Journal of Building Construction and Planning Research

Vol.04 No.03(2016), Article ID:70277,15 pages

10.4236/jbcpr.2016.43010

Comparison of Risk Assessment for a Nuclear Power Plant Construction Project Based on Analytic Hierarchy Process and Fuzzy Analytic Hierarchy Process

Dae-Woong Shin1, Yoonseok Shin2*, Gwang-Hee Kim2

1Department of Architectural Engineering, Kyonggi University, Suwon-si, South Korea

2Department of Plant & Architectural Engineering, Kyonggi University, Suwon-si, South Korea

Copyright © 2016 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: August 3, 2016; Accepted: August 28, 2016; Published: September 1, 2016

ABSTRACT

Recently, plant construction throughout the world, including nuclear power plant construction, has grown significantly. The scale of Korea’s nuclear power plant construction in particular, has increased gradually since it won a contract for a nuclear power plant construction project in the United Arab Emirates in 2009. However, time and monetary resources have been lost in some nuclear power plant construction sites due to lack of risk management ability. The need to prevent losses at nuclear power plant construction sites has become more urgent because it demands professional skills and large-scale resources. Therefore, in this study, the Analytic Hierarchy Process (AHP) and Fuzzy Analytic Hierarchy Process (FAHP) were applied in order to make comparisons between decision-making methods, to assess the potential risks at nuclear power plant construction sites. To suggest the appropriate choice between two decision-making methods, a survey was carried out. From the results, the importance and the priority of 24 risk factors, classified by process, cost, safety, and quality, were analyzed. The FAHP was identified as a suitable method for risk assessment of nuclear power plant construction, compared with risk assessment using the AHP. These risk factors will be able to serve as baseline data for risk management in nuclear power plant construction projects.

Keywords:

Component, Analytic Hierarchy Process (AHP), Fuzzy Analytic Hierarchy Process (FAHP), Nuclear Power Plant, Reactor Containment Building (RCB), Risk Assessment

1. Introduction

The global plant construction market, including nuclear power plant construction, reached a scale of USD1.6 trillion as of August 2008 [1] . Korea started to expand its horizons in the field of nuclear power plant construction when it won a contract to build four advanced light water reactors in the United Arab Emirates in 2009 [2] . It is expected that the scale of Korea’s nuclear power plant construction will gradually increase.

While the number of nuclear power plant construction projects has been on the rise globally, numerous issues are being reported at construction sites, including delays in construction duration, rising construction costs, and safety accidents. This is due to the lack of an appropriate risk analysis and planning process at the beginning phase of nuclear power plant construction projects, considering that a nuclear power plant requires longer construction duration and involves a higher construction cost compared with other construction projects.

However, there is scant research that has attempted to analyze the risks that can occur during a nuclear power plant construction project. Lee, Lee and Chang (2013) [3] performed a quantitative analysis using the AHP of the risks of six types of work, including civil engineering, construction, and machining. Other related studies include a cost risk analysis for construction projects using FAHP [4] , and the development of a risk assessment model using AHP for overseas construction projects [5] . However, the risks inherent in a construction project were drawn from a wider perspective in the previous studies, and it is difficult to identify the specific of risks to each unit of work type [6] .

A nuclear power plant construction project can be securely implemented by identifying the risk factors that may occur in each work type of the construction. It usually takes 50 months to complete the Reactor Containment Building (RCB) for a nuclear power plant construction project, consisting of 6 phases from ground breaking to post- tensioning [7] . Based on this fact, not only are more resources required, but also more risk factors must be taken into account in the process, unit cost, safety, and quality. Therefore, this study aims to use decision-making methods to analyze risk factors that could potentially arise from the RCB construction for a nuclear power plant. To assess the risk factors identified in the study, AHP and FAHP will be used as the decision- making methods. Through this analysis, the most appropriate decision-making method for performing a risk assessment of the RCB construction of a nuclear power plant construction will be chosen.

2. Literature Review

2.1. Previous Studies on Risk Assessment

Risk is an umbrella term covering both the possibility of damage and the loss of opportunities [8] . Considering this definition, risk can serve as an obstacle to the attainment of a goal in any construction project [6] . Therefore, risk analysis has the goal of adjusting risk factors to be in an optimal or acceptable condition by identifying and assessing the risk factors in a systematic manner.

In the construction management field, a number of previous studies on risk analysis have been conducted. These studies can be divided into risk analysis using AHP and risk analysis using FAHP.

The major studies using AHP include Cho, Song, Ahn and Choi (2007) [9] , Makarand and Aury (2000) [5] and Mohammad and Jamal (1991) [10] . Cho et al. (2007) [9] analyzed the importance of risk factors that can affect the quality management of steel structures by dividing steel structure construction into the design phase, the pre-construction phase, the pre-fabrication phase, and the site installation phase using AHP. Makarand and Aury (2000) [5] proposed a risk analysis model, based on the AHP, for an overseas construction project. Mohammad and Jamal (1991) [10] assessed the potential risk factors from a bridge construction project in Bangladesh by applying AHP.

The major studies using FAHP include Carr and Tah (2001) [11] , Debasish, Joy and Animesh (2013) [12] , Lee and Kim (2003) [4] , and Taylan, Bafail, Abdulaal and Kabli (2014) [13] . Carr and Tah (2001) [11] built a prototype by applying fuzzy theory to a construction project risk management system. Debasish et al. (2013) [12] verified a case by using fuzzy reasoning and the FAHP to analyze the potential risks at a construction site. Lee and Kim (2003) [4] analyzed the cost risk of a construction project based on quantitative results derived through the AHP. Taylan et al. (2014) [13] proposed a construction project selection theory based on the risk assessment of a construction project by dividing it into time, cost, quality, and environment sustainability using fuzzy theory.

Previous studies on the risks that may occur in a construction project were done using either AHP or fuzzy theory as the decision-making method. Each of the decision- making methods used to analyze the risks of a construction project have their own advantages and disadvantages, and one of the methods could be selected considering the construction project type. Therefore, the previous studies are limited, in that they presented a single decision-making method, with no consideration of the construction project type.

For this reason, unlike previous studies, this study aims to provide a decision-making method that is appropriate for the construction of an RCB at a nuclear power plant by comparing the AHP and FAHP-based risk analysis methods. The construction of a nuclear power plant consists of five types of work, 20 unit work types, and 91 detailed work types, and takes about 120 months to complete, requiring more resources compared with other construction projects, including apartment construction [3] . For this type of construction project, it is necessary to choose an appropriate decision-making method, as a risk analysis method cannot be uniformly applied to all projects.

2.2. Analytic Hierarchy Process (AHP)

The AHP is a decision-making method that was developed by Saaty in the 1970s [4] . This method determines the relative priority of alternatives through classification by objective, criterion, and alternative to resolve risks in some classes [3] . As such, the AHP is an optimal technique for resolving diverse criteria and alternatives through a complicated decision-making algorithm [3] . In addition, this decision-making method is characterized by its theoretical simplicity, simple application, and interpretational clarity, and can be applied to diverse decision-making situations [14] .

The AHP is performed through four steps:

Step 1: Assessment criteria and alternatives are defined, and the factors needed for decision-making are structured [4] . Figure 1 is a basic analysis model to which the AHP can be applied.

Step 2: The contribution of the factors in sublevels (importance) is assessed through a pairwise comparison, in order to attain the decision-making goal [14] .

Step 3: The reliability obtained through the pairwise comparison by specialists who responded to the questionnaire is determined as a measurement of the consistency index. It is found to be a reasonable evaluation when it is less than 0.1, while it is determined to be an acceptable evaluation when it is less than 0.2 [14] . When the consistency index is higher than 0.2, the questionnaire responses of the professionals should be re-evaluated and excluded [14] .

Step 4: Each alternative is ranked based on the importance derived in Step 3, and the final choice is made [4] .

The risk analysis using the AHP assesses the risk factors consisting of specialists’ and practitioners’ subjective opinions as specific values; this method is advantageous for performing an analysis with a simple theory. Through a risk analysis using AHP, the insight and knowledge of specialists and practitioners working for a nuclear power plant need to be clearly analyzed.

Thus, to assess the risk that occurs in RCB construction, an AHP-applied analysis is one of the appropriate decision-making methods. Risk factors are subjective opinions from specialists and practitioners, which can be utilized through a clear analysis using AHP, and then need to be used in risk management.

Figure 1. Basic structure of decision-making for AHP.

2.3. Fuzzy Analytic Hierarchy Process (Fuzzy AHP)

Fuzzy AHP is a decision-making method developed by Laarhven and Pedrycz (1983) that combines the existing AHP and the fuzzy theory [15] . Like AHP, the FAHP structures the major criteria and factors into levels and sublevels, and weights are calculated by completing a pairwise comparison matrix. However, unlike AHP, an arithmetic operation including a triangular fuzzy number or trapezium fuzzy number is used in the process of the weight calculation [15] .

The fuzzy AHP is performed through the following three steps:

Step 1: As in AHP, the assessment criteria and sub-alternatives are determined and structured [4] . Based on this, triangular fuzzy numbers are applied as shown in Table 1 to obtain a matrix through a pairwise comparison between sub-alternatives. The matrix is composed of values calculated using a geometric or arithmetic average of weights assessed by a number of evaluators.

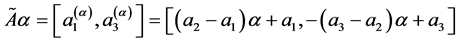

Step 2: To make it easy to calculate triangular fuzzy numbers, it is defuzzified by applying an α-cut to the triangular fuzzy numbers (Seo, 2004).  in which the α-cut is applied to the triangular fuzzy numbers is shown in Equation (1) and Figure 2. The lower value of the group is

in which the α-cut is applied to the triangular fuzzy numbers is shown in Equation (1) and Figure 2. The lower value of the group is , while

, while  is the upper value in the group (Seo, 2004).

is the upper value in the group (Seo, 2004).

(1)

(1)

Step 3: Through Equation (2), a linear combination where  is applied, a pairwise comparison matrix is composed to convert

is applied, a pairwise comparison matrix is composed to convert  into the final real number (Seo, 2004).

into the final real number (Seo, 2004).

Table 1. Membership function of triangular fuzzy number based on AHP results.

Figure 2.  and α-cut of a fuzzy graph.

and α-cut of a fuzzy graph.

(2)

(2)

Equation (2) is a linear combination that  is applied.

is applied.

The utilization of FAHP is appropriate for an analysis in which the assessors’ subjective opinions are reflected through a triangular fuzzy function, meaning a relative weight of whether a risk factor is an upper value, a mean, or a lower value (Lee and Kim, 2003) [4] . This decision-making method can theoretically complement the limitation of the AHP in the assessment process of risk factors that are usually composed of vague language expressions (Lee and Kim, 2003) [4] . In summary, the AHP calculates a specific value, while the FAHP draws a p-value of the subjective assessment by specialists and practitioners. For this reason, it is necessary to present a more appropriate decision-making method for the risk analysis of the RCB construction by comparing the two methods.

3. Risk Factor Identification and Classification

3.1. Major Risk Factors

To determine and structure the assessment criteria and their alternatives, the risk factors that could potentially occur in RCB construction are classified in Table 2. The risk factors were selected based on the likelihood of their occurring, and of their affecting the upper levels. The selected risk factors were classified into sublevels of process, cost, safety and quality. These sub-alternatives were derived through a construction plan report of a nuclear power plant and a review of the literature. They were then verified by two specialists and practitioners with more than 10 years of experience in nuclear power plant construction, and by one practitioner with at least two years of experience in a related field. The sub-alternatives verified by the specialists above were assessed in terms of appropriateness through a preliminary questionnaire survey of three practitioners with at least five years of work experience in nuclear power plant construction in both Korea and Middle East Asia, based on which the risk factors were selected as final choices.

・ Use either SI (MKS) or CGS as primary units (SI units are encouraged). English units may be used as secondary units (in parentheses). An exception would be the use of English units as identifiers in trade, such as “3.5-inch disk drive”.

・ Avoid combining SI and CGS units, such as current in amperes and magnetic field in oersteds. This often leads to confusion because equations do not balance dimensionally. If you must use mixed units, clearly state the units for each quantity that you use in an equation.

・ Do not mix complete spellings and abbreviations of units: “Wb/m2” or “webers per square meter”, not “webers/m2”. Spell out units when they appear in text: “...a few henries”, not “…a few H”.

・ Use a zero before decimal points: “0.25”, not “0.25”. Use “cm3”, not “cc”.

3.2. Risk Analysis Model

This study establishes a hierarchical structure model utilizing derived the risk factors to

Table 2. Major risk factors of RCB construction.

perform the AHP-based analysis (Figure 3). The defined risk factors of RCB construction were structured into three hierarchical levels.

4. Results and Discussion

4.1. Outline of the Questionnaire

In this study, a 9-point scale pairwise comparison was used in the questionnaire survey to evaluate the importance of the various risk factors in RCB construction consisting of three levels. The questionnaire survey was conducted from January 1 to January 28, 2015.

The survey subjects for the questionnaire survey were specialists and practitioners who were conducting or had experience in the nuclear power plant construction projects of Companies G, H, and S. There were a total of 36 people surveyed: 5 people from Company G, 8 people from Company 8, and 23 people from Company 23 (Table 3).

Figure 3. AHP model for risk analysis of RCB construction.

Table 3. Summary of characteristics about respondents

The reliability of how consistent the pairwise comparisons were made in the questionnaire survey was verified using the consistency ratio (CR). If there were more than 9 out of 36 questions in the questionnaire that had a CR over 0.2, we asked the respondent to correct or complement the questionnaire again. The priority was determined based on the geometric mean, which was calculated after adding all the numbers assessed by all of the 36 respondents within the criteria.

4.2. Risk Assessment by AHP

The importance and priority of risk factors that may presumably occur in RCB construction were determined by using the AHP, and the results are shown in Table 4.

The risk assessment of the RCB construction using the AHP was carried out to have a CR of less than 0.2 in all of the categories of process, cost, safety and quality, including in questionnaires corrected or complemented for the purpose of obtaining reasonable and acceptable results. Therefore, the importance and priority of the calculated risk factors can be considered effective.

In the second level, “Cost” at 0.488, was shown to be the highest of all four categories, followed by “Safety”, “Process” and “Quality” in that order. However, the relationship between the second and the third levels was not expressed quantitatively, so the alternative with the highest points in the “Cost” category does not mean it is the highest priority in the risk assessment of RCB construction.

Despite the “Process” category, “Deterioration in constructability with an increase in the lateral pressure when concrete is in place” was shown to be the highest in importance at 0.409. “Interruption of sub-operation to cure water for concrete” came next, with “Rush work performance for processing retrieval” following. Risk factors arising from the concrete work were of high importance in the “Process” category.

In the “Cost” category, “Technologies cannot meet required performance” was shown to be of highest importance at 0.452. “Delay in a progress payment by an owner” came next, and then “Lack of temporary electricity and water supply,” in that order. Considering the fact that the ordering party’s preposterous demand for performance and delay in progress payment was placed at a higher level, the problems arising out of the ordering party’s responsibility and roles were identified as risk factors that have high importance.

In the “Safety” category, the most important alternative was “Lack of safety of the piping within the reactor containment building for the earthquake load,” at 0.370. “Occurrence of thermal stress in the work inside of the reactor containment building” came next, and then “Accident due to insufficient preparation in advance.” Respondents appeared to put the structural safety of the reactor containment building first.

In “Quality” the alternative of highest importance was “Inappropriate curing of a part requiring curing” at 0.224. “Inappropriate quality assurance procedure” came next, and then “Placement height limit of the form” and “Coating of inappropriate coating curing compound due to the coarse surface of concrete.” It appeared that there were no great differences in importance between the 1st, 2nd, 3rd and 4th risk factors.

Table 4. Assessment of risk factors in construction of RCB by AHP.

4.3. Risk Assessment by FAHP

Based on the survey results, the importance and priority of the risk factors in RCB construction classified by category were determined using the FAHP; the results are indicated in Table 5. Risk assessment using the FAHP is the geometric mean of the numbers calculated through a triangular fuzzy arithmetic operation after converting the AHP analysis result into triangular fuzzy numbers. The basic data converted as triangular fuzzy numbers in an AHP analysis were defuzzified by applying an α-cut in the composition process of the membership function of the triangular fuzzy numbers. At this time, α was set at 0.5. In addition, based on the results, in the conversion process into final real numbers, the linear combination was set as λ = 0.5.

In the second level, “Quality” was the highest priority, with an importance of 0.463, followed by “Safety”, “Cost” and “Process” in that order. However, the FAHP is based on the AHP, which means that the relationship between the second and the third levels is not expressed quantitatively. Therefore, the alternative with the highest importance in “Quality” category cannot be determined to be the highest priority in the risk assessment of RCB construction.

In the “Process” category, “Determination in constructability with the increase of the lateral pressure when concrete is placed” had the highest importance at 0.409. “Acceleration claim by an owner” came next, followed by “Rush work performance for process retrieval”. In the “Process” category, other than concrete work, problems related to fulfillment of a contract were shown to have high importance and priority.

In the “Cost” category, “Technologies cannot meet required performance” had the highest importance and priority at 0.422. “Delay in a progress payment by an owner” came next, and then “Lack of temporary electricity and water supply”. Through this, in “Cost,” it was shown that the risk factors related to the Ordering party’s responsibility and roles appeared to have high importance.

In the “Safety” category, the alternative with the highest priority was “Lack of safety of the piping with the reactor containment building for the earthquake load” at 0.371. “Occurrence of thermal stress in the work inside of the reactor containment building” came next, and then “Accident due to insufficient preparation in advance”. In the “Safety” category, as in the AHP, the risk factors related to the structural safety of the reactor containment building appeared to have highest importance.

In the “Quality” category, “Placement height limit of the form” was the highest priority at 0.270. “Inappropriate curing of a part requiring curing” came after, and then “Inappropriate quality assurance procedure”. In the “Quality” category, the risk factors that can occur in the process of form work or concrete work were ranked higher.

4.4. Comparative Analysis of Results

A comparative analysis of the results obtained using the AHP and the FAHP was performed in this study to present the most reasonable decision-making method for the risk analysis of RCB construction. In the analysis of risk factors in the second level of RCB construction, “Cost” was the most important in the AHP analysis, while “Quality”

Table 5. Assessment of risk factors in construction of RCB by FAHP.

was the most important in the FAHP analysis. However, the greatest decrease in importance was seen in the “Cost” category. In the “Process” category, there was no change in the alternative with the highest importance, although changes took place in the second and lowest places. In the “Process” category, the risk factors arising from concrete work showed high importance in the risk assessment using the AHP, while the risk factors related to the fulfillment of a contract or construction duration showed high importance in the risk assessment using the FAHP. In comparison to the identified risk factors using the AHP, the FAHP increased in importance but had no or slight changes in priority. In the “Safety” category, there were changes in the less important risk factors in the analyses, using both the AHP and the FAHP, but there was no change in the risk factor with the highest importance. In the “Quality” category, the highest importance and priority was shown in the alternative related to concrete curing in using the AHP, while the alternative related to form work was of highest importance and priority in using the FAHP.

Considering the characteristics of a nuclear power plant construction site and the effectiveness of the analysis results using the AHP and the FAHP, the risk assessment of the RCB construction using the AHP is more appropriate for generalizing, compared with the risk assessment using the FAHP. The effectiveness of the results was measured through the consistency verification in both decision-making methods. The arithmetic average of the consistency rate in the second and third levels was 0.0718 in the results using the AHP, which is effective because the consistency ratio is less than 0.2. In the analysis using the FAHP, the AHP was performed first, and then fuzzy theory was applied, so that the effectiveness could also be considered effective. The reflection of the characteristics unique to nuclear power plant construction sites were measured in the importance calculation process through the uncertainty of the RCB construction based on a handful of construction projects. The risk assessment using the AHP showed high accuracy with a specific number by converting the average of respondents into a geometric average, while the risk assessment using the FAHP showed a probabilistic value through an application of triangular fuzzy numbers to the responses from the respondents. Therefore, the FAHP is a concept in which the characteristics unique to the nuclear power plant construction site were reflected, compared with the AHP, since a relatively smaller number of nuclear power plant construction projects has been carried out compared with other types of construction projects. However, a project manager usually chooses a risk analysis method in the nuclear power plant construction project; therefore, we recommend the AHP when more weight must be put on cost, while the FAHP is recommended when more weight is put on quality.

5. Conclusions

This study proposes the most appropriate method for risk assessment of RCB construction by examining two decision-making methods: the AHP and the FAHP. By comparing risk assessments using the AHP and the FAHP, it was found that importance and priority either increased or decreased in all categories except for “Cost”, and the priority of the risk factors were changed accordingly. In terms of the analysis effectiveness and the project characteristics in nuclear power plant construction, when the two decision-making methods used in the risk assessment of the RCB construction were evaluated, it was found that the uncertainty of the RCB construction was better reflected in the analysis using the FAHP, as compared with that using the AHP, since the FAHP had a probabilistic accuracy. This finding will be utilized as fundamental data when a project manager chooses a risk assessment method in the planning phase of a nuclear power plant construction project.

However, this study was limited to a comparison of the AHP and the FAHP when applied to risk assessment for the RCB construction in a nuclear power plant. In addition to these approaches, other alternatives include the Analytic Network Process (ANP) and the Fuzzy Analytic Network Process (FANP). AHP and FAHP have a limitation that it is hard to derive the quantitative relationship between the upper and lower levels, so a comparative analysis of risk assessment of the RCB construction using the ANP and the FANP needs to be carried out. Thus, in the future study, a more appropriate decision-making method of risk assessment for the RCB construction between the ANP and the FANP will be proposed based on the results of using either the AHP or the FAHP.

Acknowledgements

This work was supported by the Nuclear Power Core Technology Development Program of the Korea Institute of Energy Technology Evaluation and Planning (KETEP), granted financial resource from the Ministry of Trade, Industry & Energy, Republic of Korea (No.20131520100750).

Cite this paper

Shin, D.-W., Shin, Y. and Kim, G.-H. (2016) Comparison of Risk Assessment for a Nuclear Power Plant Construction Project Based on Analytic Hierarchy Process and Fuzzy Analytic Hierarchy Process. Journal of Building Construction and Planning Research, 4, 157-171. http://dx.doi.org/10.4236/jbcpr.2016.43010

References

- 1. Huh, Y.K., Lim, J.H., Kim, K.U., Ahn, Y.C. and Oh, J.H. (2014) Reinforced-Concrete Works Productivity and Influence Factor Analysis on Nuclear-Power-Plant Project. Journal of the Korea Institute of Building Construction, 14, 314-312. http://dx.doi.org/10.5345/JKIBC.2014.14.4.314

- 2. Kim, K.I. (2012) A Study on Purchasing Factors Nuclear Power Plants Industry—With Emphasis on Case of Korea Electric Power Corporation. Master’s Thesis, Kyunghee University, Seoul.

- 3. Lee, J.B., Lee, J.K. and Chang, S.R. (2013) A Study on the Risk Level of Work Types in Nuclear Power Plant Construction. Journal of the Korean Society of Safety, 28, 95-99. http://dx.doi.org/10.14346/jkosos.2013.28.3.095

- 4. Lee, D.U. and Kim, Y.S. (2003) A Study on the Cost Risk Analysis for Construction Projects Using Fuzzy-AHP Method. Journal of Architectural Institute of Korea, 19, 169-176.

- 5. Makarand, H. and Aury, S. (2000) ICRAM-1: Model for International Construction Risk Assessment. Journal of Management in Engineering, 16, 59-69. http://dx.doi.org/10.1061/(ASCE)0742-597X(2000)16:1(59)

- 6. Shin, D.W., Shin, Y.S. and Kim, G.H. (2015) Analysis in Risk Factors of Reactor Containment Building Construction Using Analytic Hierarchy Process. Journal of the Korea Institute of Building Construction, 15, 425-431. http://dx.doi.org/10.5345/JKIBC.2015.15.4.425

- 7. Kim, W.J. (2012) Effectiveness of Linear Scheduling Methods in Nuclear Power Plant Construction. Master’s Thesis, Myongji University, Yongin.

- 8. Hwang, J.S. and Lee, C.S. (2004) A Risk Management Method Using Fuzzy Theory for Early Construction Stage. Korea Journal of Construction Engineering and Management, 5, 136-143.

- 9. Cho, H.M., Song, Y.W., Ahn, J.B. and Choi, Y.K. (2007) The Priority Analysis of the Risk and Countermeasures for Quality Control in the Steel Structure. Korea Journal of Construction Engineering and Management, 8, 87-96.

- 10. Mohammad, A.M. and Jamal, F.A.B. (1991) Project Risk Assessment Using the Analytic Hierarchy Process. IEEE Transactions on Engineering Management, 38, 46-52. http://dx.doi.org/10.1109/17.65759

- 11. Car, V. and Tah, J.H.M. (2001) A Fuzzy Approach to Construction Project Risk Assessment and Analysis: Construction Project Risk Management System. Advances in Engineering Software, 32, 847-857. http://dx.doi.org/10.1016/S0965-9978(01)00036-9

- 12. Debasish, M., Joy, D. and Animesh, B. (2013) Risk Analysis in Construction Sites Using Fuzzy Reasoning and Fuzzy Analytic Hierarchy Process. Procedia Technology, 10, 604-614. http://dx.doi.org/10.1016/j.protcy.2013.12.401

- 13. Taylan, O., Bafail, A.O., Abdulaal, R.M.S. and Kabli, M.R. (2014) Construction Project Selection and Risk Assessment by Fuzzy AHP and Fuzzy TOPSIS Methodologies. Applied Soft Computing, 17, 105-116. http://dx.doi.org/10.1016/j.asoc.2014.01.003

- 14. Lhee, S.C., Choi, Y.J. and Choi, Y. (2011) Determining the Priority of Factors for Reducing Energy at Deteriorated School Buildings Using AHP Method. Journal of the Korea Institute of Ecological Architecture and Environment, 11, 127-132.

- 15. Shin, J.H. (2012) A Study on the Selection of Waterproofing Construction Firms Using Fuzzy-AHP Model. Master’s Thesis, Seoul National University of Science and Technology, Seoul.