J. O. AGUNSOYE ET AL.

Copyright © 2012 SciRes. JMMCE

779

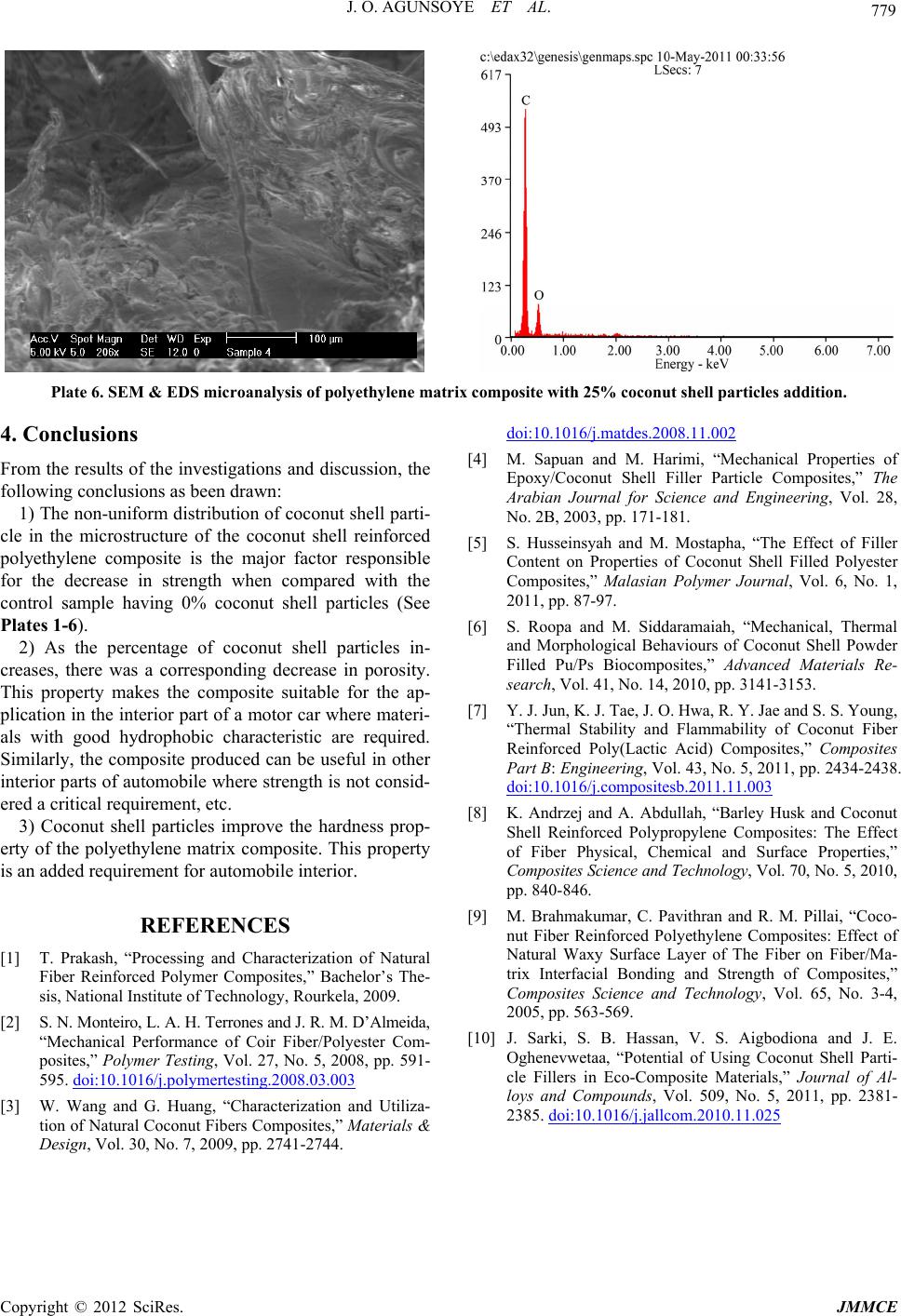

Plate 6. SEM & EDS microanalysis of polyethylene mposite with 25% coconut shell particles addition.

. Conclusions

the investigations and discussio

oconut shell parti-

cl

percentage of coconut shell particles in

cr

rove the hardness

er

REFERENCES

[1] T. Prakash, “Prization of Natura

da

matrix co

4

From the results of n, the

following con clusions as been drawn:

1) The non-uniform distribution of c

e in the microstructure of the coconut shell reinforced

polyethylene composite is the major factor responsible

for the decrease in strength when compared with the

control sample having 0% coconut shell particles (See

Plates 1-6).

2) As the-

eases, there was a corresponding decrease in porosity.

This property makes the composite suitable for the ap-

plication in the interior part of a motor car where materi-

als with good hydrophobic characteristic are required.

Similarly, the composite produced can be useful in other

interior parts of automobile where streng th is not consid-

ered a critical requirement, etc.

3) Coconut shell particles impprop-

ty of the polyethylene matrix composite. This property

is an added requirement for automobile interior .

rocessing and Charactel

,

Fiber Reinforced Polymer Composites,” Bachelor’s The-

sis, National Institute of Technology, Rourkela, 2009.

[2] S. N. Monteiro, L. A. H. Terrone s and J. R. M. D’ Al mei

“Mechanical Performance of Coir Fiber/Polyester Com-

posites,” Polymer Testing, Vol. 27, No. 5, 2008, pp. 591-

595. doi:10.1016/j.polymertesting.2008.03.003

[3] W. Wang and G. Huang, “Characterization and Utiliza-

doi:10.1016/j.matdes.2008.11.002

hanical Properties of

stapha, “The Effect of Filler

. Siddaramaiah, “Mechanical, Thermal

S. Young,

[4] M. Sapuan and M. Harimi, “Mec

Epoxy/Coconut Shell Filler Particle Composites,” The

Arabian Journal for Science and Engineering, Vol. 28,

No. 2B, 2003, pp. 171-181.

[5] S. Husseinsyah and M. Mo

Content on Properties of Coconut Shell Filled Polyester

Composites,” Malasian Polymer Journal, Vol. 6, No. 1,

2011, pp. 87-97.

[6] S. Roopa and M

and Morphological Behaviours of Coconut Shell Powder

Filled Pu/Ps Biocomposites,” Advanced Materials Re-

search, Vol. 41, No. 14, 2010, pp. 3141-3153.

[7] Y. J. Jun, K. J. Tae, J. O. Hwa, R. Y. Jae and S.

“Thermal Stability and Flammability of Coconut Fiber

Reinforced Poly(Lactic Acid) Composites,” Composites

Part B: Engineering, Vol. 43, No. 5, 2011, pp. 2434-2438.

doi:10.1016/j.compositesb.2011.11.003

[8] K. Andrzej and A. Abdullah, “Barley Husk and Coconut

mar, C. Pavithran and R. M. Pillai, “Coco-

ssan, V. S. Aigbodiona and J. E.

Shell Reinforced Polypropylene Composites: The Effect

of Fiber Physical, Chemical and Surface Properties,”

Composites Science and Technol ogy, Vol. 70, No. 5, 2010,

pp. 840-846.

[9] M. Brahmaku

nut Fiber Reinforced Polyethylene Composites: Effect of

Natural Waxy Surface Layer of The Fiber on Fiber/Ma-

trix Interfacial Bonding and Strength of Composites,”

Composites Science and Technology, Vol. 65, No. 3-4,

2005, pp. 563-569.

[10] J. Sarki, S. B. Ha

Oghenevwetaa, “Potential of Using Coconut Shell Parti-

cle Fillers in Eco-Composite Materials,” Journal of Al-

loys and Compounds, Vol. 509, No. 5, 2011, pp. 2381-

2385. doi:10.1016/j.jallcom.2010.11.025

tion of Natural Coconut Fibers Composites,” Materials &

Design, Vol. 30, No. 7, 2009, pp. 2741-2744.