Effects of Heat Treatment on Microhardness of Some Al-Cu Alloy Prepared by Vacuum Coating ()

1. Introduction

Al and Al alloys are widely used in industry and technology such as aerospace industry because of their unique properties such as good corrosion resistance, light weight and high mechanical hardness [1] . However, despite their unique properties they are normally brittle. Ductility in this material can be improved by 1) addition of certain amounts of Cu and 2) by change in preparation method to avoid crystallization. Since grain boundaries and defects are the main reasons for brittleness in crystalline materials [2] [3] . On the other hand, ductility can be improved if the material is prepared in the form of amorphous structure. But amorphous phase usually is a meta-stable phase and needs some heat treatment to get more stability provided that the heat treatment is selected carefully [4] [5] . Thermal annealing of amorphous materials can generally make several changes in these alloys. Bulk and surface crystallization, and nanocrystallisation can be imposed on these materials upon thermal annealing [6] -[8] . However low temperature thermal annealing can transfer these alloys to a more stable amorphous state through structural relaxation, enhancing their hardness, ductility and other properties and also increase in density [9] -[11] . In this paper, alloy of Al(100−x)Cux with x = 10, 15, 20 is prepared by evaporation method. Then the prepared specimens were annealed at temperatures 200, 250, and 300˚C for one hour. The value of annealing temperatures is chosen quite low as compared to crystalline temperature to avoid any crystallization due to annealing. XRD of the specimens are taken before and after each thermal annealing to show amorphous nature of the prepared and annealed specimens. Microhardness of the specimens is measured using Vickers method. SEM and AFM also are taken to observe surface morphology of the prepared samples. It is found that for x = 15 and annealing time of 200˚C the maximum hardness is obtained.

2. Experimental Procedure

Al and Cu are used in the form of powder. The required amount of Al and Cu in the form of powder is used to prepare initial samples. Then by evaporation method in vacuum of 10−5 torr is deposited on glass substrate. Prepared samples are annealed in vacuum of 10−3 torr at temperatures 200, 250 and 300˚C for 1 hour. Structure is characterized using X ray diffraction (XRD) with Cu-Ka radiation with wavelength = 1.5405 angstrom. Microhardness measurements are done using Buehler microhardness tester, with diamond pyramid, load of 10 grams and pressing time of 15 seconds. More than 10 measurements are performed and their average is considered. Jeol SEM is used to observe surface morphology and AFM is used to observe surface roughness of the samples.

3. Results and Discussions

3.1. XRD Study

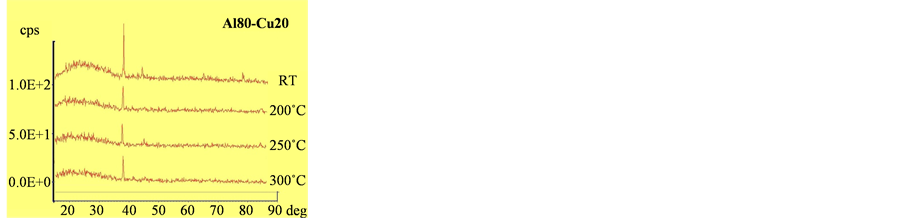

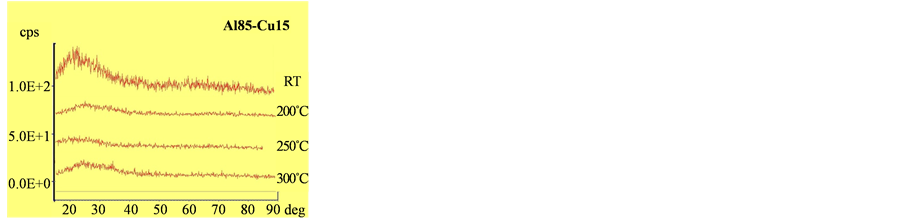

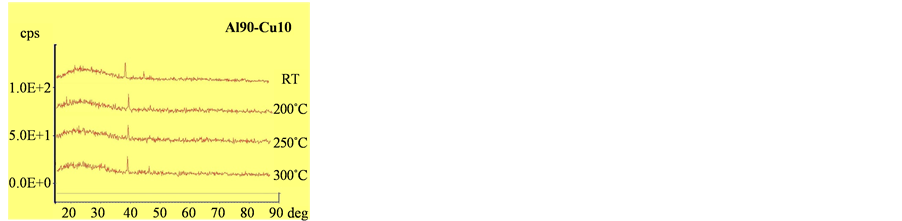

Figure 1 show the XRD patterns of all prepared specimens before and after thermal annealing. It clearly shows broad halos typical for an amorphous structure. Specimens with compositions Al90Cu10 and Al80Cu20 show some crystalline phases, but the specimen with composition Al85Cu15 seems to be quite amorphous in structure without presence of any crystalline phase.

3.2. Microhardness Measurements

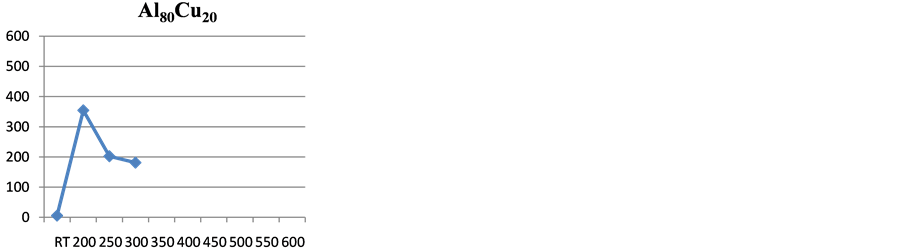

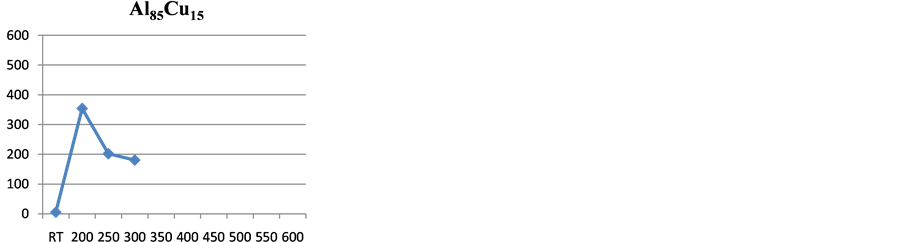

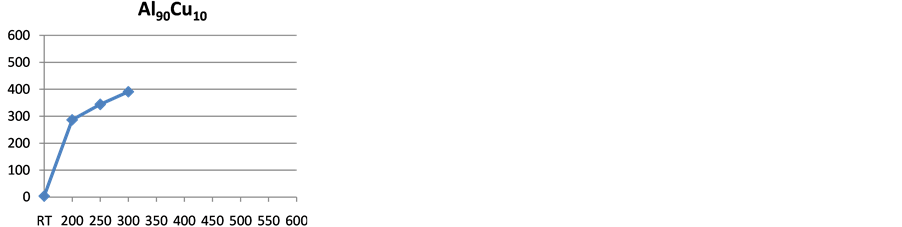

Microhardness of the specimens is measured before and after thermal annealing. Figure 2 shows the obtained microhardness values as a function of annealing temperatures.

It is observed that there is some increase in hardness of the all specimens due to thermal annealing, which can be related to densification of specimens. It can be considered that increase in hardness due to annealing is highest for sample with composition Al85Cu15 annealed at 200˚C which may be related to its amorphous structure. Thermal annealing of other specimens cannot make such amount of increase in the microhardness.

3.3. SEM Study

We have studied the sample with composition Al85Cu15 because of its good increase in amount of microhardness after thermal annealing. Figure 3 shows micrographs of specimen obtained by SEM.

It shows clearly that the inter-atomic distances are decreasing or, one can say that the density of the specimen is increases upon thermal annealing which is in good agreement with our earlier result [11] .

3.4. AFM Results

Figure 4 shows the surface roughness of the specimen by using AFM.

It shows that upon annealing the surface of the specimen becomes smoother due to structural relaxation occurred in the specimen after annealing. This phenomenon which arises due to low temperature thermal annealing can increase the density of the specimens and increase its hardness.

4. Conclusion

The effects of thermal annealing on prepared amorphous samples with composition Al100−xCux were studied using XRD, microhardness tester, SEM and AFM. It is observed that sample with composition Al85Cu15 can give

(a)

(a) (b)

(b) (c)

(c)

Figure 1. XRD patterns of samples before and after thermal annealing for different alloy compositions a: (Al80Cu20), b: (Al85Cu15), c: (Al90Cu10).

(a)

(a) (b)

(b) (c)

(c)

Figure 2. Microhardnes of the samples as a function of annealing temperatures for different alloy compositions, a: (Al80Cu20), b: (Al85Cu15) and c: (Al90Cu10).

the best amorphous structure. Thermal annealing at temperature 200 C for one hour can make maximum increase in microhardness of the specimen. And thermal annealing at selected temperatures can relax the specimen and densify it without occurrence of crystallization, hence better ductility can be achieved.

NOTES

*Corresponding author.