Preparation and Quality Evaluation of Extended Beef Rounds Containing Gum Arabic from Acacia senegal var. kerensis ()

1. Introduction

Meat extenders are substances that are added in meat products with the aim of improving the binding properties of such products. Extenders such as soy protein concentrates (SPC), whole milk, egg proteins and fillers such as starches are used for the manufacture of affordable but nutritious meat products [1] . For instance, the Food Safety and Inspection Service (FSIS) has allowed the use of SPC at a level not exceeding 3.5% of the product formulation in cured pork products. These components are used due to their water binding properties [1] . Plant based hydrocolloids consisting mainly of polysaccharides such as carrageenan [2] [3] , flaxseed gum, gellan gum [4] and gum karaya [5] have been found to improve water holding capacity and appearance of meat products. Therefore, they have been utilized in meat products to enhance quality of the meat products.

Various researchers have worked on meat extension in order to improve various quality parameters and also enhance the value of the meat. The work by Schilling, [6] reported that high quality pork was produced from low quality meat referred to as pale, soft, and exudative (PSE), and red, firm, and non-exudative (RFN) semimembranosus muscle by use of modified food starch (MFS), sodium caseinate (SC), and SPC. Combining SPC and modified food starch together in formulations had the best impact on water binding, color and texture for the produced pork and boneless deli ham roll. Researchers have patented or filed for patenting various processes of extending and improving meat and related meat products. The USA patent 6,074,682 [7] provides a ham and water product that is flavored with jalapeno peppers and a method of making a jalapeno flavored ham and water product. In this patent, the ham is injected with a pickle solution, processed to increase surface ratio, and treated with a buffered jalapeno composition. In another patent, 4,381,316 [8] , a whey protein fortified cured meat is described. The process involves utilization of whey protein to fortify cured intact skeletal meat muscle tissue. The curing brine solution contained 30% by weight whey protein on a dry solids basis.

Gum arabic, a dried exudate obtained from the stems and branches of Acacia senegal is an approved food additive, E414 [9] - [11] . Its functional uses include emulsification, stabilization and as a thickener [10] . Gum arabic from Acacia senegal var. kerensis has been reported to exhibit water binding properties that are required to function as a binder in low fat yoghurt [12] as well as a stabilizer in ice-cream and beverages [13] . The radius of gyration (Rg) of the gum from the variety kerensis was reported to be 1.5 times that of gum from the variety senegal at 40 nm and 25 nm, respectively [12] . These properties are as a result of the presence of both hydrophilic sugar residues and the amphiphilicprotein component in the arabinogalactan protein which contributes to the adsorption into air/water or oil/water interfaces [14] [15] . The gum is readily soluble in water to give relatively low viscosity newtonian solutions even at high concentrations (20% - 30% wt/wt), [16] . Its physical properties are markedly comparable to those of gum karaya which is already used in meat products as well as mesquite gum a protenacious arabinogalactan gum similar to gum arabic [17] that is used in the food industry. Furthermore, due to its antioxidant properties [18] ability to protect oil against oxidation [5] [13] , ability to reduce degradation of water soluble vitamins in food products [5] , encapsulation of flavors and aromatic compositions [19] as well as its fiber content can ensure a wholesome, healthy high sensory final product is achieved. However, utilization of gum arabic from Acacia senegal var. kerensis as a water binding agent in meat productsis yet to be reported. This is important considering that the radius of gyration (Rg) plays a significant role in water interactions with hydrocolloids hence, the respective rheological properties.

Therefore, the aim of the present study was to evaluate the physico-chemical and sensory parameters of extended beef rounds injected with curing brine containing various levels of gum arabic from Acacia senegal var. kerensis. We report the findings on physico-chemical parameters and consumer acceptability data on the cooked extended beef rounds prepared with curing brine solutions containing specific amounts of gum arabic. To the best of our knowledge, this is the first report on the physico-chemical properties of extended beef rounds containing gum arabic from Acacia senegal var. kerensis.

2. Materials and Methods

2.1. Materials

Gum arabic from Acacia senegal var. kerensis was sourced from Isiolo, Kenya. Meat was obtained from Castle Meat Products factory, Njoro, Kenya, while soy protein concentrate was procured from Archer Daniels Midland, (ADM; Decatur, Illinois, USA) through their local agent, Chemical and Solvents Company Ltd., Nairobi, Kenya.

2.2. Sample Preparation

Samples were prepared at Castle Meat Products factory, Egerton, Nakuru, Kenya. Formulation of beef injection brine was done to attain injectable solutions containing standard recommended amounts of sodium chloride, sodium nitrate, sodium tripolyphosphate, and sodium ascorbate with varying levels of gum arabic (1%, 1.5%, 2%, 2.5% and 3% of the projected final weight of extended beef rounds) maintained at 4˚C using ice flakes. Non injected control samples were prepared as well as samples injected with curing brine solutions containing SPC at 3.5% level of the projected final weight of the extended beef cut to act as a positive control. Meat cuts used were obtained from carcasses 30 hours after slaughter. Carcasses were preserved under refrigeration set at 4˚C. Cuts weighing 3.5 kg consisting of pieces from the beef round were trimmed of external fat, skin, membranes and the silver skin, and weighed before injection to obtain the green weight. Injection was achieved using a manual injector pump (Friedr. DICK Hand Brine Injector Pump) and massaging for 3 h to evenly distribute the brine. Hams were then kept for 18 hours at 4˚C after which they were weighed to get the injected weight. Possible injection level was determined as follows: Injected weight/green weight × 100. Actual gum injected was calculated based on the possible injection level for each extended beef cut. Beef cuts were arranged properly, wrapped firmly in food grade cling films and placed in steel molds consisting of a container base with a retaining rim and a lidfitted with locking teeth and a temperature monitoring hole on top. Lids were pressed to the same extend for uniformity within samples. The hams were then placed in hot water reaching the rim of the mold set at 85˚C ± 0.5˚C and cooked for 4 - 5 hours until an internal temperature of 75˚C ± 0.5˚C was reached. To ensure uniformity in treatments, temperature was constantly monitored using a thermometer (TTX 110, Ebro, Ingolstadt, Germany). After cooking, hams in the molds were allowed to cool in a cold room set at 4˚C. Slicing was aseptically done using a slicing machine (Tecmal, Torino, Italy)to a thickness of 3 mm and packaging done in a vacuum packaging machine (Multivac, Germany) using low-density polyethylene sterile vacuum bags (length 30 cm, width 15 cm). Samples were transported to the laboratories for quality evaluation under refrigeration.

2.3. Expressible Moisture and Cook Yield

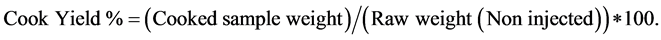

Expressible moisture was determined through centrifugation using a table top centrifuge, DSC-200A (Aron Laboratory Instruments, Taiwan). Slices from different packages representing slices from different parts of the extended beef rounds were randomly sampled for this determination. Expressible moisture of cooked extended beef rounds was found by centrifuging 10 g sample at 860 × g for 7.5 min at 20˚C [20] . Cook yield was determined as follows:

2.4. Proximate Analysis

The proximate analysis was performed according to the Official Methods of the Association of Official Analytical Chemists’ [21] . Briefly, the moisture was determined by the AOAC Method 950.46, the crude protein by AOAC method 981.10 and crude fat by AOAC Method 960.39 while the ash content was done by AOAC Method 920.153.

2.5. Sensory Evaluation

Sensory evaluation was performed by a panel of 7 trained persons. The constitution of the panelists involved pre-screening, screening, training, and performance evaluation sessions [22] . The panel evaluated each treatment in duplicate at room temperature. Cooked beef samples were evaluated for beef flavor, juiciness, hardness, springiness and saltiness using the 16-point spectrum universal intensity scale and overall liking using a 5-point hedonic scale.

2.6. Statistical Analysis

The experimentation employed a two factor factorial arrangement in a completely randomized design (7 binder levels (6 levels of gum + 1 level SPC), 2 injection levels) in triplicate. Data were reported as means ± standard error. Analysis was done using Statistical Analysis System, SAS software version 9.1.3 [23] for analysis of variance (ANOVA). Means were separated using least significant difference (LSD) method for injected beef rounds and Dunnett’s test for the mean separation between injected and non-injected beef samples at P = 0.05 level of significance. Linear correlation coefficients were also calculated.

3. Results and Discussion

3.1. Effect of Gum Arabic Level on the Processing Characteristics of Cooked Extended Beef Rounds

The processing characteristics of the extended beef rounds prepared with curing brine containing gum Arabic are shown in Table 1. The level of gum arabic from Acacia senegal var. kerensis used in curing brines significantly (P < 0.05) affected the processing characteristics of cooked extended beef rounds. Cook yield significantly (P < 0.05) increased with increase in gum arabic level. Samples injected with SPC at 3.5% had the highest yields at 89.02% ± 0.61% followed by 3% at 89.64% ± 1.20% and 2.5% at 88.14% ± 0.74% gumarabic brine injected beef samples. However, these three were not significantly (P ≥ 0.05) different from each other. There was a significant positive correlation (r = 0.730, P = 0.0003) between the cook yield and gum level indicating that the gum arabic addition increased the resulting cook yield of extended beef rounds. However, there was no significant linear correlation (r = −0.182, P ≥ 0.05) between expressible moisture and cook yield unlike what was earlier reported [24] . While studying the effect of meat cut and injection level on the tenderness and cook yield of processed roast beef, Shand, [24] reported a significant linear correlation between expressible moisture and cook yield indicating that higher yields resulted in lower water holding capacities. In this research samples with higher cook yields also had higher water holding capacity resulting in lower levels of expressible moisture. Cook yield increased with increase in gum arabic level, which means that samples with higher cook yield had higher gum arabic levels and hence, the reduced extractable moisture. Furthermore, this may also be explained by the increase in the ability of gum arabic to hold moisture after heat treatment. According to Al-Assaf and others, [25] , on heating gum arabic from Acacia senegal, the proteinaceous components aggregate producing a hydrogel form with enhanced mechanical properties and water binding capabilities which may have increased

![]()

Table 1. Effect of gum level on the processing characteristics of cooked injected beef rounds.

Data are presented as means ± standard error. a-eMeans within a column with different superscript are significantly different (P < 0.05). Dunnett’s test-used for comparing between non-injected and injected samples. LSD-used for comparing among the injected samples.

the cook yields while lowering the extractable moisture.

The non-injected samples had significantly lower (P < 0.05) yields compared to the samples injected with gum arabic containing curing brines. The 2.5% and 3.0% gum arabic containing hams recorded the lowest expressible moisture. However, there was no significant difference (P ≥ 0.05) in extractable moisture between extended beef rounds injected with 2.5% and 3.0% gum with the non-injected beef samples. This may be explained by the fact that non-injected beef samples had the lowest moisture content recorded when compared to the injected beef rounds. Therefore, the proportion of moisture lost as compared to the moisture present in the sample was higher in non- injected samples than in the injected samples. Samples containing 1.5% and 2.0% gum arabic had lower expressible moisture as compared to the SPC containing extended beef rounds. Highest significant (P < 0.05) expressible moisture was observed in extended beef rounds injected with 1% gum arabic, followed by the SPC containing ham. Correlation revealed a negative significant correlation (r = −0.746, P = 0.0002) between actual gum arabic in extended beef rounds and expressible moisture confirming the ability of gum arabic to act as a binder in meat products. Other researchers [4] have reported similar observations when carrageenan, flax seed and gellan gum binders were used in sausages.

The effects of gum levels on the proximate composition of cooked extended beef rounds are presented in Table 2. The level of gum arabic in the extended beef rounds had a significant effect (P < 0.05) on the resulting moisture content of extended beef rounds. Rounds injected with 3% gum had the highest moisture content which was higher than the SPC injected extended beef rounds. The level of gum arabic in the product also significantly (P < 0.05) affected the protein content of extended beef rounds. As expected the protein content was significantly highest (P < 0.05) in the non- injected product possibly due to the low moisture content reported. Also the SPC containing product had higher protein content as compared to the gum arabic injected extended beef rounds due to the high protein content in SPC. However, the protein content for the SPC product was not significantly different (P ≥ 0.05) from the 2.5% gum

![]()

Table 2. Effect of extender on the proximate composition of cooked injected beef rounds.

Data are presented as means ± standard error. a-fMeans within a column with different superscript are significantly different (P < 0.05). Dunnett’s test-used for comparing between non-injected and injected samples. LSD-used for comparing among the injected samples.

arabic extended beef round spossibly due to the fact that the 2.5% gum Arabic extended beef rounds had the lowest moisture content recorded. Injection with brines containing gum Arabic resulted in significantly higher (P < 0.05) ash content due to the injected salts in the brine. Ash content for samples containing gum arabic was significantly higher (P < 0.05) than that for non-injected samples. Samples with 2.5% gum had significantly higher (P < 0.05) mean ash content possibly because of the high percent pick up while the non-injected sample had the lowest ash content. Neither injection level nor gum arabic level had a significant effect (P ≥ 0.05) on the fat content of injected beef rounds.

3.2. Effect of Injection Level on the Processing Characteristics of Cooked Extended Beef Rounds

The effect of injection level on the processing characteristics of cooked injected beef rounds is shown in Table 3. The injection of beef with the curing brine significantly (P < 0.05) affected the processing characteristics of cooked extended beef rounds. Actual injection levels achieved were lower but very close to the target injection levels. The target injection level of 30% produced a product with an actual injection level of 29.5% while 35% injection level produced a product with an actual injection level of 33.84%. This was in agreement with similar work reported by Boles and Shand, [24] . These researchers reported that higher injection levels were less achievable than lower injection levels. In their work on the effect of meat cut and injection level on the tenderness and cook yield of processed roast beef, they injected meat cuts at 110%, 125%, and 150% levels but obtained products with 109.0%, 123.9%, and 134.5% actual injection levels respectively. Cook yield as reported by McDonald and others, [26] significantly (P < 0.05) increased with increase in injection levels from 30% to 35% when injected vacuum cooled beef was analyzed. In our research, samples injected to 35% level had significantly higher (P < 0.05) yields than samples injected to 30% level. All injected samples had

![]()

Table 3. Effect of injection level on the processing characteristics of extended beef rounds.

Data are presented as means ± standard error. a-cMeans within a column with different superscript are significantly different (P < 0.05). Dunnett’s test-used for comparing between non-injected and injected samples. LSD-used for comparing among the injected samples.

significantly higher (P < 0.05) yields than non-injected beef samples implying that injection increases the cooking yield of beef products. Similar observations have been reported by other researchers [24] [26] [27] . These reports showed that there was an increase in cook yield when injected roasts were compared with non-injected ones.

Expressible moisture which may be a measure of purge in the packaged product [24] was found to be significantly higher (P < 0.05) in injected samples than non-injected beef samples. Samples injected to 35% level had higher amounts of expressible moisture than those injected to 30% level. This observation is possibly because of the higher moisture content attained as well as low levels of achieved gum content as compared to the samples injected at 30% injection level. The low levels of gum attained in the 35% injection level may have resulted in lower water binding properties. In addition, the inability to achieve targeted injection levels would result in lower ionic strength due to lower phosphate levels achieved [24] . This leads to lower water holding capacity of extended beef rounds. In our case the possible injection level was much lower than the targeted injection level at 35% level of injection than at 30% injection level. It appears that the 30% injection level may be more attractive than the 35% injection level since the targeted injection level was almost achieved as well as the higher gum levels achieved in the samples. Moisture content analysis indicated that the injection level had a significant effect (P < 0.05) on the mean moisture content of beef samples. Injection yielded significantly higher (P < 0.05) moisture content for injected beef samples than the non-injected beef samples which was also observed by Boles and Shand, [24] who reported increased moisture content of injected roasts when they were compared with non-injected roasts. The 35% injected samples had higher mean moisture content than 30% injected samples though there was no significant difference (P ≥ 0.05) in the moisture content between the two. Injection significantly (P < 0.05) affected the level of protein in the final extended beef rounds. This is as would be expected due to the dilution effect by the amounts of retained injected curing brine solutions. Injected beef rounds had lower protein content than non-injected beef rounds possibly because of the lower moisture content in the non-injected samples. Furthermore, in the injected beef rounds, 30% injection level achieved significantly higher (P < 0.05) protein content than the 35% injection. Ash content was highest in the injected samples as compared to the non-injected samples due to the curing brine salts in the injected samples. However, ash content in the 30% injected samples was significantly higher (P < 0.05) than in the 35% injection possibly due to the lower concentration of salts in the 35% injection as a result of the inability to achieve the expected injection level by a larger margin in 35% injection than the 30% injection.

3.3. The Effect of Injection and Gum Level on the Sensory Quality of Extended Beef Rounds

The effect of injection level on flavor, texture and overall acceptability of cooked injected beef rounds are shown in Table 4. The different injection levels significantly (P < 0.05) affected the hardness and springiness of cooked injected beef rounds. Increasing

![]()

Table 4. The effect of injection level on flavor, texture and overall acceptability of cooked injected beef rounds.

Data are presented as means ± standard error. a-bMeans within a column with different superscript are significantly different (P < 0.05). Dunnett’s test-used for comparing between non-injected and injected samples. LSD-used for comparing among the injected samples.

injection significantly reduced (P < 0.05) the hardness of injected beef rounds. McDonald et al., [26] reported an improvement in tenderness and juiciness when hams were injected up to 145%. Baublits et al. [28] reported that enhancement at 18% pump rate improved the overall tenderness of steaks. Injection level had no significant effect on beef flavor, juiciness, and saltiness. However, juiciness was rated higher for the hams injected to 35% level of injection indicating that higher levels of injection may improve juiciness of extended beef rounds which further confirms the work of other researchers [24] [26] . In the current study, the moisture content of extended beef rounds injected to 35% level was significantly higher (P < 0.05) which further explains the improvement in juiciness for the same samples. Furthermore, hardness reduced with the injection level. Saltiness and beef flavor also increased with increase in injection level. Moreover, injection did not significantly affect (P ≥ 0.05) the overall liking of extended beef rounds.

The effect of gum arabic level on flavor, texture and overall acceptability of cooked injected beef rounds are shown in Table 5. The level of gum arabic used in extended beef rounds significantly (P < 0.05) affected all sensory attributes in cooked beef round samples. Beef flavor was more retained in the extended beef rounds containing gum arabic as compared to those containing SPC. The sample containing 1% gum arabic had the highest beef flavor rating followed by 3% and 2.5% gum arabic containing extended beef rounds. SPC containing samples had the highest juiciness score followed by the 2% and 2.5% gum arabic extended beef rounds all of which were not significantly different (P ≥ 0.05). As expected, the SPC containing product had least hardness due to the high moisture content. Denseness was higher in the gum arabic extended beef rounds but comparable to the SPC extended beef rounds. Springiness was found significantly highest (P < 0.05) in the 3% gum product and least in the SPC containing product. Saltiness was rated highest in the 2.5% gum arabic product followed by the SPC extended beef rounds. However, there was no significant difference (P < 0.05) in saltiness between these two samples.

4. Conclusion

The results indicate that both brine injection and gum arabic significantly improved the quality of cooked extended beef rounds. Cook yield was rated highest in the SPC product, 2.5% and 3.0% gum arabic products while the lowest expressible moisture and the highest beef flavor rating was recorded in gum arabic injected beef rounds. Targeted

![]()

Table 5. The effect of binders on flavor, texture and overall acceptability of cooked injected beef rounds.

Data are presented as means ± standard error. a-dMeans within a column with different superscript are significantly different (P < 0.05). Dunnett’s test-used for comparing between non-injected and injected samples. LSD-used for comparing among the injected samples.

gum arabic levels and brine injection levels were achieved well with the 2.5% gum arabic level and 30% injection levels respectively. Also, targeted brine injection levels were best achieved at 2.5% gum arabic level. Therefore, an optimum level of gum arabic at 2.5% of the formulated final weight of beef round has the potential of providing a high quality product comparable to the SPC containing product. Understanding the functionality of gum arabic in meat product will permit its utilization in the food industry. This research has provided information which may be used in value addition of meat and meat products especially beef as well as enhanced utilization of gum arabic from Acacia senegal var. kerensis in the food industry.

Acknowledgements

This research was funded through a research grant from the Association of African Universities, Accra, Ghana and the Egerton University Council Graduate Scholarship, Egerton University, Kenya. The extended beef rounds were prepared at the Castle Meat Products factory.