Evaluation of Corrosion Product Activity in a Typical PWR with Extended Cycles and Flow Rate Perturbations ()

1. Introduction

Recent Pressurized Water Reactors (PWRs) are aiming at better performance of nuclear plants by increasing the fuel cycle length as high burn-up leads to better utilization of fuel as well as generation of higher revenues [1] . Recent studies indicate that enriched boric acid (EBA) decreases the requirement of high concentrations and the high value of pH (~7.4) can be done with 2.2 ppm of lithium. It also does not introduce the corrosion cracking problems in Pressurized Water Reactors (PWRs) [2] [3] [4] . This can improve the discharged burnup from average value of 33 MWd/kgU to 40 - 50 MWd/kgU.

However, extended cycles put higher safety limits on fuel integrity for longer fuel residence time in core and corrosion induced cracking is one of the major reasons for material failure in PWRs [5] . When the corrosion elements come from the magnetite (Fe3O4), the pH levels of 7.3 - 7.4 are needed instead of 6.9. Also, high values of temperature in the system can cause highly corrosive coolant and decomposition of water further increases its corrosion [1] [4] . The corrosion rate in PWRs increases with the effective full power days [6] . The observed increase involves many factors including phase transformations that occur due to aging and decomposition of stainless steel [7] etc. The corrosion elements get activated by circulation in reactor core. Large value of corrosion product activity (CPA) in the primary loop does become a problem to the reactor maintenance [6] [8] .

In PWRs, the CPA mainly comes from short-lived 56Mn and 24Na. However; iron, molybdenum and cobalt make almost all of the activity after shutdown of reactor. Table 1 shows some properties of these isotopes [9] . Primary coolant in PWRs maintains very high dose due to the CPA even after the reactor shutdown. Also, the end of cycle coolant activity can further increase due to any transient condition during reactor operation [8] [9] . The soluble forms of 60Co, 58Co and 54Mn show dependence on flow rate, pH values and boron [10] [11] .

Several studies have been carried out on coolant activation in nuclear reactors with focus on the flow rate & power transients. Reactor transient studies indicate that reactivity as well as flow rate perturbations result in neutron flux peaking [12] For PWRs, Venz and Weidmann showed that the coolant chemistry is important for extended fuel cycles. Coolant Activity at Beznau nuclear power plant was reduced when the pH levels in the coolant were raised to 7.4 [13] .

![]()

Table 1. Activation products and their reaction properties.

*Interactive chart of Radionuclides NuDat 2.6, NNDC Databases, Brookhaven National Laboratory (http://www.nndc.bnl.gov/nudat2/chartNuc.jsp).

The time dependent CPA in primary loops of PWRs was carried out for flow rate and power changes using constant corrosion rate models [14] . Program CPAIR was written in FORTRAN-77 and it was developed for assessment of primary coolant activity due to several corrosion products in light water reactors. The program was modified as CPAIR-P for effects of fast as well as slow transients on CPA in coolant. Recently the time dependent corrosion product activity calculations were performed after modifying CPAIR-P code for PWRs with long-term operating cycles using coolant chemistry parameters [11] .

In this work we focus on time dependent behavior for CPA in primary circuits of PWRs with extended cycles having flow rate transients and necessary changes were made in CPAIR-P code for nonlinear corrosion rates and pH values . Then for two extended operating cycles the CPA is estimated in the presence of both nonlinear corrosion rates and changes in pH values under flow rate transients.

2. Coolant Chemistry for Extended Cycles

Numerous studies have revealed that operating cycle in light water reactors is extendable to burnup value of 45 MWd/kgU in PWRs. The operating cycles of 18 to 24 month duration show an increase in the capacity factor from 3% to 7% [2] [3] [4] . At the beginning of the cycle for a PWR, 1200 ppm of boron is used in a 12 month cycle. Also initially the pH value of 6.9 is obtained with the help of lithium levels. Initial boron concentration must be higher (~1500 to 1900 ppm) for long operating cycles. This in turns translates into much higher pH values in the coolant. The Enriched Boric Acid reduces the required amount of chemical shim. Therefore, high pH value (7.4) is used in the reactor along with 2 ppm of lithium to keep long operating cycles [4] .

The long operating cycles employ this scheme in which the coolant has higher pH in start of the cycle along with high values of boron and lithium concentrations. After that, steadily pH value is elevated to 7.4 and then kept constant till the end of cycle. Various scenarios for pH changes in a typical PWR versus effective full power days are shown as Figure 1 [1] . The pH variations for long cycles are shown as Figure 1. In the first case, Natural Boric Acid (NBA) is used with lithium and pH as 2.2 ppm and 6.9 respectively.

3. Mathematical Model

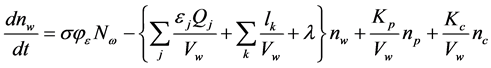

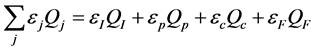

Using deterministic simulation technique a mathematical model was developed and implemented into a computer code along with a suitable numerical integration method. The time derivative of active concentration is given by [14] :

(1)

(1)

where, σ is the group constant. The effective one-group flux is given by  (#/cm2∙s) and

(#/cm2∙s) and  (#/cm3) represents the concentration of target nuclide in water. The

(#/cm3) represents the concentration of target nuclide in water. The ,

,  and

and  have meanings of target concentrations in water, piping and core, in atoms/cm3. The values of concentrations of the activation products in primary coolant, piping and core are given as

have meanings of target concentrations in water, piping and core, in atoms/cm3. The values of concentrations of the activation products in primary coolant, piping and core are given as ,

,  and

and  respectively, in #/cm3. The sum over j for

respectively, in #/cm3. The sum over j for  is given by:

is given by:

(2)

(2)

where,  ,

,  ,

,  and

and  represent values of removal rates for ion exchanger, deposition on pipes, core surface depositions and filter based removals, respectively. The primary coolant leakage rate from the kth leak is given by lk and removal rates from piping scale and from core surface are given by Kp and Kc respectively in #/cm2∙s. Table 1 gives summary of decay data for various isotope of interest. In this work, experimental values of the removal rates from the published PWR data were used [10] . Some of the values are shown in Table 2 [10] [11] .

represent values of removal rates for ion exchanger, deposition on pipes, core surface depositions and filter based removals, respectively. The primary coolant leakage rate from the kth leak is given by lk and removal rates from piping scale and from core surface are given by Kp and Kc respectively in #/cm2∙s. Table 1 gives summary of decay data for various isotope of interest. In this work, experimental values of the removal rates from the published PWR data were used [10] . Some of the values are shown in Table 2 [10] [11] .

![]()

Figure 1. The pH-value in the primary coolant for two cycles as a function of effective full power days (EFPDs) for various indicated values of 10B in boric acid.

![]()

Table 2. Experimental values of exchange rates in a typical PWR.

The temporal variation of dissolved boron in primary coolant are given by a parameter h(t):

![]() (3)

(3)

here, ![]() represents the slope estimated from the power plant operation data;

represents the slope estimated from the power plant operation data; ![]() is boric acid concentration (

is boric acid concentration (![]() ) and time dependent pH-value; a0 and b0 are fractions in the initial and final phases of operation cycle. The residence time of primary coolant in core is represented by Tc while the time taken for circulating once in primary circuit is given by TL. The temporal variation of concentration of target nuclide can be given as

) and time dependent pH-value; a0 and b0 are fractions in the initial and final phases of operation cycle. The residence time of primary coolant in core is represented by Tc while the time taken for circulating once in primary circuit is given by TL. The temporal variation of concentration of target nuclide can be given as

![]() (4)

(4)

![]() (5)

(5)

where, ![]() and

and ![]() represent the target nuclide concentration on the piping and on the core respectively and

represent the target nuclide concentration on the piping and on the core respectively and ![]() represents the corrosion production rate.

represents the corrosion production rate.

The removal rates by ion-exchanger, core deposition and leakage are function of primary coolant flow rate. The corresponding rate of the core scale activity is given by following model:

![]() (6)

(6)

where, the volume of the scale on the reactor core surface is given by ![]() (cm3). The

(cm3). The ![]() is core averaged thermal neutron flux (neutrons/cm2∙s). The temporal variation of concentration of target nuclide on the core scale (

is core averaged thermal neutron flux (neutrons/cm2∙s). The temporal variation of concentration of target nuclide on the core scale (![]() ) is:

) is:

![]() (7)

(7)

The governing equation for the rate of change of active material on the piping scaling (![]() ) is given by the following expression:

) is given by the following expression:

![]() (8)

(8)

where, the scale volume on the piping is ![]() (cm3). Then, the temporal variation of target nuclide on piping walls (

(cm3). Then, the temporal variation of target nuclide on piping walls (![]() ) is

) is

![]() (9)

(9)

Using the above system of Equations (1)-(9), the CPAIR-P computer code [14] has been upgraded in the present study to incorporate temporal variations in corrosion rates along with the pH values and chemical shim.

The upgraded version of CPAIR-P code now simulates the CPA incorporating time dependent corrosion rates and primary coolant chemistry. This program uses the core design parameters to estimate the group constants (Table 3). For this purpose, the LEOPARD [15] code is employed as subroutine in CPAIR-P/PH program. The LEOPARD is a unit cell based computer program using 54 fast & 172 thermal energy groups used for criticality calculations and group constant generations. Subsequently ODMUG program by Thomas and Edlund developed in 1980 was used for computation of detailed spatial group fluxes [16] .

4. Results and Discussion

In this work, computer simulations were done for a typical PWR with a clean system having none impurities [17] . The fractional exchange and re-solution rates were taken from the experimental data for the typical PWR. These experimental values of deposition and re-solution rates are given in Table 2. Also, the values of plant specific data are given as Table 3 [10] [11] . The corrosion prone plant surface area of 108 cm2 is in contact with the primary coolant. Also, in recent work [8] it was shown that corrosion rate approaches an equilibrium value of 2.4 × 10−13 g/cm2-s. Such a PWR has coolant volume equal to 1.3 × 107 cm3. In this work we have used the same for the simulations. Figure 2 gives algorithmic details of this program in the form of schematic flow chart.

In first part, the equilibrium value of removal rate of CPA by the ion-exchanger (![]() ) was found taking a constant value of corrosion rate and the details of methodology can be found in the Reference 14 & 17 respectively. These simulations indicate that the final value for CPA becomes constant when

) was found taking a constant value of corrosion rate and the details of methodology can be found in the Reference 14 & 17 respectively. These simulations indicate that the final value for CPA becomes constant when ![]() becomes higher than 400 cm3/s. Consequently, the value of 600 cm3 per second was used for removal rate in this work. Behavior of dominant corrosion

becomes higher than 400 cm3/s. Consequently, the value of 600 cm3 per second was used for removal rate in this work. Behavior of dominant corrosion

![]()

Table 3. Typical design specifications of a PWR.

![]()

Figure 2. Logical flow chart of the computer modified program CPAIR-P/PH.

isotopes (56Mn, and 60Co) was observed and we saw that when reactor is operating the main contribution comes from 56Mn and after the shutdown the cobalt isotopes dominate the activity.

4.1. Time Dependent pH Value

Typical behavior of the pH-values for two cycles as a function of time is shown as Figure 1. Here, different curves indicate different levels of 10B in mixed in the chemical shim. When mixed B-10 is high the pH-value becomes also high in the system. Figure shows that the pH level gradually increases from lower to higher values and it saturates to about 7.35 in both first and second cycle. Increase in pH value lowers the solubility of corrosion products in the coolant. Also high pH results in a positive temperature coefficient of solubility and this reduces the transport of corrosion products. Also, any increase in the operation length will affect the generation of corrosion product. In this work, we have assumed a constant corrosion rate during the steady state operation.

4.2. Nonlinear Changes in Corrosion and pH Effects

PWRs have in general nonlinear changes in the corrosion rate during their operation. This is in addition to the coolant chemistry effects. The following mathematical model is used for the first cycle:

![]() (10)

(10)

The variable m represents slope having a constant value in the time interval![]() . The variable

. The variable ![]() represents the optimum value of rate attained for t > b.

represents the optimum value of rate attained for t > b.

Similarly for the second cycle, the initial corrosion rate is non-zero because of a residual value from the first cycle which is enhanced by an increase in corrosion rate along with a opposing decrease due to effects of the pH-value. It is mathematically modeled by the following expression:

![]() (11)

(11)

The values of 600, 1170 and 1200 days were used for c, d, and e respectively. The activity was then determined from the modified program CPAIR-P for both cycles. These simulations were carried out for various boron concentration scenarios. When h(t) = 1, the effect of pH-value is nominal and saturation values are largest of all cases. During first cycle, saturation values for Co-60 are 0.24 µCi/cm3 (core region), 0.10 µCi/cm3 (primary pipes) and 0.016 µCi/cm3 (primary coolant).

4.3. Flow Rate Perturbations

When the cross-sectional area for flow changes and/or the primary pump speed gets reduced then the flow rate transient occurs in the reactor. As a result the fuel, moderator and coolant temperatures change and start affecting the neutron flux. This further modifies the production of activated corrosion products and their loss terms. In this work, we have introduced a flow rate perturbation taking PWR operating at full power and the activated products has reached to their saturation values. Here we have not allowed the reactor to scram during these simulations to study the consequences of these simulations. Using the modified CPAIR-P program, the corrosion product activity was estimated in the coolant, primary pipe scale and in the reactor core. Flow rate changes were assumed to be linear and were started at time, tin and remained effective for tmax-tin time period. Such a model is introduced by the parameter g(t):

![]() (12)

(12)

Flow rate decrease has a slope of α and tin is the time of initiation of mass flow rate perturbation.

The mass flow rate perturbation is initiated at t0 = 300 d for several

![]() values. In time period of ten days the flow rate decreases from

values. In time period of ten days the flow rate decreases from ![]() to

to![]() . The reactor remains at full power and it is not allowed to undergo a scram. Simulation results for first and second cycle are shown as Figure 3 for activity due to 60Co for 40% 10B in chemical shim. The results for the first cycle indicate that CPA approaches a higher final value. The new saturation value keeps on increasing when

. The reactor remains at full power and it is not allowed to undergo a scram. Simulation results for first and second cycle are shown as Figure 3 for activity due to 60Co for 40% 10B in chemical shim. The results for the first cycle indicate that CPA approaches a higher final value. The new saturation value keeps on increasing when ![]() is increased. If the flow rate is allowed to change,

is increased. If the flow rate is allowed to change, ![]() is varied from 0 to 0.8 w0. Then, the new saturation activity in coolant increases from 0.011 µCi/cm3 to 0.017 µCi/cm3. When the ion-exchanger purification rate,

is varied from 0 to 0.8 w0. Then, the new saturation activity in coolant increases from 0.011 µCi/cm3 to 0.017 µCi/cm3. When the ion-exchanger purification rate, ![]() , becomes low than these saturation value will increase further. Also, an increased deposition, re-solution and leakage can also get increased in these transients. Similarly, for the second cycle the simulations predict higher peak values in comparison with peak values in the first cycle (Figure 3). Also, the saturation values in the second operating cycle are about 14% higher as compared with the values in the first cycle. These results indicate that flow rate perturbations substantially affect the balance of CPA in PWRs and their effects propagate in next operating cycles.

, becomes low than these saturation value will increase further. Also, an increased deposition, re-solution and leakage can also get increased in these transients. Similarly, for the second cycle the simulations predict higher peak values in comparison with peak values in the first cycle (Figure 3). Also, the saturation values in the second operating cycle are about 14% higher as compared with the values in the first cycle. These results indicate that flow rate perturbations substantially affect the balance of CPA in PWRs and their effects propagate in next operating cycles.

5. Conclusion

The CPA under flow rate perturbations was investigated in primary loop of a

![]()

Figure 3. Comparison of specific activity due to 60 Co in the primary coolant under flow rate perturbation having nonlinearly rising corrosion rate and 40% 10B in dissolved boric acid. Flow rate perturbation is introduced at 300 day for Δt = 10 days.

typical PWR with long operating cycle. These cycles affect the primary coolant chemistry in terms of operational levels of boron and optimum pH values. These simulations indicate that for the normal reactor operation conditions the values of specific CPA approach equilibrium value fairly quickly. The pH values, removal rates and cycle length affect the saturation level of CPA in the system. The CPA levels have been compared for flow rate transients in the presence of higher levels of 10B in chemical shim. When the flow rate transient is applied, the saturation values of CPA go up. If the flow rate is allowed to change, ![]() is varied from 0 to 0.8 w0. Then, the new saturation level in the coolant increases from 0.011 µCi/cm3 to 0.017 µCi/cm3. The saturation values in the second operating cycle are about 12% higher when compared with values in the first cycle.

is varied from 0 to 0.8 w0. Then, the new saturation level in the coolant increases from 0.011 µCi/cm3 to 0.017 µCi/cm3. The saturation values in the second operating cycle are about 12% higher when compared with values in the first cycle.