Journal of Electromagnetic Analysis and Applications

Vol. 3 No. 6 (2011) , Article ID: 5348 , 5 pages DOI:10.4236/jemaa.2011.36029

SF6 Byproducts in High-Humidity Environment: An Experimental Evaluation between 200C and 500C

![]()

Electric Power Test Research Institute, Guangdong Power Grid Company, Guangzhou, China.

Email: wangyu_0306@126.com

Received February 15th, 2011; revised April 6th, 2011; accepted April 15th, 2011.

Keywords: Sulfur Hexafluoride, Overheating Faults, Byproducts, Sulfur Dioxide, Sulfureted Hydrogen, Hydrofluoric Acid

ABSTRACT

In the occurrence of arc discharges, spark discharges, corona discharges and overheated faults in electrical equipment, SF6 would be decomposed to complicated byproducts, such as SO2, H2S and HF. Analyzing these byproducts is an effective method to judge the internal operation condition of electric equipment. In order to study characters of SF6 byproducts at different temperature of overheated faults in the electric equipment, a series of overheated faults of electric equipment were simulated. SF6 is very stable and not significantly decomposed at 200˚C, 250˚C and 300˚C. SF6 is significantly decomposed to SO2, H2S and HF at 350˚C. The concentration of SO2, H2S and HF was 7.2, 1.6 and 1.9 μL/L after heating for 5 hours in environment of SF6 with 3616 μL/L water, and it was increased to 23.0, 3.0 and 1.2 μL/L 3 hours later. SF6 is more easily to be decomposed and decomposed more rapidly at higher temperature. The concentration of SO2, H2S and HF was 62.2, 15.6 and 3.6 μL/L after heating for 5 hours in environment of SF6 with 4064 μL/L water, and it was increased to 91.4, 25.2 and 2.3 μL/L 3 hours later. SF6 will be decomposed to format HF, which is strongly corrosive and whose concentration is likely to decrease when it is above a certain concentration.

1. Introduction

Sulfur hexafluoride (SF6) is a colorless, orderless, nontoxic, and non-flammable gas. The gas is strongly electronegative and tends to attract free electrons. SF6 is widely used as insulative gas in electric transmission and distribution equipment and its insulation property is about 2.5 times to those of air, which was traditionally used as isolative materials in electric equipment. The SF6 electric equipment takes less area, has less operation noise and has no danger of fire, so SF6 electric equipment elevates operation security.

In the occurrence of arc discharges, spark discharges and corona discharges, SF6 would be reacted with little water, electrode and solid insulated material. SF6 were decomposed to complicated gas and solid byproducts. Gas byproducts include carbon tetrafluoride (CF4), thionyl sulfide (SOF2), sulfuryl fluoride (SO2F2), and sulfur dioxide (SO2), and solid byproducts include aluminum fluoride, tungsten fluoride, and so on [1-9].

It is difficult to judge the internal operation condition of electric equipment, while analyzing the concentrations of SF6 byproducts is an effective method to judge the internal operation condition of electric equipment. There are many cases these years about how to judge faults by analyzing SF6 byproducts, such as CF4 and SO2, in Guangdong, and many similar examples were reported in the literature as well [10,11]. In past successful examples, we can only judge the faults of electric equipment and the position of the faults in the electric equipment by analyzing SF6 byproducts. There is still little experience about characters of SF6 byproducts in different condition of different types of faults in the electric equipment. A series of overheated faults about different temperature of electric equipment were simulated. The paper reports different types of SF6 byproducts and their concentrations about different condition of overheated faults in electric equipment.

2. Method

The experiments were simulated in a section of bushing of a breaker, which can be found in Figure 1 in detail. The moisture of the SF6 was between 3616 μL/L and 5189 μL/L, and the temperature was 200˚C, 250˚C, 300˚C, 350˚C, 400˚C, 450˚C and 500˚C, respectively. The pressure of SF6 in the simulator was 0.3 Mpa. There was a contact, which can simulate overheated faults through 900A current, but the heat was not enough for simulation requirements. There was a heating rod and a controller that was binding with the contact as well. The device can strictly control the temperature of simulation. In each simulated temperature, SF6 was taken by a 1.25 L steel bottle from the simulator every hour to analyze SF6 byproducts, such as fluoride 1 (probable SF4), fluoride 2 (probable S2F10), SO2, H2S, HF and CO. The analysis method can refer to the literature [12-17]. The chromatograph used in the simulation was Agilent 7890 N with a flame photometric detector and a Gaspro capillary column(0.32 mm × 30 m).

3. Results and Discussion

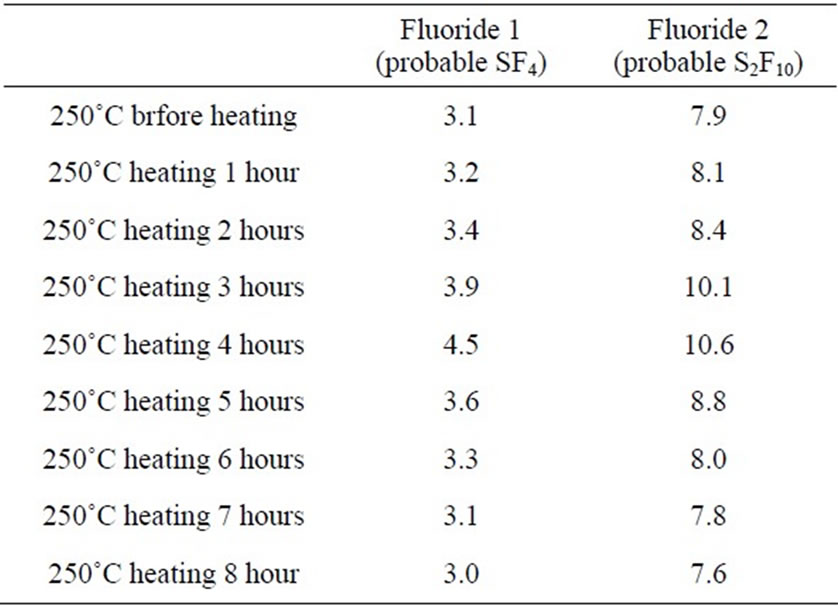

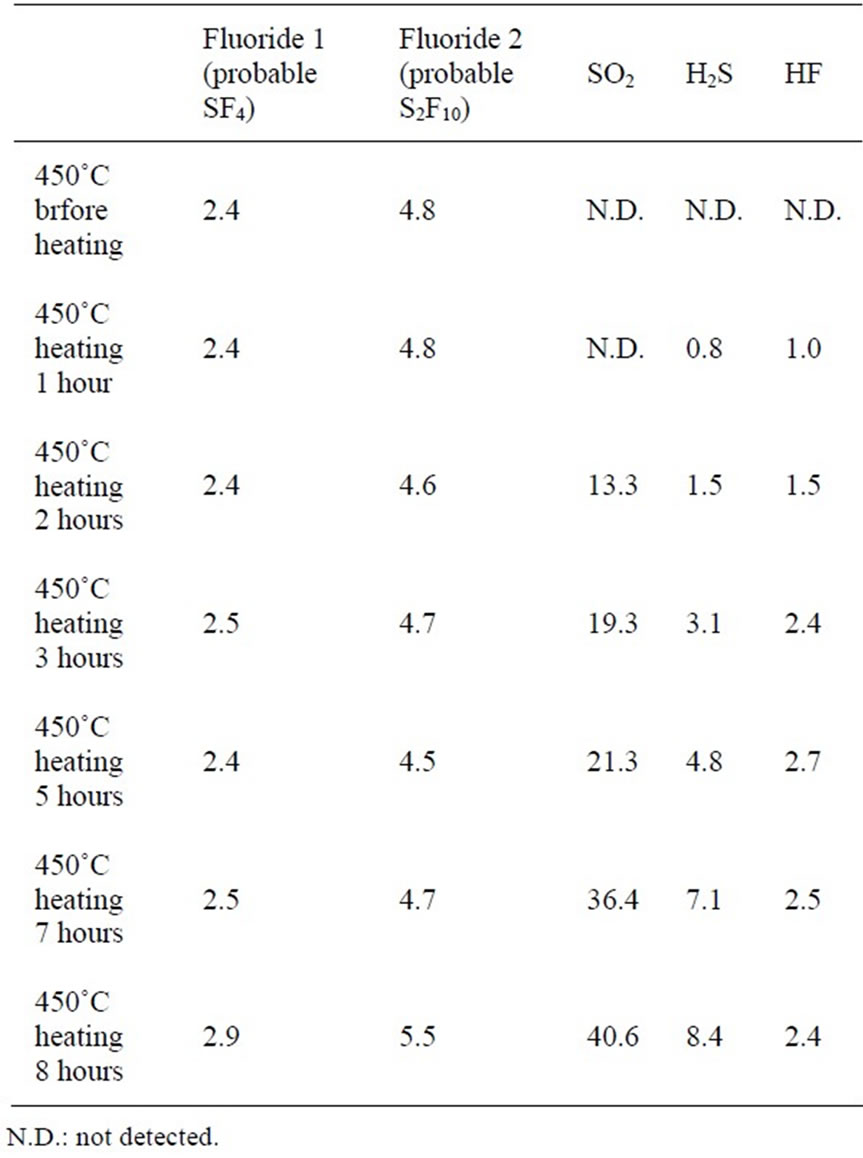

Table 1-7 show SF6 byproducts and their concentrations of overheated faults simulation at 200, 250, 300, 350, 400, 450 and 500˚C in high humidity. Moisture of the SF6 was 4049, 4098, 4218, 3616, 3642, 5789 and 4064 μL/L respectively.

At 200, 250 and 300˚C, the concentrations of fluoride 1 and fluoride 2 (probable SF4 and S2F10) were not increasing significantly. The concentrations of SO2, H2S, HF and CO were below detection limits. SF6 is stable and not decomposed significantly at 200, 250 and 300˚C. The concentrations of fluoride 1 (probable SF4), fluoride 2 (probable S2F10) and SO2 are not significantly increased with the time of heating.

Table 1. SF6 byproducts of overheated faults simulation at 200˚C (unit: µL/L).

Table 2. SF6 byproducts of overheated faults simulation at 250˚C (unit: µL/L).

Figure 1. The experiment equipment.

Table 3. SF6 byproducts of overheated faults simulation at 300˚C (unit: µL/L).

Table 4. SF6 byproducts of overheated faults simulation at 350˚C (unit: µL/L).

At 350˚C, the concentrations of fluoride 1, and fluoride 2 (probable SF4 and S2F10) were not increasing significantly. The concentration of SO2, H2S and HF was 7.2, 1.6 and 1.9 μL/L after heating for 5 hours, and it was increased to 23.0, 3.0 and 1.2 μL/L 3 hours later. The concentration of CO was below detection limits. SF6 will decompose and produce 0.3 μL/L H2S and 0.5 μL/L HF after heating for 1 hour, and will produce 7.2 μL/L SO2, 1.6 μL/L H2S and 1.9 μL/L HF after heating for 5 hours. The concentration of HF decreased when its concentration increases up to 1.9 μL/L. It may be because that HF was strongly corrosive and its corrosion to inner equipment made the concentration of HF decreasing. The

Table 5. SF6 byproducts of overheated faults simulation at 400˚C (unit: µL/L).

Table 6. SF6 byproducts of overheated faults simulation at 450˚C (unit: µL/L).

Table 7. SF6 byproducts of overheated faults simulation at 500˚C (unit: µL/L).

conntrations of fluoride 1 (probable SF4) and fluoride 2 (probable S2F10) are not significantly increased with the time of heating, while the concentration of SO2 is significantly increased.

At 400˚C, the concentrations of fluoride 1, and fluoride 2 (probable SF4 and S2F10) were not increasing significantly. The concentration of SO2 was 17.6 μL/L after heating for 5 hours, and it was increased to 26.1 μL/L 3 hours later. The concentration of H2S was 1.6 μL/L after heating for 2.5 hours, and it was increased to 5.3 μL/L 5.5 hours later. The concentration of HF was 2.4 μL/L after heating for 5 hours and it was decreased to 1.6 μL/L 3 hours later, the tendency of which was the same with that at 350˚C. The concentration of CO was below detection limits. SF6 will decompose and produce 0.6 μL/L H2S and 0.9 μL/L HF after heating for 1 hour at 400˚C, and will produce 17.6 μL/L SO2, 3.3 μL/L H2S and 2.4 μL/L HF after heating for 5 hours. The concentrations of fluoride 1 (probable SF4) and fluoride 2 (probable S2F10) are not significantly increased with the time of heating, while the concentration of SO2 is significantly increased.

At 450˚C, the concentrations of fluoride 1 and fluoride 2 (probable SF4 and S2F10) were not increasing significantly. The concentration of SO2 and H2S was 13.3 and 1.5 μL/L after heating for 2 hours, and it was increased to 40.6 and 8.4 μL/L 6 hours later. The concentration of HF was 2.7 μL/L after heating for 5 hours, and it was decreased to 2.4 μL/L 3 hours later, the tendency of which was the same with that at 400˚C. The concentration of CO was below detection limits. SF6 will decompose and produce 0.8 μL/L H2S and 1.0 μL/L HF after heating for 1 hour, and will produce 13.3 μL/L SO2, 1.5 μL/L H2S and 1.5 μL/L HF after heating for 2 hours. The concentrations of fluoride 1 (probable SF4) and fluoride 2 (probable S2F10) are not significantly increased with the time of heating, while the concentration of SO2 is significantly increased.

At 500˚C, the concentrations of fluoride 1 and fluoride 2 (probable SF4 and S2F10) were not increasing significantly. The concentration of SO2 was 33.4 μL/L after heating for 2 hours, and it was increased rapidly to 91.4 μL/L 6 hours later. The concentration of H2S was 4.6 μL/L after heating for 1 hour, and it was increased to 25.2 μL/L 7 hours later. The concentration of HF was 3.7 μL/L after heating for 2 hours and it was decreased to 2.3 μL/L 6 hours later, the tendency of which was the same with that at 400˚C and 450˚C. The concentration of CO was below detection limits. SF6 will decompose and produce 4.6 μL/L H2S and 3.4 μL/L HF significantly after heating for 1 hour, and will produce 33.4 μL/L SO2 significantly after heating for 2 hours. The concentrations of fluoride 1 (probable SF4) and fluoride 2 (probable S2F10) are not significantly increased with the time of heating, while the concentration of SO2 is significantly increased.

4. Conclusions

SF6 is very stable and not significantly decomposed at 200˚C, 250˚C and 300˚C. SF6 will decompose and produce 0.3 μL/L H2S and 0.5 μL/L HF after heating for 1 hour at 350˚C, and it will produce 7.2 μL/L SO2, 1.6 μL/L H2S and 1.9 μL/L HF after heating for 5 hours. At 400˚C, SF6 will decompose and produce 0.6 μL/L H2S and 0.9 μL/L HF after heating for 1 hour, and it will produce 17.6 μL/L SO2, 3.3 μL/L H2S and 2.4 μL/L HF after heating for 5 hours. At 450˚C, SF6 will decompose and produce 0.8 μL/L H2S and 1.0 μL/L HF after heating for 1 hour, and it will produce 13.3 μL/L SO2, 1.5 μL/L H2S and 1.5 μL/L HF after heating for 2 hours. At 500˚C, SF6 will decompose and produce 4.6 μL/L H2S and 3.4 μL/L HF after heating for 1 hour, and it will produce 33.4 μL/L SO2, 7.0 μL/L H2S and 3.7 μL/L HF significantly after heating for 2 hours. According to above simulated experiments, SF6 is beginning to format significant SF6 byproducts at 350˚C, and it is more easily to be decomposed at higher temperature. SF6 will be decomposed to format HF, which is strongly corrosive and whose concentration is likely to decrease when it is above a certain concentration.

REFERENCE

- M. Averyt, “SF6 By-products: Safety, Cleaning and Disposal Concerns,” U.S.EPA’s International Conference on SF6 and the Environment, San Antonio, 29 November 2006.

- J. L. Bessede and W. Krondorfer, “Impact of High Voltage SF6 Circuit Breakers on Global Warming-Relative Contribution of SF6 Losses,” U.S.EPA’s Conference, San Diego, 2-3 Novermber 2000.

- IEC60480, “Guidelines for the Checking and Treatment of Sulfur Hexafluoride (SF6) Taken from Electrical Equipment and Specification for Its Reuse,” 2nd Edition, 2004.

- M. Mastroianni, “SF6 Analysis is the Key to Maintenance,” Electrical World, Vol. 194, No. 9, 1980, pp. 92-96.

- I. Sauer, “Neutral Decomposition Products in Spark Breakdown of SF6,” IEEE Transactions on Electrical Insulation, Vol. 21, No. 2, 1986, pp. 111-115. doi:10.1109/TEI.1986.348932

- IEC 62271-303-2008, “High-Voltage Switchgear and Controlgear–Part 303: Use and Handling of Sulphur Hexafluoride (SF6),” 1st Edition, 2008.

- X. X. Zhang, Y. Yao, J. Tang, C. X. Sun and L. Y. Wan, “Actuality and Perspective of Proximate Analysis of SF6 Decomposed Products Under Partial Discharge,” in Chinese, High Voltage Engineering, Vol. 34, No. 8, 2008, pp. 664-669.

- J. Tang, T. Li, L. Y. Wan, X. X. Zhang and Y. Yao, “Gaseous Decomposition Components Analysis System,” in Chinese, High Voltage Engineering, Vol. 34, No. 4, 2008, pp. 1583-1588.

- Y. Wang, Z. Li, W. J. Yao, X. S. Zhuang and C. J. Huang, “Situation and Analysis of SF6 Byproducts of Gas Insulated Switchgear (220kV and above) in Guangdong Province,” in Chinese, High Voltage Engineering, Vol. 35, No. 4, 2009, pp. 823-828.

- Z. Q. Zhang and H. S. Lian, “Using SO2 Detection for Failure Checking of SF6 Electricity Equipment,” in Chinese, Electric Power, Vol. 34, No. 1, 2001, pp. 77-80.

- Y. Y. Wang, “Discussion of Analyzing Internal Faults of SF6 Electric Equipment by SO2 Concentrations,” in Chinese, Fujian Electric Power and Electrician, Vol. 21, No. 1, 2001, pp. 56-57.

- W. J. Yao and N. W. Cheng, “Detection of Fault Characteristic Gases in SF6-Insulated Transformers,” in Chinese, Guangdong Electric Power, Vol. 12, No. 4, 1999, pp. 20-21.

- L. M. Song, Q. Wu and L. C. Li, “Chromatograph Analysis of Toxic Impurities in SF6,” in Chinese, Liming Chemistry, Vol. 3, 1992, pp. 18-21.

- W. Z. Wang, F. P. Yue and S. G. Xia, “Application of GC-MS in Analyzing Trace Impurities in SF6,” in Chinese, Electric Technology, Vol. 4, 1981, pp. 3-4.

- L. Wang, “Analysis Technology of Trace Impurities in SF6 and Its Application in Purifying Decomposition Gas of Arc Discharge,” in Chinese, Electric Technology, Vol. 6, 1988, pp. 10-14.

- L. Wang and J. Z. Wang, “Preparation Technique of S2OF10 Gas Standard Sample and Determination Method of the Trace S2OF10 in SF6,” in Chinese, Chinese Journal of Chromatography, Vol. 17, No. 5, 1999, pp.55-57.

- W. W. Cheng, G. L. Ma and Q. L. Zhu, “Gas Chromatographic Determination of Trace Bispentafluorosulfur oxide in Sulfur Hexafluoride Using a Post-Column Switching and Temperature Programming Method,” in Chinese, Chinese Journal of Analytical Chemistry, Vol. 26, No. 12, 1998, pp. 1468-1470.