World Journal of Condensed Matter Physics

Vol.3 No.1(2013), Article ID:28316,4 pages DOI:10.4236/wjcmp.2013.31009

Preparation and Characterization of Cu-Zn Nano-Structural Ferrite Thin Films Produced by Pulsed Laser Deposition (PLD)

![]()

Department of Physics, Nizam College, Osmania Universitry, Hyderabad, India.

Email: *ravindergupta28@rediffmail.com

Received March 8th, 2012; revised July 16th, 2012; accepted August 7th, 2012

Keywords: Nano-Structural Thin Films; Pulsed Laser Deposition; Cu-Zn Ferrite Nano Thin Films

ABSTRACT

Cu-Zn ferrite nano thin films were deposited from a target of Cu-Zn ferrite onto a sapphire substrate using XeCl excimer laser operating 308 nm with an energy of 225 mJ and a frequency of 30 Hz. Films were deposited from the target onto sapphire (001) substrates heated to 650˚C in an oxygen atmosphere of 100 m Torr. The laser beam was incident On the target face at an angle of 45˚. Studies on crystal structure were done by X-ray diffactometry (XRD). The surface texture, cross-section morphology and grain size was observed by JEOL-JSM-6400 scanning electron microscopy, atomic force microscopy (AFM) and magnetic force microscopy (MFM) [Model DI 3000, Digital instruments].

1. Introduction

Cu-Zn Ferrites and ferrite thin films can be used as deflection yoke core in television picture tubes, memory core devices in computers and antenna cores. They are also widely used in inductors, memory and switching devices, microwave latching devices, transformers, etc. At microwave frequencies, ferrites are extensively used in a number of microwave devices such as-isolators, circulators, gyrators and phase shifters.

Magnetic and electric properties of ferrites are having fundamental and technological and potential applications. Potential applications such as: 1) high density information storage in computers; 2) ferrofluid technology, magnetocaloric refrigeration, magnetic resonance imaging (MRI) enhancement, magnetic guided drug delivery, microwave devices and magnetic recording media and magnetic sensors.

Cu-Zn ferrite Superparmagnetic nanoparticles also have been used in biomedicine and bio-technology as contrast agents in magnetic resonance imaging (MRI) and as drug carriers for magnetically guided drug delivery.

Although bulk Cu-Zn has been studied extensively over a long period, Cu-Zn ferrite thin films have recently received considerable attention on account of their potential industrial applications in high-density magnetic recording media, microwave devices, permanent magnets, magneto caloric refrigeration and the contract agents for magnetic resonance imaging.

Pulsed Laser Deposition (PLD) has now proved to be a very useful technique for obtaining thin films of ferromagnetic oxides [1,2] and perovskite oxides [3,4].

In view of the wide ranging potential industrial applications Cu-Zn ferrite nano thin film has been chosen for the present study.

2. Experimental

The targets of Cu0.1Zn0.9Fe2O4 ferrite were prepared by citrate precursor method. The targets were sintered at 1000˚C. Cu-Zn ferrite nano thin films were prepared by pulsed laser deposition system (LAMBDA Physic model LEXtra 200, XeC1 excimer laser) in the vacuum chamber with O2 atmosphere. The detailed deposition conditions are listed in Table 1.

Table 1. PLD system conditions for the deposition of Cu-Zn ferrite nano thin films.

The structure of the film was determined by using X-ray diffractometer with CuKα radiation of Rightku DMAX II. The surface structure, morphology and grain size were observed by atomic and magnetic force microscopy (Modal DI 3000 Digital Instruments).

3. Results and Discussion

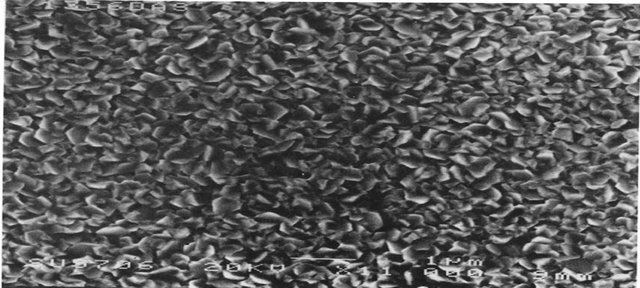

X-ray diffraction patterns of the Cu-Zn ferrite nano thin film is shown in Figure 1. It can be seen from the figure that all the prominent lines corresponding to the bulk CuZn were observed. Film surface morphology was examined by AFM. Figure 2(a) shows the surface topography of a film. The film surface was smooth and consisted of crystallites with a size of 50 - 60 nm. It can be seen from Figure 2(b) which reveals the presence of smaller spherecal of irregular features, needle-shaped grains and numerous pyramidal hills. The overall surface roughness is determined by the crystallites with a grain size of 10 - 20 nm.

The surface roughness factor differs from one spot to another, with a mean value of 22.12 and depends on the surface enlargement. MFM image is shown in Figure 2(c). It can be seen from the figure that the Cu-Zn ferrite nano thin films consists of single domain particles.

Figure 1. X-ray diffractogram for Cu-Zn nano ferrite thin film grown on a SrTiO3 substrate.

(a)

(a) (b)

(b) (c)

(c)

Figure 2. (a) AFM image of the Cu-Zn nano ferrite thin film at 6.0 µm scan size; (b) oblique view of a 6 × 6 µm2 surface of a Cu-Zn Fe2O4 nano film obtained with a AFM; (c) MAFM image of Cu-Zn ferrite nano thin film at 8.0 µm scan size.

4. Acknowledgements

The authors are grateful to Prof. P. Kistaiah, Head, Department of Physics, Osmania University, Hyderabad for his encouragement.

REFERENCES

- H. J. Masterson, J. G. Lunney, D. Ravinder and J. M. D. Coey, “Properties of (111) Li0.5Fe2.5O4 Films,” Journal of Magnetism and Magnetic Materials, Vol. 140-144, 1995, pp. 2081-2082.

- S. B. Ogale, K. Ghosh, R. P. Sharma, R. L. Green, R. Ramesh and T. Venkatesan, “Magnetotransport Anisotropy Effects in Epitaxial Magnetite (Fe3O4) Thin Films,” Physical Review B, Vol. 57, No. 13, 1998, pp. 7823-7828.

- N. Sharma, A. K. Nigam, R. Pinto, N. Venkataramani, S. P. G. Chandra and S. P. Pai, “Giant Magnetoresistance Studies on La(0.8−x)RxSr0.2MnO3 Thin Films (R = Pr, Nd, Gd, Ho),” Journal of Magnetism and Magnetic, Vol. 166, No. 1-2, 1997, pp. 65-70.

- M. Sahana, R. N. Singh, C. Sivakumara, N. Y. Vasantlachaiga, M. S. Hegde, S. Subramanyam, V. Prasad and S. V. Subramanyam, “Colossal Magnetoresistance in Epitaxial La(1−x−y)NayMnO3 Thin Film,” Applied Physics Letters, Vol. 70, No. 21, 1997, pp. 2909-2911.

NOTES

*Corresponding author.