Cyanides Reduction and Pasting Properties of Cassava (Manihot Esculenta Crantz) Flour as Affected by Fermentation Process ()

1. Introduction

Cassava is the first most important root crop cultivated in tropical and subtropical regions of the world. More than the half of the worlds’ cassava production comes from Africa; with Cameroon being the 19th world’s leading producer [1] . Cassava tuber is highly starchy which makes “fufu” preparation easy and can equally be prepared and eaten whole like cocoyam (Colocassia esculenta) [2] . Cassava can also be processed in several ways to produce different food products. Among the processes cassava can be subjected to, are “gari” production, boiling, flour for baking, soup thickeners, specialty food for gastrointestinal disorders and fermented flour which is cooked in boiled water to form a somewhat acidic paste called fufu, which is consumed with a sauce or vegetables. Several studies have shown that cassava contains digestible starch, vitamins and a low score of amino acids [3] . However, two major limiting factors in the utilization of cassava are, low shelf life and the presence in various proportions of cyanide compounds, which hydrolysis leads to the production of hydrocyanic acid (HCN), a substance toxic to humans [4] [5] . Ingestion of foods containing cyanide compounds have also been reported to cause an upper neuron disease known as “Konzo”, which is characterized by abrupt onset of spastic paralysis, nausea and vomiting [6] . The presence of these cyanogenic glucosides necessitates the processing of roots prior to consumption. Fermentation not only enhances detoxification but may also improve the quality of the food under process [7] . Traditionally, fermented cassava flour is made by soaking cassava roots in water for 3 to 5 days, followed by the process of draining, drying and milling. [7] (Numfor et al., 1995) showed that changes in physicochemical properties of cassava flour produced were attributable to the spontaneous fermentation occurring during soaking. In order to reduce the time of root softening during the fermentation process, starters can be added to the fermentation medium at the beginning of the fermentation, which can modify physicochemical properties of cassava flour. Knowing that, application of flour from different plant sources in food systems depends greatly on information about the physicochemical properties of such food materials, the aim of this study was to determine the effect of fermentation on pasting properties and cyanogenic compounds of cassava flour.

2. Material and Methods

2.1. Flour Sample Preparation

Cassava roots of the bitter variety (containing a quantity of 655 ppm of cyanides) were collected from IITA in Yaounde, Center Region Cameroon. Flours preparation was performed according to the procedure in Figure 1. The roots were cleaned, peeled, washed, and sliced into pieces of 10 cm long, then left to ferment in tap water for 24 h, 48 h and 72 h. The fermentation studied included spontaneous fermentation (SF), i.e. water soaking of cassava roots as a control and fermentation with added starter flour (FAS) at the concentration of 1% (w/v). The fermented cassavas were drained, dried in an oven at 40˚C for 48 h and milled. The flour samples were passed through a 45 µm mesh size sieve. Unfermented cassava flour (UCF) was also produced to serve as a control.

2.2. Total Cyanide Analysis of Fermented Flour

The total cyanide content of cassava flour was determined as described by [8] .

![]()

Figure 1. Cassava flour samples preparation procedure.

For this purpose, a 100 mg sample was placed in a screwable plastic flask on top of a filter paper soaked with the pH 6 buffer phosphates and Linamarase. A volume of 0.5 ml distilled sterile water was then added in the flask as well as a yellow colored picric acid paper. The flask was immediately and hermetically closed using a screwed plug and placed at 30˚C for 18 hr. The following day, the yellow-orange paper was taken out of the flask and put in a test tube containing 5 ml of sterile water and the test tube was boiled for 5 min. The paper was taken out and the absorbance of the solution measured at 510 nm after cooling. The total cyanide in ppm (parts per million) was calculated by multiplying the absorbance by 396.

2.3. Pasting Properties Studies

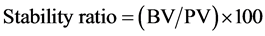

Pasting properties of flours were determined with a Rapid Visco Analyser (RVA- 4, New Port Scientific, PETERN Instrument-Australia). Flour suspension 12.5% (w/v) (3.5 g dry basis suspended in distilled water and the total weight adjusted to 28 g), was equilibrated 1 min at 50˚C, heated to 95˚C in 5 min. at the rate of 9˚C・min−1, held at 95˚C for 2 min, cooled to 50˚C for 5 min at 9˚C・min−1 and held again at 50˚C for 1 min. The stirring speed was 160 rpm. From the resulting curve, the Pasting temperature (Pt), the Peak viscosity (PV), the final viscosity (FV), the Breakdown viscosity (BV) and the Setback viscosity (SV) were recorded. These data permitted to determine the percentages of gelling and drop according to the formulas below:

2.4. Statistical Analysis

All measurements were made three times. The comparison of the averages of the values obtained was done by ANOVA on SPSS 16.0 (SPSS International Chicago, USA) with a confidence threshold of 95%. The significant differences between the averages were performed using the LSD procedure.

3. Results and Discussion

3.1. Total Cyanides Content of Fermented Flours

The results (Table 1) show that the total cyanides content of the flour decrease from 350 mg HCN equivalents.kg−1 flour (ppm) (unfermented flour) to 7.9 ppm and 3.1 ppm respectively for 72 h spontaneous fermented flour (SF) and 72 h flour fermented with added starter (FAS). Total cyanides content decreased with increase in fermentation period. There was a 97% and 99% reduction in cyanides content respectively for SF and FAS of the 72 h fermented flours when compared with unfermented cassava flour. Total cyanides content of the 24 h and 48 h fermented flours were also reduced. The most cyanide reduction was observed with flours FAS, in which the reduction percentages were 80% and 98% at 24 h and 48 h respectively compared with the 20% and 92% reductions obtained with flours SF at the same period.

The observed marked reduction caused by fermentation may be due to the effect of enzymes/acid hydrolysis of the cellular wall during the fermentation and the microbial load at the beginning of fermentation. The addition of the starter at the beginning of fermentation increases the microorganisms load in the fermentation medium indeed. Microorganisms accelerate the rate of roots softening and acidification of the medium. These two parameters are strongly correlated with the activity of the enzymes that degrade the cellular wall, phenomenon responsible for hydrolysis of the linamarine by the linamarase and then, for the detoxification [9] [10] [11] (Kabawila et al., 2005), also reported a 75% cyanides content reduction in fermented cassava roots.

3.2. Pasting Properties

The effect of different methods fermentation on pasting properties of cassava flour is presented in Tables 2-4. Our results showed that pasting properties of cassava flour were affected by fermentation process. Addition of starter culture for fermentation showed more complex effect on the pasting properties and was a function of the progress of fermentation reaction.

![]()

Table 1. Total cyanides remaining in cassava flour after different hours of fermentation.

The results reported are means of triplicate samples and SD in brackets. Different superscript letters, in the same column, indicate significantly different (p < 0.05) samples. SF spontaneous fermentation, FAS: fermentation with the addition of mixed-starter.

![]()

Table 2. Pasting properties of cassava flours at 24 hours of fermentation.

The results reported are means of triplicate samples and SD in brackets. Different superscript letters, in the same column, indicate significantly different (p < 0.05) samples. UCF: unfermented cassava flour, SF spontaneous fermentation, FAS: fermentation with the addition of mixed-starter, Pt: pasting time; PV: peak viscosity; BV: breakdown viscosity, FV: final viscosity, SV: setback viscosity, Set: setback ratio, Sta: stability ratio.

![]()

Table 3. Pasting properties of cassava flours at 48 hours of fermentation.

The results reported are means of triplicate samples and SD in brackets. Different superscript letters, in the same column, indicate significantly different (p < 0.05) samples. UCF: unfermented cassava flour, SF spontaneous fermentation, FAS: fermentation with the addition of mixed-starter, Pt: pasting time; PV: peak viscosity; BV: breakdown viscosity, FV: final viscosity, SV: setback viscosity, Set: setback ratio, Sta: stability ratio.

![]()

Table 4. Pasting properties of cassava flours at 72 hours of fermentation.

The results reported are means of triplicate samples and SD in brackets. Different superscript letters, in the same column, indicate significantly different (p < 0.05) samples. UCF: unfermented cassava flour, SF spontaneous fermentation, FAS: fermentation with the addition of mixed-starter, Pt: pasting time; PV: peak viscosity; BV: breakdown viscosity, FV: final viscosity, SV: setback viscosity, Set: setback ratio, Sta: stability ratio.

The pasting parameters (Table 2) of cassava flours made from cassava roots after 24 h of fermentation were evaluated. The pasting temperature of SF and FAS cassava flour was 72.7˚C and 70.5˚C, respectively. The pasting temperatures of the fermented flours were not significantly different from the unfermented flour (71.7˚C). These results indicate a weak granular structure of cassava compare to cocoyam (78˚C pasting temperature) [2] (Oke and Bolanriwa, 2012). The peak viscosity (PV), Breakdown viscosity (BV), Final viscosity (FV) and Setback viscosity (SV) of the SF and FAS cassava flours were not significantly different from the unfermented flour, and indicates that no major modifications occurs in starch granules of cassava root after 24 h of the fermentation. However a significant difference was observed between setback ratio of FAS flour (1.3) and unfermented flour (1.4). This result shows that FAS flour is less consistence than UCF and SF.

The pasting parameters (Table 3) of cassava flours made from cassava roots after 48 h of fermentation were evaluated. Unfermented cassava flour has peak viscosity of 5205 cP, while peak viscosity of SF and FAS flours was 6420 cP and 5749 cP respectively. Increase of PV is associated with enzymatic activity during fermentation process [12] (Farasara et al., 2014). Amylase hydrolyzes α-1, 4-D- glycosidic bond of starch thus the structure of starch granule becomes more porous facilitating water absorption to granules. This will increase PV [13] (Claver et al., 2012). Flour with a lower peak viscosity has a lower thickening power than flour with higher peak viscosity; therefore FAS flour has a lower thickening power than SF flour and 24 h fermented cassava flour has a lower thickening power than 48 h fermented flour. The final viscosity of SF flour and FAS flour after 48 h of fermentation (3086 cP and 3813 cP) was significantly different from the unfermented cassava flour (3580 cP). This result shows that, amylose content is higher in FAS flour followed by unfermented flour than in SF flour. Increase of FV can be associated with marked activity of amylases that hydrolyses amylopectin and thus releases polymeric chains of 15 monomer units which physicochemical properties are similar to those of amylose [14] .

Breakdown viscosity (BV) is the degree of viscosity reduction during heating process. It can be used as an indicator for pasting stability during the heating and stirring 2. The SF flour had the highest breakdown viscosity (3160 cP), while the UCF flour had the lowest one (2627 cP). SF flour paste (stability ratio = 0.6) was also more resistant to shear thinning than FAS and UCF (stability ratio = 0.5) (Table 3). This finding indicates that, SF flour has the ability to withstand severe processing conditions better than FAS and UCF pastes [15] . Breakdown viscosity values were also highest in the 48 h fermented flours than the 24 h fermented flours (Table 2). Breakdown increased with the increase in the fermentation period of the flour samples. This suggest that, the swollen starch granules of fermented flours can be easily been disintegrated than those of Unfermented starch granules. Thus, unfermented starch granules are more stable during heating process than fermented starch granules [16] .

The setback viscosity (SV) (Table 3) of fermented flours SF and FAS were 1081 cP and 1224 cP, respectively. Those values were highest than the SV of UCF (1002 cP). The setback obtain in this study indicates a higher retrogradation tendency of fermented cassava flour, particularly FAS flour. This property of FAS flour makes it suitable for use in jelly foods [2] .

Continued fermentation process of cassava roots up to 48 hours of fermentation, result in cassava flour with their respective pasting parameters presented in Table 4. As we can see in this table, final viscosity and setback viscosity of fermented flours were not significantly different from those of unfermented cassava flour. However, the pasting temperature of SF flour (71.5˚C) was higher than the pasting temperature of UCF (71.7˚C); while the pasting temperature of FAS flour (70.3˚C) was lower than the one of UFC. The peak viscosity of FAS flour was higher than the peak viscosity of UCF. Lower pasting temperature and rapid rise in peak viscosity indicate a weak granular structure of FAS flour at 72 h of fermentation. In general, the PV value of fermented cassava flours continued to increase to 6615 cP (SF) and 5986 cP (for FAS) with the period of the fermentation. This was also observed with the BV value of those flours. This is an indication of the weak elasticity and weak consistence of fermented flours comparing with unfermented cassava flour. The setback ratio of UCF (1.4) flour paste was higher than the one of fermented cassava flour pastes SF (0.8) and FAS (0.9), indicating that dispersed UCF flour has a higher rate of retrogradation due to the association of the leached amylose molecules.

4. Conclusion and Recommendation

Fermentation affected the total cyanides content and pasting properties of cassava flour. Cyanides content was reduced significantly. The greatest reduction was observed in the FAS cassava flour, with the cyanides reductions level of 98% and 99% respectively, at 48 h and 72 h of fermentation. This reduction was faster with the addition of starter compared to spontaneous fermentation. Pasting parameters increased markedly after 24 h of fermentation. Then, at 46 h of fermentation, SF flour paste was more resistant to shear thinning than FAS and UCF, indicating that, SF flour has the ability to withstand severe processing conditions better than FAS and UCF pastes. The use of mixed-starter culture resulted in cassava flour with higher value of PV, SV and FV after 48 h of fermentation, which decreased when fermentation was prolonged at 72 h. Further study need to be carried out on chemical composition as well as functional properties of fermented cassava flour and if possible, to characterize the microorganisms in 96 hours of fermented flour used as starter in this work.

Acknowledgements

This publication is an output of a project funded by European Union (contrat de subvention n˚ dci-food/2010/252-886), with the support of AIRD (Agence Inter-Etablissements de Recherche pour le Développement).