Radio Wave Propagation Experiment in Sugarcane Fire Environments ()

Received 20 January 2016; accepted 18 July 2016; published 21 July 2016

1. Introduction

The Burdekin Delta is known for its high sugar cane (Saccharum spp.) crop yield in Australia [1] . High annual rainfall, which is over a 1000 mm and high soil fertility, makes it suitable for sugar cane farming. Potassium enriched nutrients, such as potash, are often used to supplement soil fertility in cane paddocks in order to increase crop yields. Potassium content in sugar cane may be up to 2.2% on dry weight basis. In northeast Queensland, it is a common agricultural practice to burn foliage before harvesting sugar cane [2] . The cane burning is done when weather conditions do not favor the development of very high intensity cane fires. It is for this reason that burning is normally done at dusk when atmospheric instability is low. Otherwise the cane fires, which are often large (see Figure 1), will burn out of control. In instances where cane fires get out of control, radio wave communication systems which are commonly used in fire suppression should be able to function effectively under such environment.

Sugarcane fire flame temperatures are in the range of 600˚C - 1000˚C [3] . Potassium, which exists in cane foliage, is volatilized by the intense heat and drawn by convective currents into the flame where it is thermally ionized to give electrons [4] . The fires move rapidly and turbulently mix with convected surrounding air. Cool night air quenches the heat in the flame to temperatures lower than 1000˚C. Moist combustion conditions prevail in the cane fires. The moist conditions and up draughts promote the release of potassium into the flame as hydroxide (KOH) and K atoms [5] [6] . Potassium contributes significantly to ionization in the fires provided flame temperatures are higher than 900˚C.

The paper reports on radio wave propagation measurements carried out in a prescribed agricultural fire in a sugarcane field at Australian Tropical Agriculture College (ATAC) in Clare, Lower Burdekin. The measurements were performed using a radio wave interferometer, an instrument specifically designed to measure attenuation or phase change of a radio wave signal after passing through a fire plume [7] . Phase change measurement involves running a reference signal from a transmitter to receiver circuits for phase comparison. The reference signal is phase coherent with a signal from the transmitter unit before the latter traverses a cane fire. However in this experiment, phase measurements were not possible because the sides of the sugarcane paddock were very long to consider running a reference signal cable.

2. Theoretical Consideration

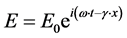

If a plane polarized electromagnetic wave is considered to travel in the positive x-direction, its signal strength (E) at any given time can be given as;

(1)

(1)

where γ is propagation constant, ω is cyclic propagation frequency (=2pf) and E0 is initial electric field strength of the radio signal. According to Akthar [8] , propagation constant (γ) is related to attenuation (a) and shift (b) coefficients in a medium by the relation; γ = a + i(b). Equation (1) can therefore be expressed as:

![]()

Figure 1. Large sugarcane fire (Photo: John Maddocks, 2003).

(2)

(2)

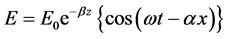

Classical electromagnetic wave theory predicts significant loss of signal amplitude and a change of phase when an electromagnetic wave traverses a lossy medium such as a sugarcane fire plume. The induced phase shift and loss in signal are due to electric dielectric permittivity which is not equal to unity (1). Dielectric permittivity of vacuum is equal to unity. The two effects in a lossy medium are measurable and can be related to those in free space. Amplitude of a radio signal that propagates through a sugarcane fire is attenuated and is given by;

(3)

(3)

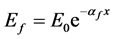

Without a canefire intercepting the propagation path, the amplitude of the signal that traversed air is not attenuated, and is given by;

(4)

(4)

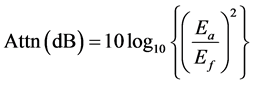

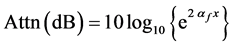

as attenuation coefficient (af) is zero (0). Attenuation (Attn) of the signal that traverses canefire expressed in dB is;

(5)

(5)

3. Materials and Methods

3.1. The Study Area

The sugarcane paddock where the prescribed burn was carried out was at the Burdekin Agricultural College in Clare. Clare is 90 km south of Townsville in the Burdekin Delta (19˚35'S and 147˚24'E) (Figure 2). It is 40 km from Ayr and 30 km from Home Hill. The paddock is one of the 400ha of sugar cane paddocks owned by the Agricultural College. The climate in the area is monsoonal with hot wet summers and warm dry winters. Average rainfall in the region is 1032 mm. The soils are fertile alluvial with variable layering [9] . This fertile soils and the high rainfall in the regions makes it suitable for sugar cane farming.

3.2. Fuel Characteristics

The sugarcane considered for harvesting was a year old (mature) and nearly 6 m tall. Its leaves in the bottom 3 m were fully dried while those in the rest of height of straw were half dried. Separation between the cane rows

![]()

Figure 2. The location of the study area (adapted from: Charles worth et al. 2002).

in the paddock was 1 m. The crops were closely packed and almost impossible for one to walk across the rows. Though the cane was mature, most of it had not flowered. The length of the paddock was roughly 1000 m and 100 m wide (see Figure 3).

3.3. Radio Wave Propagation Measurements

Receiver (Rx) and transmitters (Tx) units of a Radio Wave Interferometer were set up on adjacent sides of the sugar cane paddock (sides AB and BC in Figure 3). The distance separating the units (Tx − Rx) was 581.5 m. The units were set some distance away from the paddock so that they are not affected by heat from the burning sugarcane. Rx was set 20 m from AB such that from B1 to the Rx was 115 m. Tx was 30 m from BC such that Tx was 570 m from B2. The distance of Be to Bf was 556 m. The Rx and Tx antennas were set 3.2 m high from the ground facing each other to maximize the amount of signal strength received at Rx. The antennas were tuned such that the maximum strength received at Rx was 689 mV. Signal strength readings at Rx were then logged into HOBOâ data logger for continuous monitoring.

The Tx and Rx units were enclosed in polystyrene boxes wrapped with aluminum foil to reflect heat from cane fire. The radio wave interferometer was switched on at 6.20 pm while the HOBO data logger was switched on at 6.24pm to allow the instrument to stabilize.

3.4. Sugarcane Fire Behavior

The sugarcane fire was ignited along the side AB (Figure 3) with liquid flame. At the time of ignition, a mild wind blew form the easterly direction. The wind forced the fire to propagate along the length of the paddock thus intercepting the propagation path (shown in Figure 3) at an angle of approximately 79˚.

3.5. Temperature Measurements

A thermocouple tower of height 6.1 m was constructed from a steel pipe (stem) of diameter 0.15 m. The tower was erected inside the paddock, a few meters from its edge. To the steel pipe stem, six steel pipes of diameter 20 cm were screwed to the stem forming “branches” at every 1.0 m of the stem height. Thermocouples were mounted at each branch.

![]()

Figure 3. Set up for the transmitter and receiver units at the study site.

The thermocouples were cut from a 100 m roll of double braided fiberglass insulated chromel-alumel (24-G/G) thermocouple wire 50 mm in diameter. The type K thermocouple wires were electro-fused at one end to make perfect junctions and tested with a hot air gun and a multimeter. The thermocouples were then fixed to branches by means of muffler tape and the electro-fused junctions were left protruding 2.5 cm beyond the branch length into the flame. The thermocouples wires were buried in a trench 20 cm deep and connected to the SPECTRUMâ data logger 50 cm away from the tower.

The thermocouples were wired to a SPECTRUMâ SP 1700 - 51 W thermocouple data logger to read in temperatures throughout the experiment. Operational cold junction temperature of the data logger ranges from −45˚C to 85˚C; therefore it was necessary to protect the logger from heating beyond 85˚C as this may invalidate the data. The data logger was dug 75 cm into ground and wrapped around with an insulating material (Fiberflexâ) to protect it from heat that may the produced in the grassfire. SP 1700-51w logger has the capability to read temperatures up to 1370˚C, therefore is ideal for measuring cane fire flame temperatures.

4. Experimental Results and Discussions

4.1. Sugar Cane Fire Temperature

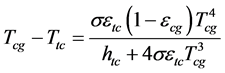

There is a discrepancy between the actual combustion gas temperature and that measured by a bare bead thermocouple [10] . The error is mainly due to the convection and radiation heat transfer to and from thermocouple bead. The error, which could be up to 200 K, is also attributable to bead physical characteristics such as emissivity and size [11] . However, actual cane fire temperatures could be reconstructed from thermocouple readings using heat balance equation. The discrepancy between the actual sugarcane fire and thermocouple measured temperature is given by Silvani and Morandini [11] as;

(6)

(6)

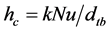

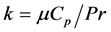

where  is heat transfer coefficient. Nu, k and dtb are Nusselt number, diffusivity and bead diameter, respectively. Diffusivity is related to the specific heat capacity (Cp) and Prandtl number (Pr) by the relation,

is heat transfer coefficient. Nu, k and dtb are Nusselt number, diffusivity and bead diameter, respectively. Diffusivity is related to the specific heat capacity (Cp) and Prandtl number (Pr) by the relation, . For combustion gases, Pr is 0.71. Following Dupuy [10] , Equation (6) is solved for Tcg which is actual flame gas temperature. The corrected flame temperatures are shown in Figure 4.

. For combustion gases, Pr is 0.71. Following Dupuy [10] , Equation (6) is solved for Tcg which is actual flame gas temperature. The corrected flame temperatures are shown in Figure 4.

![]()

Figure 4. Sugar cane fire flame temperatures as the flame front passed the tower.

The corrected thermocouple temperature for the sugarcane fire within the vegetation stratum was observed to increase with distance above the ground. The maximum temperature was observed at 6 m above the ground and was recorded to be 1154 K. The next highest was be 1065 K at 5 m above ground. The maximum temperatures occurred at 6:49:20 pm. At other heights (2 and 4 m), temperature maxima occurred 10 s later because the canefire was wind-blown. The maximum temperature recorded at 2 m above ground was 915 K. At 4 m, temperature was observed to be 960 K. From the temperature measurements, it appears that the northeasterly winds that blew across the paddock affected the flame up 1 m deep from the sugar cane canopy.

4.2. Sugarcane Fire Behavior

As the sugarcane fire front raced across the paddock from the east, it left leafless and charred cane straws standing behind. The chaff was completely burnt. The flames of the sugarcane fire were observed to be about 5 - 10 m high. The flames were hottest near the cane canopy and its temperature decreased with the increase in height above the ground. The cane fire took 21 minutes to burn through the whole paddock.

Average Rate of Spread (ROS) for the flame which is calculated from length of the paddock and time taken by the flame to reach the side CD is 0.79 m∙s−1. If it is assumed that flaming occurs at temperatures more than 573 K [13] then the resident time (Tr) of flames above the canopy as obtained from the analysis of temperature data from SPECTRUMâ SP 1700 - 51 W data logger is 11.

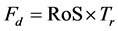

Noting that the head fire was rectangular, then flame depth (Fd) is related to flame residence time (Tr) and rate of fire spread (RoS) by the relation:

(7)

(7)

Equation (7) gives the average canefire flame depth of 8.69 m.

4.3. Attenuation of 151 MHz Signal

Signal reflections due to movements by team members in the first 4 mins after the logger was switched affected signal intensity. This is shown by signal dip AB in Figure 5. Figure 5 shows a 10-point adjacent averaging smoothing of real time data which is blue in color. Signal strength increased soon after that to a value of 686 mV. The ACTA fire crews moved in to set the sugar cane paddock alight at 6.36 pm. As they intercepted the propagation path the signal strength decreased to a minimum of 666 mV which is show by a prominent dip at C in the

![]()

Figure 5. Signal strength response to crew and cane fire interception of the propagation path.

same figure. As the crew moved out of the propagation path, the cane fire grew. The signal never gained its reception strength of 686 mV, but it only rose to a maximum strength of about 682 mV (shown as D in Figure 5). As the fire gained strength and intercepted the propagation path the signal strength fell to a minimum of 653 mV at 6:48:32 pm (E). Soon after the fire has passed the Propagation path, signal strength slowly rose to an average value of 660 mV at 6.55pm (F in Figure 5) until the instruments were disconnected at 7:10 pm.

Using the smoothed data attenuation of the 150 MHz signal due to the sugarcane fire flame as per Equation (5) is:

![]()

After the dry chaff has been consumed by the cane fire, stalks of sugar cane remained standing in the propagation path of the 150 MHz signal. The carbon covered stalks together with the hot air in the environment affected the signals markedly. Before the fire, the stalks are there with leaves and have the same water/sap content but do not have the carbon coating. As leaves do not attenuate radio signals at the frequency, carbon covered stalks may be the main cause of attenuation after the fire. The attenuation induced on the signal by the stocks was observed to be:

![]()

5. Conclusions

The sugarcane fire investigated had a front which was 8.7 m deep. The weather condition during the experiment was characterized by strong up draughts which cooled the flame intensity to maximum temperatures of 1150 K at the cane canopy. The temperature trend in the fuel stratum was such that it increased with height. Cane stratum temperature rose from maximum of 915 K at 2 m to a maximum of 1154 K at 6 m above the ground surface. The rate of spread for the cane fire was approximately 0.79 m∙s−1.

At 151 MHz, radio waves were slightly affected by an 8.7 m thick cane fire to a maximum signal loss of 0.43 dB. The loss in signal intensity was comparable to propagation over carbon coated stalks which registered a loss of 0.34 dB. Considering the magnitude of attenuation, vhf radio waves were not severely impaired by the sugarcane fire; however, signal attenuation is a factor of type of modulation. Very large fires may affect the signal significantly.

Acknowledgements

We would like to gratefully acknowledge Staff Development Office of the University of Botswana for the financial support for this work. The work was partly supported by Emergency Management Australia under project no. 60/2001.

NOTES

![]()

*Corresponding author.