Comprehensive Evaluation of Service Level of Transmission Equipment Maintenance Plan ()

1. Introduction

With the expansion of the scale of power grid and the reliability of power supply requirements of the increase, the importance of power outages is increasingly apparent. In China’s power enterprises, according to the power outage period of pre-arranged power outage has been an important factor affecting the reliability of power supply. Reasonable arrangements for power outages, power outages plan is the focus of power supply reliability management. If the maintenance plan of power equipment is unreasonable, there will be many adverse effects. The arrangement of equipment maintenance plan is directly related to the interests of power grid enterprises and users, and the safety and economy of the power system and society as a whole.

China’s power grid has entered the era of UHV; the transmission network topology is more complex, the regional power network, and electrical contact is more closely. The characteristics of AC/DC coupling, coupler coupling, coupling between upper and lower coupling are beginning to appear. The safe operation of power grid is facing new challenges, and the requirements for power system security and flexibility are higher and higher. Transmission network equipment maintenance from 2015 to the national grid began to implement “a plan”, that is a centralized, unified planning approach. In this context, according to the actual needs of power grid enterprises, the establishment of a comprehensive evaluation of supervision and evaluation of power grid maintenance plan has important theoretical value and practical significance.

At present, the study on the maintenance level of the maintenance plan is still rare. Literature 3 and literature 4 focuses on the optimization of maintenance plan of power network equipment, mainly discuss how to arrange power grid equipment maintenance, in order to achieve economic and security results. In this paper, the safety evaluation of the maintenance plan is carried out, and the safety of the maintenance plan is evaluated in advance through the indexes of “bus load supply adequacy” and “equivalent generation capacity loss”.

In the literature 5, the safety evaluation of the maintenance plan will be carried out. Two indexes, “bus load supply adequacy” and “equivalent generation capacity loss”, are studied in this paper. These two indicators are used to assess the safety of the maintenance plan prior to the event.

In general, few technologies and patents are currently being developed to develop service level assessment models for maintenance plans.

The relevant research focused on the prior assessment of the impact of the maintenance plan on the safety of the grid. It is a defensive and predictive assessment and does not provide an assessment model for the maintenance plan itself. In this paper, a new service level evaluation model for maintenance planning is established, which is an evaluation and relative evaluation after the occurrence of the incident. This model can help to improve the scientific evaluation of maintenance planning. The evaluation method is used to prepare the business process for the maintenance plan. It focuses on the inspection efficiency, maintenance cycle connection, non-force majeure inspection and so on. It solves the technical problem of the quantitative evaluation of the business plan implementation.

2. Grid Outage Maintenance Business Overview

As a means of ensuring a stable operation of the grid equipment, scheduled maintenance is still an important component of the maintenance form. China’s primary energy base and energy demand areas were far reverse distribution characteristics. And now has basically formed a large-scale power west to east, north power transmission pattern. Large-scale, long-distance cross- province inter-regional transmission channels more and more, leading to the main grid electrical contact is very close.

Maintenance plan arrangements cannot be considered as a unit of equipment, the overall, overall consideration of the transmission grid maintenance program to better adapt to the current situation and objective requirements of the grid. In general, the maintenance plan in accordance with the time span is divided into annual maintenance plan, monthly maintenance plan, and day maintenance plan and so on. Usually at the end of each year to arrange the second year of the annual maintenance plan, the annual maintenance plans the largest time span. The strategic and guiding annual power outage plan is a program for the maintenance and repair of power grids within one year, which will have a great impact on the safety, capacity and production arrangement in the coming year. Due to unforeseen circumstances, the monthly maintenance plan is more accurate and specific than the rougher annual plan. Monthly plan is the annual plan refinement, but also according to the actual situation of the month to add maintenance program. Day maintenance plan is mainly the implementation of the maintenance plan is the last part of maintenance planning arrangements [6].

3. Evaluation Index of Maintenance Level

Grid maintenance plan evaluation indicators are designed to improve the business level and business efficiency of participating organizations by assessing scoring ranking. Through the analysis of the evaluation object and evaluation content, we will assess the level of the maintenance plan, maintenance efficiency, maintenance process integrity and other content, while constructing the corresponding evaluation index.

3.1. Equipment Maintenance Plan Development Level Evaluation Index

This indicator mainly evaluates the level of the maintenance plan, which is composed of the monthly business level assessment and the annual business level evaluation. By comparing the actual duration of maintenance equipment and maintenance equipment plan duration, to measure the planners in a number of areas of knowledge, which include maintenance content, maintenance project implementation, power grid operation is expected. If the maintenance of equipment, “the actual duration of the planned duration”, we will deduct points in accordance with the function to carry out the assessment;

Through the “planned duration” and “average plan duration” to compare, to measure the level of maintenance planning between the planned units.

The indicators are evaluated by deducting the “scheduled duration > average planned duration” of the maintenance equipment according to the deduction function. The focus of this indicator assessment is the planned duration is not accurate or the planned duration is too long.

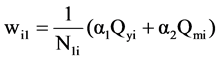

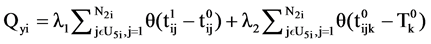

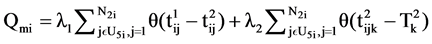

For the i-th evaluation object, the formula of the index is:

(1)

(1)

Among them,  is the annual business level assessment:

is the annual business level assessment:

(2)

(2)

is the monthly business level assessment:

is the monthly business level assessment:

(3)

(3)

is the annual business level and the monthly business level of the weight value, are taken 0.5;

is the annual business level and the monthly business level of the weight value, are taken 0.5;

said that the equipment type, a total of equipment type m;

said that the equipment type, a total of equipment type m;

represents the yearly planned duration of the j-th equipment of the i-th inspection unit;

represents the yearly planned duration of the j-th equipment of the i-th inspection unit;

represents the actual duration of the j-th equipment of the i-th inspection unit;

represents the actual duration of the j-th equipment of the i-th inspection unit;

represents the i-th maintenance unit of the j-th device monthly planned duration;

represents the i-th maintenance unit of the j-th device monthly planned duration;

represents the annual average actual duration of the maintenance equipment with equipment type

represents the annual average actual duration of the maintenance equipment with equipment type ;

;

Represents the yearly planned average planned duration of the maintenance equipment with equipment type K;

Represents the yearly planned average planned duration of the maintenance equipment with equipment type K;

Represents the monthly planned average planned duration of the maintenance equipment with equipment type K;

Represents the monthly planned average planned duration of the maintenance equipment with equipment type K;

, and

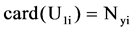

, and  In an evaluation cycle, the i-th unit has an annual planned set of equipment;

In an evaluation cycle, the i-th unit has an annual planned set of equipment;

, and

, and  In an evaluation cycle, the i-th unit has a monthly planned set of equipment;

In an evaluation cycle, the i-th unit has a monthly planned set of equipment;

![]() , and

, and ![]() In an evaluation period, the i-th unit is actually a set of equipment with power-off maintenance conditions;

In an evaluation period, the i-th unit is actually a set of equipment with power-off maintenance conditions;

![]() ,

, ![]() and

and ![]() the number of units involved in the assessment of the i-th unit during one evaluation cycle;

the number of units involved in the assessment of the i-th unit during one evaluation cycle;

![]() ,

, ![]() and

and ![]() the i-th maintenance unit planning cycle number of complete equipment;

the i-th maintenance unit planning cycle number of complete equipment;

![]() ,

, ![]() ,

, ![]() for the i-th repair unit cycle is not complete number of devices.

for the i-th repair unit cycle is not complete number of devices.

3.2. Efficiency of Equipment Overhaul Evaluation Index

By comparing the actual duration of the overhaul equipment with the average actual duration of the equipment, if the “actual duration > average actual duration”, the equipment is deducted according to the deduction function. To the actual implementation of the number of days more than the average number of days to punish the unit, in order to encourage units to improve the efficiency of maintenance implementation.

The solution to the index of the i-th evaluation object:

![]() (4)

(4)

![]() is the evaluation efficiency evaluation index of the i-th assessment object;

is the evaluation efficiency evaluation index of the i-th assessment object;

![]() is the actual duration of the j-th participating equipment of the i-th participating unit (whose equipment type is K).

is the actual duration of the j-th participating equipment of the i-th participating unit (whose equipment type is K).

![]() is the annual average actual duration of the maintenance equipment with the equipment type K;

is the annual average actual duration of the maintenance equipment with the equipment type K;

i represents the participating units;

j means participating equipment.

3.3. Equipment Maintenance Planning Cycle Integrity Evaluation Index

The maintenance plan is a process of approaching from a large cycle to a small cycle. The main cycle of the maintenance plan includes annual maintenance, monthly maintenance, day maintenance, which day maintenance for the implementation phase of the plan. In this paper, the complete maintenance cycle of each equipment to be repaired includes annual, monthly and day maintenance plans. Through the assessment of the cycle integrity of the equipment maintenance plan, you can assess the maintenance unit in the maintenance plan to set the maintenance cycle rolling is closely connected. The index can be an indirect assessment of temporary maintenance, sudden maintenance.

Calculation formula:

![]() (5)

(5)

![]() denotes the evaluation index of the object maintenance plan cycle incomplete;

denotes the evaluation index of the object maintenance plan cycle incomplete;

![]() is the number of equipment which is not complete in maintenance cycle of the i-th inspection unit;

is the number of equipment which is not complete in maintenance cycle of the i-th inspection unit;

![]() denotes the periodic loss penalty function;

denotes the periodic loss penalty function;

![]() is the maintenance cycle missing type of the jth device of the i-th unit of evaluation;

is the maintenance cycle missing type of the jth device of the i-th unit of evaluation;

i represents the participating units;

j means participating equipment.

3.4. λ1 and λ2 Weight Determination Method

The weight coefficient of λ1 and λ2 is 0.5. The purpose of this indicator is to promote the improvement of each evaluation object in the level of preparation, if λ1, λ2 is not equal weight; it will lead to the assessment object in the “planned duration” when the irrational estimate. For example, if λ1 > λ2, then the “actual duration > planned duration ‘will be greater than the’ planned duration > average planned duration”, which will lead to artificial extension of the “planned duration”, so that the assessment of the object in the maintenance plan Fewer penalties, and vice versa.

3.5. Penalty Function θ(x)

In the above indicators, the selection of the subtractive function θ(x) is very important. The first function can reflect the objective reality and the second function is easy to solve. Reference to the θ(x) function:

![]() (6)

(6)

Overhaul of equipment over the planned number of maintenance days will result in non-linear growth of penalty points, and more days beyond the penalty heavier. When the number of super-planned days is greater than the average number of super-planned days, the penalty score will increase.

3.6. Function σ(x)

The default x in the penalty function is the missing type in Table 1. The value of this function is the corresponding deduction in Table 1. The type of schedule missing and its deductions are as follows (1 means that there is a maintenance plan for the period, 0 means no maintenance plan for the cycle).

4. Maintenance Plan Business Level Assessment Method

The evaluation of the operational level of the maintenance plan is carried out through a comprehensive indicator of the operational level of the maintenance program that reflects the units participating in the assessment. The composite indicators are translated by way of mathematics, taking into account the measures

![]()

Table 1. Cycle missing penalty situation.

that measure the operational level of the maintenance plan aspects [7] [8]. In order to be able to objectively and fairly respond to the situation of each participating unit, this paper uses the mean square error method based on the principle of “differential drive” [9] to calculate the weight of the evaluation index, and the comprehensive evaluation method is used to evaluate the service level of the maintenance plan.

4.1. Mean Square Method

In order to avoid interference in the determination of the weight factor by human factors, we can use the “differential drive” principle of the weight method. Its basic idea is that the weighting coefficient is the coefficient of variation of the individual indicators in the indicator population and the measure of the corresponding degree of the other indicators. The original information of the empowerment comes directly from the objective environment, and the weight coefficient of the corresponding index can be determined according to the size of the information provided by each index.

The mean square error method is a measure of the degree of deviation of the data. The larger the standard deviation of the indicator, the greater the variation of the index between the different assessment objects, the greater the amount of information provided, which means that the greater the effect in the comprehensive assessment Weight should also be greater, on the contrary, then the weight should be smaller.

The formula of the weight of the h-th index calculated by the standard deviation is:

![]() (7)

(7)

![]() (8)

(8)

![]() (9)

(9)

H is the total number of participating indicators, the value of 3; ![]() is the standard deviation of the calculated value of the participating units on the hth index.

is the standard deviation of the calculated value of the participating units on the hth index. ![]() is the calculated value of the i-th participating unit on the h-th indicator.

is the calculated value of the i-th participating unit on the h-th indicator. ![]() is the mean value of the participating units on the hth index; n is the total number of participating units.

is the mean value of the participating units on the hth index; n is the total number of participating units.

The mean square error method emphasizes the local difference, which reflects the degree of importance according to the degree of difference between the observed values of the same index. If the data of each index of each system is not very different, it reflects that the index has little effect on the evaluation system and the calculated weight coefficient is not large.

4.2. Evaluation Model

Comprehensive evaluation solution formula:

![]() (10)

(10)

Among them, ![]() is the evaluation result matrix;

is the evaluation result matrix;![]() ,

,

![]() is a normalized matrix;

is a normalized matrix; ![]() dimensionless

dimensionless

processing yields![]() ;

; ![]() is the weight matrix of each index. According to the deduction points, the larger the calculated results the more backward. The value of the index

is the weight matrix of each index. According to the deduction points, the larger the calculated results the more backward. The value of the index ![]() on each evaluation object is

on each evaluation object is![]() },

}, ![]() represents the evaluation value of the i-th evaluation object on the j-th index. The method of non-dimensional processing is as follows: [10]

represents the evaluation value of the i-th evaluation object on the j-th index. The method of non-dimensional processing is as follows: [10]

![]() (11)

(11)

5. Examples and Analysis

A total of eight evaluations were conducted in the study, and the assessment data for the year 2015 annual maintenance plan data. First of all, the mean square error method is used to determine the level of maintenance operations, maintenance efficiency, and maintenance cycle integrity of the index weight. And then conduct a comprehensive assessment based on the evaluation model described in 2.2.The key indicators of the participating units are shown in Table 2.

1) Data preprocessing

Prior to the evaluation, the metrological processing of the indicator type and the non-dimensional processing of the indicator type are performed first. After data preprocessing, we can eliminate the difference of the data in each index, and avoid the influence of the difference between the dimension of the index and the number of the number.

![]()

Table 2. Evaluate the calculated value of the indicator.

The resulting normalized matrix is:

![]()

2) Determine the weight of the indicator

The mean square error method is used to determine the weight of the maintenance service, the maintenance efficiency and the maintenance cycle integrity. The weight values of the indicators are shown in Table 3

3) Comprehensive assessment results

The scores of the participating units on the three indicators and the comprehensive score are shown in Table 4.

4) Result analysis

From the data according to table 4 can be obtained in the maintenance plan at the level of the final ranking. Program A7 is ranked first, and program A2 has the lowest ranking. From Table 3, it can be concluded that the level deviation of each participant unit is relatively large in the two indexes of overhaul efficiency and maintenance cycle integrity, so the weight obtained by “difference drive” is also relatively large on these two indexes. With the lower rankings in the maintenance efficiency, maintenance plan cycle integrity and other two indicators on the continuous improvement of the three assessment indicators will change the weight. The higher weights are used to reflect the greater differences in indicators, thereby promoting the production units to improve production methods. And ultimately promote the entire power outage plan to improve the level of business, for the power grid security, economic operation to provide protection.

![]()

Table 3. Weight values for each indicator.

![]()

Table 4. Example of the comprehensive evaluation of the results.

6. Conclusion

In view of the practical needs of the power transmission and maintenance plan for the transmission network, this paper, in combination with the actual operation of the power outage plan, evaluates the operational level of the blackout maintenance plan through three indicators, which are the maintenance plan to develop the level of assessment indicators, maintenance plan implementation efficiency, maintenance plan cycle integrity. This paper presents a method of assessing the business level of maintenance plan. This method uses the mean square error method based on the principle of “difference drive” as the index weight calculation method, and uses the comprehensive evaluation model to evaluate the operational level of the power transmission plan. The numerical analysis shows that the method can reflect the order of the participating units in the maintenance planning level. And through the results of the corresponding improvement measures, and thus promote the unit in the overall improvement of the business for the scientific assessment of transmission network maintenance program to provide a level of effective reference.

NOTES

![]()

*This work is supported by Science and Technology Project of SGCC (Research on key technologies of integrated power grid dispatching intelligent assistant decision).