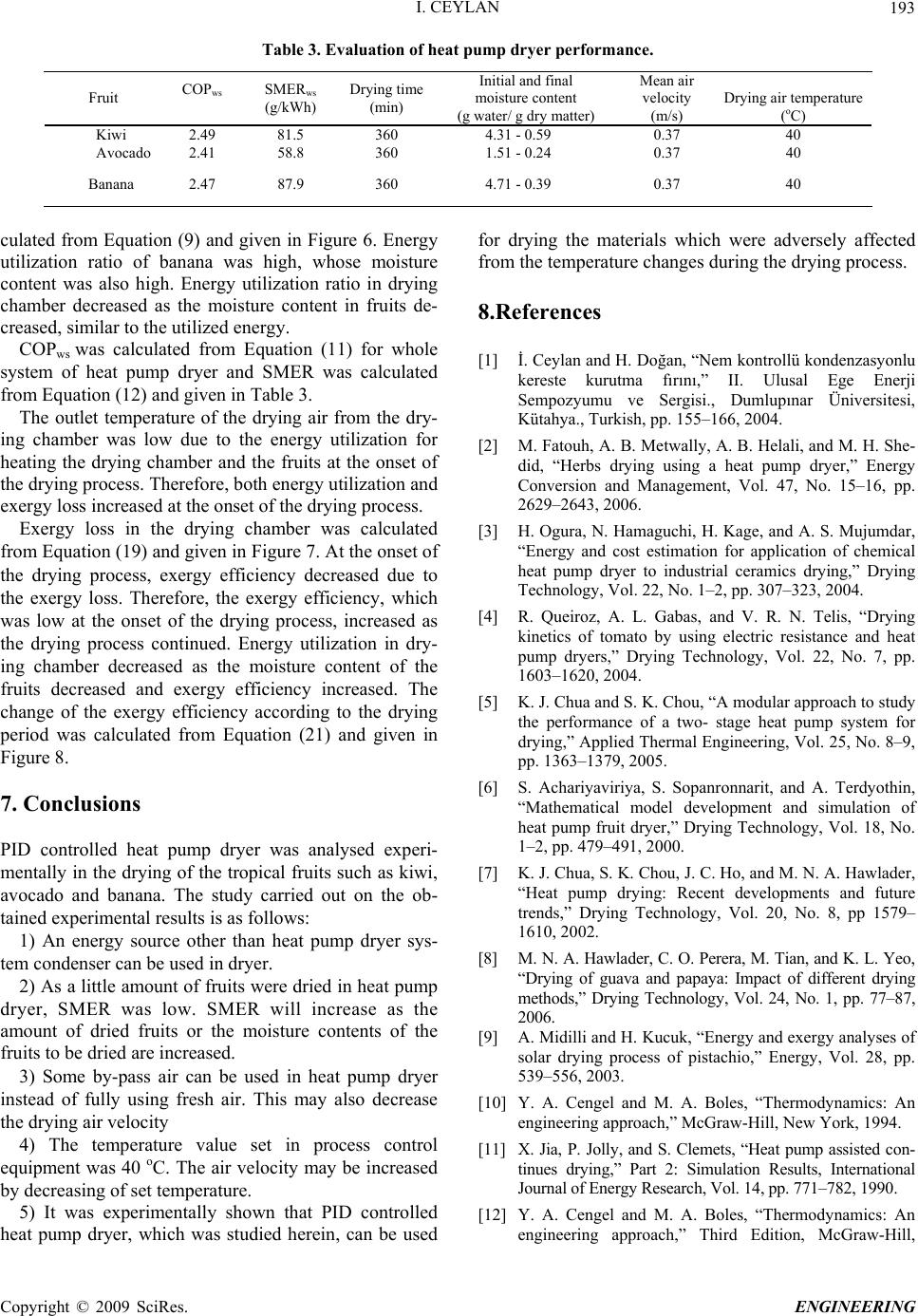

COPws was calculated from Equation (11) for whole

system of heat pump dryer and SMER was calculated

from Equation (12) and given in Table 3.

The outlet temperature of the drying air from the dry-

ing chamber was low due to the energy utilization for

heating the drying chamber and the fruits at the onset of

the drying process. Therefore, both energy utilization and

exergy loss increased at the onset of the drying process.

Exergy loss in the drying chamber was calculated

from Equation (19) and given in Figure 7. At the onset of

the drying process, exergy efficiency decreased due to

the exergy loss. Therefore, the exergy efficiency, which

was low at the onset of the drying process, increased as

the drying process continued. Energy utilization in dry-

ing chamber decreased as the moisture content of the

fruits decreased and exergy efficiency increased. The

change of the exergy efficiency according to the drying

period was calculated from Equation (21) and given in

Figure 8.

7. Conclusions

PID controlled heat pump dryer was analysed experi-

mentally in the drying of the tropical fruits such as kiwi,

avocado and banana. The study carried out on the ob-

tained experimental results is as follows:

1) An energy source other than heat pump dryer sys-

tem condenser can be used in dryer.

2) As a little amount of fruits were dried in heat pump

dryer, SMER was low. SMER will increase as the

amount of dried fruits or the moisture contents of the

fruits to be dried are increased.

3) Some by-pass air can be used in heat pump dryer

instead of fully using fresh air. This may also decrease

the drying air velocity

4) The temperature value set in process control

equipment was 40 oC. The air velocity may be increased

by decreasing of set temperature.

5) It was experimentally shown that PID controlled

heat pump dryer, which was studied herein, can be used

for drying the materials which were adversely affected

from the temperature changes during the drying process.

8.References

[1] İ. Ceylan and H. Doğan, “Nem kontrollü kondenzasyonlu

kereste kurutma fırını,” II. Ulusal Ege Enerji

Sempozyumu ve Sergisi., Dumlupınar Üniversitesi,

Kütahya., Turkish, pp. 155–166, 2004.

[2] M. Fatouh, A. B. Metwally, A. B. Helali, and M. H. She-

did, “Herbs drying using a heat pump dryer,” Energy

Conversion and Management, Vol. 47, No. 15–16, pp.

2629–2643, 2006.

[3] H. Ogura, N. Hamaguchi, H. Kage, and A. S. Mujumdar,

“Energy and cost estimation for application of chemical

heat pump dryer to industrial ceramics drying,” Drying

Technology, Vol. 22, No. 1–2, pp. 307–323, 2004.

[4] R. Queiroz, A. L. Gabas, and V. R. N. Telis, “Drying

kinetics of tomato by using electric resistance and heat

pump dryers,” Drying Technology, Vol. 22, No. 7, pp.

1603–1620, 2004.

[5] K. J. Chua and S. K. Chou, “A modular approach to study

the performance of a two- stage heat pump system for

drying,” Applied Thermal Engineering, Vol. 25, No. 8–9,

pp. 1363–1379, 2005.

[6] S. Achariyaviriya, S. Sopanronnarit, and A. Terdyothin,

“Mathematical model development and simulation of

heat pump fruit dryer,” Drying Technology, Vol. 18, No.

1–2, pp. 479–491, 2000.

[7] K. J. Chua, S. K. Chou, J. C. Ho, and M. N. A. Hawlader,

“Heat pump drying: Recent developments and future

trends,” Drying Technology, Vol. 20, No. 8, pp 1579–

1610, 2002.

[8] M. N. A. Hawlader, C. O. Perera, M. Tian, and K. L. Yeo,

“Drying of guava and papaya: Impact of different drying

methods,” Drying Technology, Vol. 24, No. 1, pp. 77–87,

2006.

[9] A. Midilli and H. Kucuk, “Energy and exergy analyses of

solar drying process of pistachio,” Energy, Vol. 28, pp.

539–556, 2003.

[10] Y. A. Cengel and M. A. Boles, “Thermodynamics: An

engineering approach,” McGraw-Hill, New York, 1994.

[11] X. Jia, P. Jolly, and S. Clemets, “Heat pump assisted con-

tinues drying,” Part 2: Simulation Results, International

Journal of Energy Research, Vol. 14, pp. 771–782, 1990.

[12] Y. A. Cengel and M. A. Boles, “Thermodynamics: An

engineering approach,” Third Edition, McGraw-Hill,

C

opyright © 2009 SciRes. ENGINEERING