Electrical Performance of Porcelain Surge Arrester in 22 kV Distribution System under Contaminated Conditions ()

1. Introduction

Electric power is an important ingredient for the industry and all round development of a country. With the increasing of electrical demand, the leads to a growing interconnection of electrical distribution system. And to satisfy of electrical demand, SAs of distribution system had been improved efficiency or withstand ability of distribution system. The efficiency of the system is based mainly on the continuity of the service, avoiding faults that supposed economic losses for distribution system and users.

Over voltages in power system may occur due to lightning, fault or switching operation. These over voltages could reach dangerous amplitudes for power system apparatus. To protect the system electrical equipment and to guarantee an economic and reliable operation, SAs are applied in almost all types of electrical power network. Gapless zinc oxide (ZnO) surge arresters or Metal Oxide Surge Arresters (MOSAs) are widely used. SAs are usually connected between the phase and ground terminals. They limit the voltage level in equipments such as transformers below the withstand voltage level.

MOSAs are exposed to heavy thermal and electrical stresses if the porcelain housings of the arrester units are polluted. Together with other environmental stresses such as temporary overvoltages or high temperatures, this can lead to thermal runaway of MOSA. In the past in pollution research of MOSAs, a lot of attention was paid to the coupling in of currents at the flanges of a multi-unit arrester with the porcelain housings non-uniformly polluted. This effect has also been taken into account in the testing standard [1] [2] for pollution tests of MOSAs. The effect of coupling in currents at the flange due to in homogeneously polluted housings can be avoided if the total varistor column is included in a single housing [2] - [4] . Another problem caused by pollution of MOAs is the partial discharge phenomena inside the MOSAs [3] . These discharges have been responsible for the destruction of a complete arrester [5] [6] .

Problem of dry band formation and elongation on the polluted surface of housing of the MOSA may not only cause the temperature rise but may distort the voltage distribution and leakage current flow externally and internally. This may sometimes become serious in extreme pollution conditions. Formation of dry band on the housing may result in to [3] - [5] :

Increase in internal leakage current, causing local heating and thermal instability of varistors.

Puncture or crack on the surface.

Flashover on the housing of a unit or the complete MOSA.

Chemical reaction inside MOSA and formation of corona.

Adiabatic heating due to leakage current and dry band arcing causing flashover on the housing and imbalance in heat energy distribution with absorption in varistors, leads to Stress degradation and finally thermal runaway. Internal ionization resulting into the decomposition of the medium surrounding the varistor reduces the oxygen concentration and as a result varistor characteristics might get changed. Dry band formation is a dynamic process and depends on contaminant conductivity, wetting conditions, voltage levels, ambient conditions etc. In artificial pollution tests, there are three polluting methods frequently used, including quantitative Brushing Method, Dipping Method and Spraying Method. Base on measurements of ac flashover performance of four types of porcelain and composite insulators in the artificial climate chamber. In this paper to study of leakage current and temperature absorption of porcelain surge arrester under polluted condition using spraying method [2] - [5] . The equivalent salt deposit density (ESDD) is the most commonly used method to characterize pollution quality and quantity on the surface of porcelain surge arresters. The method determines the salt deposition density by washing down the SAs surface with a known amount of water and then measuring the conductivity of the water. A major disadvantage of the ESDD method is that the SAs must be removed from the distribution line for an exact measurement [1] [2] [4] . Separately this method is lab or intensive and is subject to the experience level and attention to detail of the field personnel. Determination of ESDD on insulators installed on distribution line towers is possible but it requires skilled personnel [4] - [6] .

Therefore to guideline for solving problems above, in this work to study Evaluation of Leakage Current Measurement of Porcelain Surge Arrester for Site Pollution Severity Assessment testing by setup the artificial pollution chamber based on IEC 60507.

2. Properties of MOASs in Polluted Conditions

MOASs operating in polluted areas may be subject to enhanced environmental stress, causing and increased risk of external flashover, internal partial discharges, and increased varistor temperature. The influence of these phenomena on the design and operating performance of MOSAs is discussed in the following. Regarding the risk of external flashovers, the MOSAs should be treated in the same way as other high voltage insulators. Hence, the requirements on the external insulation, e.g. creepage distance and shed shape, shall be based on the actual pollution severity, in order to keep the risk of flashover at a sufficiently low level. The second point of interest is related to the Occurrence of partial discharges (PD) inside the porcelain housing. Although the arrester may be completely free from partial discharges when dry, internal PD may appear during periods of pollution [5] [6] . The PD is caused by the difference between the internal voltage distribution (as determined by the varistor column), and the external voltage distribution (as determined by the wet pollution layer). However, the ZnO varistors can be efficiently protected against the additional chemical stress resulting from the internal PD. Furthermore, proper selections of insulating materials for other internal parts cans are the complete surge arrester resistant to PD. The third basic phenomenon related to MOSAs operating in polluted conditions is the temperature rise that may occur due to the uneven voltage distribution created by surface leakage currents. Varistor temperature, energy absorption capability and temporary overvoltage (TOW withstand, are closely related for MOSAs; there is a certain temperature limit above which the arrester is not thermally stable when energized at the continuous operating voltage. Hence, a considerable temperature rise of the varistors due to severe pollution will reduce the TOV and/or energy absorption capability. Among the three basic properties of MOSAs described above, the temperature rise phenomenon is of the greatest interest today. The amount of field data on temperature rise in polluted conditions is still limited, and the most appropriate laboratory test methods are not yet identified. The studies presented in this paper deals, therefore, entirely with the temperature rise of MOSAs during artificial and natural pollutions.

3. Measurement of Contamination Severity [7] - [9]

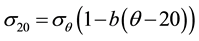

Contamination severity on the surface of MOSA can be given in terms of ESDD as explained earlier. The measurement of ESDD in case of porcelain and glass has been standardized in the International Electrotechnical Commission document 60507 ESDD is measured by dissolving the contaminants on the surface of MOSAs, in deionized water and then measuring the conductivity of the water. The ESDD is then calculated using the following formula

(1)

(1)

= the measured conductivity in S/m.

= the measured conductivity in S/m.

= 0.01998 (constant).

= 0.01998 (constant).

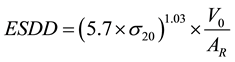

(2)

(2)

= Volume of dissolvent (distilled water) in m3.

= Volume of dissolvent (distilled water) in m3.

= Area of MOSA surface in m2.

= Area of MOSA surface in m2.

This method is observed to be good for measuring ESDD for porcelain surge arresters, as these are com- pletely wettable [8] .

4. Test Specimens, Setups, and Procedures

4.1. Test Specimens

The specimens are the Porcelain Surge Arrester in 22 kV distribution systems as shown in Figure 1. Table 1 shows the dimensional details of the samples test.

4.2. Test Setup

The test circuit of ZnO SA is provided schematically in Figure 2. The voltage elevation transformer is supplied by a Variac, thus resulting in a controlled gradual voltage increase. The transformer secondary coil is connected in series resistance R0 = 2 MΩ and parallel with a capacitive voltage divider comprised of capacitors C1 and C2 respectively. In parallel with the voltage divider is the series connected of MOSA. The voltage across C2 is measured by a scope meter (190B Scope Meter Series: Fluke) and connected to a computer where it is recorded and visually displayed with the use of appropriate software. The technical characteristics of the capacitors C1 and C2 were 224 pF, 100 kV 50 Hz and 2 µF, 1000 V/50 Hz, respectively.

4.3. Test Procedures

The research was carried out on Porcelain Surge Arrester of 22 kV distribution system of PEA. The experimental set-up is schematically shown in Figure 2. Referring to the test standard [7] -[9] , the test procedures in the paper were as follows. After the connected circuit in Figure 2 completely, ac voltage was applied to the specimens and increased at a constant rate till the voltage is 12.8 kVrms. Then ac voltage supplied to specimens is a long time 3 hours. The thermal image camera (Fluke Ti32) records the temperature profile and the leakage current shows in Figure 3 and Figure 4.

5. Test Results of Porcelain Surge Arrester

The results form experiments are show in Figure 5 and Figure 6. At an A.C. test voltage of 12.8 kVrms no partial arcs were burning across the dry zone and at the pollution layer. The wetting of the dried pollution layer was accomplished by relative air humidity in the test room of more than 75%.

The leakage current (LC) of MOSA increased to 20 mA at ESDD = 0.8 mg/cm2 at nominal voltage. Because of the capacitive coupling between the varistor column and the pollution layer the current in the arrester discs is influenced by the voltage distribution along the external pollution layer. This leads to locally higher stresses of

![]()

Table 1. Dimensional details of porcelain surge arrester.

![]()

Figure 3. Leakage Current of testing MOSA at 12.8 kVrms and ESDD at 0.415 mg/cm2.

![]()

Figure 4. Temperature of arrester with 12.8 kVrms ac voltages applied and ESDD at 0.285 mg/cm2.

![]()

Figure 5. Leakage Current versus ESDD at 12.8 kVrms ac voltages applied.

![]()

Figure 6. Temperature versus ESDD at 12.8 kVrms ac voltages applied.

varistor elements near the dry zone. And Figure 6 shows the evaluation of temperature of the central ZnO element versus ESDD. When a voltage is applied to the electrodes, the heat dissipated by the leakage current flowing in the contamination will raise the surface temperature above ambient and moisture will be lost from the surface. This loss will become significant when it causes a measurable increase in the surface resistance; this is the first step in dry-band formation. This heat is lost from the surface by convection, by conduction through the contamination and by conduction through the body of the insulator. In the present work, heat transfer by conduction was found to be small or negligible by comparison with the heat transfer by convection.

6. Conclusions

In this paper, experimental investigation of 22 kV distribution SA electrical performances under pollution conditions according to IEC 60507 with porcelain surge arrester. The following conclusions are obtained.

The leakage current (LC) of MOSA increased to 20 mA at ESDD = 0.8 mg/cm2 at nominal voltage. Because of the capacitive coupling between the varistor column and the pollution layer the current in the arrester discs is influenced by the voltage distribution along the external pollution layer. This leads to locally higher stresses of varistor elements near the dry zone.

The evaluation of temperature of the central ZnO element versus ESDD. The heat dissipated by the leakage current flowing in the contamination will raise the surface temperature above ambient and moisture will be lost from the surface.

These data will be useful to be guideline in case to take porcelain surge arrester of distribution system to reduce the investment cost. Moreover, it will be useful to select or design the suitable insulators for using in pollution area in Thailand as well.