1. Introduction

Extrusion cooking is a continuous process commonly used in industry to produce snacks, breakfast cereal and pet foods [1] . It is considered as a high-temperature and short-time cooking process. Many order-disorder transi- tions take place during extrusion, such as starch gelatinization and dextrinization, protein denaturation, and com- plex formation between lipids and amylose [2] . These complex physical and chemical transitions depend on processing variables. The processing variables including screw profile and rotating speed, barrel temperature profile, feed rate and composition of the material being extruded have significant effects on the product charac- teristics [1] [3] .

Expanded starch-based foods are considered as high-energy and low-nutrient dense foods, which raises blood sugar rapidly after consumption and are termed as “high glycemic foods” [4] [5] . High glycemic foods elevate blood glucose thereby increasing insulin responses rapidly. Frequent consumption of high glycemic foods is as- sociated with increasing risk of Type II diabetes, obesity and cardiovascular diseases [6] [7] . Glycemic index (GI) of starch-based food has been reported to be affected by many factors such as botanical source of starch, degree of starch gelatinization, types of native crystalline structures, amylose to amylopectin ratio, average molecular weight and complex formation between starch and protein or lipid [6] [8] -[12] .

Processing conditions in anextrusion process also have significant effects on physiological properties of the products. Extreme extrusion conditions (low-moisture, high-temperature and high-shear) cause extensive starch gelatinization and dextrinization as well as the destruction of other nutrients. High degree of starch gelatiniza- tion and dextrinization lead to increased susceptibility of starch to enzymes and high glycemic index (GI) [2] [13] . Mild extrusion conditions (high moisture content, low residence time and low temperature) would favor higher retention of nutrients [14] , which also is capable of producing expanded foods with potentially lower glycemic index.

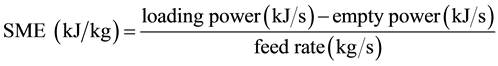

Specific mechanical energy (SME) has been proposed to establish the relationship between processing va- riables and properties of expanded products such as density, expansion ratio, solubility and degree of gelatiniza- tion [3] [13] [15] . As a system parameter, SME represents the amount of mechanical energy transferred to the feed material during extrusion, and it can be used to indicate extrusion conditions. SME was found to be depen- dent on feed moisture, feed rate, screw speed and barrel temperature [3] . In general, feed moisture content is the most significant factor affecting the amount of SME [16] . Li and others [17] reported that SME alone cannot be used to predict thermal-mechanical modification in a conventional extruder because additional thermal energy input (i.e. external heating) should also be considered. However, SME has the potential to predict the properties of extruded products when there is no additional thermal energy input.

Rice has become an attractive ingredient in the extrusion industry in recent years because of its neutral taste and white color [18] [19] . It has been proposed that rice has a wide range of glycemic index (GI) depending on varieties and types [20] . Brown rice has been reported to have a significantly lower glycemic index than white rice because of the rich fiber content [21] [22] . In general, rice with higher amylose content tends to have lower glycemic index (GI) than rice with lower amylose content, which is due to starch crystalline type. Amylose has a tendency to form type-B crystalline in starch, and type-B crystalline type was considered to be resistant to α-amylase [12] [23] . Conflicting results had also been reported indicating that amylose content alone was not a good predictor of starch digestion rate [24] . A comparison of digestive properties of extruded snacks is pro- duced by different types of rice has not been studied. In addition, the effect of the system parameter, SME, on the glycemic behavior of products is still unknown. The objective of this research is to investigate the relation- ship between SME and extruded rice properties such as glycemic behaviors, degree of gelatinization and physi- cal properties. The relationship between SME and the digestive and physical properties of extruded rice-based snacks was studied using medium grain brown rice (BR), medium grain sushi rice (SR), and long grain jasmine rice (JR).

2. Materials and Methods

2.1. Raw Materials

All rice was purchased from a local grocery store. The types of rice that used in this study were medium grain brown rice (BR) (CJ, Los Angeles, CA, USA), medium grain white sushi rice (SR) (CJ, Los Angeles, CA, USA), and long grain jasmine rice (JR) (Three Elephants, Thailand).

2.2. Extrusion

Extrusion process was performed using a single screw extruder (Welly puffing machine S2, Jain Inc., South Korea). Screw dimension was 118.9 × 33.6 (Lengthxdiameter, mm), barrel diameter was 41.2 mm and die dia- meter was 3.4 mm. For all extrusion processes, screw speed was set at 120 rpm. Barrel temperature during extrusion varied from 88˚C to 130˚C depending on the types of rice and feed moisture content. There was no ex- ternal heating applied. DI water was pumped into the extruder by the varying rate (0 g/min - 3.13 g/min) (FMI “Q” Pump Model QG50, Fluid Metering Inc., Syosset, USA) to control the feed moisture content. All types of rice were fed at the feed rate range of 61.6 g/min - 65.51 g/min with varying feed moisture content between 9.9% and 14.39% (wet basis). The feed rate was calculated as the sum of rice feed rate and water pumping rate. The extrudate was cut using a cutting blade rotating at 240 rpm. The extrudate was collected in air tight glass jars and stored at room temperature for further analyses.

2.3. Specific Mechanical Energy (SME)

Power consumption during the extrusion was measured by a Three-Phase Power Logger (Model 1735, Fluke Corp., Everett, WA). The power consumption is measured directly by the power logger instead of calculating from %torque, rated power and screw speed. SME was calculated using Equation (1). In this Equation, empty power was measured by the power logger when running the extruder without feeding the rice. Loading power was measured when running during feeding. Power consumptions were recorded every 2 seconds for 2 minutes and the average values during the extrusion were used to calculate SME.

(1)

(1)

2.4. Texture Analysis

Two pieces of the extruded samples were weighed and placed on a TA-XT2i texture analyzer (Texture Tech- nologies Corp., Scarsdale, NY, USA) using a mini Kramer shear press (TA-91M). The test speed was 1 mm/s and the shear press traveled 100% of the sample’s diameter. The area under force (N) vs. distance (mm) curve represents the energy required to break a sample, which can be translated to the hardness of the sample [16] . The breaking energy divided by the mass of the sample represents the fracture energy (FE) per unit mass.

2.5. Bulk Density and Expansion Ratio

Each extruded sample was placed to fill a 200 ml cylinder to measure bulk density. Bulk density was calculated as weight (g) per unit volume (ml). Expansion ratio is the ratio of the extrudate’s cross-sectional area to the ex- truder die orifice cross-sectional area. The diameters used for calculating cross-sectional area were measured using a caliper (Mecanic Type 6911, Manostat Corp., Woodstock, NY).

2.6. Degree of Gelatinization

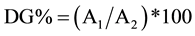

Degree of gelatinization was measured by modified Wootton’s method [9] . The extruded sample (1 g) was ground using a grinder (CBM-18, Cuisinart, East Windsor, NJ) and screened by No. 45 US sieve. The portion of particle size less than 355 µm was collected and used. The ground sample (1 g) was dispersed in 50 ml DI water for 30 min with stirring speed at 300 rpm. The suspension was then centrifuged (MiniSpin Plus, Eppendorf, Germany) at 8000 g for 10 min at room temperature. Duplicate of 1 ml supernatant was taken and mixed with 8.9 ml DI water and 0.1 ml iodine solution containing 4% KI and 1% I2. Absorbance (A1) was measured at 600 nm against blank. Ground raw rice (1 g) in duplicate was mixed with 20 ml DI water (5% w/v) and boiled for 50 min. The solution was then cooled down to room temperature and the final volume was adjusted to 50 ml using DI water. The mixture was dispersed evenly by constant stirring for 30 min at speed 300 rpm and then centri- fuged for 10 min at 8000 g. The supernatant was then diluted and treated with the iodine solution and the absor- bance was measured at 600 nm (A2) as described above. Degree of gelatinization (DG%) was calculated using the following Equation (2).

(2)

(2)

2.7. In-Vitro Glycemic Behavior

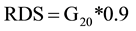

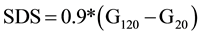

An in-vitro glycemic behavior was tested using modified Englyst’s [25] method. In gastric phase, 100 mg (±10 mg) extruded sample was incubated with 10 ml pepsin (P7000, Sigma-Aldrich, St. Louis, MO) solution (5 g/L pepsin dissolved in 0.01 M HCl), 5 g/L guar gum and 5 glass beads (d = 5 mm) at 37˚C with shaking at 250 rpm for 30 min. pH was then adjusted to 5.8 using 5 ml 0.25 M sodium acetate buffer. 3 mL mixture of pancreatin (4 g/L) (P1750, Sigma-Aldrich, St. Louise, MO) and amyloglucosidase (22.2 unit/ml) (A7095, Sigma-Aldrich, St. Louise, MO) solution was added to start the intestinal phase. After 20 min of incubation in the intestinal phase, 0.2 ml sample was taken and immediately placed into 1.8 ml of 99.5% ethanol (Sigma-Aldrich, St. Louise, MO., USA) to inactivate enzymes. The sample and ethanol mixture was then centrifuged at 4696 g for 20 min at −10˚C (SorvallST16R, Thermo Fisher Scientific Inc., USA). 0.1 ml of the supernatant was taken to determine the glucose concentration (G20) using Glucose kit GAGO-20 (Sigma-Aldrich, St. Louise, MO). Another sample was taken at 120 min after intestinal incubation and the glucose concentration (G120) was determined using the same procedure for G20. G20 was measured as the total amount of glucose released after intestinal incubation for 20 minutes. G120 was also measured as the total amount of glucose released after intestinal incubation for 120 minutes. Rapidly digestible starch (RDS) is calculated by Equation (3) and slowly digestible starch (SDS) is de- scribed as Equation (4) [26] .

(3)

(3)

(4)

(4)

2.8. Statistical Analysis

The collected data were analyzed using analysis of variance (ANOVA) and least significant differences (LSD) (Version 9.4, SAS Institute, Cary, NC). Results with a corresponding probability value of p < 0.05 were consi- dered to be significantly different.

3. Results and Discussion

3.1. Specific Mechanical Energy (SME) and Feed Moisture Content

Specific mechanical energy (SME) during extrusion was inversely correlated with feed moisture content (Figure 1) due to viscosity change via adding water [16] [27] . In an extrusion process, SME is a function of many va- riables such as screw speed and rheological properties of feeding materials. At a given feed rate of dry material, SME decreases with the increasing feed moisture for all samples because water worked as a lubricant and re- duced the viscosity of the feed melt in the extruder. SME also differs from different types of rice due to their va- ried compositions. At given feed moisture content, long grain jasmine rice (JR) has a higher SME value than brown rice (BR) and sushi rice (SR). Long grain rice generally contains higher amylose content than medium grain rice such as brown rice (BR) and sushi rice (SR) [28] . Viscosity of starchy material can increase due to the release of amylose upon heating [29] . Since jasmine rice (JR) contains higher amylose content, the melt might be more viscous during extrusion and eventually requires higher SME than brown rice (BR) and sushi rice (SR). Brown rice (BR) and sushi rice (SR) are both from the same botanical source but differ in degree of milling [30] . Milling process removes bran layer where the majority of lipid in rice exists [31] . During an extrusion process, lipid also works as a lubricant that decreases SME. As a result, the brown rice (BR), with lower degree of mil- ling than the sushi rice (SR), required slightly less SME than the sushi rice (SR) at the same feed moisture as shown in Figure 1.

3.2. Starch Gelatinization

For all three types of rice, starch gelatinization and SME increased with the reduction of feed moisture content (Table 1). This result is consistent with the results reported in previous studies [13] [17] [32] . In an extruder, part of the mechanical energy input is converted to thermal energy through mechanical shearing. With more SME input, the more energy will be converted to thermal energy and therefore a higher die temperature can be reached. In the past studies, degree of gelatinization (DG%) has been reported to be proportional to die tempera- ture [33] . In this study, DG% was also found to be positively related to die temperature (data not shown).

In an extrusion process, destruction of starch structure and gelatinization of starch are achieved by both ther- mal cooking and physical shearing [2] [34] [35] . In this study, higher SME indicated higher degree of mechanical

![]()

Figure 1. Effect of feed moisture content on specific mechanical energy (SME) for medium grain brown rice (BR), medium grain sushi rice (SR) and long grain jasmine rice (JR). Screw speed 120 rpm; Dry feed rate BR 61.6 g/min, SR 61.5 g/min and JR 62.6 g/min.

![]()

Table 1. Effect of feed moisture content and specific mechanical energy (SME) on the properties of the product.

Means with the same letters in the same column within each rice type are not significantly different at α = 0.05. BR = medium grain brown rice, SR = medium grain sushi rice and JR = long grain jasmine rice.

shearing on starch granules, which resulted in higher DG%. The DG% value of the samples produced by this short-screw extruder was lower than the reported DG% of products processed by other extruders possibly due to reduced residence-time of the short-screw extruder [34] . Previous studies reported that starch-based foods with lower DG% are likely to cause less glycemic response during digestion because gelatinization makes starch sus- ceptible to enzymatic reactions [8] [12] [36] . Therefore, decreasing DG% can contribute to lower glycemic in- dex, which can be controlled by extrusion process parameters.

3.3. In-Vitro Glycemic Behavior

Estimating glycemic index (GI) using in-vivo experiments is a time consuming process and the GI results could be affected by the health conditions and the age of panelists. Several approaches have been developed to predict GI using in-vitro methods, which are economical, convenient, and more likely to produce objective results [5] [26] [35] . According to Englyst et al. [37] , starch can be classified to three categories based on digestibility: ra- pidly digestible starch (RDS), slowly digestible starch (SDS) and resistant starch (RS). Rapidly digestible starch (RDS) has been used to characterize in-vivo glycemic index (GI) due to a positive correlation between the two [23] [37] . Slowly digestible starch (SDS) has been proposed to exhibit many health benefits such as a slow in- crease of postprandial blood glucose, good stability and sustainability of blood glucose level, mild hormonal responses and desirable satiety and diabetes management [38] [39] . Previous studies made efforts to lower gly- cemic potential through re-formulation such asprotein fortification [4] and chemical modification of starch to increase the amount of resistant starch (RS) and slowly digestible starch (SDS) in native starch [26] [39] .

As the results presented in Table 1, across all types of rice, a significant decrease of rapidly digestible starch (RDS) was observed when decreasing SME gradually through the control of feed moisture content. In contrast, the amount of slowly digestible starch (SDS) increased with decreasing SME. This was attributed partially to the decreased degree of gelatinization as less SME was applied during the extrusion processes. Figure 2 illustrates the correlation between DG% and RDS or SDS as well as SME and RDS or SDS. The coefficient of determina- tion values (R2) for SME vs. RDS and SDS (Figures 2(d)-(f)) were greater than those for DG% vs. RDS and SDS (Figures 2(a)-(c)). These results suggested that RDS and SDS may be better correlated to SME than DG%. In previous studies, only DG% has been correlated to in-vitro glycemic index (GI) because of the difficulty of quantifying starch dextrinization [8] . However, the results shown in Figure 2 indicate that DG% may not be a proper indicator to predict in-vitro GI because the effect of dextrinization is also indispensable in an extrusion process. Dextrinization is a fragmentation of starch molecules caused by physical shearing. During extrusion, the degree of dextrinization was observed to be positively correlated to shear-speed and negatively correlated to feed moisture content [2] . The relationship of increased SME during an extrusion process and decreased average molecular weight in the extrudate has been reported [40] . Starch molecules with less molecular weight and shorter chain length were proved to be more susceptible to enzymatic digestion [2] [12] . Therefore SME, as a parameter to include the combined effect of both gelatinization and dextrinization, is preferred than DG% to predict the digestive properties of starch-based extruded foods. The total amount of digestible starch (RDS + SDS) does not change with SME or DG% at p = 0.05.

Comparing medium grain brown rice (BR), medium grain sushi rice (SR) and long grain jasmine rice (JR), there were no significant differences regarding RDS and SDS although they are different in composition. JR contains 15% amylose [41] , which is slightly higher than medium grain BR (13.8%) and medium grain SR (14.2%) [42] . BR contains higher fat, protein and fiber content than SR [31] . However, in this study, JR and SR exhibited similar RDS and SDS, because their differences in composition may not be significant enough, espe- cially for the amylose to amylopectin ratio when comparing to other starch sources such as waxy rice. Brown rice has been considered as low GI rice because it contains higher fat, protein and fiber content than white rice. Those components could help to form a protective structure to inhibit starch granules from diffusion by hydro- lytic enzymes [39] [43] . However, extrusion is an extreme process with high temperature and extensive shearing, which does not allow the formation protective structures. Therefore, extruded brown rice exhibited similar in- vitro glycemic behavior compared to white rice such as SR.

3.4. Physical Properties

Data in Table 1 show that physical properties change significantly with feed moisture content and specific me- chanical energy (SME). The equations and R2 values using linear regressions between SME and physical

![]()

Figure 2. Rapidly digestible starch (RDS) and slowly digestible starch (SDS) as a function of degree of gelatinization (DG%) and specific mechanical energy (SME) for medium grain brown rice (BR), medium grain sushi rice (SR) and long grain jas- mine rice (JR). (a) BR: RDS, SDS vs. DG%; (b) SR: RDS, SDS vs. DG%; (c) JR: RDS, SDS vs. DG%; (d) BR: RDS, SDS vs. SME; (e) SR: RDS, SDS vs. SME; (f) JR: RDS, SDS vs. SME.

properties are shown in Table 2. Expansion ratio is positively correlated to SME while fracture energy and bulk density are negatively correlated. The results are consistent to a previous study [16] . Overall, the physical prop- erties of the rice products produced using this single-variable extrusion process were explained by SME alone. Onwulata et al. (1994) proposed that bulk density of extruded corn meal can be characterized adequately by SME in a twin-screw extrusion process. However, only three data points has been used to build the Equation between specific volume (bulk density) and SME [3] . In this study, more physical properties of extrudates were analyzed and more data points (six) were measured to improve the accuracy of regression equations.

4. Conclusion

In an extrusion process without additional thermal energy input, SME as a system parameter could work as a good indicator of many properties of extrudates such as physical and digestive properties. Medium grain brown rice (BR), medium grain shush rice (SR) and long grain jasmine rice (JR) were used as raw material to study the relationship between SME and properties of extrudates. Reducing SME input during extrusion was found to sig- nificantly reduce the amount of rapidly digestible starch (RDS) in the products, and increase the amount of slowly digestible starch (SDS). The physical properties including fracture energy, expansion ratio and bulk density

![]()

Table 2. Fitted Equations using SME and R2 statistics for physical properties.

*X = SME (kJ/kg); FE = fracture energy (mJ/g); ER = expansion ratio; BD = bulk density (g/cm3).

could be characterized by SME. Further study could be conducted by incorporating more processing variables such as screw speed and residence time.

Acknowledgements

The authors acknowledge the support from Dr. Juan Andrade and Mr. Brian Jacobson.