Received 15 December 2015; accepted 3 February 2016; published 6 February 2016

1. Introduction

Nanomaterials (NMs) have received a great deal of interest because of their size dependent amazing properties and versatile applications [1] -[3] . Many methods have been developed for synthesis of NMs [4] - [9] . However, to prepare the nanomaterial from precursor foam, metal salt with an organic binder is generally used [4] . Among the organic binders, polyvinyl alcohol (PVA) can be used as an organic binder [4] , because the PVA is completely removed at relatively lower temperature leaving behind metal oxide mostly in porous form [10] . Moreover, the PVA can reduce the agglomeration problem of nanoparticles. On the other hand, among the NMs, nano iron oxide has attracted much attention due to its application in various fields such as biosensor [11] , gas sensor [12] , magnetic resonance imaging [13] , drug delivery system [14] , magnetic devices [15] etc. Iron oxide is mainly found as FeO, Fe2O3 and Fe3O4 (magnetite) in which Fe2O3 has four crystallographic phases, α-Fe2O3 (hematite), β-Fe2O3, γ-Fe2O3 and ε-Fe2O3 but the hematite (band gap, 2.1 eV) phase is the most stable iron oxide, capable of forming hierarchical microstructures such as hollow fibres [16] , rhombohedra [17] , cubes [18] , rods [19] etc. It is noted that the properties of NMs can be advanced [14] by incorporation of suitable element into nanometal oxide. To the best of our knowledge, no report is yet available in the literature on the synthesis of cobalt incorporated pyramidal shaped hematite in using PVA in the precursor.

Therefore, in the present work, we report cobalt incorporated α-Fe2O3 nanoparticles mostly in pyramidal shape by simple solution route from a foam-like precursor having Fe(NO3)3∙9H2O and CoCl2∙6H2O salts as the sources of iron oxide and cobalt, respectively in presence of PVA as an organic binder and in water as solvent respectively. To obtain the final product, the precursor was calcined at 600˚C in air atmosphere. The structural property of samples was characterized by X-ray diffraction and field emission scanning electron microscope whereas the spectral properties were measured by using UV-Vis, FTIR and Raman spectral studies. Finally, photocatalytic activity of the samples towards degradation of rhodamine B dye was checked under visible light irradiation.

2. Experiments

2.1. Materials

Ferric nitrate (Fe(NO3)3∙9H20) (Merck, purity 98%), cobaltous chloride (CoCl2∙6H2O, Merck; purity, ³98%) as the sources of iron and cobalt, respectively and polyvinyl alcohol (PVA, BDH, molecular weight ~22,000; purity, 98%) as organic binder were purchased and used without their further purifications. Double distilled water was used as a solvent to prepare the precursor solution.

2.2. Synthesis of Pure and Co Incorporated α-Fe2O3

Pure and 10% Co incorporated α-Fe2O3 were prepared by a simple and cost effective solution method. In this work, the preparation strategy of iron oxide from foam-based precursor is reported for the first time. In a typical synthesis, 2.88 g iron nitrate and 0.19 g cobalt chloride was dissolved (Fe:Co, 90:10; atomic ratio) in double distilled water and heated the solution at 70˚C to obtain a gel like material. The gel was formed after 2 h with continuous stirring of the precursor solution. On the other hand, a clear solution containing 4 wt% PVA was made by stirring and warming the solution at 40˚C. After that an appropriate amount PVA solution (7 ml) was added slowly to the gel with vigorous stirring. The solution was found to transform into a gel after stirring and warming at 70˚C for an hour. The gel was kept at 100˚C in an air oven and obtained a foam-like material. In the next, the foam was heat-treated under air atmosphere at 600˚C for 60 min to remove the organics and the product of cobalt incorporated α-Fe2O3 (AFC) was obtained. Similar procedure was also adopted for preparation of undoped α-Fe2O3 (AF) without the addition of hydrated cobaltous chloride in the precursor solution. A flowchart of the overall synthesis process is shown in Figure 1. It is worthy to note that the foam formation depends upon the PVA weight percentage (wt%). In this respect, initially the synthesis was made by adding 2 wt% PVA solution but there was no formation of the foam-like material.

3. Characterizations

3.1. Materials Characterization

X-ray diffraction (XRD) study of the samples was performed by X-ray diffractometer (Bruker D8 Advance with DAVINCI design X-ray diffraction unit) with nickel filtered CuKα radiation source (λ = 1.5418 Å) in the 2θ range, 20˚ - 80˚. Morphological property of the samples were measured by adopting field emission scanning electron microscope (FESEM and FESEM-EDS, ZEISS, SUPRATM 35VP). Raman spectra were recorded using micro-Raman (Renishaw in Via Raman microscope). An argon ion laser with an incident wavelength of 514 nm was used as an excitation source for the Raman measurement. FTIR spectral study was carried out by using Thermo Electron Corporation, USA make FTIR spectrometer (Nicolet 5700). For each experiment, the number

![]()

Figure 1. Flowchart for the synthesis of cobalt incorporated iron oxide (AFC) nanoparticles.

of scans was fixed at 100 (wavenumber resolution, 4 cm−1). A Netzsch STA 409 C/CD thermoanalyzer was used for thermogravimetric analysis (TG-DTA) of the composite using Al2O3 as a reference maintaining the heating rate of 10 K/min in air. For the TG-DTA run, a maximum temperature was chosen up to 800˚C. The UV-Vis spectra were obtained by UV-Vis-NIR spectrophotometer (UV3600, Shimadzu, Japan) by the diffuse reflectance mode with ISR 3600 attachment.

3.2. Photocatalytic Activity Study

The α-Fe2O3 (AF), and Co incorporated α-Fe2O3 (AFC) samples were dispersed separately in 50 ml 10−6 M of aqueous rhodamine B (RhB) solution for measurement of photocatalytic activity of the samples. The suspension was stirred in a dark for 1 h to establish adsorption-desorption equilibrium. The amount of samples in the dye solution was kept fixed (1.0 mg/ml). The photocatalytic activity (PA) of samples under visible light (Philips India make tungsten bulb, 200 Watt) towards the degradation of RhB (10−6 M solution) was monitored by measuring the concentration change of the RhB dye at ~555 nm. The details of PA measurement under visible light were given in our previous report [20] . During the irradiation process, 5 ml of the suspensions were taken out at different time intervals and measured their UV-Vis absorption spectra. The PA of the samples was analyzed by plotting ln (C0/C) (dye concentration; C0, initial and C, remnant) versus irradiation time and the degradation rate constant (considering first order kinetics) for sample was determined from the individual plot.

4. Results and Discussion

4.1. Thermal Analysis

Thermogravimetric and differential thermal analyses (TG-DTA) (Figure 2) were performed on as-prepared Co incorporated precursor foam to determine an appropriate calcination temperature of the foam towards formation of cobalt incorporated iron oxide. In the TG curve of the sample, two steps of weight losses,13% and 51% with the corresponding peaks at ~185˚C (endothermic, very broad) and ~330˚C (exothermic, sharp), respectively are observed in the DTA curve. There is also an exothermic peak appeared at ~250˚C in DTA curve. The first endothermic peak at ~185˚C could be attributed to the removal of water [16] whereas the exothermic peak ~250˚C could be ascribed to expulsion of nitrates. However, the main pyrolysis of PVA would happen at ~350˚C with the weight loss is about 51%. The curve shows that at 600˚C calcination temperature there is no appreciable weight loss took place in the sample. Therefore, we selected the calcination temperature of 600˚C of the precursor foam to obtain the oxide materials.

4.2. Structural Property

The crystal phase and crystallite size present in the samples were determined by X-ray diffraction (XRD) study.

![]()

Figure 2. TG and DTA curves of precursor foam for iron oxide.

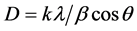

The XRD patterns of pure iron oxide (AF) as well as cobalt incorporated iron oxide (AFC) samples are shown in Figure 3. In both the samples, the XRD peaks (2q) are observed at 24.1˚, 33.1˚, 35.6˚, 40.8˚, 49.4˚, 54.1˚, 57.5˚, 62.4˚, 64.1˚, 71.9˚, and 75.3˚ that could be indexed to the crystal planes (012), (104), (110), (113), (024), (116), (018), (214), (300), (1010) and (220), respectively of α-Fe2O3 [JCPDS No. 33-0664] [16] . Therefore, cobalt doping is not affecting crystal structure of the iron oxide. Further, no separate phase of metallic cobalt [21] or cobalt oxide crystals [22] was detected in AFC sample. It is worthy to note that the ionic sizes of cobalt ions (Co3+) and iron (Fe3+) ions are approximately similar [23] . Therefore, a considerable amount of dopant could expect to be entered into the Fe2O3 crystal lattice [24] . This would be a reason for the non-formation of cobalt/cobalt oxide [25] or its concentration might not be beyond the detection limit by the XRD measurement. The average crystallite size (D) that was estimated by using Debye-Scherrer’s equation (Equation (1)) [26] and it was found to be changed in AFC sample. From the XRD patterns, the calculated average crystallite size (±0.3) of α-Fe2O3 is 15.5 nm and 14.5 nm for AF and AFC, respectively. It is noted that the XRD peak at 2q, corresponds to (104) plane of iron oxide was used to calculate the average crystallite size. In brief, the XRD analysis confirms that both the samples possess nanocrystalline α-Fe2O3 but the crystallite size of iron oxide is found to reduce slightly in AFC. This result would indicate that the Co would enter into the host lattice [27] . However, the size of the crystallites remained within the nano regime.

(1)

(1)

where k is proportionality constant (~0.9), λ is wavelength of X-ray (1.5406 Å), β is FWHM (full width at half maximum) for maximum intensity peak in radians, θ is diffraction angle and D is the crystallite size.

FESEM images of AF and AFC are shown in Figure 4. No definite feature of iron oxide (Figure 4(a)) was observed in AF whereas the morphology of iron oxide nanoparticles (0.5 - 1.0 μm) in cobalt incorporated sample (AFC) was mostly in pyramidal shape (inset i, Figure 4(b)).

4.3. FTIR Analysis

FTIR analysis of pure α-Fe2O3 (AF) and Co incorporated α-Fe2O3 (AFC) was done in the spectral range, 4000 - 400 cm−1 (Figure 5) to reveal the presence of Fe-O bond vibration and to confirm the absence of organics (PVA) in the calcined samples. The FTIR peaks appeared at 460 cm−1 and 580 cm−1 in AF and AFC samples could be assigned to Fe-O stretching vibration [28] . This observation supports the XRD result (Figure 3). It is worthy to mention that a Co-O stretching vibration peak might be overlapped within the 580 cm−1 FTIR peak of Fe-O. A broad peak at 3432 cm−1 and also the existence of absorption band in the range of 1670 - 1600 cm−1 [29] would indicate the presence of -OH groups that would present on iron oxide surface. It is important to note that after curing the samples at 600˚C for 1 h, the organic materials from PVA decomposition [30] completely removed and formed α-Fe2O3 as observed from TG-DTA study (Figure 2).

![]()

Figure 3. XRD patterns of AF and AFC cured at 600˚C.

![]()

Figure 4. FESEM images of (a) AF and (b) AFC samples.

![]()

Figure 5. FTIR spectra of AF and AFC samples.

4.4. UV-Visible Spectra

UV-visible spectra of the samples, measured by diffused reflectance spectroscopy are shown in Figure 6. Generally, the band edge absorption of α-Fe2O3 could observe in the wavelength range of 520 - 565 nm [31] . The AF sample shows a strong absorption at 530 nm (2.34 eV, would correspond to band gap energy, 2.2 eV of α-Fe2O3). This result would also indicate the formation of α-Fe2O3 nanoparticles [31] . However, in AFC sample,

![]()

Figure 6. UV-visible absorption spectra of AF and AFC measured by diffuse reflectance method.

the absorption peak is found to shift slightly in the blue wavelength region (520 nm, ~2.4 eV). The decrease of crystallite size in the cobalt incorporated iron oxide as measured from XRD study (Figure 3) would be the reason for the peak shifting. The possible reason for the spectral broad in the region 400 - 500 nm in AFC sample would be due to the formation of very low content of cobalt oxide that would remain on the surface of iron oxide nanoparticles. This statement could be justified from the observation of a prominent absorption peak at ~275 nm due to Co3O4 [22] .

4.5. Raman Spectra

Micro-Raman spectral study (Figure 7) of AF and AFC samples was performed to investigate the presence of α-Fe2O3 as well as there lative change of structural defects in the crystals [32] .

The Raman peaks appeared at 229, 294, and 413 cm−1, could be assigned to A1g mode (229 cm−1) and Eg mode (294 and 413 cm−1) [31] of α-Fe2O3. This result also confirms the presence of α-Fe2O3 phase and strongly supports the XRD (Figure 3), FTIR (Figure 5) and UV-Vis (Figure 6) spectral results.

4.6. Photocatalytic Activity

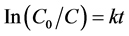

Photocatalytic activity (PA) of samples towards degradation of RhB under visible light irradiation was investigated after adsorption-desorption process in the dark environment. Time dependent absorption spectra (remnant dye concentration vs. irradiation time) of aqueous RhB dye solution using AF and AFC as photocatalysts are shown in Figure 8(a). In this experiment, C0 and C are the initial concentration after adsorption-desorption equilibrium in the dark and actual concentration of RhB dye solution at different irradiation time, respectively. As shown in Figure 8(a), AFC sample showed higher photocatalytic activity compare to AF. The photocatalytic efficiency of the materials was evaluated by calculation of pseudo first order reaction rate constant based with the help of Equation (2).

(2)

(2)

where, k is the reaction constant and t is the time.

The calculated degradation rate constants, k (×10−3 min−1) of AF and AFC samples were found to be 2.5 and 5.3 (Figure 8(b)), respectively. Therefore, the maximum k value was obtained in AFC. Generally, particle size (inversely related to band gap energy) and surface area (inversely proportional to particle size), shape of particles etc. would control the photocatalytic activity of metal oxide semiconductor [33] . In this work, the lower particle size due to cobalt doping and pyramidal shaped of iron oxide in AFC could be considered the favourable factors for the enhancement of PA.

![]()

Figure 8. (a) Photocatalytic degradation (remnant dye concentration versus irradiation time) of aqueous RhB dye solution in presence of AF and AFC as photocatalysts; (b) First-order plot for the degradation of RhB under visible light using AF and AFC samples. The rate constants for the dye degradation reaction are embedded in the figure.

5. Conclusion

Nanocrystalline pure and Co incorporated α-Fe2O3 (AFC) were successfully synthesized at 600˚C calcination temperature from precursor foam by simple solution method using PVA as gelling and stabilizing agent. The formation of α-Fe2O3 nanoparticles was confirmed by XRD measurement and reduction in crystallite size was found after cobalt incorporation. Field emission scanning electron microscopy revealed the existence of pyramidal shaped iron oxide in AFC. FTIR and Raman spectra also confirmed the presence of α-Fe2O3. Photocatalytic activity study showed that the cobalt incorporated α-Fe2O3 was better photocatalyst than pure α-Fe2O3. The cobalt incorporated iron oxide nanoparticles could be used for drug delivery application and this simple method could be adopted for synthesis of other transition metal oxides.

Acknowledgements

Authors are grateful to the Director, CSIR-CGCRI, Kolkata for his kind support and encouragement for this work. The authors AN and SB thankfully acknowledge UGC-RGNF and CSIR, respectively, Govt. of India for providing their Ph.D. research fellowships. The authors also acknowledge the help rendered by Materials Characterization Division for several measurements of the samples. The work has been done as an associated research work of 12th Five Year Plan project of CSIR (No. ESC0202).

NOTES

![]()

*Corresponding author.