World Journal of Mechanics

Vol. 1 No. 3 (2011) , Article ID: 5776 , 5 pages DOI:10.4236/wjm.2011.13017

Definition of Increasing the Fibre Capturing Surface of Saw Teeth of Cotton Ginning Machine through Mathematic Modelling

Department of Mechanical Engineering, Namangan Engineering and Economics Institute, Namangan, Uzbekistan

E-mail: sokrat.uz@mail.ru

Received April 5, 2011; revised May 5, 2011; accepted May 16, 2011

Keywords: Factor of Proportionality, Radius of a Saw, Fibre, Gin, Teeth, Linear Speed, New Profile

ABSTRACT

Theoretical and the experimental researches executed in Uzbekistan and abroad explored some ways of a substantiation of a rational profile of a tooth of a saw and its fibre capturing ability. Despite that, untill now, optimum parameters of a saw gin which provides high quality ginning without harming the quality of cotton fibre have not been found. Considering the stated above in the given job the influence of the changed form of saw teeth on fibre-capturing area is examined. The analytical formulas for the additional area promoting to double the fibre capture quantity by saw teeth are received.

1. Introduction

It is known, that productivity of saw gin depends on the structure of teeth or on other parameters of saw gin. On defined selection of saw teeth’s profile or other parameters, it is possible to achieve the maximum capture of fibre. It promotes the increase of the productivity of a saw gin. Theoretical experimental researches in Tashkent textile institute noted some ways of substantiating the rational profile of saw teeth and its fibre capturing capacity.

On Figure 1 the circuit of meeting saw teeth with cotton roll in the zone of seed combing developed by G.I. Boldinskiy is given. A centrifugal force influences on fibre seized by saw teeth trying and forces the fibre to escape from the teeth. At the same time another force— friction force influences on fibre which helps to hold the fibre at front lines of the saw teeth.

Defining the corner, at which the fibre is held on saw teeth, by ψ, we can write following formula:

(1)

(1)

Where —a front corner of a tooth

—a front corner of a tooth —corner between a radial surface of a saw and surface of shift of a fibre.

—corner between a radial surface of a saw and surface of shift of a fibre.

For defining the corner , an equation is developed on the movement of the element of fibre, descending from a tooth of a saw, in relation to mobile axes OXY:

, an equation is developed on the movement of the element of fibre, descending from a tooth of a saw, in relation to mobile axes OXY:

(2)

(2)

Here m—Weight of descending element of a fibre;

c—Coefficient of proportionality;

υ—Speed of saw teeth;

R—Radius of a saw;

μ—Coefficient of internal friction of a fibre;

N—Reaction;

ek—Koriolisovo speed-up;

t—Step of teeth;

After this

(3)

(3)

Or

2. Materials and Methods

This Table 1 shows the values of parameters in Figure 1.

This Table 2 shows the values of parameters in Figure 2.

Or

(4)

(4)

The capturing ability of a tooth is proportional to the area of a triangle ABC1 which fibre does not leave

(5)

(5)

—The area of a triangle with—applicable indexes;

—The area of a triangle with—applicable indexes;

(6)

(6)

(7)

(7)

Here

γ1—Corner between vectors of relative speed and tangent to a circle;

and tangent to a circle;

(8)

(8)

—Linear speed of cotton roll in its meeting point with saw;

—Linear speed of cotton roll in its meeting point with saw;

—Corner between the radius of a saw and vector of speed.

—Corner between the radius of a saw and vector of speed.

By placing the received figures by formula (6) and (7) on formula (5) we can find the area of capturing surface of saw teeth.

(9)

(9)

To increase the area of capturing surface of saw we offer a new changed profile of saw of saw cylinder. This work examines the influence of the changed form of tooth of saw cylinder on the area of fibre capturing surface (Figure 2).

The profile of a tooth resembles an arch, on which the corner of tooth’s tip will be about 250 - 300.

Vв—Speed of a particle of cotton roll at the moment of its meeting with saw tooth;

V—Linear speed of the end of a saw tooth;

θ—The central corner of an arch ВВ1;

ξ—Corner between a tangent carried out arc and straight line shoulder of teeth structure;

β1—Corner between the radius of saw and direction of movement of light fibre approaching saws;

φ—Corner of friction of fibre on fibre;

γ—Front corner of tooth.

The tooth of a saw will seize a fibre which is kept in a triangle AВС1, and also in an additional triangle АВВ1 and a segment described by arch ВВ1. The area of the triangle  is determined by well-known formula:

is determined by well-known formula:

(10)

(10)

As we see, fibre capturing ability of saw teeth is determined by the areas of triangles AВС1 and АВВ1, and also the segment ВВ1. Last two areas are additional to the basic area of a triangle AВС1.

The area of a triangle АВВ1 is determined as follows:

From a triangle ΔВВ1С under the theorem of sine we can define СВ1:

then

then

(11)

(11)

The additional area of a triangle АВВ1:

(12)

(12)

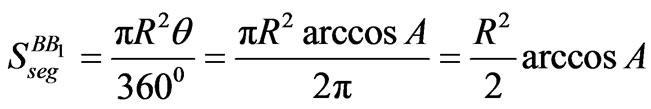

Now we pass to definition of the area of a segment ВВ1, chord which is determined under the formula:

(13)

(13)

The central corner of a segment

where:

(14)

(14)

Then the area of a segment:

(15)

(15)

Thus, the additional areas promoting the increase of fibre capture by saw tooth is determined by the formula:

(16)

(16)

From the formula (16), it can be seen that the area Sdop mainly depends on corners γ, γ1 and ξ.

At the appropriate selection of these corners, the optimum additional area of fibre capture by saw teeth is achieved.

3. Numerical Results and Discussion

Figure 3 shows changes of the central corner θ arches ВВ1, in dependence of a corner ξ between a tangent of the spent bow-shaped and direct back of a profile of teeths. The red line on a schedule figure means changes θ = θ (ξ) at R = 20 cm. The yellow line on a figure shows changes θ = θ (ξ) at R = 10 cm. We take corner radius from the given schedule R = 10 cm because at this value the tooth height will be equal h =4mm and a tooth step t = 4mm. At these data the most optimum value is θ = 250 - 300 at ξ = 140. If we accept optimum value θ = 250 - 300 and ξ = 140 and radius R = 20 cm that leads to increase of a step and tooth heights. It leads to seed jamming in a backlash between teeth. As a result it will lead to intensive crash of seeds between tooth of a saw and a grid-iron saw gin. From this follows that the central corner θ arches ВВ1 should be in θ = 250 - 300 limits and not exceed these values. Change of the additional area of a segment depending on a corner ξ pi various radiuses of curvature of a new profile of teeth. Optimum value of the area of a segment is Sseg = 0.01 cm2 which corresponds R = 10 cm, ξ = 140.

In Figure 3 when the maximum value of ξ eqauals to 140 and when the maximum value of θ equals to 300, the

level of teeth capturing fiber reaches its maximum degree.

In Figure 4, the area of Sseg (S1) has been determined at different radiuses according to the value of ξ.

In Figure 5, the area of  (S2) triangle has been found at different radiuses according to the value of ξ.

(S2) triangle has been found at different radiuses according to the value of ξ.

In Figure 6, in order to find Sdop(S3), we have added the area of Sseg (S1) to the area of  (S2) triangle.

(S2) triangle.

Since we know the area of  (S4) triangle, we have added the area of S4 to the area of S3 and as a result, we have determined the area of capturing fiber of new profiled teeth based on the mathematic modeling and graphics (Figure 7). There are 100 micron fibers in the area of

(S4) triangle, we have added the area of S4 to the area of S3 and as a result, we have determined the area of capturing fiber of new profiled teeth based on the mathematic modeling and graphics (Figure 7). There are 100 micron fibers in the area of . Using the new teeth profile, we can increase the amount of fiber.

. Using the new teeth profile, we can increase the amount of fiber.

4. Conclusion

Theoretical and the experimental researches executed at

Tashkent Textile institute by B. A. Levkovich, N. G. Gulidov, G. I. Boldinskiy and G. I. Miroshnechenko and analytical formulas (10) for definition of the area of capture of a fibre by saw tooth are offered. Values of area  calculated under the standard data of saw gin equal

calculated under the standard data of saw gin equal  = 0.031 cm2 which contains 100 mkr fibres. If to consider a new profile of a tooth of saw gin offered by us it will increase the useful area of capture of fibre. At the expense of a bow-shaped profile of a tooth it will generate the additional areas in the form of triangle

= 0.031 cm2 which contains 100 mkr fibres. If to consider a new profile of a tooth of saw gin offered by us it will increase the useful area of capture of fibre. At the expense of a bow-shaped profile of a tooth it will generate the additional areas in the form of triangle  and segment Sseg. On Figure 3 optimal values of the central corner of an arch θ = 40 and value of a corner between a tangent of the spent bow-shaped and direct back of teeth ξ = 140 are identified. Within this data the areas of additional triangle

and segment Sseg. On Figure 3 optimal values of the central corner of an arch θ = 40 and value of a corner between a tangent of the spent bow-shaped and direct back of teeth ξ = 140 are identified. Within this data the areas of additional triangle  = 1.2 mm2 and segment Sseg = 1 mm2 are calculated and as a result an additional area is received:

= 1.2 mm2 and segment Sseg = 1 mm2 are calculated and as a result an additional area is received:

.

.

The given figures in Table 2 show that the area of fibre capturing surface of saw tooth widened two times. The highest figure of the area of the surface is achieved at R = 10. Proportionally, at R = 20 the area of segment decreases and fibre capturing capacity also decreases.

Through this additional area, 200 - 250 mkr of fibre is achieved. Thus the offered new profile of a tooth of a saw gin will increase fibre capture 2 - 3 times.

The values have been checked and prepared in Maple 9.5. Drawings have been prepared and projected through T-Flex CAD programm using the calculated values.

Stemming from these facts, it can be concluded that the application of the offered new design of a saw on cotton processing industry will increase the productivity of ginnng, and also will bring to saving of power resources.

REFERENCES

- G. I .Miroshnechenko, “Bases of Designing of Machines of Primary Processing of Cotton,” Moscow, 1972.

- V. I. Roganov et al., “Primary Processing of Cotton,” Moscow, 1965.

- Sh. M. Azizov and A. I. Karimov, “The Analysis of the Influence of the Clearance between Saw on Length Filament,” Journal of the Problem Mechanical Engineers, 2004.

- Sh. M. Azizov and A. I. Karimov, “Defining the Interaction of Cotton with Hilly Ginning Kolosnic,” Journal of the Problem Mechanical Engineers, Vol. 3, 2005.

- J. Ergashev and A. I. Karimov, “The Analysis of Working Parts Cotton Gin,” Journal of the Problem Mechanical Engineers, Vol. 1, 2004.

- T-Flex CAD Engineering Programm.

- Maple 9.5. Mathematical Programm.