Received 29 February 2016; accepted 9 May 2016; published 12 May 2016

1. Introduction

Biomass contains stored energy which is a versatile fuel for energy and power generation in many countries [1] [2] . Wood remains the largest biomass energy source today and several different kinds of biomass, such as wood chips, corn, and some types of garbage, are used to produce electricity. The biomass is converted into liquid fuels called biofuels that can power cars, trucks, and tractors. Leftover food products like vegetable oils and animal fats can create biodiesel, while corn, sugarcane, and other plants can be fermented to produce ethanol. The combustion characteristics of trees in various parts of the world were reported [3] - [13] . The calorific value (CV) of the biomass depends on several physiological and climatic factors. However, the bio-power has environmental risks and may damage ecosystems, produce harmful air pollution, consume large amounts of water, and produce net global warming emissions [14] . In this work, the combustion characteristic of 53 topical trees (i.e. Amla, Amaltas, Asoka, Bachain, Badam, Bael, Bamboo, Babool, Bahera, Ber, Bija, Chhatim, Chironji, Dhawda, Dumar, Gandherwa, Goriar, Guava, Gulmohar, Harra, Haldu, Imli, Jamun, Jungle jalebi, Kadambh, Kahuaa, Karanj, Karra, Kasahi, Khamar, Kumahi, Kusum, Mahua, Mango, Menda, Mithineem, Munga, Neem, Nilgiri, Palas, Ramphal, Sagwan, Saja, Sal, Salai, Samel, Seetaphal, Shisham, Siris, Shoe babool, Sonpatti, Tendu and Unjain) grown in Raipur area, CG, India is described in order for sustainable renewal energy demand of the country. Among them, the most energetic Bahera tree is described in the details.

2. Materials and Methods

2.1. Collection of Tree Sample

The Chhattisgarh state, central India is situated in Deccan bio-geographical area with rich in unique biological diversity. The forest of the State is extended over » 5.5 × 104 km2 area. At least 1500 plants exist in this area. The tree species were identified by using physico-genetic characteristics prescribed in the literatures [15] [16] . The wood of 53 trees grown in Raipur area, capital, Chhattisgarh state, India (21˚15'0"N, 81˚37'48"E) were collected manually in December, 2015 randomly. The different tree parts of the most energetic Bahera tree were collected for determining calorific value. They were dried in oven at 50˚C for one day. All wood samples were crushed and sieved out particles of size ≤ 0.25 mm.

2.2. Determination of Bulk Density, Moisture, Calorific Value and Ash Residue

The bulk density (BD) of the biomass affect significantly the heat value. The BD of the biomass was measured by the water replacement method [17] . A 50 mL pure water was taken into a 100-mL graduated cylinder. A 10 g of the sample was poured in the cylinder by noting the volume enhancement. The mass of the displaced water was calculated by multiply with water density at the particular working temperature.

The moisture content of the tree samples was analyzed by heating it at 105˚C ± 2˚C for a period of 60 min. The ash content of the materials was determined by heating the sample at 600˚C for 4 hr [18] .

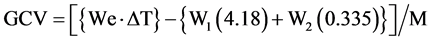

The calorific value was determined experimentally using a Digital Microprocessor Based Bomb CalorimeterUTS 1.34, Advance Research Instruments Co, New Delhi as described in the literature. A 1.0 g of wood sample was weighed and placed in the combustion capsule. The sample was then lowered in the wire bomb head while the bomb head was on its support. A 10 cm long fuse wire was firmly fixed to the electrodes to facilitate complete combustion by adding 1 mL of water to the bomb cylinder and moistening the sealing ring of the bomb head. The bomb was carefully lowered into the cylinder with tightly closing the sealing ring. The oxygen gas was flowed into the combustion cylinder. The bomb cylinder was then lowered into the calorimeter bucket. The calorimeter cover was carefully placed and the thermometer bucket lowered. The power was then switched on to start the auto temperature adjustment and the stirring motor. The initial temperature was recorded after equilibrium attained i.e. after 5 min. The bomb was then fired using the ignition switch. The bucket temperature i.e. final temperature was recorded after stabilization i.e. after 5 min. The difference between the original length and the new length was multiplied by 0.335 to obtain the number of calories liberated by combustion of the fuse (fuse wire correction). For every sample, calorific value in kcal/kg was calculated using the following equation [19] :

where, GCV, M, We, W1, W2 and ∆T represent gross calorific value of species (kcal/kg), weight of sample, water equivalent, weight of cotton thread, weight of fuse wire and rise in temperature, respectively.

The content of volatile compounds including moisture was analyzed by using a Mettler Thermogravimetric Analyzer-TG-DGA-2 at heating rate of 20˚C/min.

2.3. Emission Fluxes of Particulate Matters

The flux of PM10 was determined by burning the Bahera sample in a closed chamber (0.5 × 0.5 × 0.5 m3) equipped with the exhaust fan and UC Davis (USA) portable air sampler in December, 2015. The PM10 emitted in a closed chamber was collected over the weighted 47-mm quartz filter. The PM10 mass was weighted out, and the flux was evaluated by dividing the PM10 mass with amount of the material burnt.

2.4. Segregation of Particulate Matters

The Anderson sampler (1531-107B-G289X) with eight stage cartridge: PM10.0 - 9.0, PM9.0 - 5.8, PM5.8 - 4.7, PM4.7 - 3.3, PM3.3 - 2.1, PM2.1 - 1.1, PM1.1 - 0.7 and PM0.7 was used for the collection of respirable particulate matters (PM10) in the segregation modes. The sampler was run for 2 hr during burning of Bahera tree sample in December, 2015. The mass of dried loaded and blank filters were weighted out.

2.5. Analysis

The pH value of ash extract was determined by the Hanna pH meter. The Dionex ion chromatography-1100 was used for monitoring of anions and cations. The content of elemental carbon (EC) and organic carbon (OC) were determined by the thermal method.

The IBM SPSS Statistics 23 was used for the statistical and cluster analysis in the present work [20] .

3. Results and Discussion

The combustion of biomass produces energy with emission of volatile materials and particulate matters by remaining left ash residue. The parameters i.e. bulk density (BD), moisture content (MC), volatile organic matter (VOCs), particulate matter (PM) and ash residue (AR) were measured.

3.1. Combustion Characteristics

The parameters i.e. color of wood dust, BD, MC and AR of 53 wood dusts is summarized in Table 1. The wood dust color was found to be of various different color as shown in Table 1. The BD is important parameter in the energy generation, as well as in pulp production where it influences the inflow of wood to a digester or to a refine. The value of BD of 53 wood dusts was ranged from 700 - 2500 kg/m3 with mean value (p = 0.05) of 1103 ± 82 kg/m3. The highest BD of Kahua tree was observed as shown in Figure 1. The MC value of 53 wood dusts were ranged from 2.7% - 6.7% with mean value (p = 0.05) of 4.9% ± 0.3% as shown in Figure 2.

The calorific value (CV) of 53 tree samples was varied from 5193 - 8133 kcal/kg with mean value (p = 0.05) of 6383 ± 170 kcal/kg as shown in Table 1. The Skew and Ku value of the data was found to be 0.50 and 0.29, respectively. The positive skewness and kurtosis value indicated that data were found to skew right with moderate tailed distribution. The CV was found to be fairly positively and negatively correlated with the BD (r = 0.55) and MC (r = −0.72) of the wood dust as shown in Figure 3. The CV value of tree woods of the present studied was found to be comparable to the heat value reported for trees of other regions of the country and the World [3] - [13] .

The cluster analysis was carried out for grouping of CV of tree samples by using the BD, MC and AR as discriminating factor [20] . They were grouped into two clusters, Figure 4. The Cluster-I included 36 tree samples having lower CV. The Cluster-II was composed of 18 tree samples of Bahera, Ramphal, Ber, Tendu, Kusum, Mendra, Imli, Jamun, Palas, Seetaphal, Gandherwa, Mithineem, Neem, Bachain, Bija, Khamar, Kahua and Chhatim, having higher CV. The highest CV of Bahera wood dust was detected, may be due to higher content of the fixed carbon. Seven common trees i.e. Bahera, Ber, Imli, Kusum, Mendra, Ramphal and Tendu imparted the CV above 7000 kcal/kg as shown in Figure 6(a).

Bahera is a large deciduous tree found throughout India. The tree height was up to 30 m, while the bark is brownish grey in color with leaves of » 15 cm long and crowded toward the ends of the branches as shown in Figure 5. It contains β-sitosterol, gallic acid, ellagic acid, ethyl gallate, galloyl glucose and chebulagic acid, which render its therapeutic properties. The CV for different parts of the Baheratree was found to be comparable as shown in Figure 6(b).

The TG-DGA chromatogram scanned for the Bahera wood sample is shown in Figures 7. The pyrolytic decomposition of Bahera tree sample was occurred in four stages. In the first stage, a 7.4% weight loss over temperature range 50˚C - 100˚C was seen, may be due evaporation of light volatile compounds including water. In second stage, a 1.9% weight loss over temperature range 100˚C - 200˚C was marked, may be due evaporation of higher volatile compounds. In the third stage, a remarkable high weight loss of 58.7% over temperature range of 200˚C - 400˚C was observed, may be due to decomposition of hemicellulose and cellulose materials. In the last stage, the large decomposition of lignin and non-volatile compounds (fixed carbon) over temperature range of 400˚C - 1000˚C was observed.

3.2. Particulate Matters

The PM10 emission fluxes for Bahera tree (n = 3) during burning period was found to be 2310 ± 180 mg/kg. The

![]()

![]()

Table 1. Physical and combustion characteristics of wood

Br = Brown, PW = Pale white, W = White, Rd = Reddish, DY = Dark yellow, CrW = Cream white, DBr = Dark brown, Gr = Greenish, LGr = Light green, Br = Brown, Yellowish white = YW.

PM10 was segregated into 8 modes i.e. PM10.0 - 9.0, PM9.0 - 5.8, PM5.8 - 4.7, PM4.7 - 3.3, PM3.3 - 2.1, PM2.1 - 1.1, PM1.1 - 0.7 and PM0.7 - 0.0 modes to know their distribution pattern. The highest fraction of the PM was found in the ultra fine mode as shown in Figure 8. The fraction of EC and OC in the PM10 was found to be 13 ± 2 and 64% ± 3%, respectively. Among ions, the highest content of Cl− followed by Ca was marked in the PM10 as presented in Figure 9. The large fraction of the PM was composed of the OC.

3.3. Ash Residue

The AR of woods influenced negatively (r = −0.55) the heat value as shown in Figure 3. The fraction of AR of 53 wood dusts was ranged from 7.1% - 16% with mean value (p = 0.05) of 11.5% ± 0.6% as shown in Figure 10. The pH value of the ash extracts (5.0 g ash residue was extracted with 25 mL of deionized water for 6 hr in ultrasonic bath) was found to be alkaline in nature, ranging from 7.1 - 16.0 with mean value (p = 0.05) of 11.5 ± 0.6. The fraction (n = 3) of EC, OC, Cl−,  , Na, K, Mg and Ca of Bahera wood ash was found to be 7.6 ± 0.8, 0.7 ± 0.2, 6.4 ± 0.9, 5.2 ± 0.8, 1.8 ± 0.5, 6.3 ± 1.4, 2.2 ± 0.2 and 12.7% ± 1.3%, respectively.

, Na, K, Mg and Ca of Bahera wood ash was found to be 7.6 ± 0.8, 0.7 ± 0.2, 6.4 ± 0.9, 5.2 ± 0.8, 1.8 ± 0.5, 6.3 ± 1.4, 2.2 ± 0.2 and 12.7% ± 1.3%, respectively.

4. Conclusion

The fast growing trees of wild nature i.e. Ber, Bahera, Imili, Kusum, Menda, Ramphal and Tendu are found to exhibit the higher CV >7000 kcal/kg, may be due to their higher biomass productions and containing higher combustible carbons. Among 53 trees tested, the Bahera tree was observed to be the most energetic biomass in the present investigation. Five trees namely: Dhawda, Kauha, Bahera, Harra and Saja included in Combretaceae family are seemed to be energetic biomass to use as solid fuel instead of coal in the near future.

![]()

Figure 2. Moisture content of wood samples.

![]()

![]()

![]()

Figure 3. Correlation matrices of CV with bulk density (a), moisture (b) and ash residue (c).

![]()

Figure 4. Dendrogram of calorific value of 53 wood samples.

![]()

Figure 5. Bahera tree grown in University area, Raipur.

![]()

![]()

Figure 6. Calorific value of energetic trees and different parts of Bahera tree.

![]()

Figure 7. TG-DGA chromogram of Bahera wood dust.

![]()

Figure 8. Segregation of PM10 of Bahera tree sample during combustion period.

![]()

Figure 9. Fraction of ions in PM10 of the Bahera wood.

![]()

Figure 10. Ash residue fraction in wood samples.

Acknowledgements

We are thankful to our University for grating special equipment grant to the Environmental Science Department.

NOTES

![]()

*Corresponding author.