Paper Menu >>

Journal Menu >>

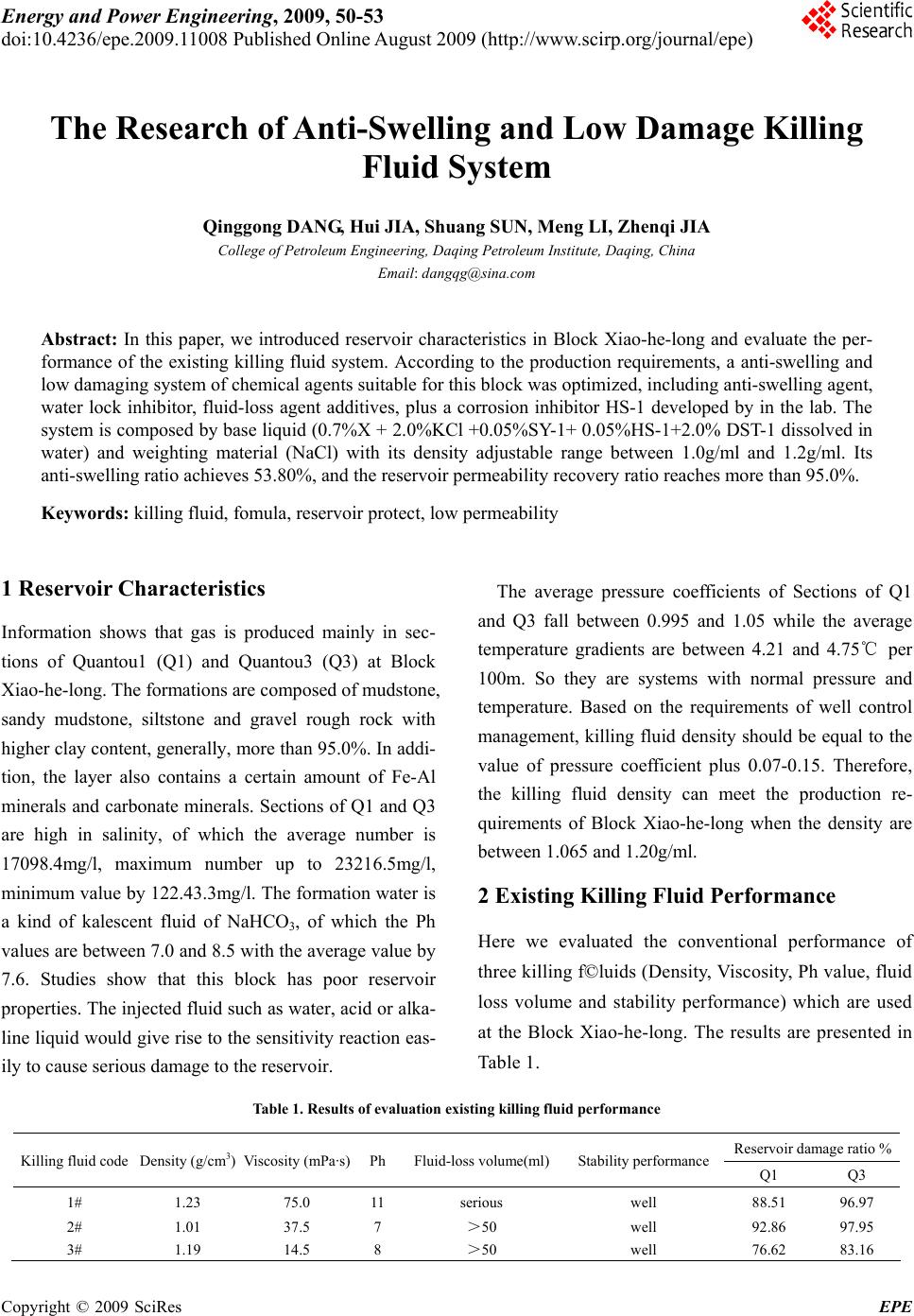

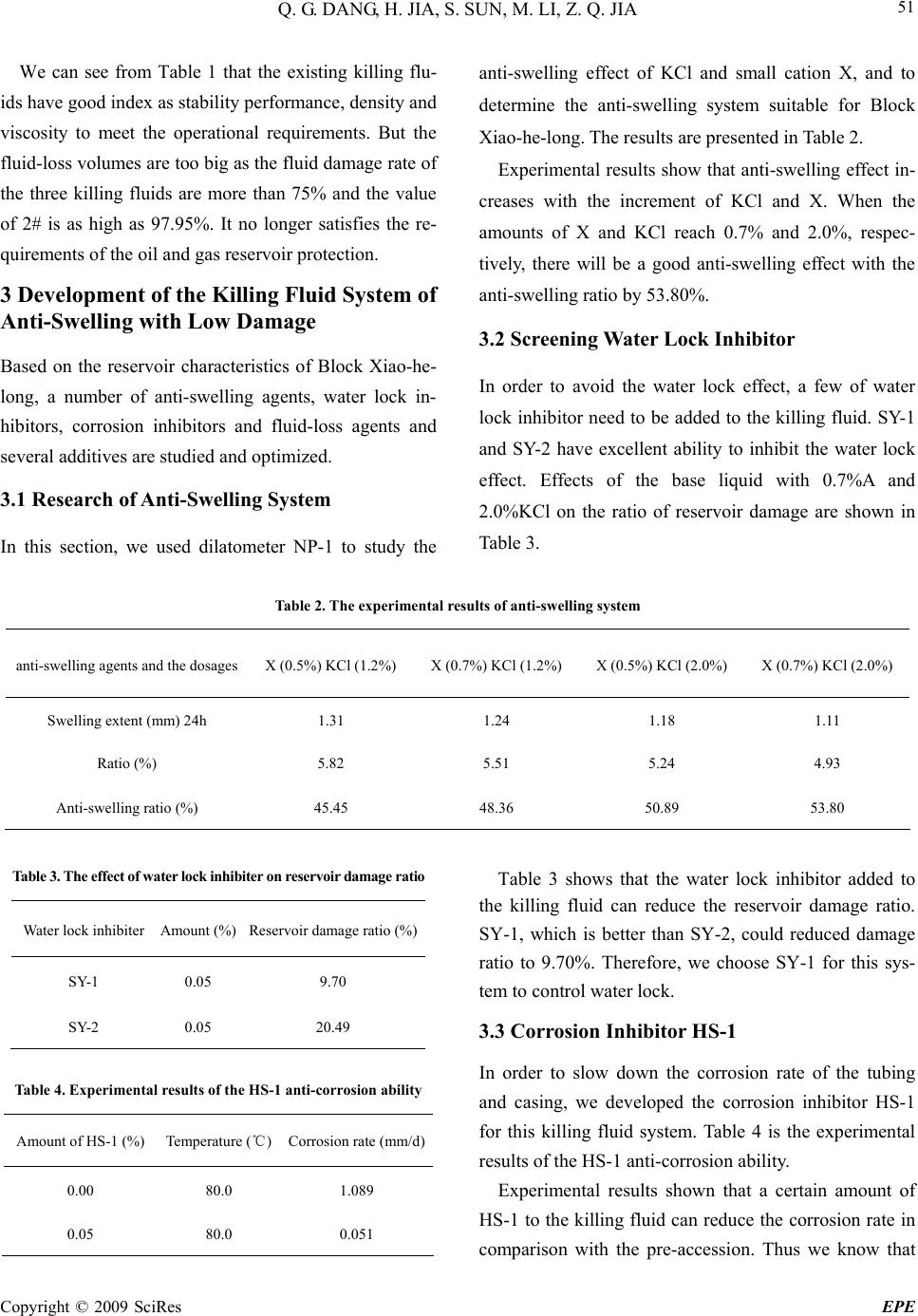

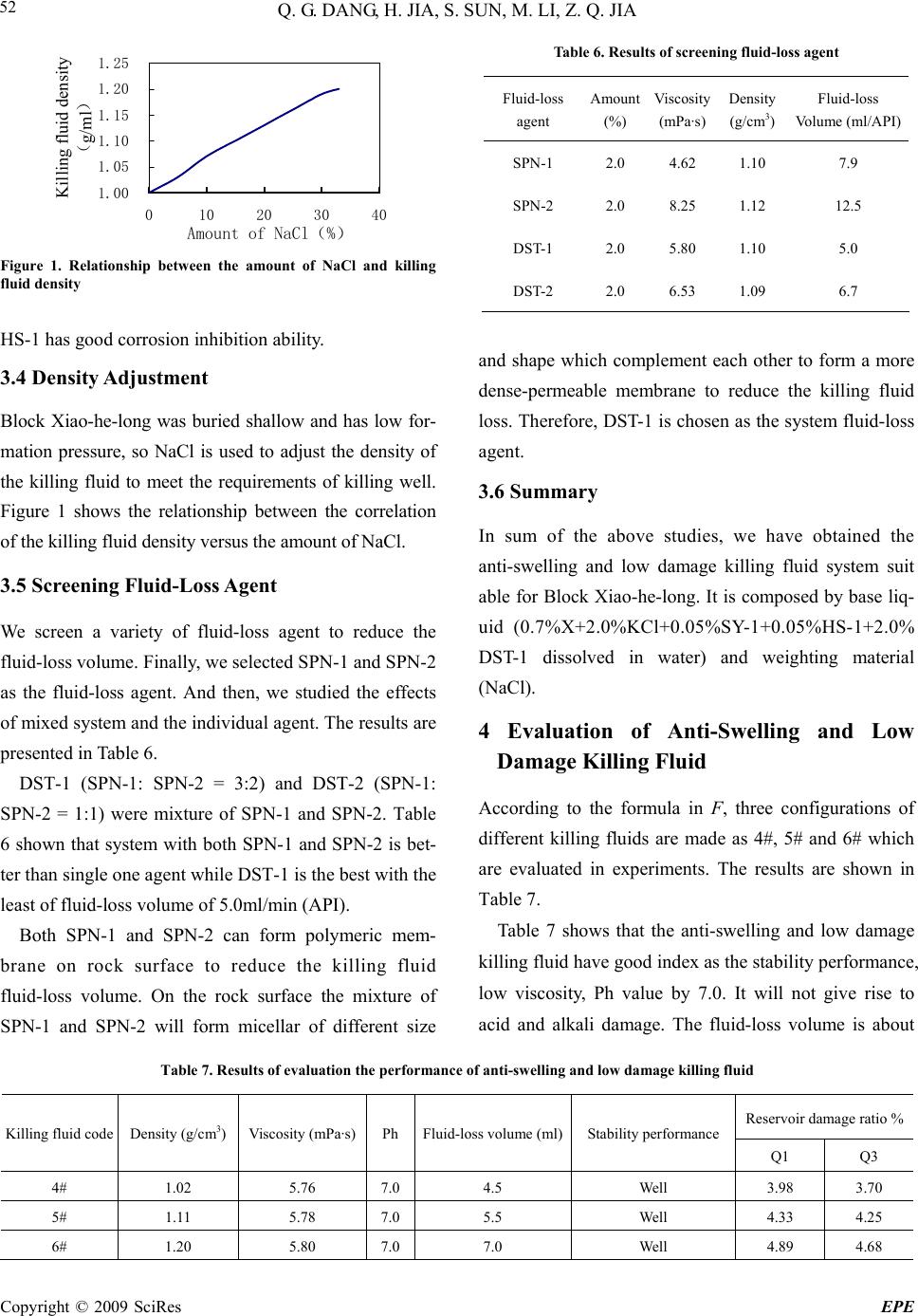

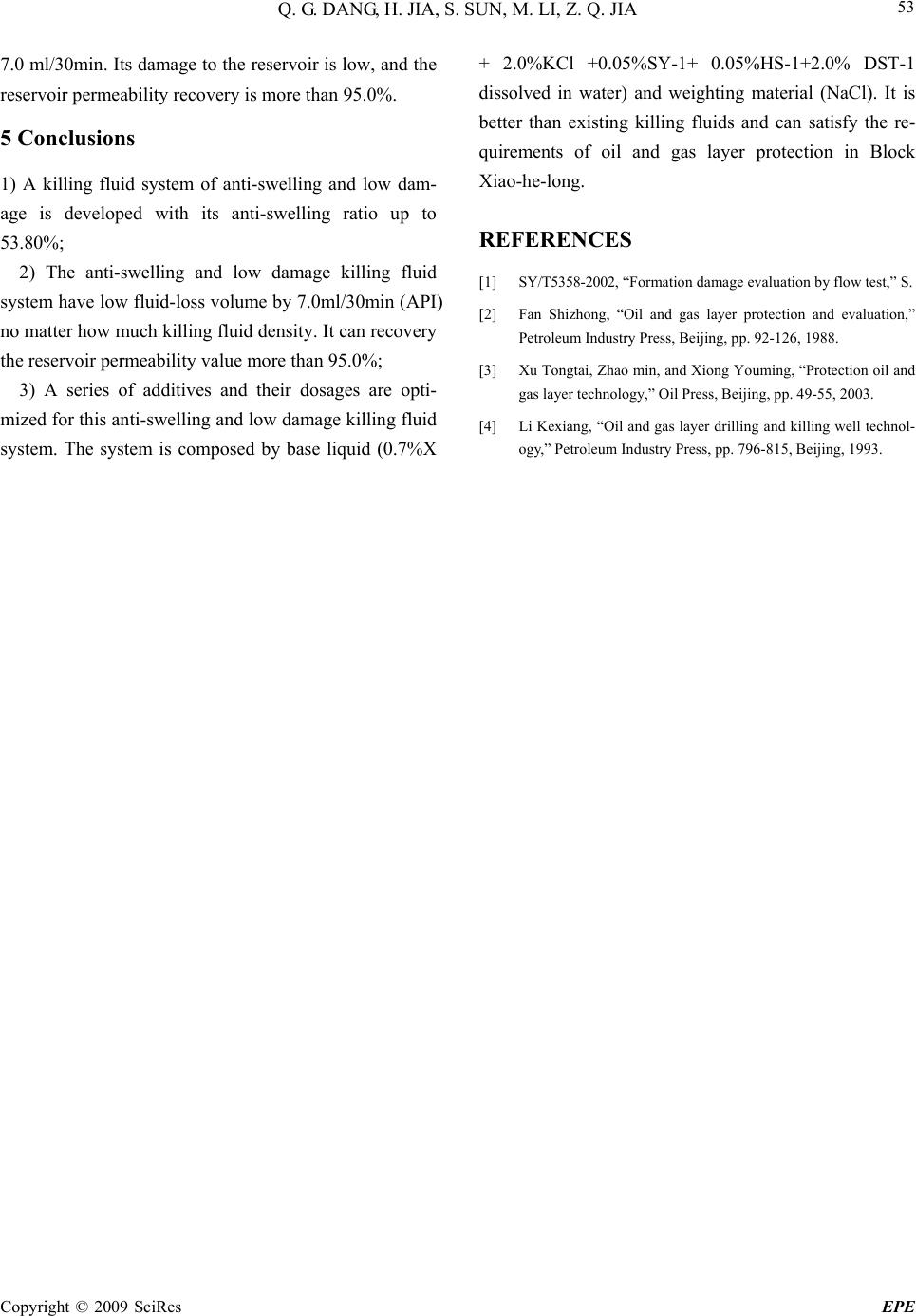

Energy and Power Engineering, 2009, 50-53 doi:10.4236/epe.2009.11008 Published Online August 2009 (http://www.scirp.org/journal/epe) Copyright © 2009 SciRes EPE The Research of Anti-Swelling and Low Damage Killing Fluid System Qinggong DANG, Hui JIA, Shuang SUN, Meng LI, Zhenqi JIA College of Petroleum Engineering, Daqing Petroleum Institute, Daqing, China Email: dangqg@sina.com Abstract: In this paper, we introduced reservoir characteristics in Block Xiao-he-long and evaluate the per- formance of the existing killing fluid system. According to the production requirements, a anti-swelling and low damaging system of chemical agents suitable for this block was optimized, including anti-swelling agent, water lock inhibitor, fluid-loss agent additives, plus a corrosion inhibitor HS-1 developed by in the lab. The system is composed by base liquid (0.7%X + 2.0%KCl +0.05%SY-1+ 0.05%HS-1+2.0% DST-1 dissolved in water) and weighting material (NaCl) with its density adjustable range between 1.0g/ml and 1.2g/ml. Its anti-swelling ratio achieves 53.80%, and the reservoir permeability recovery ratio reaches more than 95.0%. Keywords: killing fluid, fomula, reservoir protect, low permeability 1 Reservoir Characteristics Information shows that gas is produced mainly in sec- tions of Quantou1 (Q1) and Quantou3 (Q3) at Block Xiao-he-long. The formations are composed of mudstone, sandy mudstone, siltstone and gravel rough rock with higher clay content, generally, more than 95.0%. In addi- tion, the layer also contains a certain amount of Fe-Al minerals and carbonate minerals. Sections of Q1 and Q3 are high in salinity, of which the average number is 17098.4mg/l, maximum number up to 23216.5mg/l, minimum value by 122.43.3mg/l. The formation water is a kind of kalescent fluid of NaHCO3, of which the Ph values are between 7.0 and 8.5 with the average value by 7.6. Studies show that this block has poor reservoir properties. The injected fluid such as water, acid or alka- line liquid would give rise to the sensitivity reaction eas- ily to cause serious damage to the reservoir. The average pressure coefficients of Sections of Q1 and Q3 fall between 0.995 and 1.05 while the average temperature gradients are between 4.21 and 4.75℃ per 100m. So they are systems with normal pressure and temperature. Based on the requirements of well control management, killing fluid density should be equal to the value of pressure coefficient plus 0.07-0.15. Therefore, the killing fluid density can meet the production re- quirements of Block Xiao-he-long when the density are between 1.065 and 1.20g/ml. 2 Existing Killing Fluid Performance Here we evaluated the conventional performance of three killing f©luids (Density, Viscosity, Ph value, fluid loss volume and stability performance) which are used at the Block Xiao-he-long. The results are presented in Table 1. Table 1. Results of evaluation existing killing fluid performance Reservoir damage ratio % Killing fluid code Density (g/cm3)Viscosity (mPa·s) PhFluid-loss volume(ml)Stability performance Q1 Q3 1# 1.23 75.0 11 serious well 88.51 96.97 2# 1.01 37.5 7 >50 well 92.86 97.95 3# 1.19 14.5 8 >50 well 76.62 83.16  Q. G. DANG, H. JIA, S. SUN, M. LI, Z. Q. JIA Copyright © 2009 SciRes EPE 51 We can see from Table 1 that the existing killing flu- ids have good index as stability performance, density and viscosity to meet the operational requirements. But the fluid-loss volumes are too big as the fluid damage rate of the three killing fluids are more than 75% and the value of 2# is as high as 97.95%. It no longer satisfies the re- quirements of the oil and gas reservoir protection. 3 Development of the Killing Fluid System of Anti-Swelling with Low Damage Based on the reservoir characteristics of Block Xiao-he- long, a number of anti-swelling agents, water lock in- hibitors, corrosion inhibitors and fluid-loss agents and several additives are studied and optimized. 3.1 Research of Anti-Swelling System In this section, we used dilatometer NP-1 to study the anti-swelling effect of KCl and small cation X, and to determine the anti-swelling system suitable for Block Xiao-he-long. The results are presented in Table 2. Experimental results show that anti-swelling effect in- creases with the increment of KCl and X. When the amounts of X and KCl reach 0.7% and 2.0%, respec- tively, there will be a good anti-swelling effect with the anti-swelling ratio by 53.80%. 3.2 Screening Water Lock Inhibitor In order to avoid the water lock effect, a few of water lock inhibitor need to be added to the killing fluid. SY-1 and SY-2 have excellent ability to inhibit the water lock effect. Effects of the base liquid with 0.7%A and 2.0%KCl on the ratio of reservoir damage are shown in Table 3. Table 2. The experimental results of anti-swelling system anti-swelling agents and the dosagesX (0.5%) KCl (1.2%) X (0.7%) KCl (1.2%) X (0.5%) KCl (2.0%) X (0.7%) KCl (2.0%) Swelling extent (mm) 24h 1.31 1.24 1.18 1.11 Ratio (%) 5.82 5.51 5.24 4.93 Anti-swelling ratio (%) 45.45 48.36 50.89 53.80 Table 3. The effect of water lock inhibiter on reservoir damage ratio Water lock inhibiter Amount (%)Reservoir damage ratio (%) SY-1 0.05 9.70 SY-2 0.05 20.49 Table 4. Experimental results of the HS-1 anti-corrosion ability Amount of HS-1 (%) Temperature (℃) Corrosion rate (mm/d) 0.00 80.0 1.089 0.05 80.0 0.051 Table 3 shows that the water lock inhibitor added to the killing fluid can reduce the reservoir damage ratio. SY-1, which is better than SY-2, could reduced damage ratio to 9.70%. Therefore, we choose SY-1 for this sys- tem to control water lock. 3.3 Corrosion Inhibitor HS-1 In order to slow down the corrosion rate of the tubing and casing, we developed the corrosion inhibitor HS-1 for this killing fluid system. Table 4 is the experimental results of the HS-1 anti-corrosion ability. Experimental results shown that a certain amount of HS-1 to the killing fluid can reduce the corrosion rate in comparison with the pre-accession. Thus we know that  Q. G. DANG, H. JIA, S. SUN, M. LI, Z. Q. JIA Copyright © 2009 SciRes EPE 52 1.00 1.05 1.10 1.15 1.20 1.25 0 1020304 Amount of NaCl(%) Killing fluid density (g/ml) 0 Figure 1. Relationship between the amount of NaCl and killing fluid density HS-1 has good corrosion inhibition ability. 3.4 Density Adjustment Block Xiao-he-long was buried shallow and has low for- mation pressure, so NaCl is used to adjust the density of the killing fluid to meet the requirements of killing well. Figure 1 shows the relationship between the correlation of the killing fluid density versus the amount of NaCl. 3.5 Screening Fluid-Loss Agent We screen a variety of fluid-loss agent to reduce the fluid-loss volume. Finally, we selected SPN-1 and SPN-2 as the fluid-loss agent. And then, we studied the effects of mixed system and the individual agent. The results are presented in Table 6. DST-1 (SPN-1: SPN-2 = 3:2) and DST-2 (SPN-1: SPN-2 = 1:1) were mixture of SPN-1 and SPN-2. Table 6 shown that system with both SPN-1 and SPN-2 is bet- ter than single one agent while DST-1 is the best with the least of fluid-loss volume of 5.0ml/min (API). Both SPN-1 and SPN-2 can form polymeric mem- brane on rock surface to reduce the killing fluid fluid-loss volume. On the rock surface the mixture of SPN-1 and SPN-2 will form micellar of different size Table 6. Results of screening fluid-loss agent Fluid-loss agent Amount (%) Viscosity (mPa·s) Density (g/cm3) Fluid-loss Volume (ml/API) SPN-1 2.0 4.62 1.10 7.9 SPN-2 2.0 8.25 1.12 12.5 DST-1 2.0 5.80 1.10 5.0 DST-2 2.0 6.53 1.09 6.7 and shape which complement each other to form a more dense-permeable membrane to reduce the killing fluid loss. Therefore, DST-1 is chosen as the system fluid-loss agent. 3.6 Summary In sum of the above studies, we have obtained the anti-swelling and low damage killing fluid system suit able for Block Xiao-he-long. It is composed by base liq- uid (0.7%X+2.0%KCl+0.05%SY-1+0.05%HS-1+2.0% DST-1 dissolved in water) and weighting material (NaCl). 4 Evaluation of Anti-Swelling and Low Damage Killing Fluid According to the formula in F, three configurations of different killing fluids are made as 4#, 5# and 6# which are evaluated in experiments. The results are shown in Table 7. Table 7 shows that the anti-swelling and low damage killing fluid have good index as the stability performance, low viscosity, Ph value by 7.0. It will not give rise to acid and alkali damage. The fluid-loss volume is about Table 7. Results of evaluation the performance of anti-swelling and low damage killing fluid Reservoir damage ratio % Killing fluid code Density (g/cm3)Viscosity (mPa·s) Ph Fluid-loss volume (ml)Stability performance Q1 Q3 4# 1.02 5.76 7.04.5 Well 3.98 3.70 5# 1.11 5.78 7.05.5 Well 4.33 4.25 6# 1.20 5.80 7.07.0 Well 4.89 4.68  Q. G. DANG, H. JIA, S. SUN, M. LI, Z. Q. JIA Copyright © 2009 SciRes EPE 53 7.0 ml/30min. Its damage to the reservoir is low, and the reservoir permeability recovery is more than 95.0%. 5 Conclusions 1) A killing fluid system of anti-swelling and low dam- age is developed with its anti-swelling ratio up to 53.80%; 2) The anti-swelling and low damage killing fluid system have low fluid-loss volume by 7.0ml/30min (API) no matter how much killing fluid density. It can recovery the reservoir permeability value more than 95.0%; 3) A series of additives and their dosages are opti- mized for this anti-swelling and low damage killing fluid system. The system is composed by base liquid (0.7%X + 2.0%KCl +0.05%SY-1+ 0.05%HS-1+2.0% DST-1 dissolved in water) and weighting material (NaCl). It is better than existing killing fluids and can satisfy the re- quirements of oil and gas layer protection in Block Xiao-he-long. REFERENCES [1] SY/T5358-2002, “Formation damage evaluation by flow test,” S. [2] Fan Shizhong, “Oil and gas layer protection and evaluation,” Petroleum Industry Press, Beijing, pp. 92-126, 1988. [3] Xu Tongtai, Zhao min, and Xiong Youming, “Protection oil and gas layer technology,” Oil Press, Beijing, pp. 49-55, 2003. [4] Li Kexiang, “Oil and gas layer drilling and killing well technol- ogy,” Petroleum Industry Press, pp. 796-815, Beijing, 1993. |