Development and Performance Evaluation of Palm Kernel Shells Fueled Stove Converting Waste to Energy ()

1. Introduction

In Nigeria, agriculture has remained one of the important sectors of the economy. It generates employment for about seventy percent of Nigeria’s population and contributes about forty percent of the gross domestic product (GDP) with crops production accounting for eighty percent, livestock thirteen percent, and fisheries four percent [1] [2] . The Council for Renewable Energy of Nigeria (CREW) estimates that power outage brought about a loss of 126 billion NGN (984.38 Million USD) annually [3] [4] . The predominant energy resources for domestic and commercial uses in Nigeria are fuel, wood, charcoal, palm kernel shell, palm fibre, kerosene, cooking gas and electricity [5] . Other sources, though less common, are sawdust, agricultural crop residue of cornstalk, cassava stick, and in extreme cases, cow dung.

Development and utilization of renewable energy should be given a high priority especially in the lights of increased awareness of the adverse environment impact of fossil and based generation. The need for sustainable energy is rapidly increasing in the world. A wide spread use of renewable energy is important for achieving sustainability in the energy sector in both developing and industrialized countries [6] [7] .

[8] studied combustion characteristic of palm kernel using an inclined grate combustor. The inclined grate fixed bed combustion chamber used to burn the palm shell exhibits low capability with conversion rate of twenty percent to thirty two percent of its calorific value. Main design faults were identified for the combustion-air distribution system as well as fuel and distribution. [9] [10] conducted a review on electricity generation based on biomass residue in Malaysia.

[11] performed economic analysis of diesel-fuel replacement by crude palm oil in Indonesian power plants. Their analysis was basically on the needs to find an alternative fuel to substitute diesel in their power plants in order to reduce the use of non-renewable energy sources in Indonesia.

[12] studied progress and challenges in utilization of palm oil biomass as fuel for decentralized electricity. His findings revealed that generating electricity such as biomass power would help transform the entire economic activity and large part of rural population would be able to use the energy for various basic needs. [13] [14] compared the combustion efficiency of palm waste such as palm fibre, palm kernel shell (PKS) and empty fruit bunches in a fluidized bed and spouted bed. The result showed that for combustion of palm fibre and palm kernel shell, the fluidized bed has higher combustion efficiency compared to spouted bed.

[15] [16] presented a comprehensive review of biomass resources and biofuel production potential in Nigeria. The review shows that a variety of biomass resources exist in Nigeria and that there is also immense opportunity for their conversions for various types of biofuel using different biomass conversion technologies that are currently available.

Stove is an enclosed space in which fuel is burned to provide heating, either to heat the space in which the stove is situated, or to heat the stove itself and the item placed on it. Table 1 shows the summary of available stoves with their pictures, description, efficiency and price range where available.

![]()

![]()

Table 1. Overview of current available stove, [17] .

In order to determine which type of heating fuel is the best value, four different variables were considered in literature which are: the type of heating fuels (solid, liquid, electricity, or gas); the unit cost of heating fuels (amount of money cost by unit measure); per unit content of fuel (measured in Btu’s); and annual fuel utilization efficiency (AFUE).

Table 2 shows the demerits in the existing stoves.

Table 3 demonstrates the different types of fuels used by stoves and their comparison of entropy constant.

2. Methodology

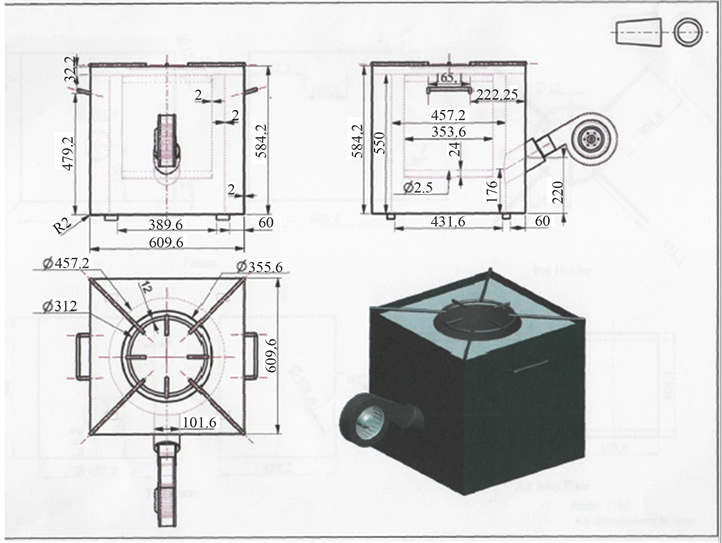

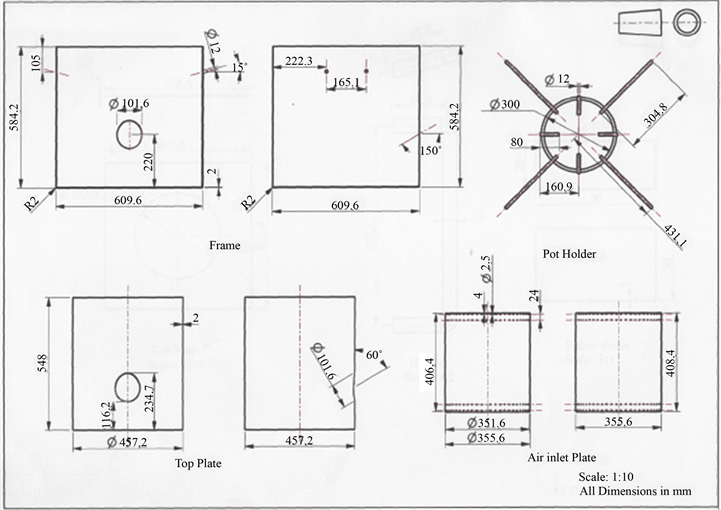

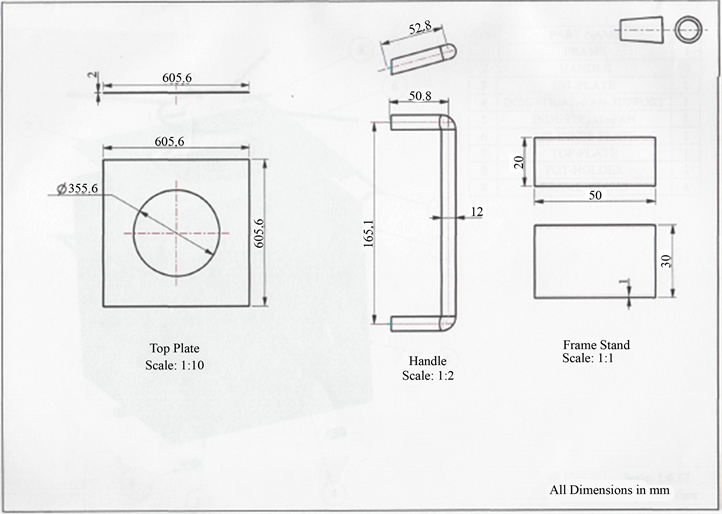

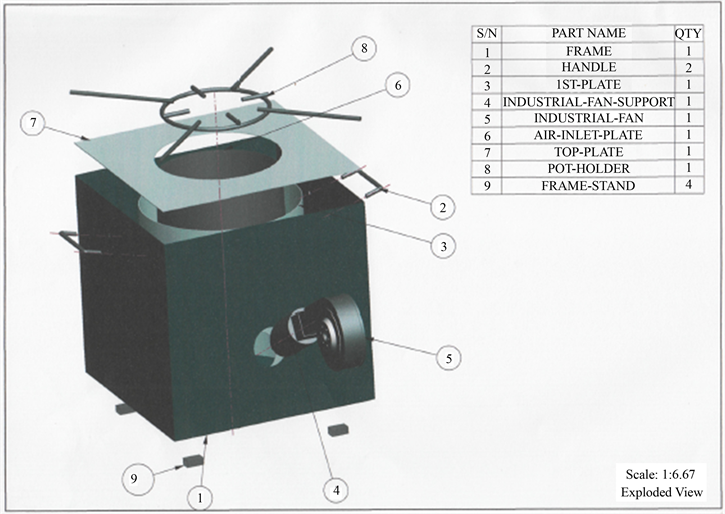

The method used in this research covered: identification of required components of the proposed stove design, analysis of each component, components material selection, engineering drawing of the stove, components’ production and their assembly, test of the stove and comparison with the existing ones to evaluate its performance.

Components: the components are pot holder, air inlet plate, centrifugal fan, outlet plate, top plate and the frame.

![]()

Table 2. Different types of stoves and their demerits.

![]()

Table 3. Different types of fuels used by stoves and comparison of entropy constant.

Design Analysis of the Component

1) Design Analysis of the Frame Support

The PKS stove was designed for maximum strength load it can carry.

Mass of water and the pot used is 45 kg (4.413 KN);

Length (L) of the full cross bar = 860 mm;

Load is to be uniformly distributed over the support.

Support reaction

(1)

The shear force

at section

(2)

The maximum shear force

(3)

The maximum bending moment (

) of the support

(4)

= 0.41 KNm.

Design Analysis of the Fuel Chamber

Volume

(5)

V = 0.04 m3.

Mass density of palm kernel shell = 560 kg/m3;

Calorific value of palm kernel shell = 16.9 MJ/kg.

Therefore, the mass of fuel in the stove = mass density of palm kernel shell × volume of the fuel chamber

(6)

= 22.4 kg

Available energy (

) =

×

(7)

= 378.6 MJ

2) Design Analysis of the Blower

a) Propeller Fan Design

The design power (P) of the fan is 100 W while working under a head (H) of 600 m at running speed, N of 2000 rpm.

Diameter of impeller (d) is 0.03 m;

Blade thickness at the inlet (

) is 40 mm;

Blade thickness at the outlet (

) is 15 mm;

Inlet blade angle (

) is 22.5˚;

Outlet blade angle (

) is 50˚;

Mass density of air (

) is 1.0 kg/m.

Figure 1 demonstrates the inlet and outlet velocity diagram.

Blade velocity at inlet

(8)

where

is inlet diameter and N is fan speed in revolutions per minute

= 1.591 m/s.

Blade velocity at outlet

(9)

Vb2 = 3.142 m/s.

![]()

Figure 1. The inlet and outlet velocity diagram.

b) Quantity of Air Delivered (Q)

(10)

But velocity of flow at inlet Vf1 is expressed as

(11)

The Q i.e. the required discharge to produce power

(12)

Q = 0.034 m3/s.

Hence,

= 18.02 m/s [velocity of flow remains constant throughout the runner i.e.

=

]

The flow rate τ is given by the ratio of the velocity of flow at the inlet to the theoretical velocity

(13)

τ = 5.25 m/s.

The speed ratio Ø is given by the ratio of the blade velocity at the inlet Vb1 to the theoretical velocity

(14)

Ø = 0.5.

Table 4 explains the ultimate analysis of palm kernel shell.

c) Determination of the Quantity of Heat Released

Figure 2 shows a solid cylinder of radius r, insulated with an insulation thickness (r2 - r1).

Where L is length of the cylinder, T1 is the surface temperature of the cylinder; Tair is temperature of air; ho is heat transfer coefficient at the outer surface of the insulation and K is thermal conductivity of the insulating material.

The rate of heat transfer from the surface of the solid cylinder to the surrounding is given by

(15)

Q = 39.2 W/m.

Qi (without insulation) =

(16)

Qi = 22.6 W/m.

d) Minimum Insulation Thickness (Tm)

(17)

where Tm is minimum insulation thickness, rc is critical radius of insulation, and r1 is radius of the fuel chamber.

![]()

Table 4. Ultimate analysis of palm kernel shell.

Note

, Tm = 0.644 mm.

e) Percentage Increase in Head Dissipation (Hd)

(18)

Hd = 73.5%.

The required drawing to this developed stove is found in the Appendix.

3) Developed PKS stove Performance Evaluation

The palm kernel shell stove performance is evaluated by observing its efficiency in cooking relative to other forms of heat source using a stop watch for time taken. Other materials used are thermometer, aluminum pots, sawdust stove, charcoal stove, electric stove, gas cooker, kerosene stove and the PKS stove.

Procedure

a) 3 litres of water are measured into the pot.

b) Light up the stove and allow proper combustion to circulate round before placing the water pot carrying the 3 litres of water with thermometer on the fire.

c) Watch and record the time required for water to attain its boiling point.

d) Repeat the same action on the remaining five sources of heat.

3. Results and Discussion

The palm kernel shell stove has been successfully developed having frame of shear force of 1.90 KN, maximum bending moment of 0.41 KNm, fuel chamber of 0.04 m3 and available energy of 378.6 MJ with the blower capable of delivering 0.034 m3/s of air. The rate of heat transfer from the surface when insulated to the surrounding is 22.6 w/m having a minimum insulating thickness of 0.644 mm while the percentage increase in dissipation is 73.5%.

Evaluating the performance of the stove compared with the other five types of different source of fuel (gas, kerosene, sawdust, electric cooker and charcoal). Sawdust has the highest time for the three liter of water to boil. The results to this experiment in descending order are: Sawdust, 38.35 min; charcoal, 33.45 min; kerosene, 25.00min; electric cooker, 23.00 min; gas cooker 25.28min; and palm kernel shell stove, 2.30 min. This experiment shows that palm kernel fueled stove is the fastest due to its short time of 2.30 min followed by gas fueled stove of time 15.28 min.

Figure 3 shows the fuel performance chart.

4. Conclusions

The design and fabrication of the Palm kernel shell stove has been achieved successfully as well as performance evaluation on the stove. Its performance evaluation was carried out by comparing the developed stove with other stoves fueled by sawdust, charcoal, gas, kerosene and electric cooker, and it was discovered it got the shortest time for boiling 3 liters of water in 2.30 minutes. The kernel shells are always available in bag which can last for several months with only five hundred naira (₦ 500) which are equivalent in dollar rate to more than one US dollar (US$1.43) compared with the cost of other fuels.

![]()

Figure 3. Performance evaluation results on a pie chart.

Palm kernel shells are attractive renewable energy resource that has been utilized in agricultural industries as a secondary energy source. Due to certain physical characteristics, palm shells are a relatively hard-to-burn biomass fuel, and the combustion chamber design as well as the combustion process should be optimized to enhance combustion efficiency.

Appendices