International Journal of Geosciences

Vol.07 No.09(2016), Article ID:70410,7 pages

10.4236/ijg.2016.79080

Risk Analysis of Gas Hydrate Formation during Deepwater Gas Well Testing

Hongjun Yang, Liang Hao, Muwang Wu

Zhanjiang Branch of CNOOC Ltd., Zhanjiang, China

Copyright © 2016 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: July 13, 2016; Accepted: September 4, 2016; Published: September 7, 2016

ABSTRACT

During deep-water gas wells testing period, predicting the generating zone of hydrate precisely in the whole flow range (bore holes and surface flow lines) is the key prerequisite of guarantee for testing flow. The unusual deep-water environment and low gas density make it easy to meet the conditions of hydrate generation during deep- water gas wells testing period, such as low temperature and high pressure, especially under the testing conditions, for instance, near mud line, surface chock line, low gas generating rate and surface shut-in. Wherefore, in view of all the operational modes during testing period (clean-out, variable rate flow, downhole and surface shut-in), based on temperature field of the whole flow range and phase equilibrium condition of hydrate, predicting method of hydrate generation zone is published; by taking enthalpy as the object of study, temperature calculation model increases the accuracy of temperature prediction; by integration of bore holes and surface lines, predicting plate of hydrate generation in the whole flow range is published. During flow period, the generating condition of hydrate is affected by rate of flow, and the lower the rate of flow is, the wider the hydrate generation zone is; during the stage of shut-in and initial flow, if pressure of strings is higher and temperature is lower, risk of hydrate generation will be greater and hydrate generation zone will be larger, so relevant actions should be taken to restrain hydrate generation.

Keywords:

Risk Analysis, Deepwater, Gas Well, DST, Gas Hydrate

1. Introduction

During deep-water testing period, prediction of hydrate generation zone is the prerequisite of prevention for hydrate and flow guarantee for the whole flow range [1] - [3] , and three aspects are needed: 1) prediction of temperature and pressure―we start study from temperature field of monophasic fluid in vertical wells, then take factors, such as two-phase flow, particular bore frame of deflected wells, marine environment and choking effect and so on, into consideration gradually. But the above study is specifically aimed at bore holes without continuously considering the surface flow lines behind bore holes; 2) determination of hydrate generation condition―in engineering applications, judgment according to empirical plate is generally of low accuracy, but statistical thermodynamic method is of general commonality and can facilitate the use of computers in a wide range of continuous calculation; 3) presentation of judgment method for hydrate generation zone―the engineering method to estimate the hydrate generation zone by means of critical temperature is simple, but of low accuracy, and the method makes temperature in bore holes not less than environment temperature a prerequisite, neglecting flow restriction and temperature drop.

Foreign scholars have given a more comprehensive exposition [4] - [6] , but it lacks theoretical basis. And domestic scholars have proposed many predicting methods of hydrate generation zone in deep-water drilling bore holes and heat transfer law in bore holes during deep-water gas well test period [7] - [11] , but these methods divide the whole flow range and present judgment plate of bore holes and that of surface flow lines, increasing the complexity of predicting hydrate generation. Based on the theoretical analysis, combined with specific conditions of deep-water gas wells test during different period, computing method for pressure and temperature of strings has been proposed and used to analyze the potential zone of hydrate generation under the circumstances, flow test, downhole and surface shut-in, and initial well startup by combining conditions of phase equilibrium.

2. Computing Model of Temperature Field

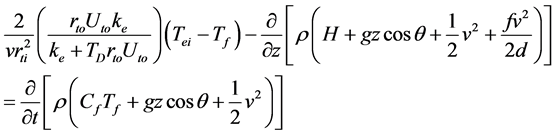

2.1. Temperature Field Equation of Bore Holes

Taking factors which affect temperature distribution in bore holes into comprehensive consideration, including environmental temperature, wellbore structure, structure of testing strings, job condition and formation fluid property, traditional method only based on heat transmission is changed, considering choking effect and work by volume change during flow behavior of high speed gas, and taking enthalpy of compactible gas during flow behavior as subject in the study, then temperature field equation of bore holes for deep-water wells during testing progress is established.

Hole section below mud line:

(1)

(1)

In the formula: ―inside radius of testing string, m;

―inside radius of testing string, m; ―outside radius of testing string, m;

―outside radius of testing string, m; ―total coefficient of heat transfer with outside surface of oil tube as datum, W/(m2∙K);

―total coefficient of heat transfer with outside surface of oil tube as datum, W/(m2∙K); ―formation coefficient of heat transfer, W/(m∙K); H―gas enthalpy, J;

―formation coefficient of heat transfer, W/(m∙K); H―gas enthalpy, J; ―formation temperature, K;

―formation temperature, K; ―fluid temperature, K.

―fluid temperature, K.

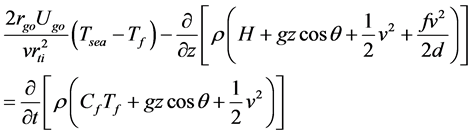

Hole section above mud line:

(2)

(2)

In the formula: ―outside radius of marine riser, m;

―outside radius of marine riser, m; ―inside radius of testing string, m;

―inside radius of testing string, m; ―total coefficient of heat transfer with outside surface of marine riser as datum, W/(m2∙K);

―total coefficient of heat transfer with outside surface of marine riser as datum, W/(m2∙K); ―sea water temperature, K.

―sea water temperature, K.

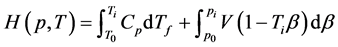

Computing formula of enthalpy is:

(3)

(3)

In the formula: V―specific volume, m3/kg; ―temperature of triple point, K;

―temperature of triple point, K; ―pressure of triple point, MPa;

―pressure of triple point, MPa; ―heat absorption capacity, J/(kg∙˚C); β―coeffi- cient of thermal expansion, 1/˚C.

―heat absorption capacity, J/(kg∙˚C); β―coeffi- cient of thermal expansion, 1/˚C.

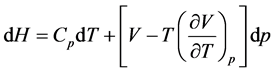

The above formula can be transformed into differential form:

(4)

(4)

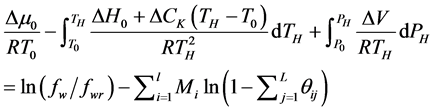

2.2. Computing Model for Hydrate Generation Condition

Adopting the thermodynamic computing method of hydrate generation condition, according to Vander Waals model [10] , the equation of hydrate generation condition is:

(5)

(5)

If alcohol depressant added, formula (5) is changed into:

In these formulas:

3. Hydrate Generation Zone during Testing Period

According to the computing method of temperature in oil tubes for deep-water testing, temperature and pressure distribution of Well X1 in different testing period are predicted. Well X1 is with operating water depth of 1447.20 m, mud surface temperature of 3˚C - 4˚C, reservoir porosity of 25.6%, water saturation of 31.1%, and so on; component analysis indicates 0.4% of its natural gas component being CO2, 89.961% of that is C1, 4.843% of that being C2, 2.23% of that being C3 and the rest of that being other component. Gas component model is adopted to compute PVT parameters under reservoir condition: volume factor of natural gas being 3.283 × 10−3 m3/m3, viscosity being 0.031 mPa∙s and compressibility coefficient being 0.0137 1/MPa.

3.1. Clean-Out and Blow-Down Period

Generating zone of hydrate under different condition of gas production rate is predicted in Figure 1, indicating that during clean-out and blow-down period there is minimum testing flow rate because that the strings are of high pressure and low temperature during low yield period and the lower the yield is, the higher the risk of hydrate generation is.

3.2. Downhole Shut-In

With deliverability of 20 × 104 m3/d, generating zone of hydrate at different downhole shut-in time is showed in Figure 2, indicating that under the condition (deliverability

Figure 1. Generating zone of hydrate during clean-out and blow-down period.

Figure 2. The generating characteristic of hydrate at different downhole shut-in time.

being 20 × 104 m3/d), if no preventive action is taken, there may be generating hydrate within the 600m range below the surface of the water (intersection range of temperature of strings curve and hydrate generation temperature (phase state) curve), and that after downhole shut-in, though temperature of strings decreases gradually, pressure in testing strings decreases fast and the risk of hydrate generation is low (there is no generating zone of hydrate of strings after shut-in).

3.3. Surface Shut-In

During the period of deep-water gas well test, surface shut-in can lead to serious problem of hydrate generation. Over shut-in time the temperature of strings will come into contact with environment temperature gradually, but the pressure keeps a higher value, and the zone of hydrate generation has changed gradually from the 1000 m range below the surface of the water to the 1950 m range which is 600 m below mud line. Once there is hydrate in a relatively long string, the consequences will be serious causing new difficulties for deep-water test due to hydrate being non-decomposable, so surface shut-in should be avoided (Figure 3).

3.4. Deliverability Testing

Figure 4 indicates that there is no risk of hydrate generation during high-speed flow period, so keeping fluid in strings flowing fast can avoid block-up caused by hydrate generation.

4. Conclusions

1) A new temperature and pressure calculation model during deep-water gas well

Figure 3. The generating characteristic of hydrate at different surface shut-in time.

Figure 4. The generating characteristic of hydrate under high-speed flow condition.

testing has built up, and prediction method of hydrate form region at different construction stages in testing is obtained combining with the formation condition of hydrate.

2) Result shows that the surface shut-in period has the risk of hydrate generation, in which gas hydrate is easy to generate as the temperature of and inside strings gradually decreases to the seawater temperature.

3) During flow period, the lower the yield is, the higher the risk of hydrate generation is. At the stage of initial well startup, the high pressure and low temperature make it easy for gas hydrate to generate.

Cite this paper

Yang, H.J., Hao, L. and Wu, M.W. (2016) Risk Analysis of Gas Hydrate Formation during Deepwater Gas Well Testing. International Journal of Geo- sciences, 7, 1057-1063. http://dx.doi.org/10.4236/ijg.2016.79080

References

- 1. Yang, S.K., Dai, Y.D., Lv, Y. and Guan, L.J. (2009) Key Techniques of Gas Well Testing in South China Sea Deep Water. China Offshore Oil and Gas, 4, 237-241.

- 2. Dai, Z., Luo, D.H., Liang, W., et al. (2012) A DST Design and Practice in Deep-Water Gasfields, South China Sea. China Offshore Oil and Gas, 1, 25-28.

- 3. Yin, B.T., Li, X.F., Du, H., et al. (2011) An Optimization Design for the Well Completion Test Technology. Acta Petrolei Sinica, 6, 1072-1077.

- 4. Chen, S.-M., Gong, W.X.W. and Antle, G. (2008) DST Design for Deepwater Well with Potential Gas Hydrate Problems. Offshore Technology Conference, Houston, 5-8 May 2008, OTC 19162.

- 5. Chen, S.-M. (2010) Un-Planned Shut-In and Deepwater Gas Hydrate Prevention. Offshore Technology Conference, Houston, 3-6 May 2010, OTC 20436.

- 6. Mogbo, O.C. (2010) Deepwater DST Design, Planning and Operations—Offshore Niger Delta Experience. SPE Production and Operations Conference and Exhibition, Tunis, 8-10 June 2010, SPE 133772.

http://dx.doi.org/10.2118/133772-ms - 7. Zhou, X.M., Duan, Y.G., He, Y.F., You, Y., Li, G. and Deng, K. (2014) The Flow Assurance of Deep Water Gas-Well Testing. Journal of Oil and Gas Technology, 5, 149-152.

- 8. Yan, Z.H., Liu, Y.J., Tang, S.L., et al. (2010) Calculations of Shut-In Wellbore Temperature and Pressure for Offshore Condensate Gas Wells. Natural Gas Industry, 30, 36-38.

- 9. Li, Y.C., Wang, Z.B. and Zhong, H.Q. (2010) Annulus Pressure Unloading Technology against Generation of Natural Gas Hydrate in the Wellbore of Gas Well. Acta Petrolei Sinica, 31, 318-321.

- 10. Li, J.Z., Gao, Y.H., Zheng, Q.H., Sun, B.J. and Guan, L.J. (2012) Hydrate Formation Prediction in Deepwater Gas Well Testing. Oil Drilling & Production Technology, 3, 77-80.

- 11. Yu, H.-M., Zuo, J.-L. and Zhang, Q. (2010) Prediction of Formation Conditions for Gas Well Hydrate. Natural Gas Geoscience, 3, 522-527.