Design and Test of the Semi-Automatic Test-Bed with Inclined Belt of Garlic Transplanting Machine ()

Received 14 October 2015; accepted 28 December 2015; published 31 December 2015

1. Introduction

In order to meet the agricultural requirements of planting garlic [1] [2] , garlic is mainly planted manually in our country at present [3] . With low efficiency, each person can only plant about 230 m2 per day, and the working conditions are very poor. As the labor cost rises year by year, the garlic planting cost greatly increases [4] . So garlic planting has become the key restricting the developing of garlic industry [5] , and the farmers are crying for the mechanization of garlic planting [6] .

There are two problems of garlic planting machine [7] in our country: the first is that mechanization cannot solve the problem of turning around the garlic perfectly by various means of gravity, image identification [8] [9] ; the second is that the bud is not sure to erect upward after being planted into seed ditch [10] . In order to solve the two problems, a new way is proposed in the paper-using the semi-automatic test-bed with inclined belt of garlic transplanting machine. Before planting, we put the garlic seed in the garlic box made by degradable material [11] [12] , which is then put on the belt to be transported into seed ditch. In order to verify the new way of planting, the semi-automatic test-bed with inclined belt of garlic transplanting machine was designed and tested to provide data support for the theory.

2. Test-Bed and Major Parameter

2.1. The Structure and Working Principles

As showed in Figure 1, the semi-automatic test-bed with inclined belt of garlic transplanting machine includes the institution of planting garlic box, the institution of support garlic box, the rod of angle change, transmission systems, the deflector, the rack, the motor and the motor control system. The institution of support garlic box prevents the garlic box from slipping and turning over on the belt, and guides the garlic box into seed ditch. The rod of angle adjusting could adjust the angle between the belt and earth, to obtain the consequences of changes in different angle; The deflector is an institution of transition between the belt and earth, parallel to belt, to guide the garlic box into seed ditch stably at the end of the belt.

The speed of the test-bed was controlled by IPC. When IPC motor is started, the garlic box with garlic seed can be put on the belt manually, which will be transported to the deflector with guidance of the institution of support. The deflector then drops the garlic box into seed ditch stably and completes the progress of planting.

2.2. Major Parameter

The parameter was shown in Table 1.

3. Transmission Systems and Motion Analysis of Garlic Box

3.1. Transmission Systems Design

3.1.1. The Structure of Transmission Systems Design

Figure 2 is the sketch of transmission systems, the arrows point out the positions of power transmission. The middle shaft makes sure that the transmission point of running shaft and transport shaft move in opposite direc-

![]()

Figure 1. Text-bed. 1: The institution of support garlic box; 2: The institution of planting garlic box; 3: The deflector; 4: The rod of angle change; 5: Transmission systems.

![]()

Figure 2. Sketch of transmission systems. 1: power output shaft; 2: middle shaft I; 3: transport shaft; 4: middle shaft II; 5: running shaft.

tion. The transmission uses triple retarding mechanism in running structure and two-grade reducing mechanism in transport structure to improve the motor speed [13] .

3.1.2. Transmission Ratio

The suitable transmission ratio guarantees the garlic box to fall end to end in seed ditch. This ratio can be fixed according to the test-bed’s running speed and the transport speed of belt.

v―the test-bed’s running speed.

v1―the transport speed of belt.

t―the time from the front end of garlic box N touching ditch to the front end of garlic box F touching seed ditch.

l―the length of garlic box.

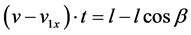

From Figure 3 it can be seen that in the time of t the garlic box transport the length is l in test-bed. In order to make sure the garlic box F and N end in end in seed ditch, in the time of t the garlic box transport the length relative to earth is

(1)

(1)

From the relationship between time and speed of the garlic box on belt, it can be obtained:

(2)

(2)

From Figure 3 it is known that

(3)

(3)

From Formulas (2) and (3), the result is

(4)

(4)

According to Formula (4), the transmission ratio can be worked out from the walking wheel’s and belt wheel’s diameter.

3.2. Motion Analysis of Garlic Box

The motion of the garlic box on belt and the garlic box front end touching the seed ditch are analyzed to research the tail of garlic box N’s speed and the front end of garlic box F’s speed. In this way the length between two garlic box end to end can be worked out.

When the garlic box is transported on the belt, the speed is v. when the garlic box front end touches the seed ditch, the speed of garlic box tail can be got from Figure 4 [14]

(5)

(5)

In Figure 4, va―the absolute speed of the garlic box tail when the garlic box front end touches the seed ditch. Number and point change with the transport of garlic box.

ve―the convected speed, the number is same as v.

vr―the relative speed, fixed orientation, number is change with va.

θ―the angle between the garlic box and earth.

α―the belt angle.

From Figure 4 and Formula (5), it can be obtained

(6)

(6)

Figure 5 the relationship between the relative speed and θ from Formula (6).

From Figure 5, vr is increasing with the angle decreasing between garlic box and earth. when θ = 15˚, vr = v. There are three steps in the transport of the garlic boxes: first, before the front end of garlic box N touches the seed ditch, there is no relative motion between the two garlic boxes; the second, when the front end of garlic box N touches the seed ditch to vr = v, in this step vr < v, so the garlic box F will extrude the garlic box N; the third, from vr = v to all of the garlic box N touches the seed ditch, in this step vr > v, the a space will appear

According to the above analysis, the result is that the length between two garlic boxes end to end will appear, when the garlic boxes all touch the seed ditch.

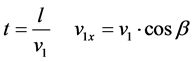

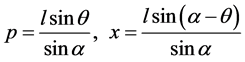

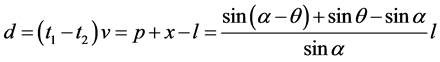

t1 is the time the garlic box transport from state b to state c. so

(7)

(7)

Because in the time t1, vr > v, the two garlic box F and N will separate, t2 is the time the garlic box transport from state b to the head of garlic box F touch earth

(8)

(8)

In Figure 6, it is known that the transport length of tail garlic F is p,

(9)

(9)

So the length between two garlic boxes end to end is d,

(10)

(10)

From Formulas (6) and (10) it can be worked out that the relationship between belt angle and length, Figure 6. Through Figure 6 we can know the length in any belt angle.

![]()

Figure 6. Relationship between belt angle and length.

4. Test of Test-Bed

Through test the feasibility of semi-automatic garlic planter with inclined belt program is to be verified and its reasonable operating parameters are to be determined. Field experiment is conducted to make sure that it will never appear slip in every belt angle and at every transport speed after the front end of garlic box touches seed ditch. Figure 7 is test-bed.

4.1. Single Factor Experiment

Experimental factor: the belt angle, the running speed [15] .

Experimental index: the length between two garlic boxes end to end.

Figure 8 is the state of garlic box in seed ditch, the distance between two garlic box is fixed.

The angle of repose is 43˚ which is the garlic box on belt [16] , the belt angle is 0˚ - 38˚. One person can make sure the biggest speed of planting machine is 0.82 km/h for 3 rows normally.

Figure 9 and Figure 10 show the result.

Through the single factor experiment it can be proved that the semi-automatic garlic planter with inclined belt is feasible; Experimental factors have influence on index.

4.2. Orthogonal Test

The belt angle and test-bed running speed both have influence on index, so belt angle and test-bed speed are selected to take the orthogonal test [17] .

4.2.1. Experiment Design

In test we choose orthogonal experimental design of L9(34) [18] [19] , each set of test is repeated for 5 times. The experiment arrangement is shown in Table 2.

4.2.2. Result Analysis

The results are shown in Table 3.

![]()

Figure 8. The state of garlic box in seed ditch.

![]()

Figure 9. Belt angle single factor experiment.

![]()

Figure 10. Running speed single factor experiment.

From Table 2 we can see the orthogonal experiment shows interaction, no empty row, having repetition test. I work out the DEVSQ, sum of squared error and DOF [20] [21] . Table 4 shows the variance analysis [22] , Table 5 shows the binary collocation.

In Table 4, FA = 4.0295 > F0.05 = 3.23, but FA = 4.0295 < F0.01 = 5.18, so factor A has the greatest effect on experimental index, and the reliability is 95%, while the influence factors of B and interaction of A × B on experimental index are less. Because FA > FB, so the order of each factor which influence the index is A, B.

Because A × B significantly affect the index, binary collocation of factor A, B (Table 5) is used to make sure the best combination. In the test, the smaller data is better. From Table 5 the best combination is A2B3.

![]()

Table 2. Orthogonal experimental design of L9(34).

![]()

Table 4. Table of variance analysis.

![]()

Table 5. Binary collocation of factor A, B.

5. Conclusions

1) The test-bed can plant the garlic box stably; the semi-automatic garlic planter with inclined belt is feasible.

2) The single factor experiment shows that belt angle and test-bed running speed have effect on length between two garlic boxes.

3) Through the orthogonal test, the best test combination is fixed―the belt angle is 30˚ and the test-bed running speed is 0.75 km/h.

4) We should cut down 20 mm at two ends of garlic box to make sure the length between the caves remain unchanged.

NOTES

![]()

*Corresponding author.