S. Z. MOHAMMADI ET AL.

248

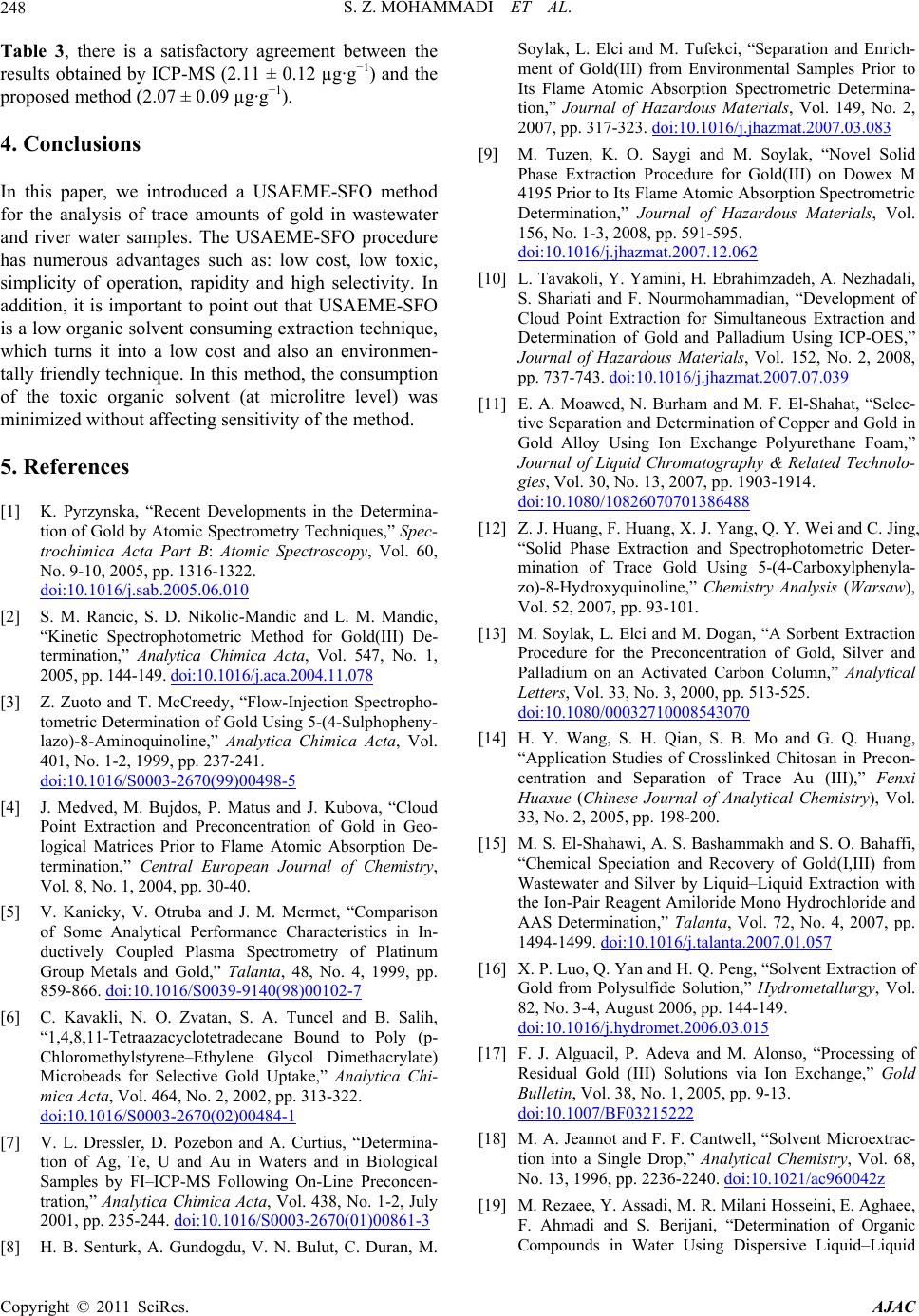

Table 3, there is a satisfactory agreement between the

results obtained by ICP-MS (2.11 ± 0.12 µg·g−1) and the

proposed method (2.07 ± 0.09 µg·g−1).

4. Conclusions

In this paper, we introduced a USAEME-SFO method

for the analysis of trace amounts of gold in wastewater

and river water samples. The USAEME-SFO procedure

has numerous advantages such as: low cost, low toxic,

simplicity of operation, rapidity and high selectivity. In

addition, it is important to point out that USAEME-SFO

is a low organic solvent consuming extraction technique,

which turns it into a low cost and also an environmen-

tally friendly technique. In this method, the consumption

of the toxic organic solvent (at microlitre level) was

minimized without affecting sensitivity of the method.

5. References

[1] K. Pyrzynska, “Recent Developments in the Determina-

tion of Gold by Atomic Spectrometry Techniques,” Spec-

trochimica Acta Part B: Atomic Spectroscopy, Vol. 60,

No. 9-10, 2005, pp. 1316-1322.

doi:10.1016/j.sab.2005.06.010

[2] S. M. Rancic, S. D. Nikolic-Mandic and L. M. Mandic,

“Kinetic Spectrophotometric Method for Gold(III) De-

termination,” Analytica Chimica Acta, Vol. 547, No. 1,

2005, pp. 144-149. doi:10.1016/j.aca.2004.11. 078

[3] Z. Zuoto and T. McCreedy, “Flow-Injection Spectropho-

tometric Determination of Gold Using 5-(4-Sulphopheny-

lazo)-8-Aminoquinoline,” Analytica Chimica Acta, Vol.

401, No. 1-2, 1999, pp. 237-241.

doi:10.1016/S0003-2670(99)00498-5

[4] J. Medved, M. Bujdos, P. Matus and J. Kubova, “Cloud

Point Extraction and Preconcentration of Gold in Geo-

logical Matrices Prior to Flame Atomic Absorption De-

termination,” Central European Journal of Chemistry,

Vol. 8, No. 1, 2004, pp. 30-40.

[5] V. Kanicky, V. Otruba and J. M. Mermet, “Comparison

of Some Analytical Performance Characteristics in In-

ductively Coupled Plasma Spectrometry of Platinum

Group Metals and Gold,” Talanta, 48, No. 4, 1999, pp.

859-866. doi:10.1016/S0039-9140(98)00102-7

[6] C. Kavakli, N. O. Zvatan, S. A. Tuncel and B. Salih,

“1,4,8,11-Tetraazacyclotetradecane Bound to Poly (p-

Chloromethylstyrene–Ethylene Glycol Dimethacrylate)

Microbeads for Selective Gold Uptake,” Analytica Chi-

mica Acta, Vol. 464, No. 2, 2002, pp. 313-322.

doi:10.1016/S0003-2670(02)00484-1

[7] V. L. Dressler, D. Pozebon and A. Curtius, “Determina-

tion of Ag, Te, U and Au in Waters and in Biological

Samples by FI–ICP-MS Following On-Line Preconcen-

tration,” Analy tica Chimica Acta, Vol. 438, No. 1-2, July

2001, pp. 235-244. doi:10.1016/S0003-2670(01)00861-3

[8] H. B. Senturk, A. Gundogdu, V. N. Bulut, C. Duran, M.

Soylak, L. Elci and M. Tufekci, “Separation and Enrich-

ment of Gold(III) from Environmental Samples Prior to

Its Flame Atomic Absorption Spectrometric Determina-

tion,” Journal of Hazardous Materials, Vol. 149, No. 2,

2007, pp. 317-323. doi:10.1016/j.jhazmat.2007.03.083

[9] M. Tuzen, K. O. Saygi and M. Soylak, “Novel Solid

Phase Extraction Procedure for Gold(III) on Dowex M

4195 Prior to Its Flame Atomic Absorption Spectrometric

Determination,” Journal of Hazardous Materials, Vol.

156, No. 1-3, 2008, pp. 591-595.

doi:10.1016/j.jhazmat.2007.12.062

[10] L. Tavakoli, Y. Yamini, H. Ebrahimzadeh, A. Nezhadali,

S. Shariati and F. Nourmohammadian, “Development of

Cloud Point Extraction for Simultaneous Extraction and

Determination of Gold and Palladium Using ICP-OES,”

Journal of Hazardous Materials, Vol. 152, No. 2, 2008,

pp. 737-743. doi:10.1016/j.jhazmat.2007.07.039

[11] E. A. Moawed, N. Burham and M. F. El-Shahat, “Selec-

tive Separation and Determination of Copper and Gold in

Gold Alloy Using Ion Exchange Polyurethane Foam,”

Journal of Liquid Chromatography & Related Technolo-

gies, Vol. 30, No. 13, 2007, pp. 1903-1914.

doi:10.1080/10826070701386488

[12] Z. J. Huang, F. Huang, X. J. Yang, Q. Y. Wei and C. Jing,

“Solid Phase Extraction and Spectrophotometric Deter-

mination of Trace Gold Using 5-(4-Carboxylphenyla-

zo)-8-Hydroxyquinoline,” Chemistry Analysis (Warsaw),

Vol. 52, 2007, pp. 93-101.

[13] M. Soylak, L. Elci and M. Dogan, “A Sorbent Extraction

Procedure for the Preconcentration of Gold, Silver and

Palladium on an Activated Carbon Column,” Analytical

Letters, Vol. 33, No. 3, 2000, pp. 513-525.

doi:10.1080/00032710008543070

[14] H. Y. Wang, S. H. Qian, S. B. Mo and G. Q. Huang,

“Application Studies of Crosslinked Chitosan in Precon-

centration and Separation of Trace Au (III),” Fenxi

Huaxue (Chinese Journal of Analytical Chemistry), Vol.

33, No. 2, 2005, pp. 198-200.

[15] M. S. El-Shahawi, A. S. Bashammakh and S. O. Bahaffi,

“Chemical Speciation and Recovery of Gold(I,III) from

Wastewater and Silver by Liquid–Liquid Extraction with

the Ion-Pair Reagent Amiloride Mono Hydrochloride and

AAS Determination,” Talanta, Vol. 72, No. 4, 2007, pp.

1494-1499. doi:10.1016/j.talanta.2007.01.057

[16] X. P. Luo, Q. Yan and H. Q. Peng, “Solvent Extraction of

Gold from Polysulfide Solution,” Hydrometallurgy, Vol.

82, No. 3-4, August 2006, pp. 144-149.

doi:10.1016/j.hydromet.2006.03.015

[17] F. J. Alguacil, P. Adeva and M. Alonso, “Processing of

Residual Gold (III) Solutions via Ion Exchange,” Gold

Bulletin, Vol. 38, No. 1, 2005, pp. 9-13.

doi:10.1007/BF03215222

[18] M. A. Jeannot and F. F. Cantwell, “Solvent Microextrac-

tion into a Single Drop,” Analytical Chemistry, Vol. 68,

No. 13, 1996, pp. 2236-2240. doi:10.1021/ac960042z

[19] M. Rezaee, Y. Assadi, M. R. Milani Hosseini, E. Aghaee,

F. Ahmadi and S. Berijani, “Determination of Organic

Compounds in Water Using Dispersive Liquid–Liquid

Copyright © 2011 SciRes. AJAC