Sensory Evaluation and Nutritional Composition of Developed Papaya-Gooseberry Jam ()

Received 3 February 2016; accepted 20 June 2016; published 23 June 2016

1. Introduction

Among the perishable commodities fruits are the essential ingredients in the human dietaries. They are high in nutritive value and make important nutritional contribution to human well being and they are cheaper and better sources of protective foods. They are naturally low in fat, sodium, calories and have absolutely no cholesterol and are a significant source of several fundamental nutrients, including dietary fiber, vitamin C, folate (folic acid), potassium, phyto-nutrients and many anti-oxidants like phenols, flavonoids and anthocyanins. These compounds protect the body from oxidative stress and degenerative diseases by developing the capacity to fight against ailments [1] .

In different regions during certain parts of the year the perishable fruits are available as seasonal surplus and they create a glut in the market but in off-seasons they become scarce. If they are supplied in fresh or preserved form throughout the year for human consumption, the post harvest losses can be minimized and more variety of wholesome nutritious and acceptable foods will be available to the people [2] .

The most common preserved fruit product is fruit-jams. Jams are solid gel prepared from ripe fruits and are one of the most important breakfast ingredients. Jams are of two kinds: one is prepared from a single fruit and another is prepared from a combination of two or more fruits [3] . Realizing the importance of fruit, as an economical, highly nutritious foodstuff and because of its perishable nature and seasonally availability, it was deemed necessary to make preserved products for human consumption throughout the year. Fruits like papaya (Carica papaya L.) and Indian gooseberry (Emblica officinalis) can be used to prepare a jam as they provide an abundant source of vitamins, minerals, fiber and antioxidants. Fruit jams are important in the diet of every age group as they provide quick boosts of energy with only half bout of calories. The presence of fiber and fructose content regulates the blood glucose levels by slowing the digestion and enhancing the satiety level. Good jam has a soft even consistency without distinct pieces of fruit, a bright color, a good fruit flavor and easy to spread semi-jel- lied texture without free liquid. This study was aimed at keeping in view the nutritional importance of papaya and gooseberry prolonging their utilizable lifespan by preserving them as jam along with an analysis of organoleptic acceptability.

2. Materials and Methods

2.1. Fruit Selection

Freshly mature papaya (Carica papaya L.) and gooseberry (Emblica officinalis) were purchased from the local market of Allahabad.

2.2. Fruit Preparation

Sorting and grading is essential to get suitable quality of fruit which was done by hand. The fruits were first thoroughly washed under running tap water to reduce soil, plant and debris load. Grading of fruit was done based on cleanliness, firmness, soundness, maturity, weight, color, size, shape, freedom from foreign matters, insect damage and mechanical injury. Undamaged fruits were selected with no symptoms of visible discoloration and soaked in warm water at (80˚C) for 2 min to reduce surface microbial load.

2.3. Extraction of Fruit Pulp

a) Papaya (Carica papaya L.)

From the graded papaya the pulp was extracted manually. It was homogenized in a mixer to obtain fine pulp.

b) Gooseberry (Emblica officinalis)

The washed gooseberry were boiled for 5 min in equal amount of water (by weight) to soften the outer skin. The boiled gooseberry were deseeded and pulped in a mixer; and the crude mixture pulp was sieved through an 800-micron sieve.

2.4. Development of Jam

The papaya-gooseberry jam was developed by incorporation of gooseberry pulp in different ratios as shown in Table 1. The entire experiment had one control T0 (100% papaya) and six variations T1 (95:5), T2 (90:10), T3 (85:15), T4 (80:20), T5 (75:25) and T6 (70:30) at different percent incorporation levels with gooseberry pulp which were replicated three times and each replication was tested for sensory evaluation by a panel of judges using 9-point Hedonic Scale.

![]()

Table 1. Different ratios of papaya and gooseberry pulp.

2.5. Preparation of Jam

Fruits are preserved in the form of jam by relying upon the high solids-high acid principle. For the preparation of Jam fruit pulp was boiled with sufficient quantity of sugar to a reasonably thick consistency, firm enough to hold fruit issues in position [4] .

Flow Chart for Papaya-Gooseberry Jam Preparation

Selection and preparation of fruit (papaya and gooseberry)

↓

Weighing of 200 g pulp

↓

Addition of 127 g sugar

↓

Cooking the pulp (cooking slowly with occasional stirring for 12 - 15 min)

↓

Adding together citric acid (1.7 g) + salt (1/2 pinch) + 2 g pectin

↓

Judging the end point (TSS-68.5% using refractometer ABBE)

↓

Packing (filled the hot jam into clean, dry sterilized bottles)

↓

Cooling, Capping and Storage (at ambient temperature)

2.6. Chemical Analysis

2.6.1. Determination of Total Soluble Solids (TSS)

The total soluble solids (TSS) of the fruit pulp and jam were determined using a hand refractometer (0% to 30% Brix, Model DIGT 0-30ATC for the pulp and 0 to 68% Brix Model DIGT 0-68ATC (The Optical Instruments Co. Ltd, Japan) for jam.

2.6.2. Proximate Analysis

The proximate composition was analyzed according to the standard methods outlined by AOAC (2005) [5] .

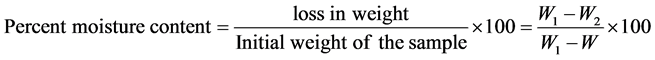

1) Determination of Moisture

5 g of the sample was weighed and taken in a tare porcelain dish (W1 g).Then dish was shaken till the contents were evenly distributed and placed in hot air oven, maintained at 105˚C ± 2˚C and dried for at least 2 hours. It was then cooled in desiccators and lowest weight was noted (W2 g).

Calculation:

Tared weight of the dish (W g);

Weight of dish with samples (W1 g);

Weight of the dish + sample after drying in oven (W2 g).

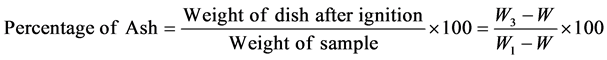

2) Determination of Total Ash

Ash comprises of the mineral content which was present in the sample which can be determined by igniting unknown amount of dried material in a muffle furnace. The dried material obtained from determination of moisture in a crucible dish was ignited on a blue flame of a burner till the smoke was given off. The porcelain/ crucible dish was then heated in a muffle furnace maintained at 500˚C ± 5˚C for 1 - 2 hours. It was cooled in a desecrator and weight was taken.

Calculation:

Weight of the dish + weight of dried sample = (W2 g);

Weight of dish + weight of ash = (W3 g).

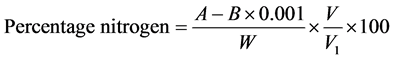

3) Determination of Protein

5.0 g of sample was accurately weighed in a cupped filter paper and transfer the contents of filter paper into the kjeldahl flask. 10 g of digestion mixture (CuSO4 + K2SO4 + Selenium oxide) and 25 ml of concentrated H2SO4 was added. It was slowly warmed to minimize frothing, and then boiled until the solution was clean. The solution was allowed to cool and transferred to a 100 ml volumetric flask and make up the volume using distilled water. In the receiver of distillation apparatus, 10 ml of aliquot and 10 ml of 40% sodium hydroxide was added. Released ammonia was collected in 25 ml of 4% boric acid solution containing few drops of mixed indicator (Mixed indicator gives pink on distillation) which was distilled for half an hour, afterwards condenser outlet was disconnected. The obtained boric acid solution was titrated with 0.01 N sulphuric acid or 0.01 N Hydrochloric acids and for the blank water or sucrose was used in place of sample.

Calculation: 1 ml of 0.01N H2SO4 for = 0.0014 g

Titre volume = A − B ml

% crude protein = N ×conversion factor (6.25);

Volume of 0.1 N H2SO4 for sample = A;

Volume of 0.1 N H2SO4 for blank = B;

Weight of sample = W = 2 gm;

Volume made (V) = 100 ml;

Aliquot distilled (V1) = 10 ml.

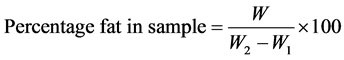

4) Determination of Crude Fat

The extraction flask was weighed accurately (W1 g) and 2 g of the sample was transferred into the extraction thimble and was carefully placed in the extractor so that it was within its siphon height. Weighed extraction flask was connected to the extractor carrying the thimble and sufficient amount of petroleum ether was poured into the extractor to start the siphon and then filled about half the extraction flask. Extractor was connected to the condenser and flask was heated on a water bath or electric mental for 3 hours. The heat vaporizes the solvent and condensed in the condenser. The condensed solvent falls drop-wise into the thimble. The solvent extracts the fat present in the food. When the level of the solvent reached the siphon height, the whole of the ether flowed down into the flask below taking along with the extracted fat behind and the process was repeated. At the end of 3 hours by which time, at least 10 - 15 siphoning was taken, flask was removed carefully. The extract was transferred in a tarred conical flask and solvent was evaporated. Cooled in desiccators and weighed (W1 g). Drying, cooling and weighing or successive weighing not diffixing by more than 0.0002 g were obtained. Finally the weight was recorded (W2 g). Percentage of ether extract was calculated by multiplying the increase in weight of the extraction flask by 100.

Calculation:

Weight of sample (W);

Weight of flask (W1);

Weight of flask + fat (W2);

(Weight of flask + fat) − (Weight of flask) = (W2 − W1).

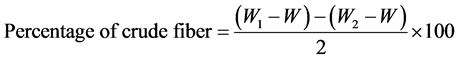

5) Determination of Crude Fiber

2 g of dried, fat free residue obtained after crude fat determination was weighed accurately and transferred into the one-liter conical flask. In a beaker, brought to boil the 200 ml dilute sulphuric acid (1.25%) and pour the boiling acid into the flask. The contents of the flask were boiled exactly for 30 minutes with constant shaking and the liquid level was maintained during boiling. At the end of 30 minutes remove the flask and filter its contents through fine lined pad held in a funnel and wash with boiling water until the washing are no longer acid to litmus.The entire residues was transferred back to the original digestion flask or beaker with a spatula and wash the residue on the linen into the digestion flask with 200 ml of boiling dilute NaOH (1.25%). The digestion flask was again boiled for exactly 30 minutes with constant rotation and maintained the liquid level as before. At the end of the specified period, the residue was washed thoroughly with boiling water till free from alkali and transferred to the prepared gooch crucible dried to constant weigh at 105˚C in an hot air oven (W g). The residue was again washed with 15 ml of 95% ethyl alcohol. The content in gooch crucible was dried at 105˚C and cooled in desiccators and weighed to constant weight (W1 g). The gooch crucible and its contents were transferred in a muffle furnace and ignited at 600˚C ± 20˚C for 1 hour, until all carbonaceous matter is burnt. Finally, cooled the gooch crucible containing the ash in desiccators and weighed (W2 g).

Calculation:

Tare weight of Gooch crucible = (W g);

Weight of Gooch crucible + sample (ash) = (W2 g);

Weight of residue = (W2 − W)g.

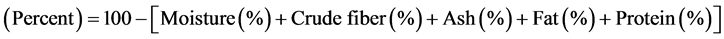

6) Determination of Carbohydrate

Total carbohydrate by difference was calculated by subtracting the sum of percentage of protein, fat, ash and moisture. Carbohydrate was divided into two groups’ crude fiber and nitrogen free extract (NFE). Total carbohydrate include crude fiber also, but NFE was calculated by subtracting the sum of percentage of ash, crude fiber, fat, protein and moisture from hundred.

Calculation:

7) Determination of Caloric Value

Energy value of the sample was calculated by multiplying the figure for percentage of protein, fat and carbohydrate by 4, 9 and 4 respectively and adding the figures obtained.

Calculation:

2.6.3. Mineral Analysis

The mineral composition was analyzed according to the standard methods as described in Ranganna [6] .

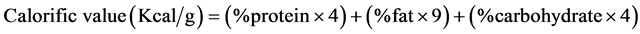

1) Determination of Calcium

10 g of ash sample was taken and 5 ml of concentrated hydrochloric acid was added to rinse the upper part of dish and evaporated to dryness. The residue was dissolved by adding 2 ml of hydrochloric acid. Covered it with watch glass and filtered the ash solution into 100 ml volumetric flask and diluted to 100 ml volume. 50 ml of ash solution was taken in a 250 ml conical flask and 8 - 10 drops of bromocresol green indicator solution was added gradually. 20% of sodium acetate was added until the solution turns blue (pH at this point was 4.8 - 5.0) covered with watch glass and heated to boiling. Slowly add 3% of oxalic acid drop wise, until the color of solution was green (pH at this point should be 4.4 to 4.6 which is optimum for precipitation of calcium oxalate). Continue boiling for one minute and allow it to stand until clear or overnight. The supernatant solution was filtered and discarded through Whatman no. 42 filter paper. Wash the conical flask and precipitate, filter it with 50 ml of dilute ammonium hydroxide solution, using small portions at a time then again wash it with some hot distilled water. Lastly, the filter paper was washed with a mixture of 125 ml distilled water and 5 ml concentrated sulphuric acid breaking the tip of filter paper and collecting the washing in original empty conical flask. Heat the solution to 90˚C and titrated with 0.1N potassium permagnate solution until pink color was obtained.

Calculation: 1ml of 0.1N KMnO4 = 2 mg Calcium

Weight of the sample (W) = 5 g;

Volume of ash solution made (V) = 100 ml;

Volume of ash solution used (V1) = 50 ml;

Volume of 0.1N KMnO4 used for sample = A;

Volume of 0.1N KMnO4 used for blank = B.

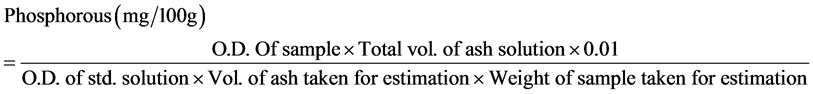

2) Determination of Phosphorous

Phosphorus reacts with molybdic acid to form phosphomolybdate complex. It is then reduced with aminonaphthol-sulphuric acid to complex molybdenum blue, which is measured at 650nm.In 5 ml of ash solution, 5 ml of molybdate reagent and 2 ml of aminonaphthol-sulphonic acid solution was added and the volume make up with distilled water to 50 ml. The blank was similarly prepared by using distilled water in place of the sample. The solution was incubated for 10 minutes and the absorbance was measured at 650 nm setting blank at 100% transmission.

Calculation:

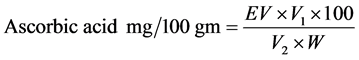

3) Determination of Ascorbic Acid (Vitamin C)

This method is based upon the reduction of the dye 2-6 dicholoro-phenol endophenol by an acid solution of ascorbic acid in the absence of interfering substance (Cu++, Fe++, and Sn++, etc.). The reduction capacity of the extract of the sample is directly proportional to the ascorbic acid content.

For the preparation of standard, 20 mg of pure ascorbic acid was accurately weighed on a tared black glazed paper and transferred to a clean 100 ml volumetric flask. Dissolve in 1% oxalic acid solution and make up the volume to the mark with the same acid. For the preparation of dye indicator, 50mg of sodium salt of 2,6 dicholorophenol-endophenol was dissolved in 150 ml of hot water containing 42mg of sodium carbonate. The solution was cooled and diluted with 200 ml of distill water and stored in a glass bottle and kept in a refrigerator or away from sunlight at 3˚C. For the standardization of dye solution, 5 ml of ascorbic acid was pipette out in a conical flask and 5 ml of 1% oxalic acid solution was added and titrated with the dye-indicator to a fame end point that persists beyond 15 seconds. The ascorbic acid equivalent of the dye was calculated in mg/ml.

1 gm of sample was weighed and dissolves in 10 ml distilled water and filtered through muslin cloth.10ml of the filtrate was taken in a 100 ml volumetric flask and diluted to the mark with 1% oxalic acid solution. Filter the diluted solution through dry filter paper if necessary. Pipette out 10ml or 25ml aliquot of the filtrate into a small flask and titrate immediately with the standardized dye indicator solution to a pink end point.

Calculation:

E = Ascorbic acid equivalent of the dye in mg/ml;

V = ml of the dye indicator used in the titration (VR);

V1 = Volume to which the fruit juice is diluted (500 ml);

V2 =Volume of filtrate taken for the titration (10 - 20 ml);

W= Weight or volume of fruit juice initially taken for the determination.

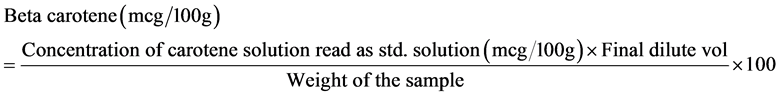

4) Determination of Beta-Carotene

Carotenoids are generally separated by chromatography. The method is based upon the separation of the biologically active carotenoid pigments from the total carotenoid pigment in an extract by using an adsorbent having varying affinities for the different pigments. 10 g of sample was in pastel mortar with 40 ml acetone and filtered. 0.1 g MgO2 diluted with 60 ml of hexane was added in the above sample and filtered. The filtrate was transferred in a separating funnel and two layers were separated. Lower layer was decanted and the upper transparent layer of hexane was taken for estimation. The upper layer was transferred into a 100 ml volumetric flask and volume make up with 100 ml hexane. For the preparation of column, aluminum and sodium sulphate was taken in 1:1 ratio (20 g + 20 g). The silica gel was poured into the column using a 10 ml beaker and the suction pump was used to force air into the column and pack the silica gel. A space of 4 - 5 cm was left on top of the adsorbent for the addition of solvent (hexanes and acetone).Hexanes and acetone solution was added to the top of the silica gel and when the bottom solvent level is at the bottom of the column, the pre-elution process is completed and the column is ready to load. The sample to be purified is dissolved in a small amount of solvent, such as hexanes or acetone and loaded into the column. The sample was collected in a beaker and the absorption was noted by using spectrophotometer at 436 nm.

Calculation:

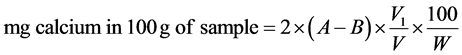

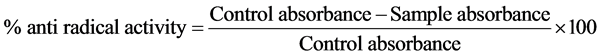

5) Percent Anti Radical Activity

10 mg of sample is taken and 10 ml of acidified methanol is added in the sample. It was heated on a water bath at 40˚C for 20 minutes. It was filtered and the supernatant is centrifuged for two minutes. Finally the resulting supernatants were used as test samples. For the preparation of DPPH (2, 2-diphenyl-1-picrylhydrazyl) solution, 4.3 mg of DPPH was dissolved in 3.3 ml of methanol which was protected from light by covering the test tubes. Pure methanol was used as blank solution. 100 µl of sample extract was taken in a test tube and diluted with 200 µl of methanol. The volume make up with 2.7 ml methanol again up to 3 ml. Then 150 µl of DPPH solution was added and test tubes were covered with brown paper or aluminum foil and mixed properly. The solution was incubated for 15 minutes at room temperature and the absorbance was recorded at 515 nm by spectrophotometer [7] .

The free radical scavenging activity (FRSA) (% antioxidant activity) was calculated by using the following equation:

2.7. Organoleptic Evaluation

The developed papaya-gooseberry jams were served to 30 semi trained panelists group for evaluating color, consistency, flavor, taste, and overall acceptability on a 9 point hedonic scale with a scores ranging from 9 to1 which represents like extremely and dislike extremely respectively. The quality parameters were quantified and the mean scores of the three evaluations were calculated.

2.8. Statistical Analysis

The collected data was analyzed and tabulated statistically and expressed as percentage; mean scores, standard error of mean, critical difference, t-test and one-way analysis of variance (ANOVA) by using statistical software SPSS version 12.0. To indicate statistically significant difference P ≤ 0.05 values were considered.

3. Results and Discussion

3.1. Organoleptic Evaluation of Developed Jam

The treatment T4 had the highest sensory scores for color (8.81), consistency (8.79), flavor (8.49), taste (8.84) and overall acceptability (8.78) than Control T0 and other treatments, making it quite obvious that the addition of 20 percent gooseberry increase the color, consistency, flavor, taste and overall acceptability of the jam. The other levels of incorporation were also liked at various degrees, although a little less than treatment T4. From the ANOVA table, it was evident that there was significant difference (p ≤ 0.05) between various treatments regarding the overall acceptability of the product. In general, addition of pectin had no significant (p > 0.05) effect on the color of the jams produced. The organoleptic scores of developed papaya-gooseberry jam were shown in Table 2. Jain et al. [8] observed the decrease in the overall acceptability of guava and papaya pulp with increase in storage period.

3.2. Nutritional Composition of Developed Jam

On the basis of sensory evaluation the best treatment of the developed papaya- gooseberry jam i.e., T4 with 80 percent of papaya and 20 percent gooseberry were identified and the chemical analysis of the treatment (T4) in comparison to control (T0) were carried out with reference to moisture, protein, fat, carbohydrate, fiber, ascorbic acid, calcium, phosphorous, beta-carotene and antioxidant activity. The data pertaining to nutritive value of developed papaya gooseberry jam is presented in Table 3. The moisture content was high in prepared jam T4 (20.30%) than in control T0 (11.09%). The maximum energy value 353 Kcal/100g was observed in treatment T0 (control). On comparing the protein, fat and carbohydrate content of the developed jam, it was found to be high-

![]()

Table 2. Average organoleptic scores of different parameters in control and best treatment of papaya-gooseberry jam.

9-point hedonic scale is as follows: 1―dislike extremely, 2―dislike very much, 3―dislike moderately, 4―dislike slightly, 5―neither like or dislike, 6―like slightly, 7―like moderately, 8―like very much, 9―like extremely. *Significant difference is at 0.05 levels. Values are means (±SEM).

(a) ![]() (b)

(b) ![]()

Table 3. (a) Proximate Composition (per 100 g) in control (T0) and best treatment (T4) of developed papaya-gooseberry jam. (b) Mineral and Vitamin Composition (per 100 g) and Percent Anti-Radical Activity (%) in control (T0) and best treatment (T4) of developed papaya-gooseberry jam.

*Significant difference is at 0.05 levels.

est in treatment T0 (0.50 g/100g, 0.19 g/100g and 87.14 g/100g). Papaya fruit is a good source of balanced nutrients it contains significantly high amount of energy and carbohydrates (i.e. 15.15% sugar and 42.28% starch in pulp) but is low in protein and fat [9] . Greatest amount of fiber content was observed in treatment T4 (1.32 g/100g) due to incorporation of gooseberry which is effective in controlling oxidation of low density lipoproteins (LDL) which releases free radicals and cause coronary artery disease or atherosclerosis. The treatment T4 was found to have maximum calcium, phosphorus and vitamin C content (92.0 mg/100g, 14.13 mg/100g and 19.16 mg/100g) in comparison to control (T0). Calcium and phosphorus are the major minerals needed by the body which plays a major role in maintaining fluid and electrolyte balance around the body and within the cells. Together they help in mineralization of bone tissue which helps in increasing the bone mineral density. The high vitamin C content was due to incorporation of gooseberry which is packed with polyphenols, vitamins and pigment antioxidants. It has a protective effect on the membrane of erythrocytes which helps in improving the blood circulation in the arteries and also facilitate in better absorption of iron in the human body [10] . Beta-ca- rotene content was found to be greatest in treatment T0 (control) (195.0 µg/100g). The selection of 100 percent papaya might be one of the contributing factors for higher beta-carotene content in control. In fruits the presence of vitamin A is in the form of carotenes (α, β and γ) which is converted into vitamin inside the body, its deficiency results in impairment of immune system, hematopoiesis and typical ocular effects (eg, xerophthalmia, night blindness) [11] . It is well recognized fact that fruits are rich in antioxidants. The percent anti-radical activity was found to be highest in treatment T4 (98.0%) than treatment T0 (control) (88.0%). Antioxidantis a powerful substance that comes from fresh fruits and it is helpful in preventing damaging effects of oxidation on cells caused by free radicals. Adetuyi et al. [12] reported that in two storage temperature, shea butter waxed papaya retains more antioxidant (total phenol, vitamin C, carotenoid and tocopherol) than unwaxed papaya. The results revealed that there was a significant difference (p ≤ 0.05) in moisture, energy, fiber, calcium, phosphorus, vitamin C, β-carotene and antioxidant activity whereas no significant difference (P ≤ 0.05) was observed in case of protein, fat and carbohydrate content between treatment T0 (papaya jam) and T4 (papaya-gooseberry jam).

4. Conclusion

From the results summarized above, it can be concluded that the incorporation of gooseberry pulp in papaya jam can improve the nutritional quality of product and add variety in the diet. The treatment (T4) incorporated with 20 percent gooseberry was considered best in sensory and nutritional qualities and showed good impact on nutritive value with regards to fiber, calcium, vitamin C, phosphorous and anti-radical activity than control (T0). Therefore, the developed papaya-gooseberry jam can be included in the daily diet of every age group which can definitely increase sensory attribute and nutrient intake by maintaining the good health and promoting immunity against infections. Thus the developed papaya-gooseberry jam is found to be acceptable in both sensory attributes and nutritional quality.