1. Introduction

During 2006, 2011 and 2016, following the implementation of a monitoring plan, contaminations with dioxins in poultry meat were found: the levels of contamination were higher than legally allowed in meat from poultry slaughtered for human consumption [1] . To identify the original source of contamination of the birds, all potential sources of contamination were analyzed and the results showed considerable high contamination with dioxins of the wood shavings used as bedding material in the poultry farms, indicating that these materials were the likely source of contamination of the animals [2] .

In those incidents of contamination of the food chain with dioxins, the investigations performed revealed that the contaminated wood shavings used as poultry bedding material were delivered by wood industries that illegally disposed wood shavings byproducts produced with treated wood.

In these episodes, contamination profiles of higher and lower concentrations in the poultry muscle and fat, seems to be very similar, being OCDD, OCDF, 1,2,3,4,6,7,8- HpCDD and 1,2,3,4,6,7,8-HpCDF responsible for 97.4% of the total contamination [2] .

In Portugal, wood treatment is performed by 23 companies and is dominated by the production of poles, beams and poles, with a production of about 84,300 cubic meters and the most widely used wood species is the maritime pine (Pinus pinaster) [2] .

The most widely used commercial products in Portugal are Celcure C4, Celcure VS725, Korasit K2 whose active principles are mainly quaternary ammonium salts and copper, the TANALITH E 8001 whose active principles are propiconazole, tebuconazole, baramina and copper and Coprol Premium whose active ingredients are propiconazole and copper. Of the twenty-three existing companies, fifteen use TANALITH E 8001, two use celcure C4 or VS725, four use Korasit and two the Coprol Premium. As the Celcure is used by the two largest companies, this product shares with TANALITH E the leadership of the domestic market, representing Korasit and Coprol a marginal share of the market [3] .

This work describes the treatment of Pinus pinaster wood with four different industrial wood preservatives and the fingerprint analysis of the dioxin contamination profile with the wood shavings samples collected during the food chain contamination incidents. The methods used were both nonpressure, one by immersing the wood samples in the preservative solution and the other by impregnation of the preservative solution with vacuum.

2. Materials and Methods

1) Wood treatment

The treatment of wood was held at the laboratory of the Center for Structural Behavior of Structures from the Department of structures of the National Civil Engineering Laboratory (LNEC).

For the comparative study of different treatments of wood, a lot of pine wood has been chosen from the same stock and a research analysis for detection and quantification of PCDD/F were made to ensure that the wood batch was not contaminated.

The procedure used in the treatment of wood that was described in Table 1.

The treatments were performed by immersion and by a vacuum method for comparing the contamination profile of the four different commercial products used for different purposes, two with an anti-bluing industrial product, or fungicidal and other two by depth vacuum impregnation with fungicide and pesticide effect.

Treatment A, for use as an industrial fungicide treatment by immersion at a dilution in water of 7%.

Composition:

![]()

Table 1. Procedures for the treatment of wood.

・ 14.0% trimetilcocoamonia chloride.

・ 4.0% sodium tetraborate pentahydrate (Na2B4O7.5H2O); Also called Borax.

Treatment B, for use as an industrial fungicide treatment by immersion at a dilution in water of 1.5% to 3.5%.

Composition:

・ 10% Bardap 26 (N,N-Didecyl-N-methyl-poly(oxyethyl)ammonium propionate).

・ 1.6% DCOIT (4,5-dichloro-2-N-octyl-4-isothiazolin-3-one).

・ 2% IPBC (3-iodo-2-carbamate proponyl).

・ 0.9% propiconazole (C15H17Cl2N3O2).

Treatment C, for use as an industrial fungicide and insecticide treatment by pressure and vacuum in an autoclave to a 2% - 4% dilution in water.

Composition:

・ 4.0% boric acid (H3BO3).

・ 4.2% Bardap 26-poly(oxy-1,2-ethanediyl), α-[2-(didecilmetilamónio)ethyl]-ω-hydroxy- propanoate (salt).

・ 20% copper (II) carbonate hydroxide, copper (II) 1:1. Cu(OH)2; CuCO3.

Treatment D, for use as an industrial fungicide and insecticide for treatment with vacuum and pressure in an autoclave at a dilution of 2% in water.

Composition:

・ 14% basic copper carbonate; CuCO3.

・ 0.50% didecyldimethylammonium chloride; (N-(3-aminopropyl)-N-dodecilpropano- 1,3-mdiamine) C22H48ClN.

・ 0.16% propiconazole (C15H17Cl2N3O2).

・ 0.16% tebuconazole (C16H22ClN3O).

To calculate the absorption of the applied solution, the following formula was used in which (mf) is the final weight; (mi) is the initial weight:

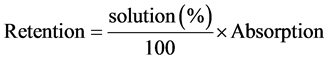

The retention of preservative solution was calculated as below:

2) Analytical Method

The analytical method used for detection and quantification of dioxin was the USA EPA method 1613 revision B [4] . This method was developed by the Environmental Protection Agency, Science and Technology of the United States for the determination of 2,3,7,8-CDDs/CDFS replaced through octa-chlorination, dibenzo-p-dioxins and dibenzofurans in aqueous matrices, solid or tissue by isotope dilution, followed by capillary column of high resolution gas chromatography (HRGC)―high resolution mass spectrometry (HRMS).

3) Statistical Analysis

Analysis of data was carried out in accordance with the methodology of the USA EPA for analysis of contaminants [5] . The methodology consists in the conversion of the concentration of the different congeners of each sample to a decimal percentage of the sum of congeners. These standard concentrations in each sample is represented in a bar plot graphic. The square of the Pearson correlation coefficient (r2) [6] is then used as a measure to assess whether the profile of the concentration of congeners in the samples (compared visually on the bar plot) is statistically similar. It is considered that the profiles are similar if the average of r2 is close to 1 and the standard deviation (SD) is next to zero.

The same methodology was applied to investigate a possible association between groups of analysis.

3. Results

The results showed a negligible contamination of 0.078 ± 0.025 pg PCDD/F-WHO- TEQ/g in the blank wood, without any chemical treatment. Those results were used to correct all the values obtained in the analysis performed to compare the treatments.

The results obtained during the treatment of wood are presented in Table 2.

Contamination levels of wood samples subjected to different treatments are presented in Table 3.

Analyses for quantification of dioxins and furans in different samples subjected to the four different treatments had a very similar profile with a very high correlation coefficient (R2 = 0.99) and a very low standard deviation (SD = 0.001) (Figure 1). For this reason, it was not made the comparison between treatments.

Given these results, it is interesting to compare the contamination profile of the total samples taken from the wood shavings used as bedding material during the episodes of poultry dioxins contamination in 2006, 2011 and 2016. For this purpose, only the samples that have showed contamination with substantial amounts, i.e. contamination with levels above 2 pg WHO-PCDD/F-TEQ WHO/g, will be used.

4. Discussion

Several authors describe wood preservative retention comparison studies in different species of wood, with different preservation methods and products with different preservatives.

Retentions obtained in this laboratory study varied with the concentrations of the solutions used. The vacuum treatment for impregnation of the solution, yielded an average retention of the solute of 16.7 Kg/m3, when a 4% concentration was used in the

![]()

Table 2. Absorption and retention of preservative solution.

![]()

Table 3. Contamination levels of the different samples/treatments.

treatment “C” and an average retention 4.45 kg/m3 when a 2% concentration was used in the treatment D.

The assessment of the wood impregnation studies is quite difficult since the retention levels vary with various factors such as the species of wood, wood moisture content, the volume of samples, the treatment time, pressure used, and the treatment used, i.e. if only applies vacuum or if vacuum is alternated with positive pressure. This difference is not as significant in immersion treatments.

The impregnation studies performed by Yildiz et al. 2004 [9] compared to this study, exhibited higher retention levels with lower concentrations but with lower volume samples and studies performed by Ozemir, et al. 2015 [7] showed similar retention levels with similar volume of samples but for less time. Studies by other authors referred in Table 4 in some cases have higher retentions and other lower, even using vacuum and pressure.

![]()

Figure 1. Profile contamination of samples from different treatments of wood.

![]()

Table 4. Comparison of preservative retention levels in different studies.

The results of the contamination levels of the treated wood chips showed very low contaminations when compared with the contaminations observed in the incidents occurred in poultry contaminations, probably due to lower retentions comparing to the retentions obtained in industrial conditions.

Contamination profiles of the different treatments used showed a very strong correlation R2 = 0.99 and a standard deviation of 0.001.

The fingerprint analysis of the profile of the wood treated in this study, with the profile of the wood shavings from the bedding material implicated in the incidents that took place in Portugal in 2006, 2011 and 2016 with food safety concern (Figures 2-4)

![]()

Figure 2. Fingerprint analysis of treated wood (line) with bedding material incident of 2006.

![]()

Figure 3. Fingerprint analysis of treated wood (line) with bedding material incident of 2011.

![]()

Figure 4. Fingerprint analysis of treated wood (line) with bedding material incident of 2016.

showed a very high correlation. R2 = 0.99 and SD = 0.002 compared with the litters tested in 2006, R2 = 0.99 and SD = 0.007 compared with the litters tested in 2011 and R2 = 0.96 and SD = 0.012 compared with the litters tested in 2016.

5. Conclusions

The study and characterization of the contaminant, in particular, the study of the influence of different products marketed in Portugal for treatment/preservation of wood, allowed the conclusion that there is no difference in terms of contamination profile, caused by the different industrial wood treatment preservative products.

The study established, at laboratory level, a clear correlation between the commercial products used in wood treatment and the contamination of wood shavings that have been used as bedding material in poultry production. The profile of the contamination of pine wood chips treated in the laboratory fits perfectly into the profile of the wood shavings implicated in the poultry contamination incidents in Portugal.

Surprisingly, the surface treatment of wood and the depth (vacuum) treatments showed very similar contamination profiles, which allows us to consider that, in general, the litters of poultry contaminated with treated wood shavings present a similar profile, since the degree of retention of the preservative in wood does not affect the profile found.

This recurrence of the profile can be important for risk managers because it allows, based on a muscle and fat analysis, immediately associate an equivalent profile to the respective source of contamination without having to waste time and resources to examine all possible sources of contamination.