Paper Menu >>

Journal Menu >>

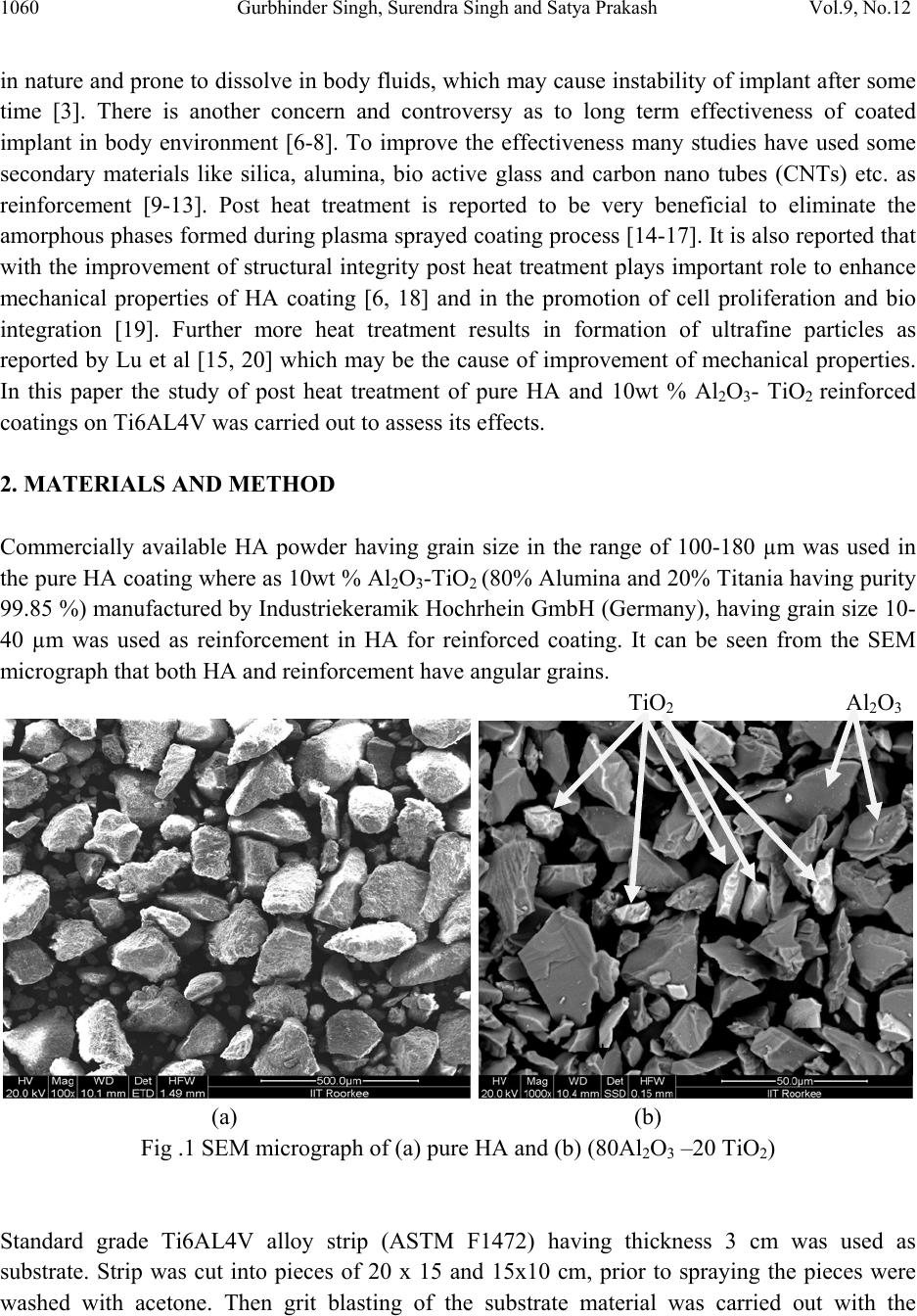

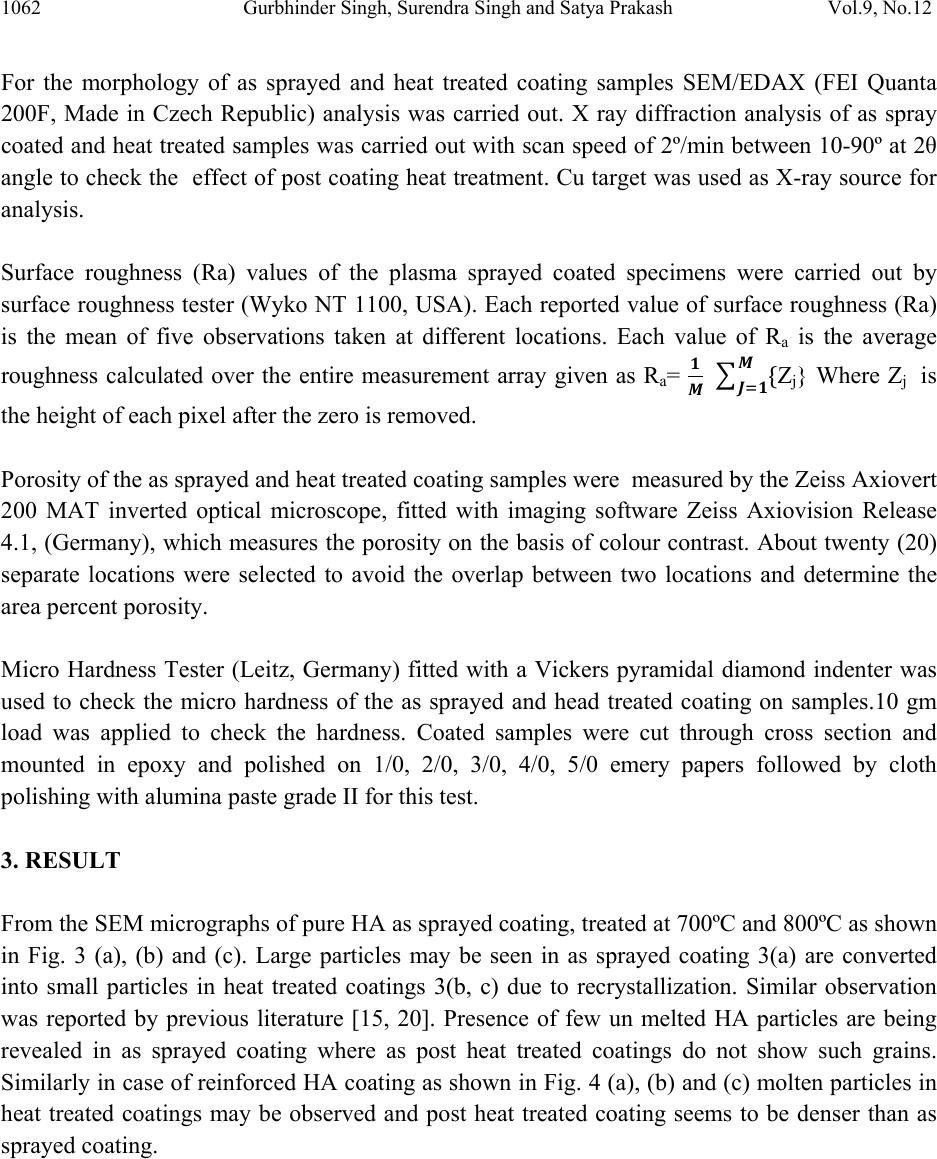

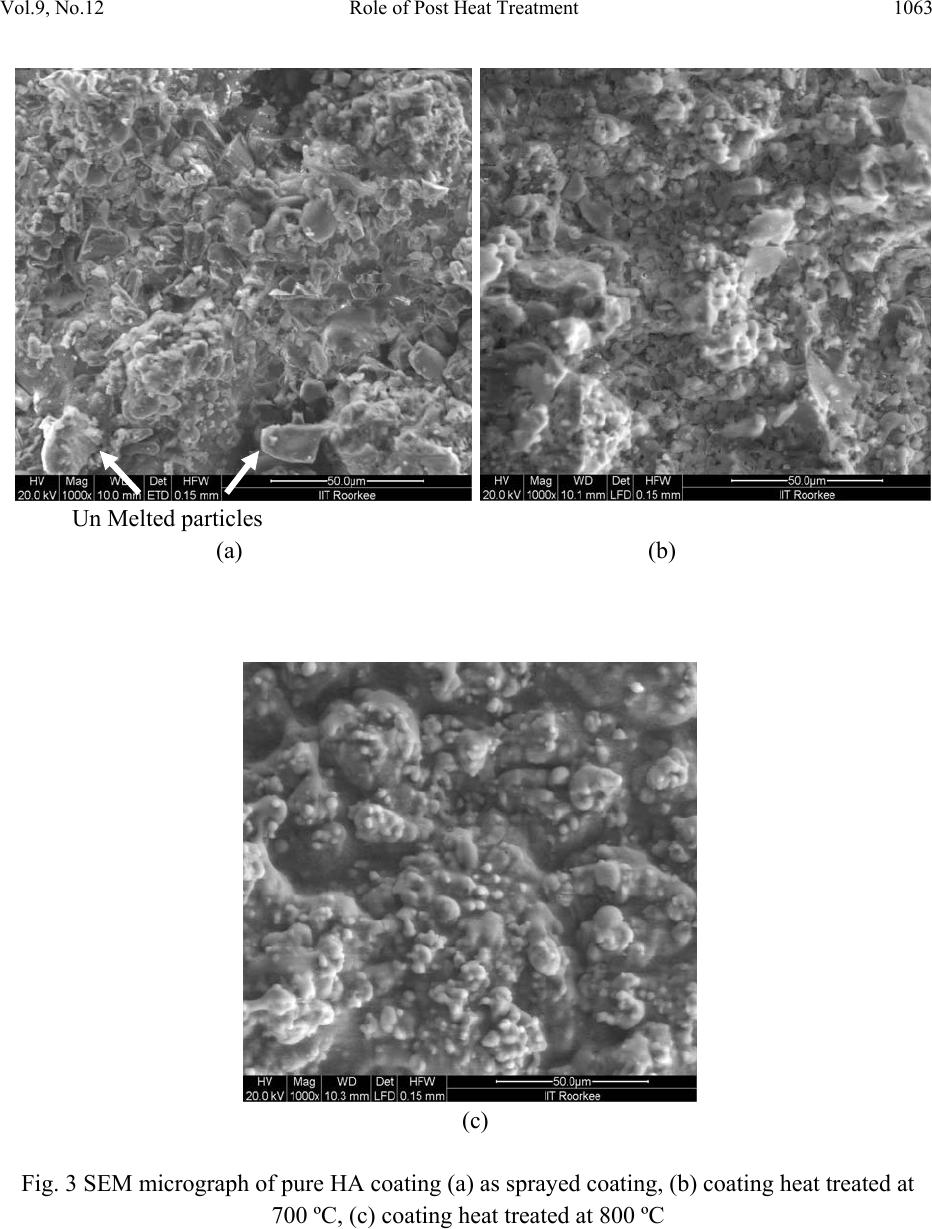

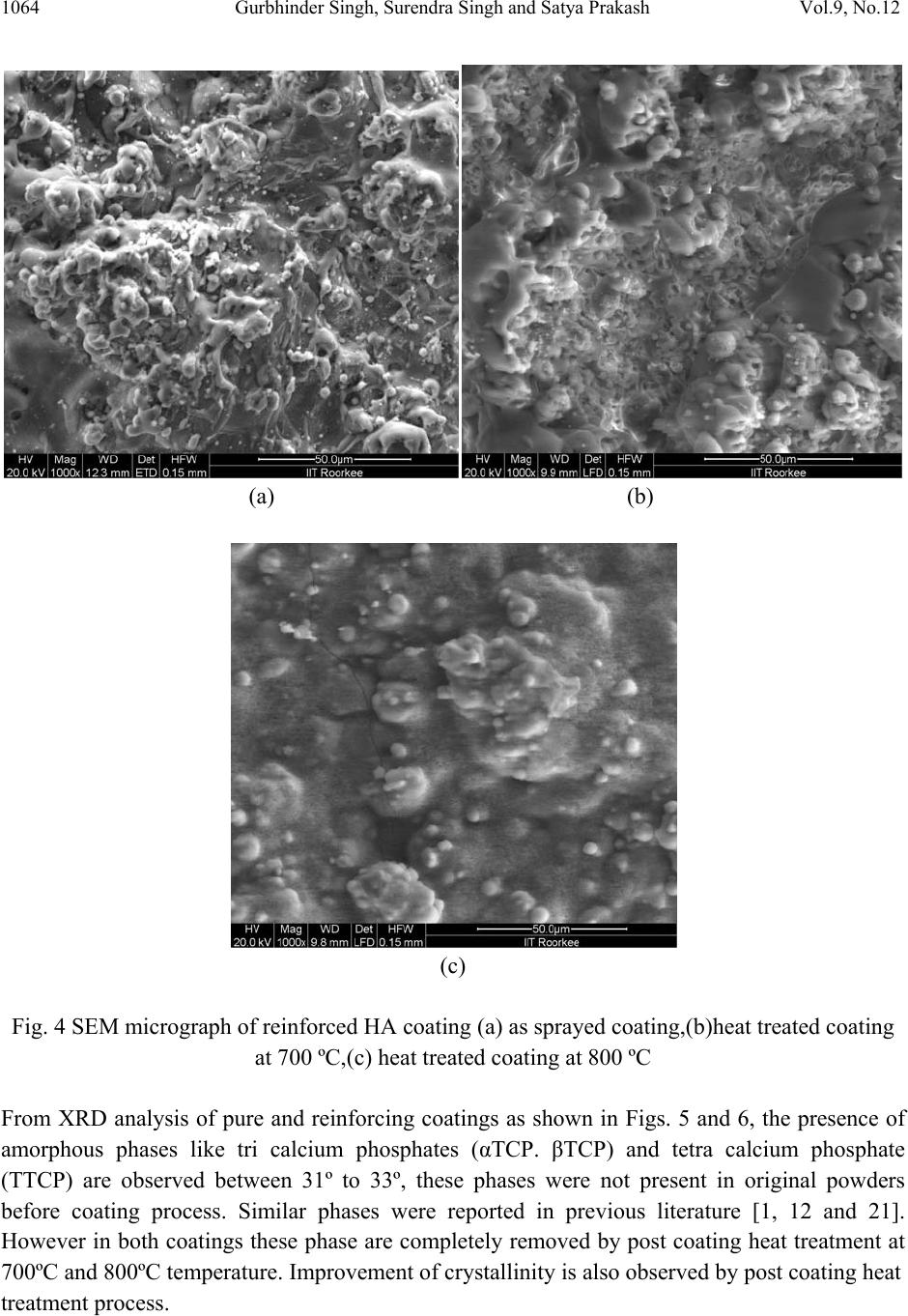

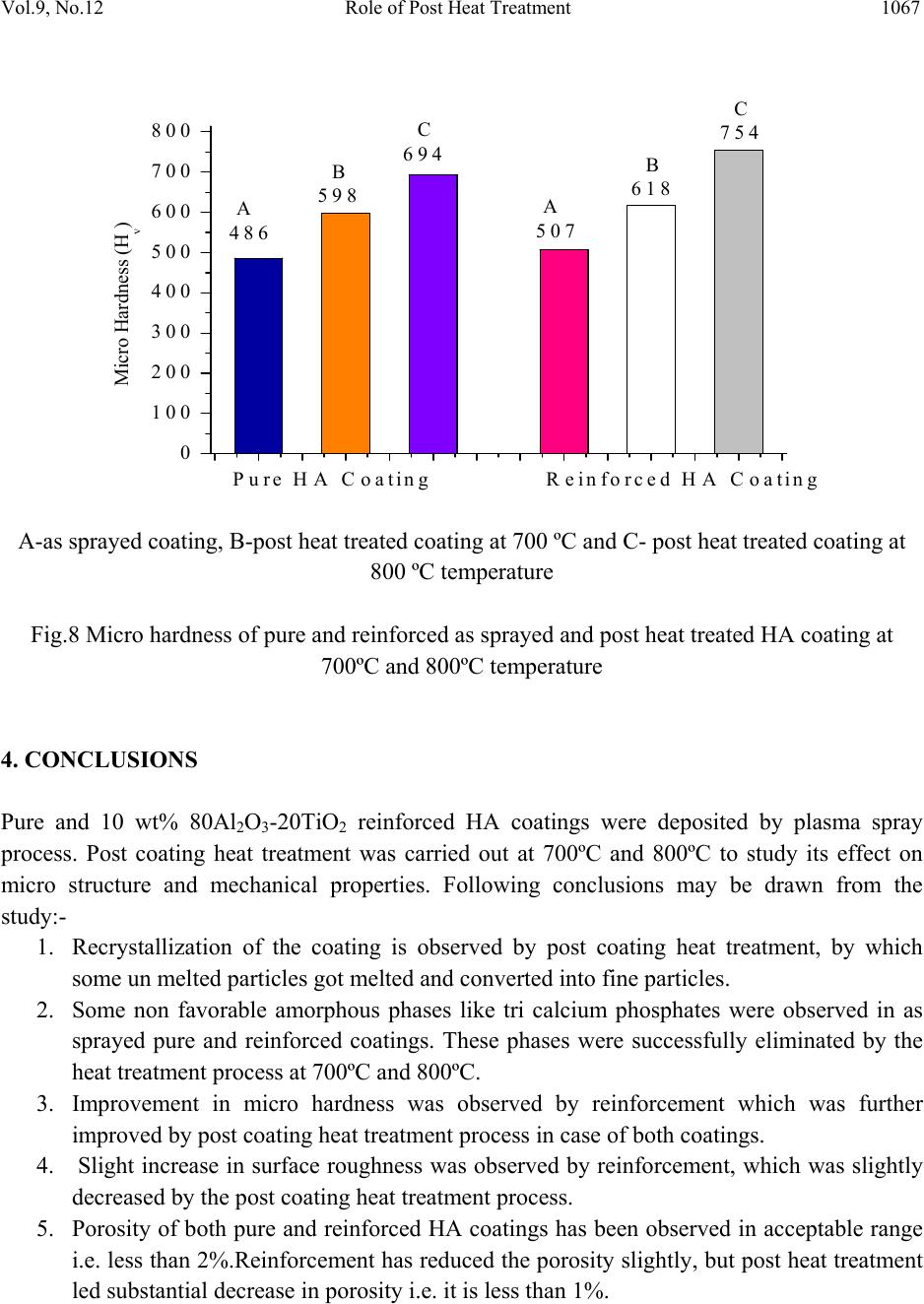

Journal of Minerals & Materials Characterization & Engineering, Vol. 9, No.12, pp.1059-1069, 2010 jmmce.org Printed in the USA. All rights reserved 1059 Role of Post Heat Treatment of Plasma Sprayed Pure and Al2O3-TiO2 Reinforced Hydroxyapatite Coating on the Microstructure and Mechanical Properties Gurbhinder Singh*, Surendra Singh and Satya Prakash Metallurgical and Materials Engineering Department, Indian Institute of Technology, Roorkee 247667, India * Corresponding Author: gurbhinder@yahoo.com ABSTRACT Pure and 10 wt% 80Al2O3-20TiO2 reinforced hydroxyapatite coatings were successfully deposited on Ti6Al4V substrate by plasma spray technique for bio medical applications. Post coating heat treatment was carried out to study the effect of heat treatment on improvement in micro structure and mechanical properties of coatings. Coating was characterized by SEM/EDAX and XRD analysis. Positive impact of post coating heat treatment was observed in microstructure, surface roughness and micro hardness of both coatings. Keywords: Hydroxyapatite, Pla sma Spray, Heat treatment, Microhardness 1. INTRODUCTION Hydroxyapatite (Ca10 (PO4)6 (OH)2,(HA) coating on metallic substrates is now becoming popular in clinically used applications due to excellent mechanical properties of substrate and good biological response of HA coating [1]. It is reported by the previous research that thermal spray techniques can develop thick, adherent and crystalline HA coatings as compared to other processes [2-4]. Hence due to superior coating characteristics of plasma spray process among the others, it is the only process which is recommended by Food and Drug Administration (FDA), USA, for clinical use [5]. It is advantageous to use plasma sprayed HA coated metallic implant in body, however it is concluded by the previous research work that in plasma spray process due to rapid cooling from very high temperature decomposition of HA takes place to form tetra calcium phosphate (TTCP), tri calcium phosphate (α-TCP, β-TCP) phases. These phases are amorphous  1060 Gurbhinder Singh, Surendra Singh and Satya Prakash Vol.9, No.12 in nature and prone to dissolve in body fluids, which may cause instability of implant after some time [3]. There is another concern and controversy as to long term effectiveness of coated implant in body environment [6-8]. To improve the effectiveness many studies have used some secondary materials like silica, alumina, bio active glass and carbon nano tubes (CNTs) etc. as reinforcement [9-13]. Post heat treatment is reported to be very beneficial to eliminate the amorphous phases formed during plasma sprayed coating process [14-17]. It is also reported that with the improvement of structural integrity post heat treatment plays important role to enhance mechanical properties of HA coating [6, 18] and in the promotion of cell proliferation and bio integration [19]. Further more heat treatment results in formation of ultrafine particles as reported by Lu et al [15, 20] which may be the cause of improvement of mechanical properties. In this paper the study of post heat treatment of pure HA and 10wt % Al2O3- TiO2 reinforced coatings on Ti6AL4V was carried out to assess its effects. 2. MATERIALS AND METHOD Commercially available HA powder having grain size in the range of 100-180 µm was used in the pure HA coating where as 10wt % Al2O3-TiO2 (80% Alumina and 20% Titania having purity 99.85 %) manufactured by Industriekeramik Hochrhein GmbH (Germany), having grain size 10- 40 µm was used as reinforcement in HA for reinforced coating. It can be seen from the SEM micrograph that both HA and reinforcement have angular grains. TiO2 Al2O3 (a) (b) Fig .1 SEM micrograph of (a) pure HA and (b) (80Al2O3 –20 TiO2) Standard grade Ti6AL4V alloy strip (ASTM F1472) having thickness 3 cm was used as substrate. Strip was cut into pieces of 20 x 15 and 15x10 cm, prior to spraying the pieces were washed with acetone. Then grit blasting of the substrate material was carried out with the  Vol.9, No.12 Role of Post Heat Treatment 1061 alumina having size 350-450 µm. After air blasting, the substrates were coated with pure and reinforced HA by air jet plasma spray technique at Anod Plasma Spray Limited Kanpur, (India).Coating parameters are given in the Table I. Table I Spraying parameters of pure and reinforced HA coating S.No Coating Parameter Units 1 Current (A): 750 2 Voltage (V): 50 3 Arc Pressure (PSI): 60 4 Powder Pressure (PSI): 80 5 Hopper RPM: 5.4 6 Hydrogen Pressure (PSI): 10 7 Stand of Distance (mm): 105 8 Powder Rate g/min: 35 9 Plasma Gun diameter (mm): 7 Post heat treatment of as sprayed coating has been carried out at a temperature of 700 ºC and 800ºC for two hours. The coated pieces were placed in the furnace as shown in the Fig. 2 and then the temperature was raised from room temperature to the desired temperatures i.e. 700 ºC and 800 ºC at the rate of nearly 5 ºC/min. After attaining the desired temperature samples were heated for two hours. After two hours furnace power supply was stopped and the coated samples were left as such for 9-10 hrs for annealing. Coated Sample Hot Zone inside the furnace Fig. 2 Experimental set up of the furnace for post coating heat treatment process  1062 Gurbhinder Singh, Surendra Singh and Satya Prakash Vol.9, No.12 For the morphology of as sprayed and heat treated coating samples SEM/EDAX (FEI Quanta 200F, Made in Czech Republic) analysis was carried out. X ray diffraction analysis of as spray coated and heat treated samples was carried out with scan speed of 2º/min between 10-90º at 2θ angle to check the effect of post coating heat treatment. Cu target was used as X-ray source for analysis. Surface roughness (Ra) values of the plasma sprayed coated specimens were carried out by surface roughness tester (Wyko NT 1100, USA). Each reported value of surface roughness (Ra) is the mean of five observations taken at different locations. Each value of Ra is the average roughness calculated over the entire measurement array given as Ra= ࡹ ሼ ࡹ ࡶୀ Zj} Where Zj is the height of each pixel after the zero is removed. Porosity of the as sprayed and heat treated coating samples were measured by the Zeiss Axiovert 200 MAT inverted optical microscope, fitted with imaging software Zeiss Axiovision Release 4.1, (Germany), which measures the porosity on the basis of colour contrast. About twenty (20) separate locations were selected to avoid the overlap between two locations and determine the area percent porosity. Micro Hardness Tester (Leitz, Germany) fitted with a Vickers pyramidal diamond indenter was used to check the micro hardness of the as sprayed and head treated coating on samples.10 gm load was applied to check the hardness. Coated samples were cut through cross section and mounted in epoxy and polished on 1/0, 2/0, 3/0, 4/0, 5/0 emery papers followed by cloth polishing with alumina paste grade II for this test. 3. RESULT From the SEM micrographs of pure HA as sprayed coating, treated at 700ºC and 800ºC as shown in Fig. 3 (a), (b) and (c). Large particles may be seen in as sprayed coating 3(a) are converted into small particles in heat treated coatings 3(b, c) due to recrystallization. Similar observation was reported by previous literature [15, 20]. Presence of few un melted HA particles are being revealed in as sprayed coating where as post heat treated coatings do not show such grains. Similarly in case of reinforced HA coating as shown in Fig. 4 (a), (b) and (c) molten particles in heat treated coatings may be observed and post heat treated coating seems to be denser than as sprayed coating.  Vol.9, No.12 Role of Post Heat Treatment 1063 Un Melted particles (a) (b) (c) Fig. 3 SEM micrograph of pure HA coating (a) as sprayed coating, (b) coating heat treated at 700 ºC, (c) coating heat treated at 800 ºC  1064 Gurbhinder Singh, Surendra Singh and Satya Prakash Vol.9, No.12 (a) (b) (c) Fig. 4 SEM micrograph of reinforced HA coating (a) as sprayed coating,(b)heat treated coating at 700 ºC,(c) heat treated coating at 800 ºC From XRD analysis of pure and reinforcing coatings as shown in Figs. 5 and 6, the presence of amorphous phases like tri calcium phosphates (αTCP. βTCP) and tetra calcium phosphate (TTCP) are observed between 31º to 33º, these phases were not present in original powders before coating process. Similar phases were reported in previous literature [1, 12 and 21]. However in both coatings these phase are completely removed by post coating heat treatment at 700ºC and 800ºC temperature. Improvement of crystallinity is also observed by post coating heat treatment process.  Vol.9, No.12 Role of Post Heat Treatment 1065 20 25 3035 40 4550 55 6065 70 7580 85 90 a bc Heat treated at 800ºC Heat treated at 700ºC As sprayed coating Powder Reletive intensity (arb.u) Diffraction angle,2 theeta (degree) a-αTCP, b-βTCP, c-TTCP Fig. 5 XRD analysis of pure HA powder, as sprayed coating and heat treated coatings at 700ºC and 800ºC temperature 20 25 3035 4045 50 55 60 65 70 7580 85 90 c b a t Heat treated at 800ºC Heat treated at 700ºC As sprayed coating Powder Reletive intensity (arb.u) Diffraction angle,2 theeta (degree) a-αTCP, b-βTCP, c-TTCP Fig. 6 XRD analysis of reinforced HA powder, as sprayed coating and heat treated coatings at 700ºC and 800 º C temperature  1066 Gurbhinder Singh, Surendra Singh and Satya Prakash Vol.9, No.12 Surface roughness of reinforced HA coating is slightly higher as shown in the Fig.7. This may be due to presence of reinforcement. Further effect of heat treatment on surface roughness of the coatings may be observed which shows slight decrease in surface roughness in case of both coatings. This may be due to the refinement of grain size by heat treatment. 0 1 2 3 4 5 6 C 3.61 B 4.52 A 6.06 C 3.54 B 4.40 A 5.86 Reinforced HA Coating Pure HA Coating Surface Roughness (µm) A-as sprayed coating, B-post heat treated coating at 700 ºC and C- post heat treated coating at 800 ºC temperature Fig.7 Surface roughness of pure and reinforced as sprayed and post heat treated HA coating at 700ºC and 800ºC temperature Porosity of coating plays an important role in case of bio implants. It is observed by the previous literature that metallic parts dissolve toxic metallic ion in body fluid environments [22, 23].So the coating must be continuous and free from through porosity. Porosity of pure and reinforced plasma sprayed coatings is in the most promising range i.e. less than 2%.Post coating heat treatment led reduction in porosity less than 1%, which may attributed refinement of grains. Micro hardness is the important property for an implant to be used in body environment. It must possess sufficient hardness to bear the stresses involve in the high load conditions like hip and knee prosthesis. Reinforcement has improved the microhardness of the coating. Post coating heat treatment has further enhanced this property as shown in the Fig. 8. It can be observed from the figure that micro hardness gets improved with post coating heat treatment in case of both coatings and as the temperature is increased from 700ºC to 800ºC the further improvement in micro hardness is observed.  Vol.9, No.12 Role of Post Heat Treatment 1067 0 100 200 300 400 500 600 700 800 C 754 B 618 A 507 C 694 B 598 A 486 Reinforced HA Coating Pure HA Coating Micro Hardness (Hv) A-as sprayed coating, B-post heat treated coating at 700 ºC and C- post heat treated coating at 800 ºC temperature Fig.8 Micro hardness of pure and reinforced as sprayed and post heat treated HA coating at 700ºC and 800ºC temperature 4. CONCLUSIONS Pure and 10 wt% 80Al2O3-20TiO2 reinforced HA coatings were deposited by plasma spray process. Post coating heat treatment was carried out at 700ºC and 800ºC to study its effect on micro structure and mechanical properties. Following conclusions may be drawn from the study:- 1. Recrystallization of the coating is observed by post coating heat treatment, by which some un melted particles got melted and converted into fine particles. 2. Some non favorable amorphous phases like tri calcium phosphates were observed in as sprayed pure and reinforced coatings. These phases were successfully eliminated by the heat treatment process at 700ºC and 800ºC. 3. Improvement in micro hardness was observed by reinforcement which was further improved by post coating heat treatment process in case of both coatings. 4. Slight increase in surface roughness was observed by reinforcement, which was slightly decreased by the post coating heat treatment process. 5. Porosity of both pure and reinforced HA coatings has been observed in acceptable range i.e. less than 2%.Reinforcement has reduced the porosity slightly, but post heat treatment led substantial decrease in porosity i.e. it is less than 1%.  1068 Gurbhinder Singh, Surendra Singh and Satya Prakash Vol.9, No.12 REFERENCES 1. M.F. Morks, Akira Kobayashi, 2007, “Effect of gun current on the microstructure and crystallinity of plasma sprayed Hydroxyapatite coating”, Appl. Surf. Sci. Vol. 253, pp. 7136- 7142. 2. X.Nie, A. Leyland, A.Matthews, 2000, “Deposition of layered bioceramic hydroxyapatite /TiO2 coatings on titanium alloys using a hybrid technique of micro-arc oxidation and electrophoresis”, Surface and Coatings Technology, Vol.125, pp. 407–414. 3. M.F Morks, Akira Kobayashi, 2006, “Influence of gas flow rate on the microstructure and mechanical properties of hydroxyapatite coatings fabricated by gas tunnel type plasma spraying, Surface and Coatings Technology”, Vol. 201, pp. 2560-2566. 4. C.S. Kim, P. Ducheyne ,1991, “Compositional variations in the surface and interface of calcium phosphate ceramic coatings on Ti and Ti-6Al-4V due to sintering and immersion”, Biomaterials, Volume 12, Issue 5, pp. 461-469. 5. Kantesh Balani, Yao Chen, Sandip P. Harimkar, Narendra B. Dahotre, Arvind Agarwal, 2007,“Tribological behavior of plasma-sprayed carbon nanotube-reinforced hydroxyapatite coating in physiological solution”, Acta Biomaterialia ,Vol. 3,pp. 944–951. 6. Yu-Peng-Lu, Gui-Yong-Xiao, Shi-Tong-Li, Rui-Xue-Sun, Mu-Sen-Li, 2006, “Microstructural inhomogeneity in plasma-sprayed hydroxyapatite coatings and effect of post-heat treatment”, Applied Surface Science, Vol. 252,pp. 2412-2421. 7. W.F. Morris, 1998, “Hydroxyapatite-coated implants: a case for their use”, J. Oral Maxillofac. Surg., Vol. 56 (II), pp. 1303–1311. 8. T. Albrektsson, 1998, “Hydroxyapatite-coated implants: a case against their use”, J. Oral Maxillofac. Surg., Vol. 56 (II), pp. 1312–1326. 9. Hu H., Ni Y., Montana V., Haddon R.C., Parpura V., 2004, “Chemically functionalized carbon nanotubes as substrate for neuronal growth”, Nano Lett, Vol.4(3),pp. 507–511. 10. Fang L., Leng Y, Gao P., 2006, “Processing and mechanical properties of nano-composite”, Biomaterials, Vol. 37, pp. 3701–3707. 11. L. Fu, K.A. Khor, J.P. Lim, 2001, “Processing, microstructure and mechanical properties of yttria stabilized zirconia reinforced hydroxyapatite coatings”, Materials Science and Engineering A, Vol.316, pp. 46–51. 12. M.F. Morks, 2008, “Fabrication and charectrization of plasma –sprayed HA/SiO2 coatings for biomedical application”, Journal of the mechanical Behaviour of Biomedical Materials, Vol.1, pp. 105-111. 13. Jorge E. Tercero, Shabnam Namin, Debrupa Lahiri, Kantesh Balani, Nikolaos Tsoukias, Arvind Agarwal,2009, “Effect of carbon nanotube and aluminum oxide addition on plasma- sprayed hydroxyapatite coating's mechanical properties and biocompatibility”, Materials Science and Engineering C, Vol. 29,pp. 2195–2202.  Vol.9, No.12 Role of Post Heat Treatment 1069 14. Huaxia Ji, P.M.Marquis, 1993, “Effect of heat treatment on the microstructure of plasma- sprayed hydroxyapatite coating” Biomaterials, Vol. 14,No. 1,pp.64-68. 15. Yu Peng Lu , Yi Zhong Song, Rui Fu Zhu, Mu Sen Li, Ting Quan Lei, 2003, “ Factors influencing phase compositions and structure of plasma sprayed hydroxyapatite coatings during heat treatment” Applied Surface Science,Vol.206,pp. 345-354. 16. Shinn-jyh Ding, Tsui-hsien Huang, Chia-tze Kao, 2002, “Immersion behavior of plasma sprayed modified hydroxyapatite coatings after heat treatment”, Surface and Coatings Technology, Vol. 165, pp. 248-257. 17. Zhao Guo-liang, Wen Guang-wu, Wu Kun, 2009, “Influence of processing parameters and heat treatment on phase composition and microstructure of plasma sprayed hydroxyapatite coatings”, Trans. Nonferrous Met. Soc. China, vol.19, pp. 463- 469. 18. H. Li, K.A. Khor, P. Cheang, 2002, “ Properties of heat treated calcium phosphate coatings deposited by high velocity oxy fuel (HVOF) spray”, Biomaterials,Vol.23,pp. 2105-2112. 19. L. Chou, B. Marek, W.R. Wanger, 1999, “Effect of hydroxyapatite coating crystallinity on biosolubility, cell attachment efficiency and proliferation in vitro, Biomaterials, Vol. 20,pp. 977-985. 20. Y.P. Lu, S.T.Li, R.F.Zhu, M.S.Li, T.Q.Lei, 2002, “Recrrystallinzation and structure of plasma sprayed hydroxyapatite coating”, Chin. J. Inorg. Chem.Vol. 18,pp. 844-848. 21. Wenxiu Que, K.A. Khor, J.L. Xu, L.G. Yu, 2008, “Hydroxyapatite/titania nanocomposites derived by combining high-energy ball milling with spark plasma sintering processe”, Eur. Ceram. Soc.,Vol.28,pp.3083-3090. 22. A. Balamurugan, G. Balossier, S. Kannan,S. Rajeswari, 2006, “Elaboration of sol–gel derived apatite films on surgical grade stainless steel for biomedical applications”, Mater. Lett.Vol. 60, pp. 2288–2293. 23. Mi Hee Lee, Dong Wook Han, Hyun Sook Baek, Hye Ryun Lim, In Seop Lee, Kwon Yong Lee, Kyung Tae Kim, Seung Jin Lee, Jong Chul Park,2007, “Differential cytokine responses of murine macrophage J774A.1 cells to stainless steel coated with and without hydroxyapatite”, Surf.Coat.Technol. Vol. 201, pp. 5729–5732. |